3

Table of Contents

Warranty and Service............................................................................................................................................2

Table of Contents..................................................................................................................................................3

Warning.................................................................................................................................................................4

Introduction ...........................................................................................................................................................6

Specifications........................................................................................................................................................6

Features and Terminology ....................................................................................................................................7

Unpacking .............................................................................................................................................................8

Shipping Contents.................................................................................................................................................8

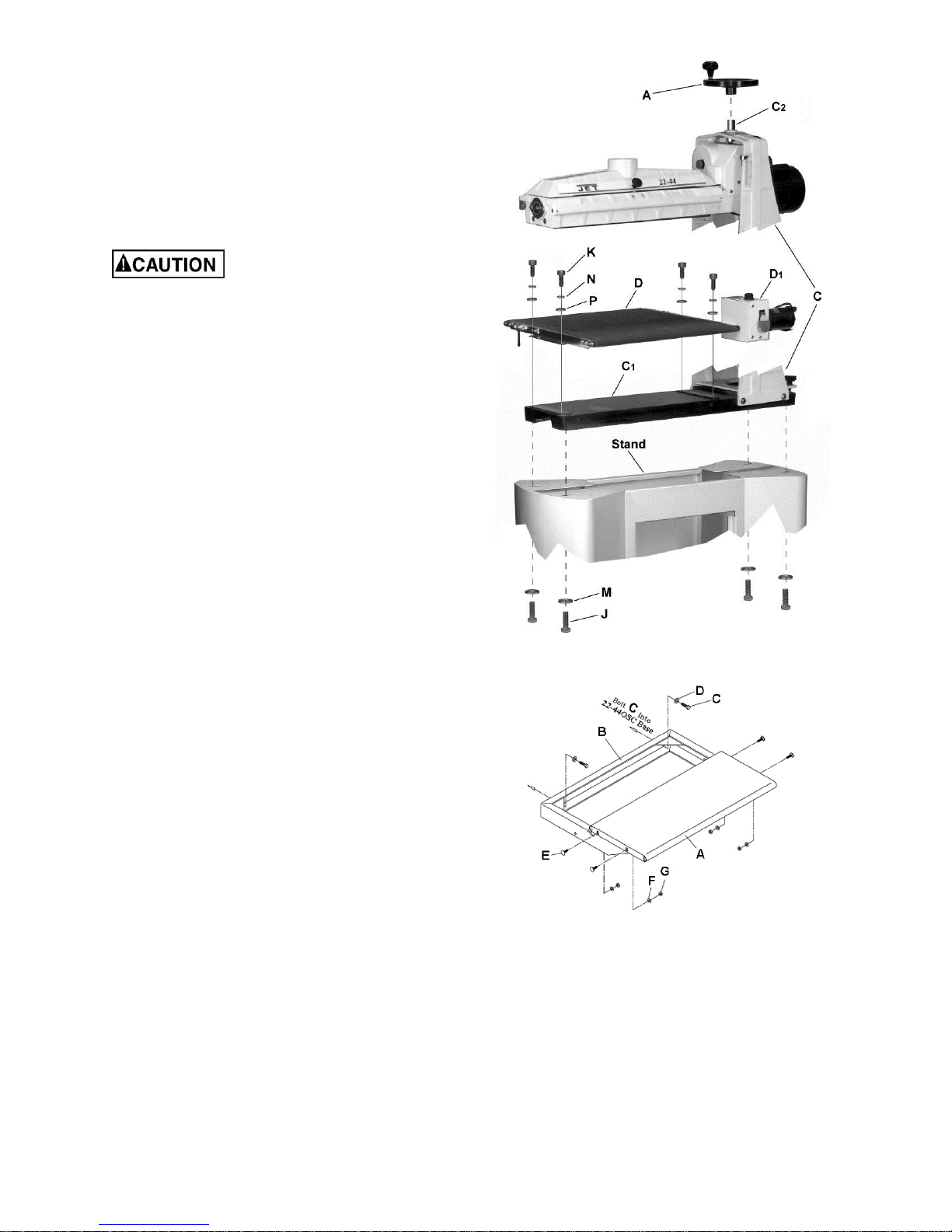

Assembly...............................................................................................................................................................9

Stand Assembly ................................................................................................................................................9

Drum Head Installation....................................................................................................................................10

Conveyor Table Installation.............................................................................................................................10

Installing Accessories..........................................................................................................................................10

Infeed and Outfeed Tables..............................................................................................................................10

Dust Cover ......................................................................................................................................................11

Dust Collection ................................................................................................................................................11

Installing Abrasives .........................................................................................................................................11

Grounding Instructions........................................................................................................................................13

Extension Cords..............................................................................................................................................13

Operating Controls..............................................................................................................................................14

On/Off Switch (Sanding Drum)........................................................................................................................14

Switch Lockout ................................................................................................................................................14

Conveyor.........................................................................................................................................................14

Drum Height Control........................................................................................................................................14

Oscillator Switch..............................................................................................................................................14

Adjustments ........................................................................................................................................................15

Depth Gauge...................................................................................................................................................15

Conveyor Belt Tension and Tracking ..............................................................................................................15

Trackers ..........................................................................................................................................................15

Conveyor Belt Replacement............................................................................................................................16

Checking Drum Alignment...............................................................................................................................16

Fine Tuning Drum Alignment...........................................................................................................................17

Tension Roller Alignment ................................................................................................................................17

Tension Roller Pressure Adjustment...............................................................................................................18

Drum Height Control Adjustment.....................................................................................................................18

Operation ............................................................................................................................................................19

Basic Operating Procedure .............................................................................................................................19

Setting Depth of Cut........................................................................................................................................19

Establishing Proper Drum Height....................................................................................................................19

Selecting SandSmart™ Feed Rates ...............................................................................................................19

Tips for Maximum Performance......................................................................................................................20

Maintenance........................................................................................................................................................21

Tracker Kit...........................................................................................................................................................22

Abrasives ............................................................................................................................................................23

Abrasive Selection Guide................................................................................................................................23

Optional Accessories ..........................................................................................................................................24

Troubleshooting ..................................................................................................................................................24

Troubleshooting – Motor and Electrical Problems...........................................................................................24

Troubleshooting – Mechanical Problems ........................................................................................................25

Troubleshooting – Operational Problems........................................................................................................26

Replacement Parts..............................................................................................................................................26

Drum Head Assembly – Exploded View..........................................................................................................27

Drum Head Assembly – Parts List ..................................................................................................................28

Conveyor and Motor Assembly – Exploded View ...........................................................................................30

Conveyor and Motor Assembly – Parts List ....................................................................................................31

Gearbox Assembly..........................................................................................................................................32

Closed Stand Assembly..................................................................................................................................33

Infeed and Outfeed Tables..............................................................................................................................34

Wiring Diagram ...................................................................................................................................................35