2

Thank you for purchasing a MAKITA prod-

uct!

Congratulations on choosing a MAKITA chain saw! We are

conÞdent that you will be satisÞed with this modern piece of

equipment.

The DCS6400 - 7901H are very handy and robust chain saws

with a new Design.

The automatic chain lubrication with variable-ßow oil pump

and maintenance-free electronic ignition ensure trouble-free

operation, while the hand-saving anti-vibration system and

ergonomic grips and controls make work easier, safer, and

less tiring for the user.

MAKITA chain saws DCS6400 - 7901H are equipped with the

latest safety features and meet all national and international

standards. These featuresinclude: hand guards on bothhandles,

grip throttle lever lock, chain catch, safety saw chain, and chain

brake. The chain brake can be actuated manually, and is also

inertia-actuated automatically in case of kickback.

The following industrial property rights apply: GBM 29616652,

EP 0560201B1.

In order to ensure the proper functioning and performance

of your new chain saw, and to safeguard your own per-

sonal safety, it is imperative that you read this instruction

manual thoroughly before operation. Be especially careful

to observe all safety precautions! Failure to observe these

precautions can lead to severe injury or death!

Packing

Your MAKITA chain saw comes delivered in a protective card-

board box to protect against shipping damage.

Cardboardisabasicrawmaterialandisconsequentlyreuseable

or suitable for recycling (waste paper recycling).

Table of contents Page

Packing ................................................................................ 2

Delivery inventory .............................................................. 3

Symbols ............................................................................... 3

SAFETY PRECAUTIONS

General precautions ....................................................... 4

Protective equipment ...................................................... 4

Fuels / Refuelling ............................................................ 5

Putting into operation ......................................................5

Kickback ......................................................................... 6

Working behavior/Method of working ...........................6-7

Transport and storage .....................................................8

Maintenance ................................................................... 8

First aid ........................................................................... 8

Technical data ..................................................................... 9

Denomination of components ........................................... 9

PUTTING INTO OPERATION

Mounting the guide bar and saw chain .................... 10-11

Tightening the saw chain ......................................... 11-12

Chain brake .................................................................. 12

Fuels ........................................................................13-14

Refuelling ......................................................................14

Checking the chain lubrication ...................................... 15

Adjusting the chain lubrication ...................................... 15

Starting the engine ........................................................ 16

Cold start ....................................................................... 16

Warm start ....................................................................16

Stopping the engine ...................................................... 16

Checking the chain brake .............................................16

Adjusting the carburetor (only for EU-countries) ............ 17

Adjusting the carburetor (only for not EU-countries) ...... 18

Working in summer / winter ............................................ 19

Handle heating (only „H“-models)........................................19

MAINTENANCE

Sharpening the saw chain .......................................20-21

Cleaning the brake band and sprocket interior ............. 22

Cleaning the guide bar .................................................23

Replacing the saw chain ............................................... 23

Replacing the suction head .........................................23

Cleaning the air Þlter and the Þlter hood ......................24

Replacing the spark plug ..............................................25

Checking the ignition spark ........................................... 25

Checking the mufßer screws ......................................... 25

Replacing the starter cable / Replacing the return spring 26

Mounting the fan housing .............................................27

Cleaning the cylinder area ............................................ 27

Replacing/cleaning the spark arrester screen ..............27

Instructions for periodic maintenance ........................... 28

Service, spare parts and guarantee ...........................28-29

Trouble shooting .............................................................. 29

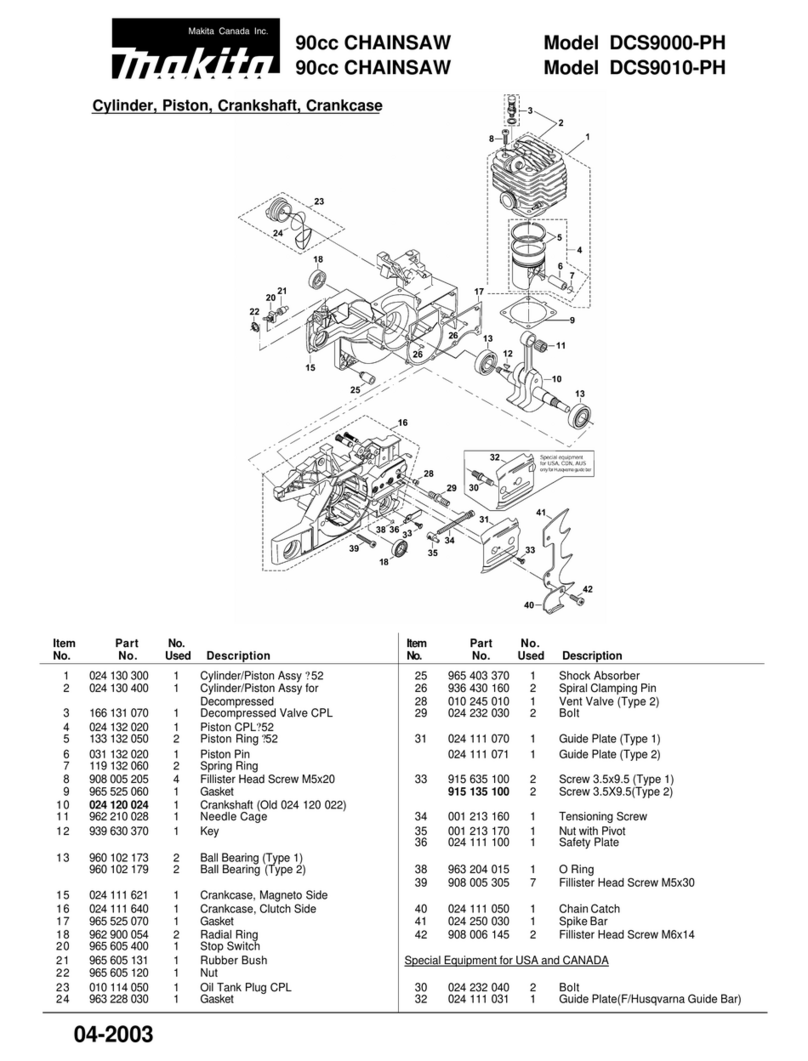

Extract from spare parts list ........................................... 30

Accessories ..................................................................30

EU conformity declaration ...............................................31