Table of contents Page

Packing ................................................................................2

Delivery inventory ..............................................................3

Symbols ..............................................................................3

SAFETY PRECAUTIONS

General precautions .......................................................4

Protective equipment ......................................................4

Fuels / Refuelling ............................................................5

Putting into operation ......................................................5

Kickback .........................................................................6

Working behavior/Method of working ...........................6-7

Transport and storage ..................................................... 8

Maintenance ...................................................................8

First aid ..........................................................................8

Technical data .....................................................................9

Denomination of components ...........................................9

PUTTING INTO OPERATION

Mounting the guide bar and saw chain .................... 10-11

Tightening the saw chain .............................................. 11

Chain brake ..................................................................12

Fuels ........................................................................13-14

Refuelling ......................................................................14

Adjusting the chain lubrication ......................................15

Starting the engine ........................................................16

Cold start .....................................................................16

Warm start .................................................................... 16

Stopping the engine.......................................................16

Checking the chain brake ............................................. 17

Set idle speed .................................................................17

MAINTENANCE

Sharpening the saw chain .......................................18-19

Cleaning the brake band and sprocket interior .............20

Cleaning the guide bar, lubricating the sprocket nose ..20

Replacing the saw chain ...............................................21

Replacing the suction head ..........................................21

Cleaningtheairlter.....................................................21

Replacing the spark plug .............................................. 22

Checking the ignition spark ...........................................22

Instructions for periodic maintenance ...........................23

Service, spare parts and guarantee ..........................23-24

Troubleshooting ...............................................................24

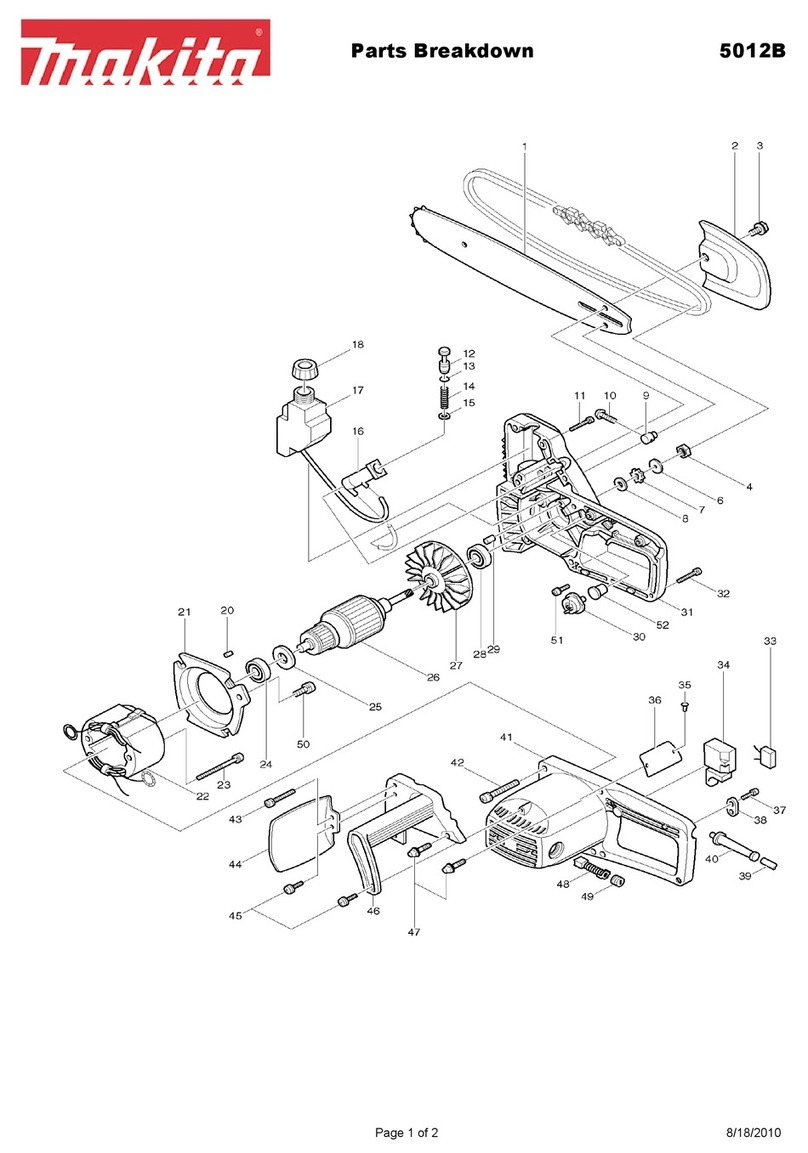

Extract from spare parts list ...........................................25

Accessories ..................................................................25

Conformity Declaration ....................................................27

Thank you for purchasing a MAKITA product!

Congratulations on choosing a MAKITA chain saw! We are

condentthatyouwillbesatisedwiththis modernpieceof

equipment.

The DCS34, DCS4610 are very handy and robust chain saws

with a new Design.

Theautomaticchainlubricationandmaintenance-freeelectronic

ignition ensure trouble-free operation, while the hand-saving

anti-vibration system and ergonomic grips and controls make

work easier, safer, and less tiring for the user.

The PS-34, chain saws are equipped with the latest safety

features and meet all international standards. These features

include: Hand guards on both handles, grip throttle lever lock,

chain catch, safety saw chain, and chain brake. The chain

brake can be actuated manually, and is also inertia-actuated

automatically in case of kickback.

The following industrial property rights apply: DE 19722629.

In order to ensure the proper functioning and performance

of your new chain saw, and to safeguard your own personal

safety, it is imperative that you read this instruction manual

thoroughly before operation. Be especially careful to ob-

serve all safety precautions! Failure to do so can result in

serious injury to the operator and/or bystanders!

Packing

TheMAKITAchainsawwillbedeliveredinaprotectivecardboard

box to prevent transport damage.

Cardboardis a basicrawmaterialand is consequentlyreuseable

or suitable for recycling (waste paper recycling).