10 ENGLISH

WARNING: The vibration emission during actual

use of the power tool can differ from the declared

emission value depending on the ways in which the

tool is used.

WARNING: Be sure to identify safety measures

to protect the operator that are based on an estima-

tion of exposure in the actual conditions of use (taking

account of all parts of the operating cycle such as

the times when the tool is switched off and when it is

running idle in addition to the trigger time).

EC Declaration of Conformity

For European countries only

The EC declaration of conformity is included as Annex A

to this instruction manual.

SAFETY WARNINGS

General power tool safety warnings

WARNING: Read all safety warnings, instruc-

tions, illustrations and specications provided

with this power tool. Failure to follow all instructions

listedbelowmayresultinelectricshock,reand/or

seriousinjury.

Save all warnings and instruc-

tions for future reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Cordless Chain saw safety warnings

1. Keep all parts of the body away from the saw

chain when the chain saw is operating. Before

you start the chain saw, make sure the saw

chain is not contacting anything. A moment of

inattention while operating chain saws may cause

entanglement of your clothing or body with the

saw chain.

2. Always hold the chain saw with your right

hand on the top handle and your left hand on

the front handle. Holding the chain saw with a

reversedhandcongurationincreasestheriskof

personalinjuryandshouldneverbedone.

3. Hold the power tool by insulated gripping

surfaces only, because the saw chain may con-

tact hidden wiring. Saw chains contacting a "live"

wire may make exposed metal parts of the power

tool "live" and could give the operator an electric

shock.

4. Wear safety glasses and hearing protection.

Further protective equipment for head, hands,

legs and feet is recommended. Adequate protec-

tiveclothingwillreducepersonalinjurybyying

debris or accidental contact with the saw chain.

5. Always keep proper footing.

6. When cutting a limb that is under tension be

alert for spring back. When the tension in the

woodbresisreleasedthespringloadedlimbmay

strike the operator and/or throw the chain saw out

of control.

7.

Use extreme caution when cutting brush and sap-

lings. The slender material may catch the saw chain

and be whipped toward you or pull you off balance.

8. Carry the chain saw by the front handle with

the chain saw switched off and away from your

body. When transporting or storing the chain

saw always t the guide bar cover. Proper

handling of the chain saw will reduce the likelihood

of accidental contact with the moving saw chain.

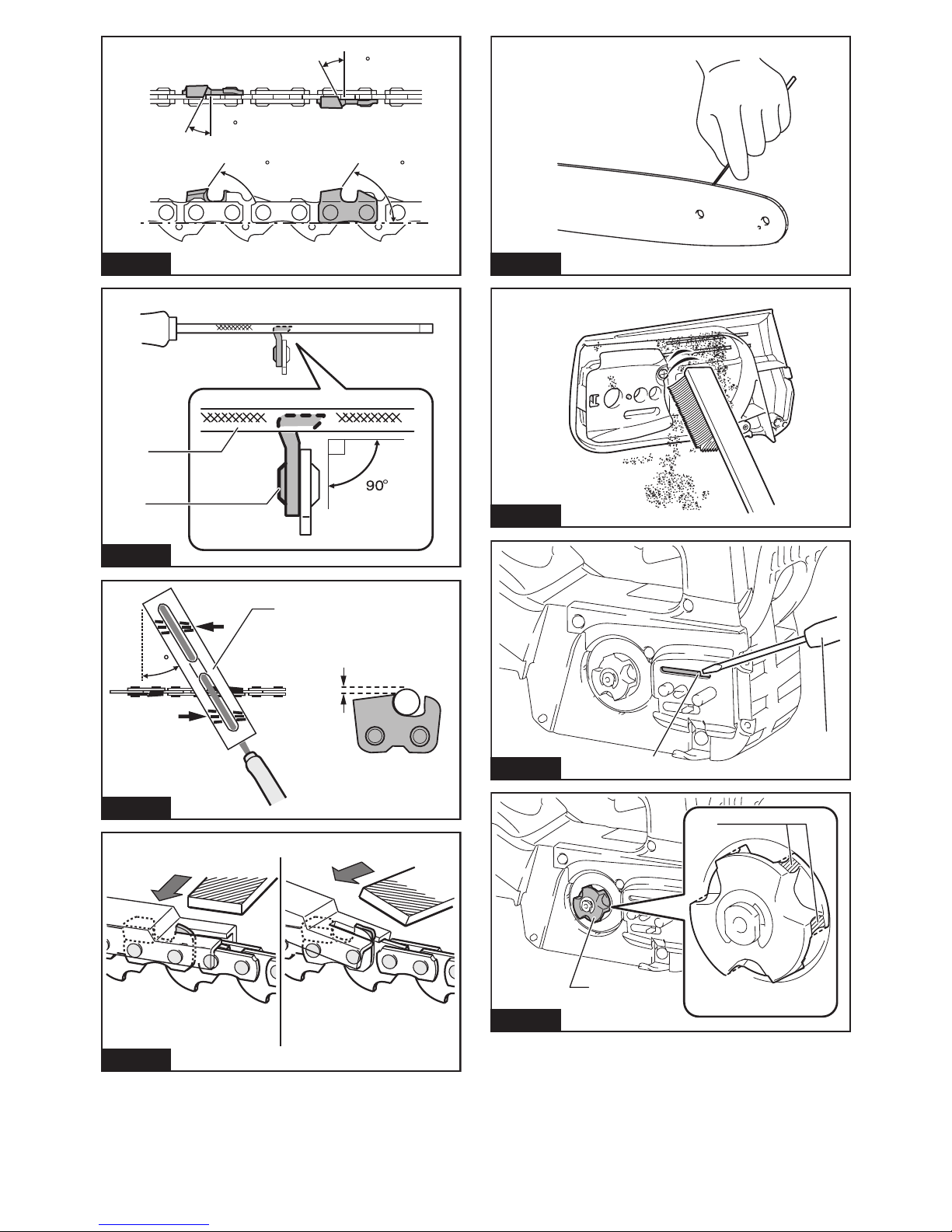

9. Follow instructions for lubricating, chain ten-

sioning and changing accessories. Improperly

tensioned or lubricated chain may either break or

increase the chance for kickback.

10. Keep handles dry, clean, and free from oil and

grease. Greasy, oily handles are slippery causing

loss of control.

11. Cut wood only. Do not use chain saw for pur-

poses not intended. For example: do not use

chain saw for cutting plastic, masonry or non-

wood building materials. Use of the chain saw for

operations different than intended could result in a

hazardous situation.

12. Causes and operator prevention of kickback:

Kickback may occur when the nose or tip of the

guidebartouchesanobject,orwhenthewood

closes in and pinches the saw chain in the cut.

Tip contact in some cases may cause a sudden

reverse reaction, kicking the guide bar up and

back towards the operator. Pinching the saw chain

along the top of the guide bar may push the guide

bar rapidly back towards the operator. Either of

these reactions may cause you to lose control of

the saw which could result in serious personal

injury.Donotrelyexclusivelyuponthesafety

devices built into your saw. As a chain saw user,

you should take several steps to keep your cutting

jobsfreefromaccidentorinjury.

Kickback is the result of tool misuse and/or incor-

rect operating procedures or conditions and can be

avoided by taking proper precautions as given below:

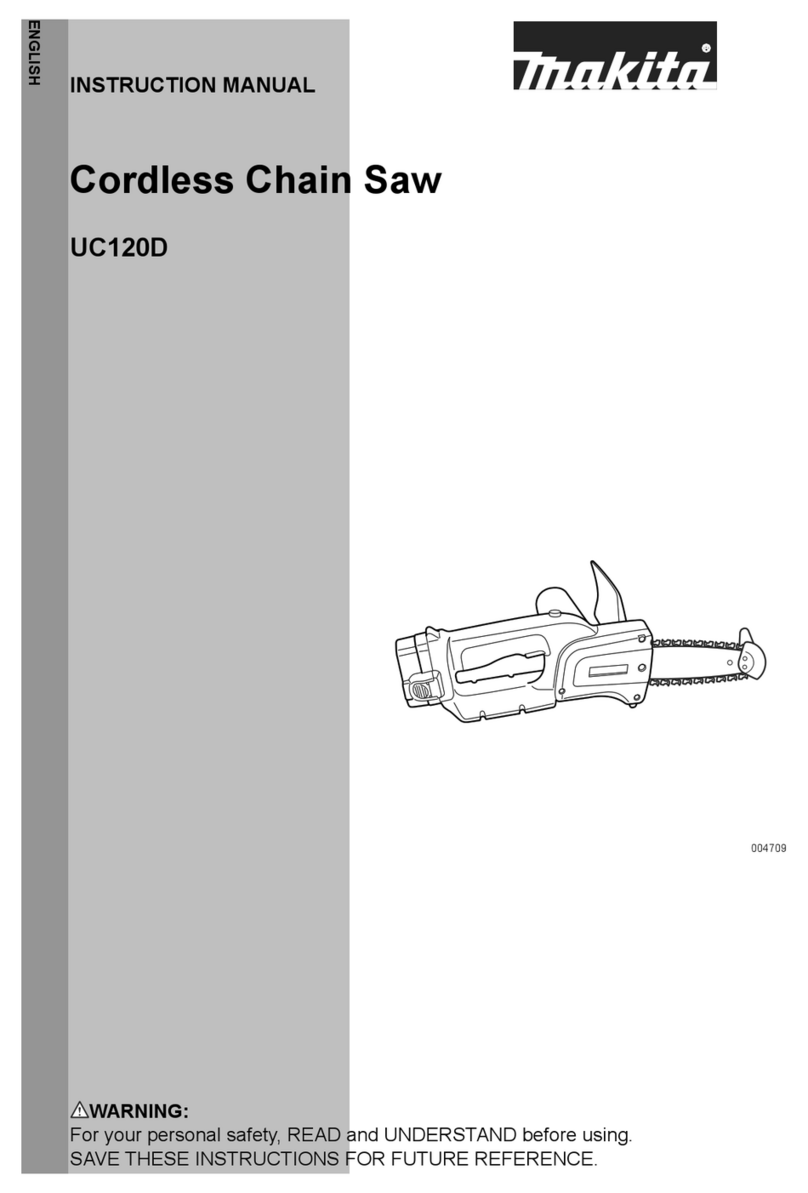

• Maintainarmgrip,withthumbsandngers

encircling the chain saw handles, with both

hands on the saw and position your body

and arm to allow you to resist kickback

forces. Kickback forces can be controlled by

the operator, if proper precautions are taken.

Do not let go of the chain saw.

►Fig.1

• Do not overreach and do not cut above

shoulder height. This helps prevent unin-

tended tip contact and enables better control

of the chain saw in unexpected situations.

• Only use replacement bars and chains spec-

iedbythemanufacturer.Incorrectreplace-

ment bars and chains may cause chain

breakage and/or kickback.

• Follow the manufacturer’s sharpening and

maintenance instructions for the saw chain.

Decreasing the depth gauge height can lead

to increased kickback.