10 ENGLISH

10. Follow instructions for lubricating, chain ten-

sioning and changing accessories. Improperly

tensioned or lubricated chain may either break or

increase the chance for kickback.

11. Keep handles dry, clean, and free from oil and

grease. Greasy, oily handles are slippery causing

loss of control.

12.

Cut wood only. Do not use chain saw for purposes

not intended.Forexample:donotusechainsawfor

cutting plastic, masonry or non-wood building materi-

als. Use of the chain saw for operations different than

intended could result in a hazardous situation.

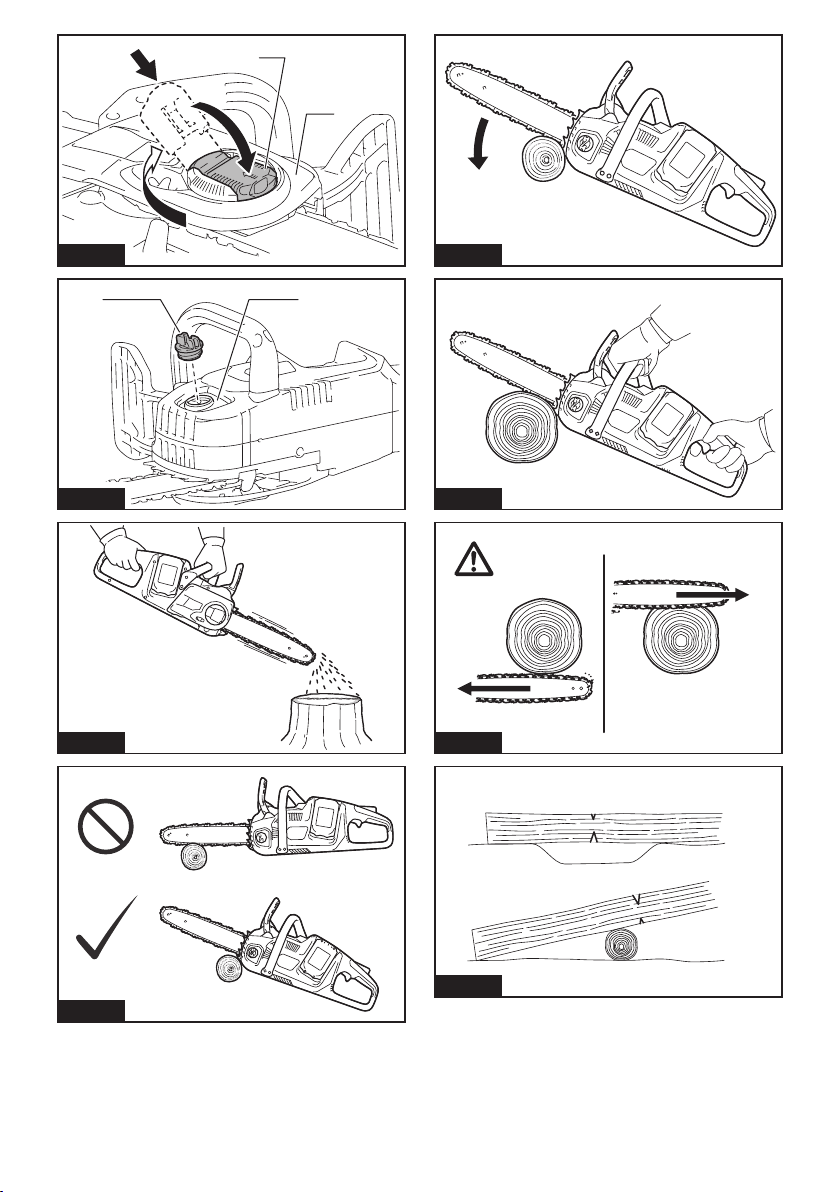

13. Causes and operator prevention of kickback:

Kickback may occur when the nose or tip of the

guidebartouchesanobject,orwhenthewood

closes in and pinches the saw chain in the cut. Tip

contact in some cases may cause a sudden reverse

reaction, kicking the guide bar up and back towards

the operator. Pinching the saw chain along the top

of the guide bar may push the guide bar rapidly back

towardstheoperator.Eitherofthesereactionsmay

cause you to lose control of the saw which could

resultinseriouspersonalinjury.Donotrelyexclu-

sively upon the safety devices built into your saw. As

a chain saw user, you should take several steps to

keepyourcuttingjobsfreefromaccidentorinjury.

Kickback is the result of tool misuse and/or incor-

rect operating procedures or conditions and can be

avoidedbytakingproperprecautionsasgivenbelow:

•

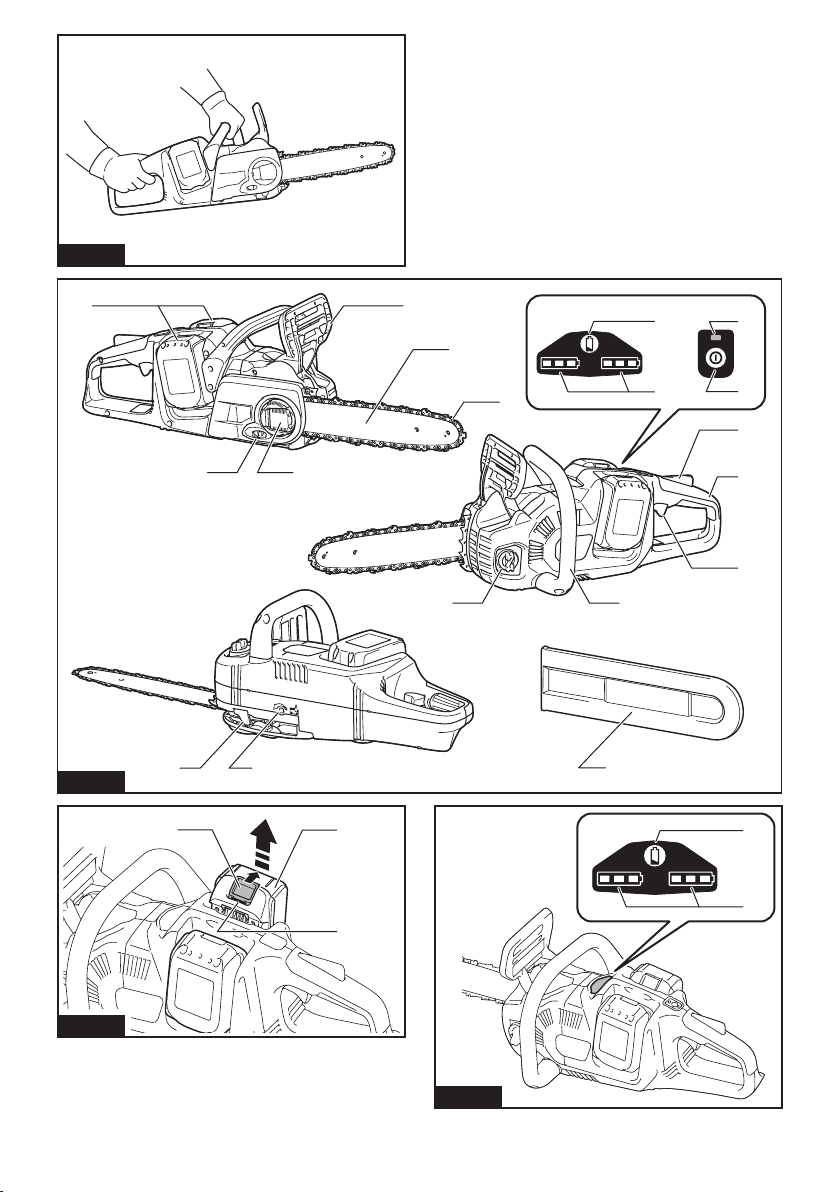

Maintainarmgrip,withthumbsandngersencir-

cling the chain saw handles, with both hands on

the saw and position your body and arm to allow

you to resist kickback forces. Kickback forces can

be controlled by the operator, if proper precautions

are taken. Do not let go of the chain saw.

►Fig.1

• Donotoverreachanddonotcutabove

shoulder height. This helps prevent unin-

tended tip contact and enables better control

of the chain saw in unexpected situations.

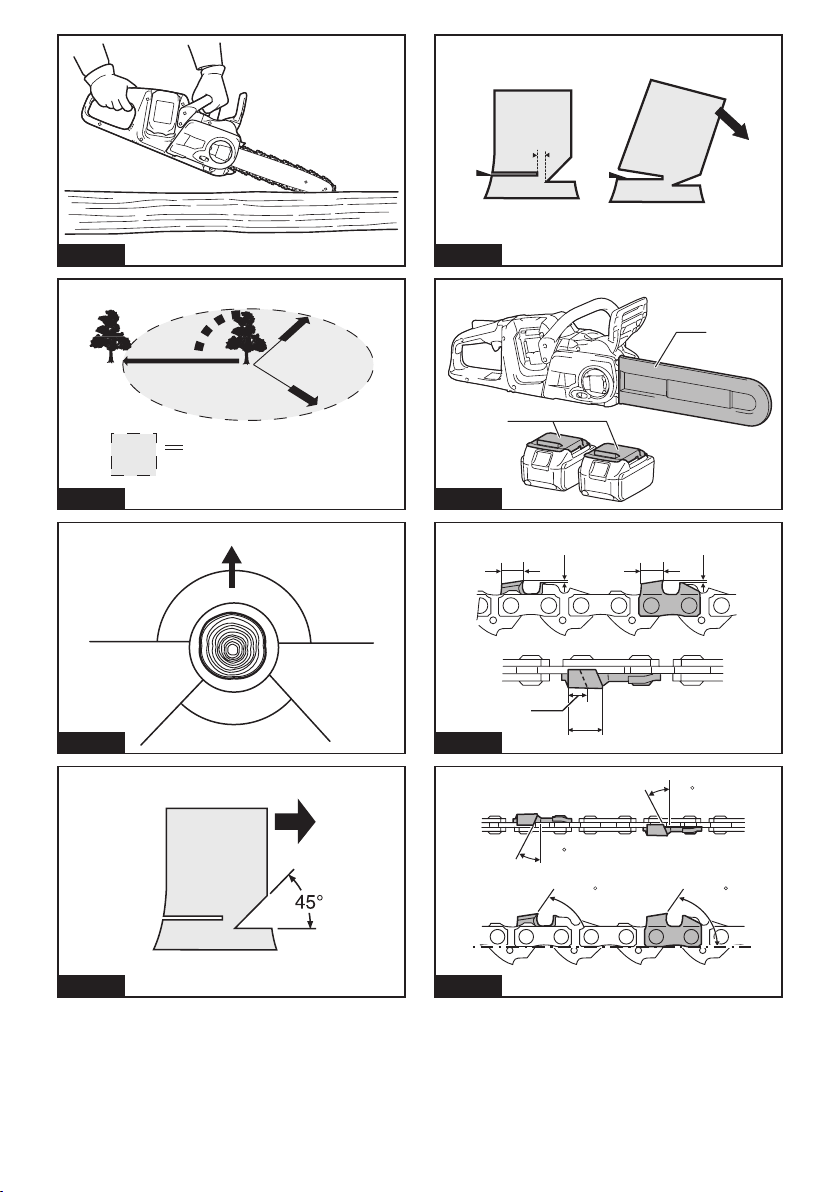

• Onlyusereplacementbarsandchainsspec-

iedbythemanufacturer.Incorrectreplace-

ment bars and chains may cause chain

breakage and/or kickback.

• Followthemanufacturer’ssharpeningand

maintenance instructions for the saw chain.

Decreasing the depth gauge height can lead

to increased kickback.

14. Before starting work, check that the chain

saw is in proper working order and that its

condition complies with the safety regulations.

Check in particular that:

• Thechainbrakeisworkingproperly;

• Therun-downbrakeisworkingproperly;

• Thebarandthesprocketcoveraretted

correctly;

• Thechainhasbeensharpenedandten-

sioned in accordance with the regulations.

15.

Do not start the chain saw with the chain cover

being installed on it. Starting the chain saw with the

chain cover being installed on it may cause the chain

covertothrownoutforwardresultinginpersonalinjury

anddamagetoobjectsaroundtheoperator.

SAVE THESE INSTRUCTIONS.

WARNING: DO NOT let comfort or familiarity

with product (gained from repeated use) replace

strict adherence to safety rules for the subject

product. MISUSE or failure to follow the safety

rules stated in this instruction manual may cause

serious personal injury.

Important safety instructions for

battery cartridge

1.

Before using battery cartridge, read all instruc-

tions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using battery.

2. Do not disassemble battery cartridge.

3. If operating time has become excessively

shorter, stop operating immediately. It may

result in a risk of overheating, possible burns

and even an explosion.

4.

If electrolyte gets into your eyes, rinse them out

with clear water and seek medical attention right

away. It may result in loss of your eyesight.

5. Do not short the battery cartridge:

(1) Do not touch the terminals with any con-

ductive material.

(2) Avoid storing battery cartridge in a con-

tainer with other metal objects such as

nails, coins, etc.

(3) Do not expose battery cartridge to water

or rain.

A battery short can cause a large current

ow, overheating, possible burns and even a

breakdown.

6. Do not store the tool and battery cartridge in

locations where the temperature may reach or

exceed 50 °C (122 °F).

7. Do not incinerate the battery cartridge even if

it is severely damaged or is completely worn

out. The battery cartridge can explode in a re.

8. Be careful not to drop or strike battery.

9. Do not use a damaged battery.

10. The contained lithium-ion batteries are subject

to the Dangerous Goods Legislation require-

ments.

For commercial transports e.g. by third parties,

forwarding agents, special requirement on pack-

aging and labeling must be observed.

For preparation of the item being shipped, consult-

ing an expert for hazardous material is required.

Please also observe possibly more detailed

national regulations.

Tape or mask off open contacts and pack up the

battery in such a manner that it cannot move

around in the packaging.

11. Follow your local regulations relating to dis-

posal of battery.

SAVE THESE INSTRUCTIONS.

CAUTION: Only use genuine Makita batteries.

Use of non-genuine Makita batteries, or batteries that

have been altered, may result in the battery bursting

causingres,personalinjuryanddamage.Itwill

also void the Makita warranty for the Makita tool and

charger.