3

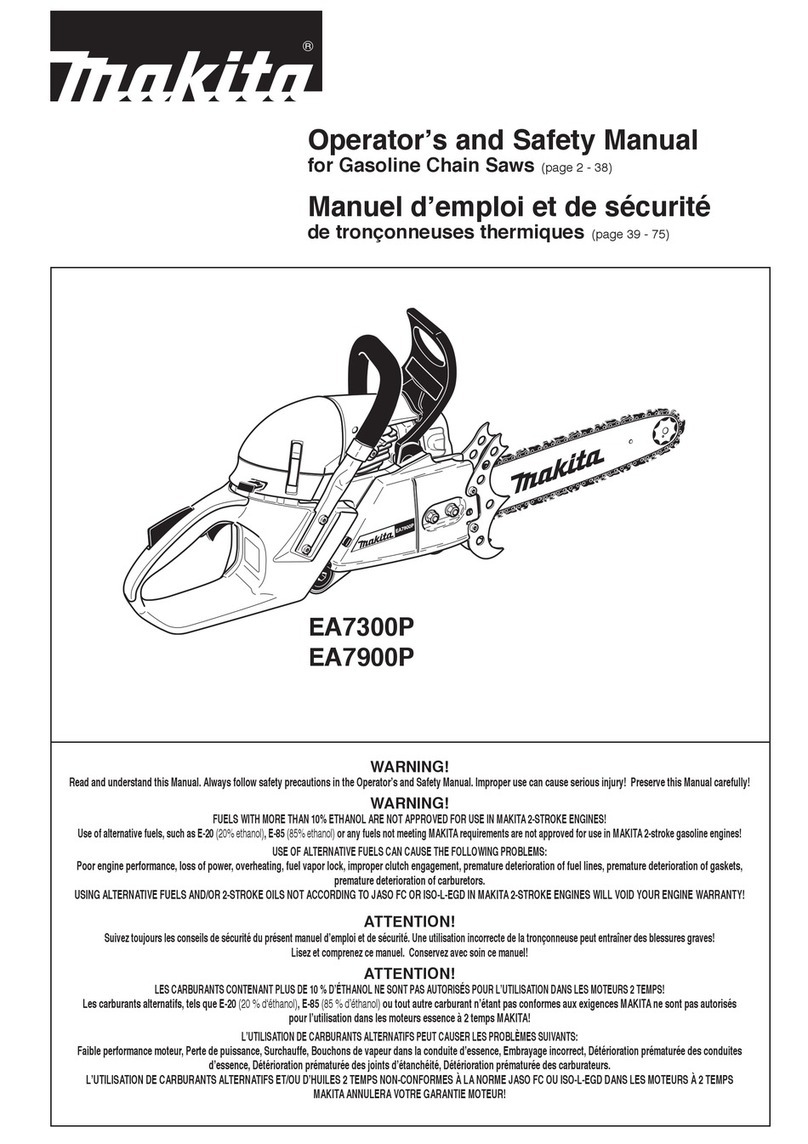

WARNING:

This chain saw is designed especially for tree care and surgery. All work with

this chain saw is to be carried out by properly trained persons only. Observe

all literature, procedures and recommendations from the relevant professional

organisation. Failure to do so constitutes a high accident risk! We recommend

always using a rising platform (cherry picker, lift) for sawing in trees. Rappelling

techniques are extremely dangerous and require special training! The operator

must be trained in and familiar with the use of safety equipment and working and

climbing techniques! Always use the appropriate belts, ropes and carabiners

when working in trees. Always use restraining equipment for both the operator

and the saw!

General precautions

• To ensure correct operation the user has to read this instruction manual to

make himself familiar with the characteristics of the chain saw. Users insufficiently

informed will endanger themselves as well as others due to improper handling.

• Lend this chain saw only to persons with training and experience in the use of tree-

surgery saws. Always hand over the instruction manual.

• Children and young persons aged under 18 years must not be allowed to operate

the chain saw. Persons over the age of 16 years may, however, use the chain saw

for the purpose of being trained as long as they are under the supervision of a

qualified trainer.

• Use chain saws always with the utmost care and attention.

• Operate the chain saw only if you are in good physical condition. If you are tired,

your attention will be reduced. Be especially careful at the end of a working day.

Perform all work calmly and carefully. The user has to accept liability for others.

• Never work under the inuence of alcohol, drugs or medication.

• A fire extinguisher must be available in the immediate vicinity when working in easily

inammable vegetation or when it has not rained for a long time (danger of fire).

• National regulation can restrict the use of the machine. Follow your county’s

regulations relating to use of chain saw.

Protective equipment

• In order to avoid head, eye, hand or foot injuries as well as to protect your

hearing the following protective equipment must be used during operation

of the chain saw:

• The kind of clothing should be appropriate, i. e. it should be tight-fitting but not be

a hindrance. Do not wear jewelry or clothing which could become entangled with

bushes or shrubs. If you have long hair, always wear a hairnet!

• It is necessary to wear a protective helmet whenever working with the chain saw.

The protective helmet (a) is to be checked in regular intervals for damage and is

to be replaced after 5 years at the latest. Use only approved protective helmets.

• The face shield (b) of the protective helmet (or the goggles) protects against sawdust

and wood chips. During operation of the chain saw always wear a goggle or a face

shield to prevent eye injuries.

• Wear adequate noise protection equipment (ear muffs (c), ear plugs, etc.). Octave

band analysis upon request.

• The protective jacket (d) consists of 22 layers of nylon and protects the operator

against cuts. It is always to be worn when working from elevated platforms (cherry

pickers, lifts), from platforms mounted on ladders or when climbing with ropes.

• The protective brace and bib overall (e) is made of a nylon fabric with 22 layers

and protects against cuts. We strongly recommend its use.

• Protective gloves (f) made of thick leather are part of the prescribed equipment

and must always be worn during operation of the chain saw.

• During operation of the chain saw safety shoes or safety boots (g) fitted with anti

skid sole, steel toe caps and protection for the leg must always to be worn. Safety

shoes equipped with a protective layer provide protection against cuts and ensure

a secure footing. For working in trees the safety boots must be suitable for climbing

techniques.

Fuels/Refuelling

• Stop the engine before refuelling the chain saw.

• Do not smoke or work near open fires (5).

• Let the engine cool down before refuelling.

• Fuels can contain substances similar to solvents. Eyes and skin should not come

in contact with mineral oil products. Always wear protective gloves when refuelling.

Frequently clean and change protective clothes. Do not breathe in fuel vapors.

• Do not spill fuel or chain oil. When you have spilt fuel or oil immediately clean the

chain saw. Fuel should not come in contact with clothes. If your clothes have come

in contact with fuel, change them at once.

SAFETY PRECAUTIONS

2

1

a

b

c

3

5

d

ef

g

4