FUNCTIONALDESCRIPTION

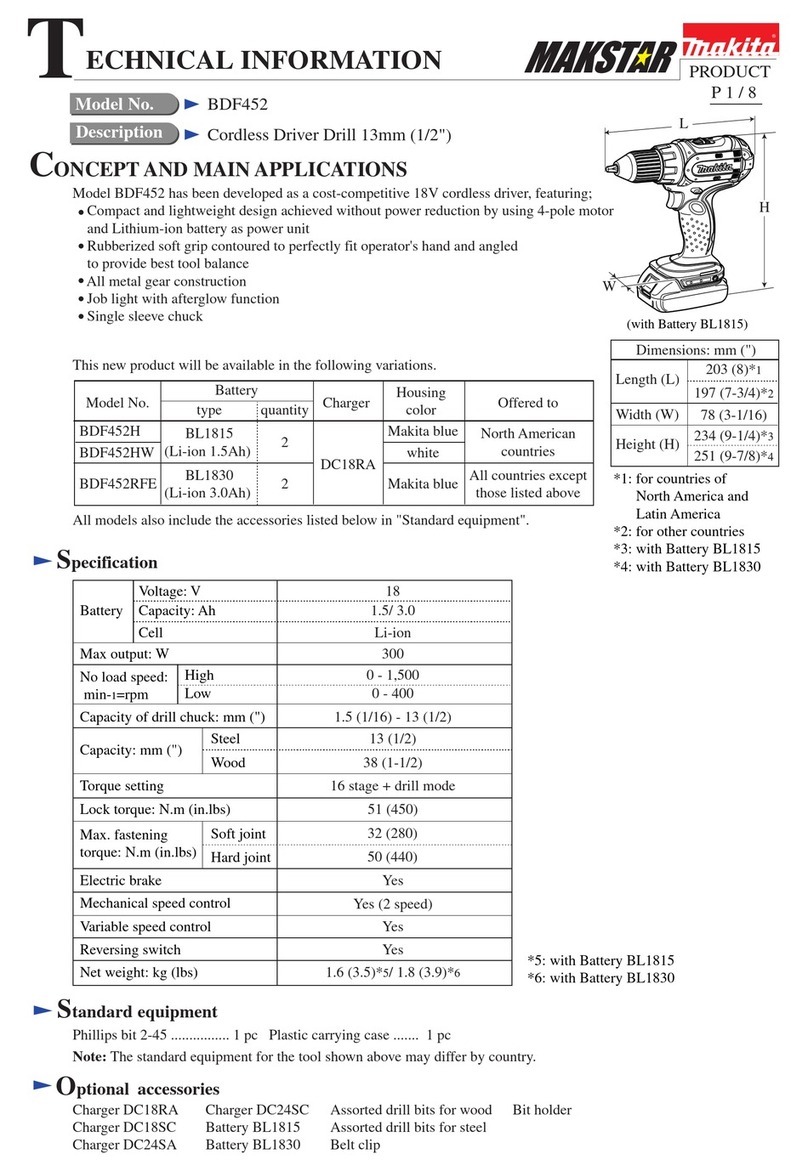

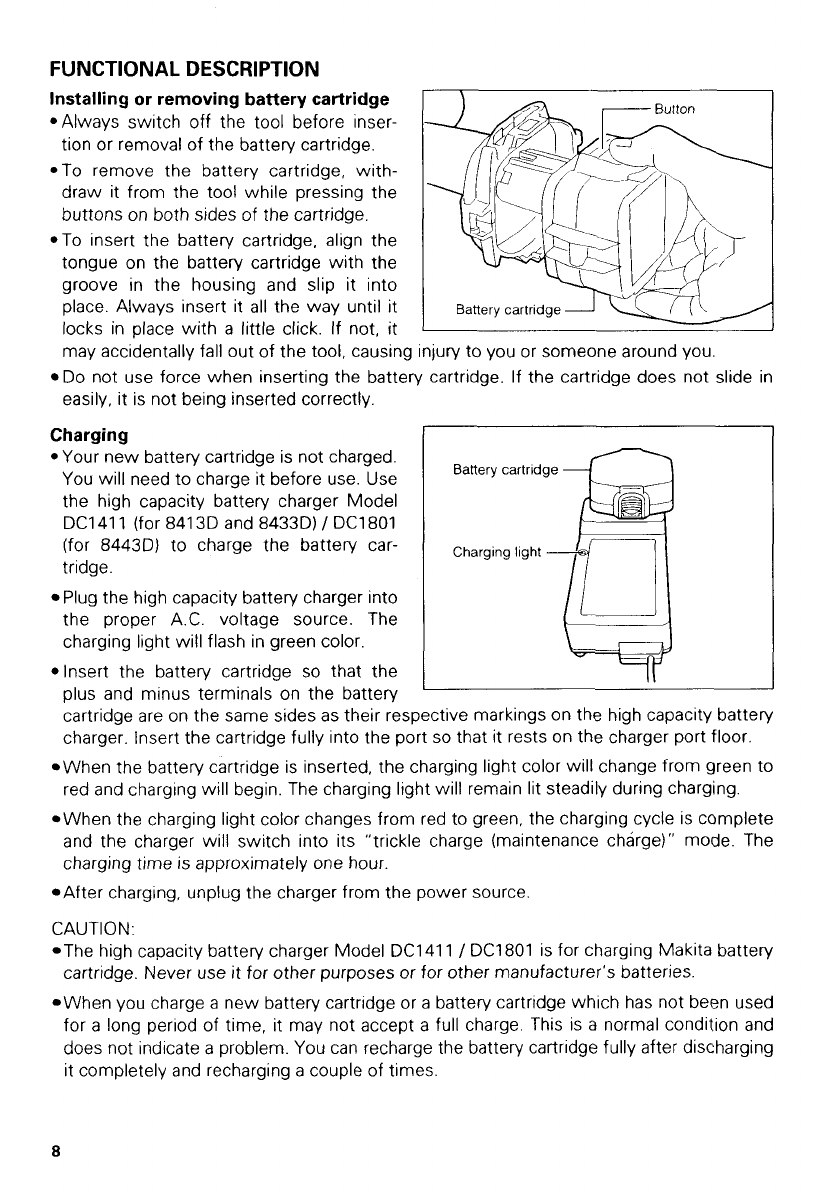

Installing or removing battery cartridge

*Always switch off the tool before inser-

tion or removal of the battery cartridge.

*To remove the battery cartridge, with-

draw it from the tool while pressing the

buttons on both sides

of

the cartridge.

*To insert the battery cartridge, align the

tongue on the battery cartridge with the

groove in the housing and slip it into

place. Always insert it all the way until it

locks in place with

a

little click. If not, it

may accidentally fall out

of

the tool, causing injury to you or someone around you

Do not use force when inserting the battery cartridge.

If

the cartridge does not slide in

easily, it

is

not being insertedcorrectly.

Charging

*Your newbattery cartridge

is

not charged.

You will needto charge it before use. Use

the high capacity battery charger Model

DCI411 (for 8413D and 8433D)

/

DC1801

(for 8443D) to charge the battery car-

tridge.

Plugthe high capacity battery charger into

the proper

A.C.

voltage source. The

charging light will flash in green color.

*Insert the battery cartridge

so

that the

plus and minus terminals on the battery

cartridge are on the same sides as their respective markings on the high capacity battery

charger. Insertthe cartridge fully into the port

so

that it rests on the charger port floor.

When the battery cartridge is inserted, the charging light color will change from green to

redand charging will begin. The charging light will remain lit steadily during charging.

When the charging light color changes from red to green, the charging cycle

is

complete

and the charger will switch into its ”trickle charge (maintenance charge)” mode. The

charging time

is

approximately one hour.

After charging, unplug the charger from the power source

CAUTIO

N:

The high capacity battery charger Model DC1411

/

DC1801 isfor charging Makita battery

cartridge. Never use it for other purposes or for other manufacturer’sbatteries.

When you charge

a

new battery cartridge or

a

battery cartridge which has not been used

for a long period of time,

it

may not accept a full charge. This

is

a

normal condition and

does not indicate

a

problem. You can recharge the battery cartridge

fully

after discharging

it completely and recharging

a

couple of times.

a