Coolingsystem

This charger is equipped with cooling fan for heatedbattery in order to enable the battery

to prove its own performance. Sound of cooling'air comes out during cooling, which

means not trouble on the charger.

-Trouble on coolingfan

-Incomplete cool down of battery, such as, beingcloggedwith dust

The batterycan be chargedinspite

of

the yellow warning light. But the chargingtime will

be longer than usual in this case.

Check the sound of cooing fan, vent on the charger and battery, which can be sometime

cloggedwith dust.

The cooling system is in order although no sound of cooling fan comes out,

if

the yellow

warning lightwill not flash.

Always keep clean the vent on charger and battery for cooling.

The products should be sent to repair or maintenance,

if

the yellow warning light will fre-

quently flash.

Yellow lightwill flash for warning inthe followingcases.

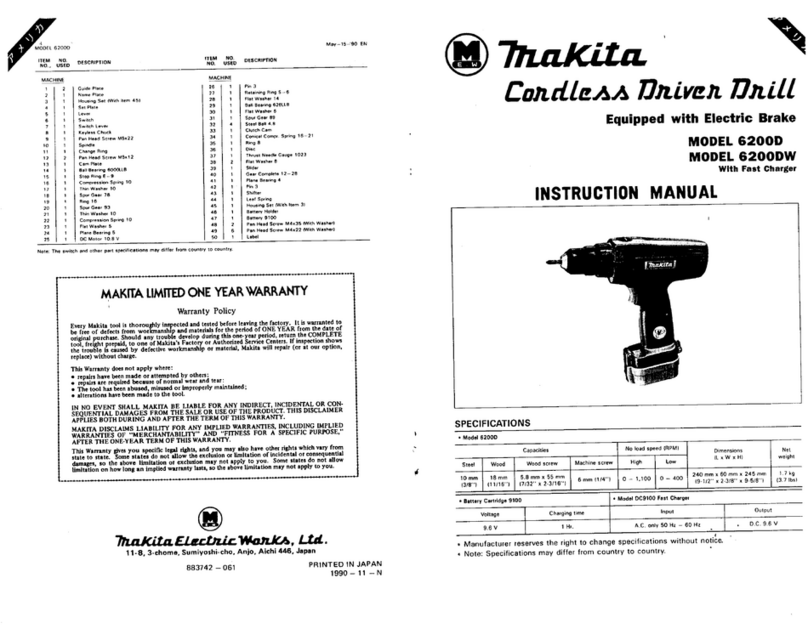

Conditioningcharge

Conditioningcharge can extend the life

of

battery by automatically searching the optimum

chargingcondition for the batteries in every situation.

The battery employed inthe followingconditions repeatedly,will be worn out shortly, and

yellow warning light may flash.

1,

Recharge

of

battery with its high temperature

2.

Rechargeof battery with its low temperature

3.

Recharge

of

full

charged battery

4. Over-dischargeof battery (continue

to

discharge battery in spite of down

of

power.)

5.

Rechargeunder brokencoolingsystem

The chargingtime of suchbattery

is

longer than usual.

Tricklecharge (Maintenancecharge)

If you leave the battery cartridge in the charger to prevent spontaneous discharging after

full charge, the charger will switch into its "trickle charge (maintenancecharge)" modeand

keepthe battery cartridge fresh and fully charged.

Tips for maintainingmaximumbatterylife

1,

Charge the battery cartridge before completely discharged.

Always stop

tool

operation and charge the battery cartridge when

you

notice

less

tool

power.

2.

Never recharge

a

fully chargedbattery cartridge.

Overchargingshortens the battery service life.

3.

Charge the batterycartridgewith room temperature at

10°C

-

40°C

(50°F

-

104°F).

Let

a

hot battery cartridgecool down before charging it.

4.

Chargethe NickelMetalHydride battery cartridge when you do not use it for more than

six months.

9