P 2/9

[2] LUBRICATION

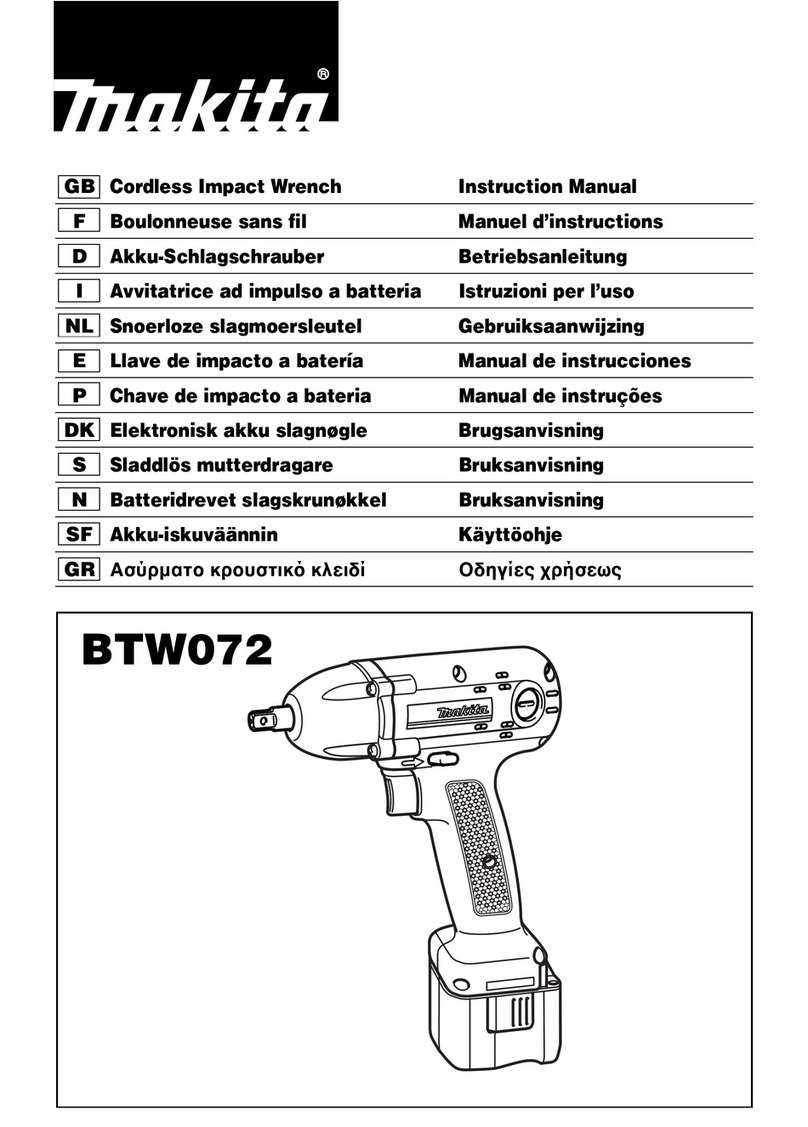

Apply the following lubricants to protect parts and product from unusual abrasion:

*Makita grease N No.2 to the Portions designated with

*Makita grease FA No.2 to the portions designated with

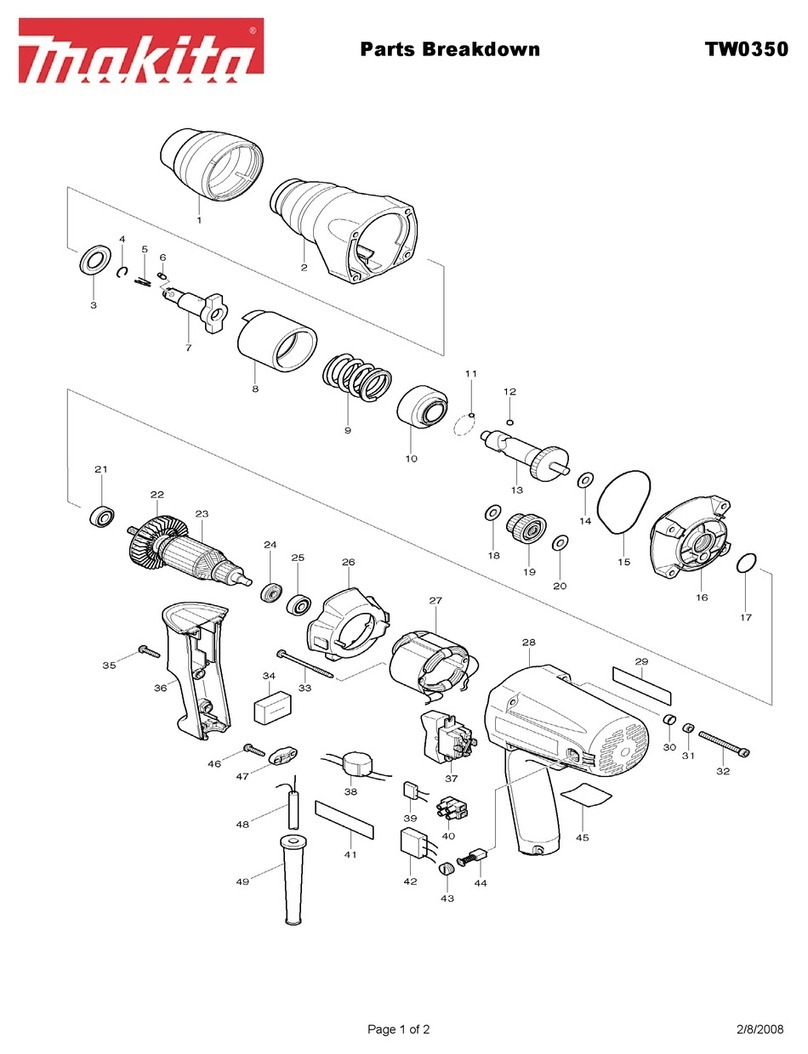

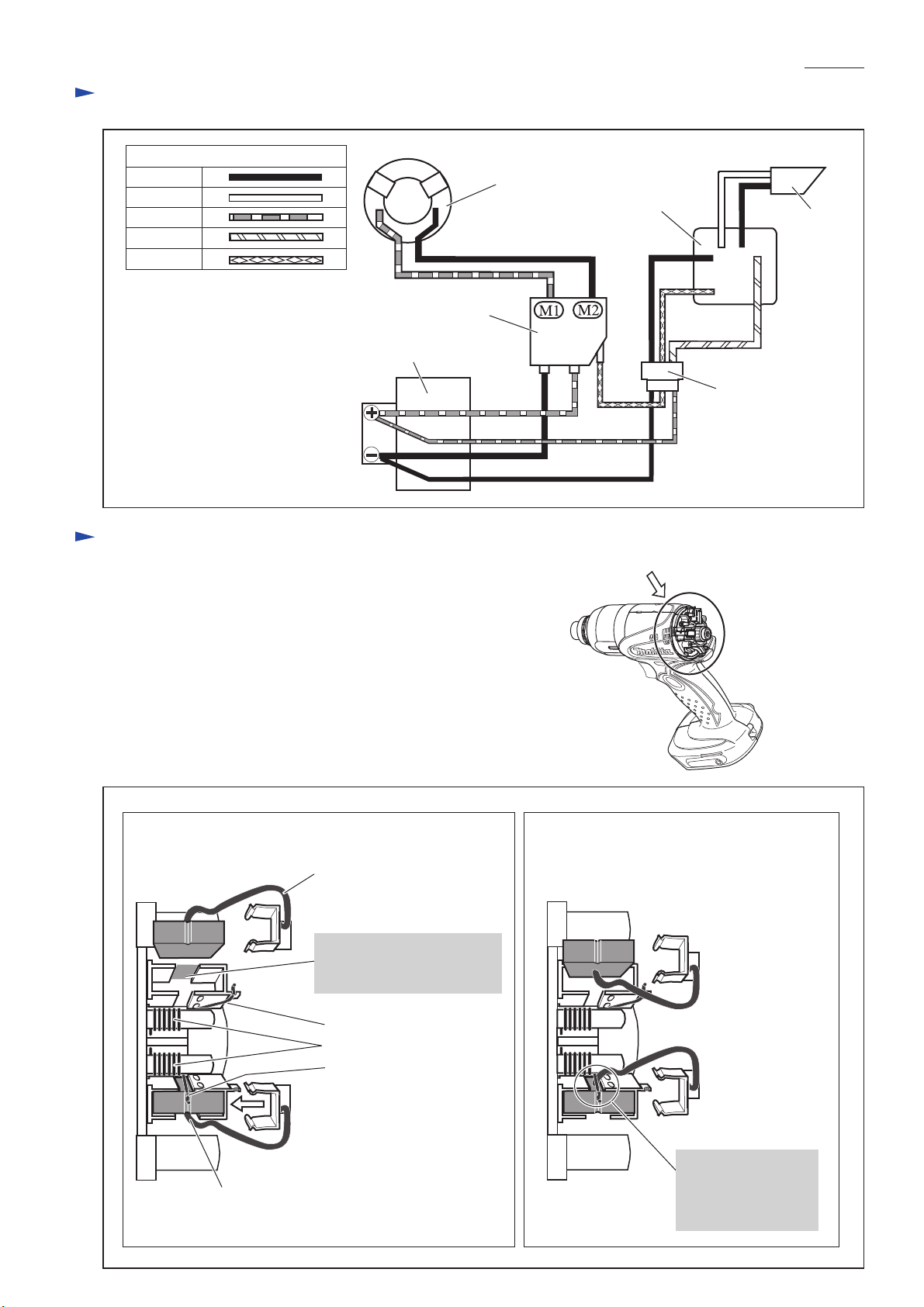

[1] NECESSARY REPAIRING TOOLS

CAUTION: Remove the battery from the machine for safety before repair/ maintenance

in accordance with the instruction manual!

Fig. 1

Repair

DescriptionCode No.

1R041 Vise Plate Protecting Hammer case, when fixing it with Vise

1R045 Gear Extractor (large) Disassembling Hammer section

1R223 Torque Wrench Shaft 20-90N.m Disassembling Hammer case

1R346 Center Attachment Attaching to 1R045

1R224 Ratchet Head 9.5 Attaching to 1R223, when disassembling Hammer case

1R232 Pipe 30 Supporting Anvil to remove Sleeve easily

1R288 Screwdriver Magnetizer Removing Steel balls

1R291 Retaining Ring S & R Pliers Disassembling Sleeve

134847-1 Socket 30-78 Disassembling Hammer case

134848-9 Socket 32-50 Fixing Bearing box, when removing Hammer case

Use for

Item No. Description Portion to lubricate

Anvil

16 Hammer case complete Sleeve 14 that accepts Anvil

21 Steel ball 3.5 (24 pcs) Whole Portion

25 Steel ball 5.6 (2 pcs) Whole Portion

27 Spindle

27a: Top portion that contacts Anvil

27b: Hole for Armature’s gear

Hammer

Flat washer 24

Cup washer 14

Flat washer 12

Internal gear 51

Bearing box

Armature

Compression spring 24

Makita grease

FA No.2 a little

Makita grease

FA No.2 a little

AmountLubricant

Makita grease

N.No.2 a little

Makita grease

N.No.2 2g