Malmet WDS User manual

Malmet (Australia) Pty Ltd

Head Office & Customer Service

9-11 McKay Avenue

PO Box 373

LEETON NSW 2705

Phone: (02) 6953 7677

ISSUE 5

Page

1

15/03/2016

ABN 95 001 717 791

WDS

Washer Disinfector Sanitizer

Operation, Maintenance and Installation Manual

Serial Number:..................................................... Supplied to: .....................................................

Date Installed:...................................................... Installed by:.....................................................

Note: Due to Malmet’s Policy of continuous product improvement;

design and technical specifications are subject to change without notice.

WDS

Operation, Maintenance and Installation Manual

ISSUE 5

Page

2

15/03/2016

Table of Contents

Forward.......................................................................................................................

Certifications and

Compliances

......................................................................................

Quality Policy ..............................................................................................................

Safety Instructions........................................................................................................

1.0 Design Parameters.................................................................................................

1.1 Operating cycles

1.2 Detergent

1.3 Device Features

1.4 LCD Display Features

1.4 Operating Features

2.0 Installation and commissioning..............................................................................

2.1 Installation

2.2 Service Connection and layout details

2.3 Plumbing

2.4 Electrical

2.5 Commissioning

3.0 Unit Loading and Operation ..................................................................................

3.1 Urine Bottle / Bedpan Loading and Operating Cycle

3.2 Urine Bottle Only Loading and Operating Cycle

3.3 Bowl and Utensil Loading and Operating Cycle

4.0 .Cycle of Operation ................................................................................................

4.1 Bedpan/Urine Urine bottle only Bowl and Utensil

4.2 Detergent Warnings

4.3 Fault Indication

5.0 Maintenance..........................................................................................................

5.1 Daily

5.2 Bi Monthly

5.3 Recommended Preventative Maintenance Schedule

5.4 Fault Codes

5.5 Purge Reset

5.6 Purge Detergent Line

5.7 Detergent Load Cell Calibration

5.8 Device service component identification and part listing

5.9 User Menu and Test Mode

6.0 . Technical Data.....................................................................................................

6.1 Power and Water Consumption

6.2 Device Specifications

6.3 Wiring Diagram 1 ph

6.3 Wiring Diagram 3 ph

6.3 Data Logging

7.0 Warranty Statement – Australia Only

.................................................................

WDS

Operation, Maintenance and Installation Manual

ISSUE 5

Page

3

15/03/2016

Forward

In order to obtain maximum life and efficiency from your Malmet WDS and to aid in the safe operation of the device,

please read and understand this manual thoroughly and follow all instructions before operating the unit.

This device is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities,

or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the unit

by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the device.

The specifications supplied in this manual were in effect at time of publication. Due to Malmet (Australia)’s policy of

continuous improvement, changes to these specifications may be made at any time without notice on the part of Malmet

(Australia).

Certifications and compliances

ARTG listed: ID 232450

Electrical Safety Cert: CS10462N

Watermark Cert: WMKA21156

Quality Policy

Malmet (Australia) Pty Ltd is Quality Certified to ISO 9001, AS 3902, NZS 9002 and guarantees the quality of this

product. Should you have any problems with your machine, contact the company from whom you purchased it, or Malmet

(Australia) Pty Ltd.

Malmet (Australia) Pty Ltd

Head Office and Factory

9-11 McKay Ave

PO Box 373

LEETON NSW 2705

Telephone: (02) 6953 7677

Web Site: www.malmet.com.au

WDS

Operation, Maintenance and Installation Manual

ISSUE 5

Page

4

15/03/2016

SAFETY INSTRUCTIONS

WARNINGS

Be aware of 240V / 415V Voltage.

Disconnect power when servicing.

Mains power ISO switch must be in an accessible position so devise can be isolated from mains power during

service.

Be aware of steam discharge

.

Utensils and racks are hot to handle.

Safety gloves and goggles must be worn when changing detergent

Safety clothing with reflective tape can activate the hands free sensor when device is in standby mode.

Be aware of hot pipes and hoses from steam and hot water.

Install temperature probes and element over temperature thermal cut-outs correctly.

Not suitable for use in the presence of a flammable anaesthetic mixture with air or nitrous oxide and mode of

operation as continuous.

WDS

Operation, Maintenance and Installation Manual

ISSUE 5

Page

5

15/03/2016

1.0 DESIGN PARAMETERS

The WDS has been designed within the following parameters

:

1.1 OPERATING CYCLES

Three available operating (cleaning, disinfection and sanitizing)

Urine / Bedpan

Load: capacity: 2 x Small slipper pans, 2 x Large slipper pans, 2 x Standard bed pans and 4 x Standard

male and female urine bottles

Cycle:

1. Flush 8 to 12 sec

2. Cold water wash 2 min

3. Hot water wash with detergent 2 min

4. Hot water rinse 35 sec

5. Disinfection/Sanitizing 1 min at 90 deg

6. Cool down 20 sec

Urine only

Load capacity: 4 x Standard male and female urine bottles

Cycle:

1. Cold water 2 min

2. Hot water wash with detergent 2 min

3. Hot water 35 sec

4. Disinfection/Sanitizing 1 min at 90 deg

5. Cool down 20 sec

Bowl / Utensil

Load capacity: 2 x Large bowls (345Dia to 305Dia), 3 x Medium bowls (240Dia to 210Dia), 6 Kidney

Dishes (sizes 300 x 50, 255 x 50 and 220 x 43 – held in kidney rack holder)

Smaller kidney dishes fit into a basket with a smaller open ended trays and utensils.

Cycle:

1. Cold water wash 2 min

2. Hot water wash with detergent 2 min

3. Hot water rinse 35 sec

4. Disinfection/ Sanitizing 1 min at 90 deg

5. Cool down 20 sec

Note: These times do not include filling and heating. These times comply with AS 2945. See Technical data for

full cycle times.

a) Two bedpans with lid and four urine bottles can be emptied, cleaned and sanitized during each automatic cycle.

b) The cradle is designed to ensure that utensils are not dislodged during the cleaning cycle, the contents are

emptied during door closure.

c) The chamber and door are self-cleaning and do not permit water or soil to remain after a properly completed

cycle. Steam sanitizing ensures all internal surfaces are totally clean and safe.

d) The Bedpan flush cycle:

i) Removes the heavy soil

ii) Clears the trap

WDS

Operation, Maintenance and Installation Manual

ISSUE 5

Page

6

15/03/2016

1. 2 DETERGENT

The 5 litre detergent container is accessed by opening the bottom door. Only use Malmet approved detergent (See

technical data for detergent details)

1. Pull handle on detergent door and open.

2. Unscrew cap and pull out with suction hose (let hose hang on detergent chamber.)

3. Remove empty bottle and replace with full bottle.

Note: Leave cap on new bottle until in position.

4. Remove cap on new bottle and fit existing hose and cap, make sure suction hose is at bottom of bottle.

5. Close detergent door.

6. Restart machine operation as normal.

7.

Check fill level indicator on display. Should show as

Note: Do not drop detergent container onto base plate. This may result in damaging the load cell.

Safety Gloves and Goggles must be worn when changing detergent. A Malmet detergent MSDS is available to

download on the Malmet website.

www.malmet.com.au

WDS

Operation, Maintenance and Installation Manual

ISSUE 5

Page

7

15/03/2016

1.3 DEVICE FEATURES

1.4 CONTROL LCD DISPLAY FEATURES

LCD

Control panel with LCD display

Emergency cycle stop

Bowl / Utensil rack hinged

Bed pan rack hinged

Door Auto open and close

Detergent access door

USB port

Wash Chamber

Urine bottle rack

WDS

Operation, Maintenance and Installation Manual

ISSUE 5

Page

8

15/03/2016

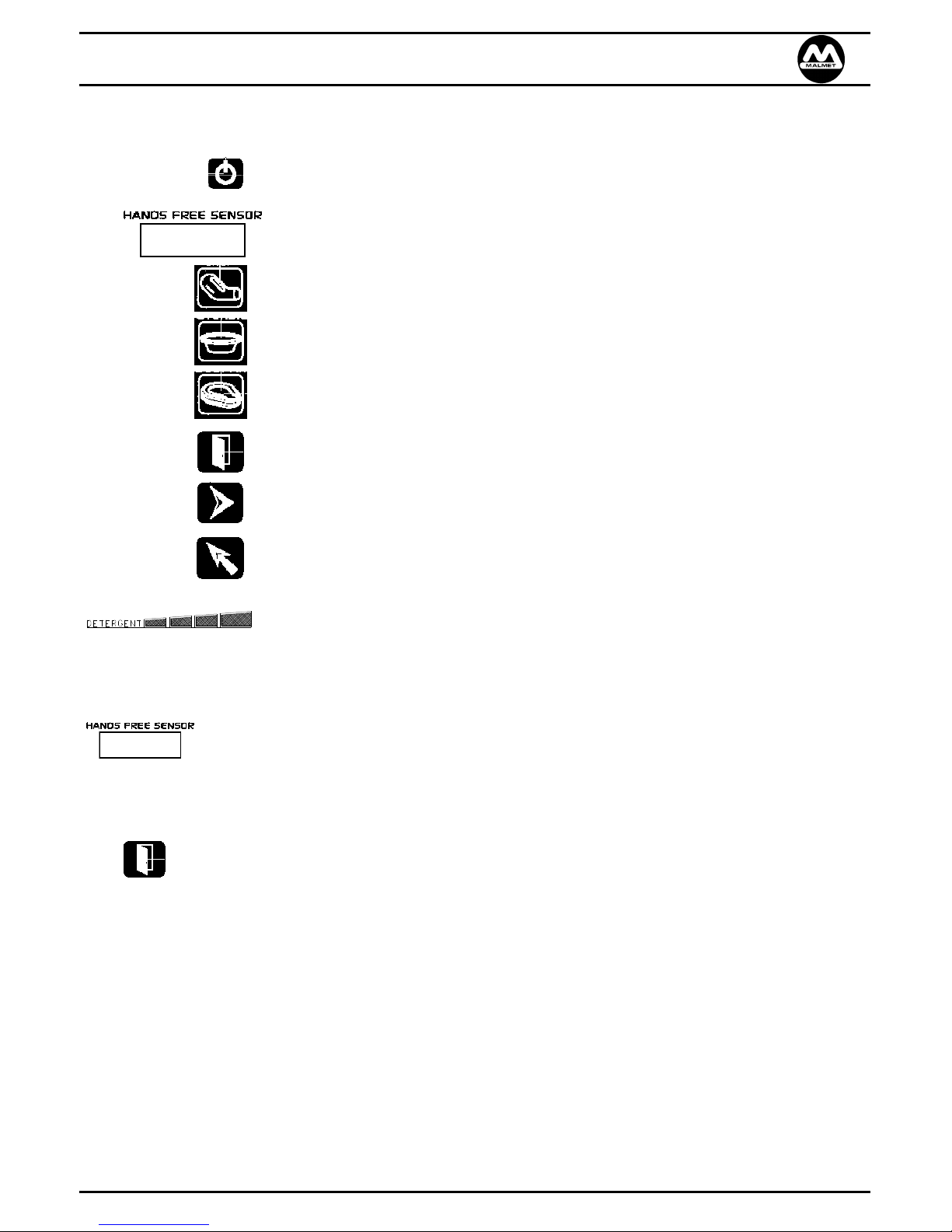

1.5 OPERATING FEATURES:

POWER: On/Off Standby

HANDS FREE SENSOR: For hands free opening and closing door. To operate, place hand

in front of sensor.

URINE ONLY:

Select for Urine bottle only cycle

BOWL / UTENSILS

: Select for Bowls / Kidney dishes etc

URINE / BEDPAN :

Select for Urine bottles / Bedpans

DOOR:

To manually open and close door

SCROLL:

Menu scroll button SERVICE ONLY

SELECT:

Menu select and enter button SERVICE ONLY

Detergent level indicator (only visible with power on)

Hands free operation

By using the hands free option the door can be opened and close automatically. When the door is

closed the cycle selected will start.

Place hand in front of window for approx 2 seconds, the door will open. To close the door the display

will show Close door. Place hand in front of hands free window for approx 2 seconds and the door

will close.

Manual operation of the door

Press the door button the door will open. To close the door the display will show door close. Press

the door button and the door closes. When the door is closed the selected cycle will start.

WDS

Operation, Maintenance and Installation Manual

ISSUE 5

Page

9

15/03/2016

2.0 INSTALLATION AND COMMISSIONING

2.1 INSTALLATION

•Before unpacking unit inspect carton for any damage relating to forklift forks and damage relating to device falling

over or for evidence of top loading.

•

Remove carton from device; inspect all external panels for damage

.

Warning unit weight

•Shipping 163 kg

•

Nett unpacked 140 kg with detergent.

2.1.1

Positioning the WDS

Freestanding Model

Model Placement Access

Required

Unit Dimensions

Height Width Depth (mm)

WDS Freestanding Both Sides 1685 605 625

For Freestanding model, please allow sufficient room for servicing purposes. Recommended space

requirements 300mm on either side and 150mm at the rear of the unit.

Buildings

•Service connections are usually pre-placed after planning and consultation with all interested parties. Installation

is by connection to the services provided.

•As the soil line (sewerage outlet) is the least flexible of all the connections, this usually influences the decision as

to where to place the WDS. If an existing soil line can be utilised this will represent a cost saving.

•The WDS is supplied with either an ‘S’ or ‘P’ Trap as nominated by the Purchaser. The ‘S’ Trap connects through

the floor and the ‘P’ Trap connects through the back wall. The trap section is easily removed if the wrong trap

has been ordered. Refer to Diagram C2 for trap connections.

Potential electromagnetic or other interference between other EQUIPMENT and other devises can possibly

affect the Infra red hands free operation sensor. It is advisable to check all the equipment and devices in the

intended installation area that have infra red operation. Electromagnetic interference can be prevented by

installing the device in non patient areas of hospital (or similar).

WDS

Operation, Maintenance and Installation Manual

ISSUE 5

Page

10

15/03/2016

Service Connections

MODEL

HOT WATER COLD WATER

SOIL LINE ELECTRIC

AL

WDS 1ph Solenoid valve

GB¾ Male

Solenoid valve

GB¾ Male

100mm ‘S’ or ‘P ’Trap

Hot water discharge

75-80°C

240V

1 phase

20 amps 50

hertz

WDS 3ph Solenoid valve

GB¾ Male

Solenoid valve

GB¾ Male

100mm ‘S’ or ‘P ’Trap

Hot water discharge

75-80°C

415V

3 phase

20 amps 50

hertz

Note: Bell ends can be cut off to suit

Diagram C2

For reasonable connection working space allow 150-200mm from rear of device to wall

The Machine is 600mm wide and the centre of the trap is 300mm from each side.

FREE STANDING

‘S’ TRAP PIPE POSITIONING FREE STANDING

‘P’ TRAP PIPE POSITIONING

The centre of the soil line to receive the ‘S’ Trap

should be approximately 272mm from the back

wall. To allow for normal recommended

minimum side service access, space soil line

600/700mm from side wall.

If space restrictions do not allow for

recommended side service access, we suggest

preference be given to providing the most space

available on the right hand side as you look at

the front of the machine. This will ease any

difficulty in servicing the steam tank element

and probe.

The centre of the soil line to receive the ‘P’ Trap

should be approximately 410mm from the floor

when the unit is positioned 150mm from the

wall. Because this pipe is graded to 5° this

measurement will vary as the unit is installed

closer or further away from the back wall.

Steam Venting

•No external vent pipe work is required as the machine is designed to condensate all visible steam within the

machine.

WDS

Operation, Maintenance and Installation Manual

ISSUE 5

Page

11

15/03/2016

2.2 SERVICE CONNECTION AND LAYOUT DETAILS

WDS

Operation, Maintenance and Installation Manual

ISSUE 5

Page

12

15/03/2016

2.3 PLUMBING

These Installation Guidelines must be followed to ensure the unit will operated as intended.

Installations must be carried out by a qualified and licensed tradesperson.

Service Connections

NOTE: Plumbing connection must comply to AS3500 and Watermark Certified.

Waste connection

•HOT AND COLD WATER CONNECTIONS ARE REQUIRED. The machine can be connected to any normal

mains pressure hot and cold water supply. A back flow prevention air gap is incorporated in the design of the

water tank. Complies to AS 2845.2

•The water supply is to be connected to an isolating valve or cistern stopcock placed approximately 1200mm

from the floor to the right-hand side of the machine. (Preferably not behind the machine)

Cold water: Flow pressure Kpa 100 min 350 max. Temperature 15°- 25°C

Hot water: Flow pressure Kpa 100 min 350 max. Temperature 55°- 60°C

Minimum water flow for 100Kpa 9.377L/min

If inlet water flow pressure is higher than 350 Kpa an inline pressure reducing valve should be fitted.

Soil Line

•Hot water. Discharge temp 75°– 80°C. Soil line to comply to AS3500

•Soil line connection is by a pan collar or other preferred method. If the belled end on the polyethylene moulded

trap is not required it can easily be cut off to provide a straight pipe connection.

•Level the unit by using the flanged screw in legs and if possible maintain approximately 100mm floor clearance

for ease of floor cleaning. We recommend that some of the leg flanges are fixed to the floor via stainless self

tapping screws to prevent sideways movements and damage to services and soil line connections.

•The soil line should protrude from the floor or wall at a minimum of 100mm

WDS

Operation, Maintenance and Installation Manual

ISSUE 5

Page

13

15/03/2016

2.4 ELECTRICAL

These Installation Guidelines must be followed to ensure the unit will operated as intended.

Installations and service must be carried out by a qualified electrical licensed tradesperson.

Model: WDS 1ph 240V 50Hz 1 ph 20Amp

WDS 3ph 415V 50Hz 3 ph 20Amp

•Units are supplied with 1700mm power supply cord extending from the rear top right hand side of the device for

hard wiring into Mains ISO switch. Position switch approximately 1500mm above floor level

•Mains power ISO switch must be in an accessible position so device can be isolated from mains power during

service.

•We recommend having a 30mA RCD in the mains supply fixed wiring.

•If the supply cord is damaged, it shall be replaced by the manufacturer or its service agent or similarly qualified

person in order to avoid any potential hazard.

2.5 COMMISSIONING

a) Before switching the unit on make sure the UNIT IS LEVEL and WATER TAPS ARE ON. Check that the

DRAIN WASTE is connected.

b) Turn on the power at the isolation switch. Turn on circuit backers inside electrical cover and press the standby

button on the front display. The LCD display will illuminate and go to standby mode.

c) Check that the water tank is filling with cold water and that it has fill to Level 3. Make sure the lid is put back on

water tank.

d) Check that the steam generator tank has filled to the full Level 3. The steam generator will pre heat to 85°C in

standby mode or during cycle.

e) Check that the 5 litre detergent bottle has been fitted. From the menu, run the DETERG/START to purge

detergent through the line to flow sensor. This may need to be done twice if the line is empty on start up. See

5.6

f) Flush approximately 1 litre of water down the steam generator tank overflow pipe. This will fill the ‘S’ Trap at

the hose junction and prevent steam coming back up into the water tank.

g) From the Menu, run Purge Reset three times. Check for any water leaks.

h) Open the door and turn power off at the control. Check racks for freedom of movement. Check that Flush

nozzles rotate freely. Check that all spray nozzles are tight. Turn power back on and close door by pressing

the door button.

i) Select the BEDPAN/URINE cycle and let it run through the cycle. Repeat the same procedure for the URINE

and BOWL cycles.

j) Replace all covers.

Note: DO NOT USE THE DEVICE WITHOUT THE WATER SUPPLY TURNED ON

WDS

Operation, Maintenance and Installation Manual

ISSUE 5

Page

14

15/03/2016

3.0 UNIT LOADING AND OPERATION

Refer to laminated WDS Instructions

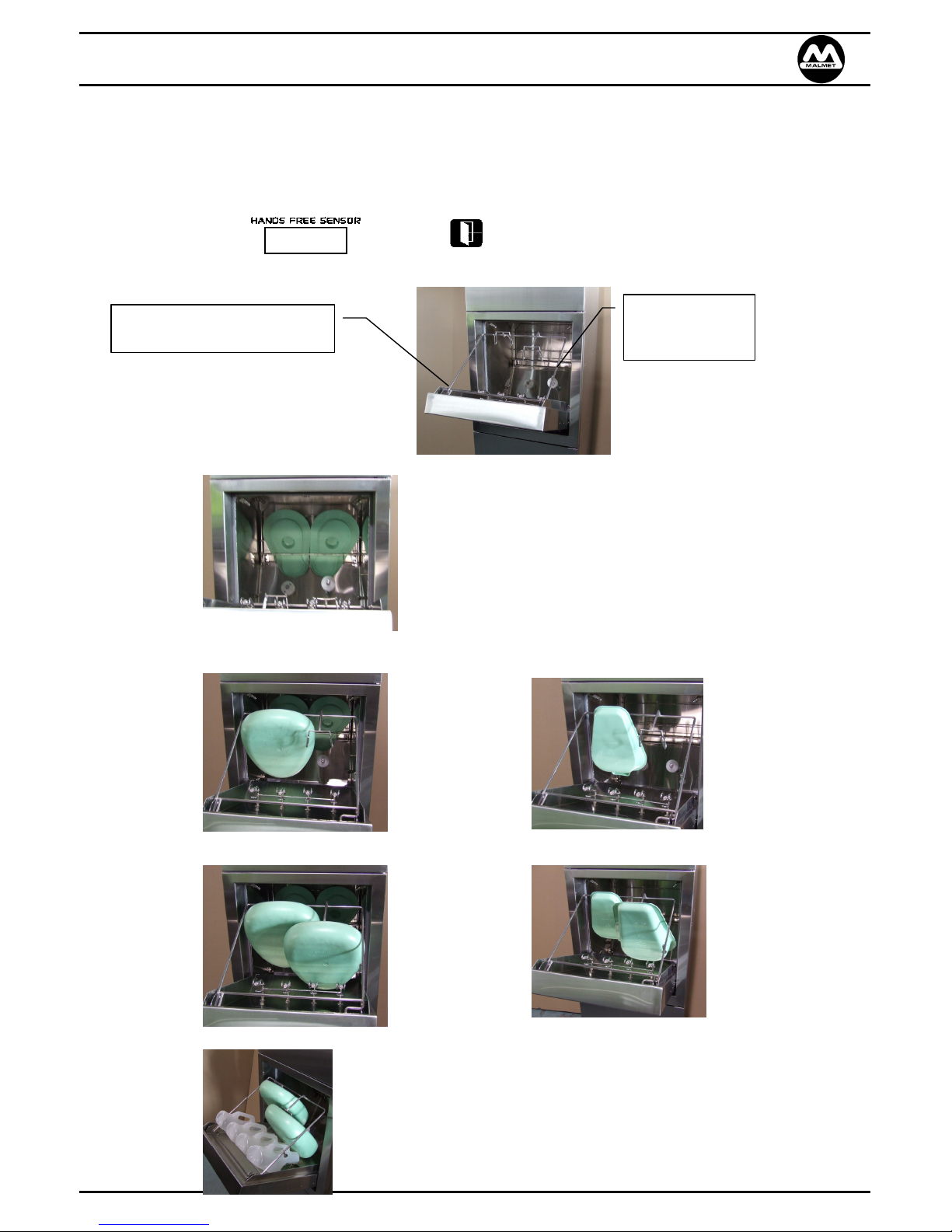

3.1 URINE BOTTLE / BEDPAN LOADING AND OPERATING CYCLE

LOADING

1. To open door, use or press

2. Place racks into the correct positions

3. Place bedpan lids into back of Bowl rack

4. Place first bedpan onto top rack, or large/small slipper pan.

5. Place second bedpan onto bottom rack or large/ small slipper pan

6. Place urine bottles into rack

Lift bedpan rack up and lock

into position.

Check that bowl

rack is in the up

position

.

WDS

Operation, Maintenance and Installation Manual

ISSUE 5

Page

15

15/03/2016

3.1.1 URINE BOTTLE / BEDPAN LOADING AND OPERATING CYCLE

Refer to laminated WDS Instructions

OPERATING CYCLE

1. Open door, use or press

2. Select URINE / BEDPAN cycle press

3. Close door, use or press

When door closes the cycle will start automatically.

Cycles will be shown on LCD display

1. Flush

2. Cold water wash

3. Hot water wash with detergent

4. Hot water rinse

5. Disinfection

6. Cool down

7. Completed

When the cycle is completed the display will show COMPLETED. OPEN DOOR

Open door, use or press

NOTE: If temperature inside the chamber is too high the display will flash, WAITING COOLING

When the temperature has dropped to a safe level the display will flash, OPEN DOOR

Open door, use or press

To run the same cycle repeat steps 1 to 3

If you don’t need to run another cycle. Close door by pressing

NOTE:

•When the cycle has started the operating cycle cannot be interrupted.

•In an emergency, if the cycle needs to be stopped press the EMERGENCY CYCLE STOP button.

•The display will show a Fault code 904 (See note below).

NOTE:

•If a FAULT code is displayed on LCD display contact the service engineer to rectify.

WDS

Operation, Maintenance and Installation Manual

ISSUE 5

Page

16

15/03/2016

3.2 URINE BOTTLE ONLY LOADING AND OPERATING CYCLE

Refer to laminated WDS Instructions

LOADING

1. Open door, use or press

2. Place racks into correct positions

3. Place urine bottles into rack

Bedpan rack can be in the

up or down position

.

Check that the

bowl rack is in the

up position

WDS

Operation, Maintenance and Installation Manual

ISSUE 5

Page

17

15/03/2016

3.2.1 URINE BOTTLE ONLY LOADING AND OPERATING CYCLE

Refer to laminated WDS Instructions

Operating cycle

1. Open door, use or press

2. Select URINE / BEDPAN cycle press

3. Close door, use or press

When door closes the cycle will start automatically.

Cycles will be shown on LCD display

1. Cold water wash

2. Hot water wash with detergent

3. Hot water rinse

4. Disinfection

5. Cool down

6. Completed

When the cycle is completed the display will show COMPLETED OPEN DOOR

4. Open door, use or press

NOTE: If temperature inside the chamber is too high the display will flash, WAITING COOLING

When the temperature has dropped to a safe level the display will flash, OPEN DOOR

To open door, use or press

5. To run the same cycle repeat steps 1 to 3

6. If you don’t need to run another cycle close door by pressing

NOTE:

•When the cycle has started the operating cycle cannot be interrupted.

•In an emergency, if the cycle needs to be stopped press the EMERGENCY CYCLE STOP button.

•The display will show a Fault code 904 (See note below).

NOTE:

•If a FAULT code is displayed on LCD display contact the service engineer to rectify.

WDS

Operation, Maintenance and Installation Manual

ISSUE 5

Page

18

15/03/2016

3.3 BOWL / UTENSIL LOADING AND OPERATING CYCLE

Refer to laminated WDS Instructions

LOADING

1. Open door, use or press

2. Place racks into the correct positions

3. Examples of bowls and utensils placed onto racks

Large and medium size bowls

Medium size kidney dishes

Kidney dish rack placed onto bowl rack Load kidney dishes into rack

Smaller items can be placed into accessory basket

Basket placed onto bowl rack

Place bedpan rack

into the down

position.

Place the bowl

rack in the down

position

WDS

Operation, Maintenance and Installation Manual

ISSUE 5

Page

19

15/03/2016

3.3.1 BOWL / UTENSIL LOADING AND OPERATING CYCLE

Refer to laminated WDS Instructions

OPERATING

1. Open door, use or press

2. Select Bowl / Utensil cycle, press

3. Close door by using or press

When door closes the cycle will start automatically.

Cycles will be shown on LCD display

Cold water wash

1. Hot water wash with detergent

2. Hot water rinse

3. Disinfection

4. Cool down

5. Complete

When the cycle is completed the display will show COMPLETED OPEN DOOR

4. Open door, use or press

NOTE: If temperature inside the chamber is too high the display will flash WAITING COOLING

When the temperature has dropped to a safe level the display will flash OPEN DOOR

To Open door, use or press

5. To run the same cycle repeat steps 1 to 3

6. If you don’t need to run another cycle close door by pressing

NOTE:

•When the cycle has started the operating cycle cannot be interrupted.

•In an emergency, if the cycle needs to be stopped press the EMERGENCY CYCLE STOP button.

•The display will show a Fault code 904 (See note below).

NOTE:

•If a FAULT code is displayed on LCD display contact the service engineer to rectify.

WDS

Operation, Maintenance and Installation Manual

ISSUE 5

Page

20

15/03/2016

4.0 CYCLE OF OPERATION

1. Press POWER ON BUTTON

Display shows

POWER

After short delay display shows alternating

OPEN

DOOR

2. OPEN DOOR:

Display shows

OPENING

3. WHEN DOOR IS OPEN:

Display shows

LOAD

ITEMS

After short delay display shows

SELECT

CYCLE

If the wrong cycle has been selected for the position of the racks.

Display shows briefly

WRONG

RACK

Then

SELECT

CYCLE

POWER

OPENING

LOAD-ITEMS

SELECT-CYCLE

WRONG-RACK

OPEN DOOR

Table of contents