MegaPod User Instruction Manual

MaltaDynamics.com | 800-494-1840 6

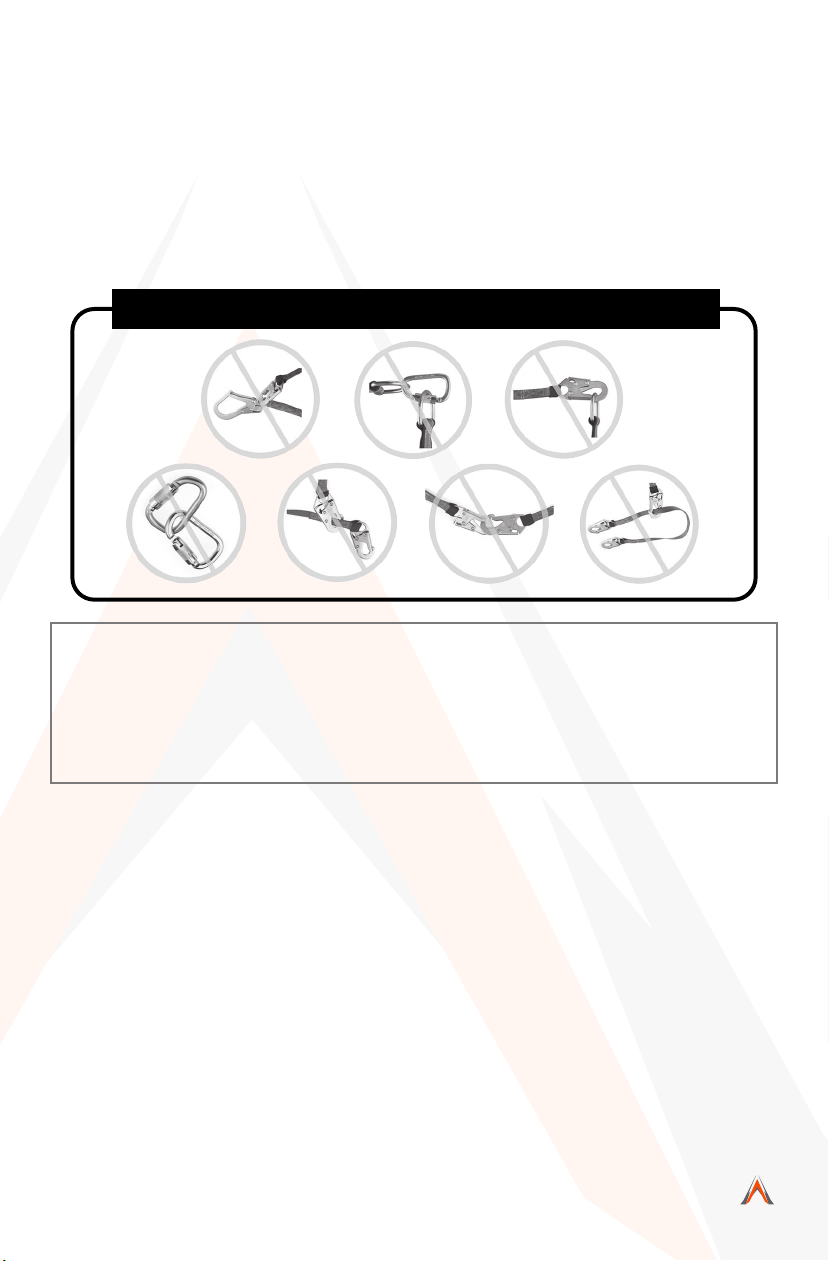

CONNECTOR COMPATIBILITY LIMITATIONS

Malta Dynamics’ equipment must be coupled only to compatible connectors that

are suitable to your application. Ensure all connections are compatible in size,

shape, and strength. Ensure all connectors are fully closed and locked. OSHA

29 CFR 1926.502 prohibits the use of snap hooks to engage objects unless the

following requirements are met:

• Snap hook must be a locking model.

• Snap hook must be explicitly designed for such a connection.

Use of a non-locking snap hook can result in rollout (a process by which a snap

hook or carabiner unintentionally disengages from another connector or the

object to which it is coupled (ANSI Z359.0-2007). Malta Dynamics connectors

(snap hooks and carabiners) are designed to be used only as specied in each

product’s user’s instructions.

Avoid the following types of connections:

• Two or more snap hooks or carabiners attached to one D-Ring.

• A snap hook connected to its integral lanyard.

• A snap hook connected to a horizontal lifeline.

• Connection in a manner that results in a load on the gate. NOTE: Large

throat opening snap hooks should not be connected to standard size

D-Rings or similar objects, as such use will result in a load on the gate

if the hook or D-Ring twists or rotates. Large throat snap hooks are

designed for use on structural elements such as rebar or cross members

that are not shaped in such a way that they may capture the gate of the

hook.

• False engagement connections, where protruding features of the snap

hook or carabiner may catch on the anchor and seem fully engaged to

the anchor point. Always conrm engagement.

• Connection to snap hooks or carabiners.

• Direct connection to webbing lanyard, webbing loop, rope lanyard or

tie-back (unless the manufacturer’s instructions for both the lanyard

and connector specically allow such a connection).

• Malta Dynamics’ Full Body Harnesses shall be used as part of a

personal fall arrest system that limits the maximum free-fall distance to

six feet (1.8 m). If used with appropriate connecting systems, the Full

Body Harnesses may be used with free falls exceeding six feet (1.8m)

• Full Body Harnesses shall only be used as part of a work positioning

system that limits the maximum free-fall distance to two feet (0.6 m).

• Personal Energy Absorbers and Energy Absorbing Lanyards marked

with, “ANSI Z359.13,” and “Six-Foot Free Fall” are designed for up to

six feet. Free-fall applications have a maximum capacity of 310 pounds.

(141 kg) including clothing, tools, etc.

•