Mamba AirCombi User manual

OPERATING MANUAL

WARNING!!! Read all instrucons carefully before assembling components and oper-

ang sprayer. Incorrect procedure could result in damage to the unit, severe personal

injury and/or property damage. When spraying ammable materials, sprayer must be

placed at least 20 feet from target in a well-venlated area. Vapours can be ignited by

stac discharge or electrical sparks and result in severe personal injury. Airless sprayers

generate high uid pressure. Improper use could result in an injecon injury.

MAMBA

AirCombi Spray Gun

AirCombi Spray Gun

MAMBA

Page 2 OPERATING MANUAL

INDEX

1. Descripon of symbols............................................................3

2. General Cauons ....................................................................4

3. Introducon............................................................................6

4. Descripon of the equipment .................................................6

4.1 Technical Data .............................................................................................. 6

4.2 Assembly details .......................................................................................... 7

5. Set-up .....................................................................................8

5.1 Grounding .................................................................................................... 8

5.2 Assembling the spray nozzle ........................................................................ 8

5.3 Spray Gun Filter ........................................................................................... 8

5.4 Air Hose Connecon .................................................................................... 9

5.5 Material Hose Connecon ........................................................................... 9

6. Hints for Airless & AirCombi Sprayer.....................................10

6.1 Painng and Tip Selecon .......................................................................... 10

6.2 Spray Painng Method .............................................................................. 10

7. How to select p and proper lter ........................................11

8. Proper system seng ...........................................................12

8.1 Spring Tension Adjustment ........................................................................ 12

9. Cleaning................................................................................13

10. Maintenance ........................................................................13

10.1 Nozzle changing ......................................................................................... 13

10.2 Gun Filter changing .................................................................................... 14

10.3 Needle changing ........................................................................................ 14

11. Troubleshoong....................................................................15

AirCombi Spray Gun

Page 3

OPERATING MANUAL

MAMBA

1. Descripon of symbols

The signs and symbols used in this manual have the following meaning:

NOTE

marks a secon of text which is especially relevant to safety. Special aenon should be paid to this secon

and its contents strictly observed.

WARNING

marks a situaon which could be dangerous. If not observed,death or very serious injury

could result. Warning concerning electrostac charging when spraying in metal containers.

Take care to ground the spray gun through contact with the container in order to prevent a

major stac discharge.

INJECTION HAZARD

marks a situaon, where pressure is in the system. Do not point the gun at anyone or any

part of the body

DANGER OF EXPLOSION

marks a situaon, where there is danger of explosion. Observaon of

this informaon is absolutely essenal.

USE BREATHING PROTECTION

For health reasons, it is very important to pay aenon to this warning.

WEAR PROTECTIVE GLOVES

To prevent burns, wear protecve gloves with lower arm protecon.

Observaon of this informaon is essenal.

AirCombi Spray Gun

MAMBA

Page 4OPERATING MANUAL

2. General Cauons

• Always follow safety precauons and warnings printed on paint container.

• Only use accessories supplied by the manufacturer. User assumes all risk and

liability when using spray guns, hoses or other parts not complying with minimum

specicaon and safety devices

• Inspect hoses before each use. Never use a damaged hose. High pressure in hoses

with wear, leaks or splits may cause the hose to rupture and cause serious personal

injury. Never try to stop or deect leaks with any part of your body.

• Use extreme cauon when cleaning spray p guard. DO NOT try to wipe o build up around the spray

p before following shut down procedure. Follow the Shutdown Procedure, then follow the spray p

manufacturer’s instrucons for removing and cleaning the spray p.

• Never aempt to change spray p or leave the unit unaended without rst shung o pump, releas-

ing uid pressure, and locking the trigger safety lock.

• Use extreme cauon when changing spray p. Follow the Shutdown Procedure, then follow the spray

p manufacturer’s instrucons for changing the spray p.

• Do not pull on hoses to move equipment, DO NOT kink or bend the hose sharply.

• Keep children or anyone not familiar with airless spray systems away from equipment and work area.

• Conducve metal containers must be used when ushing ammable uids through the system. Always

ush at low pressure with spray p removed. A metal part of the spray gun must be held rmly against

the grounded metal pail when ushing or relieving pressure from the gun.

• It is forbidden the use of the spray gun for dispensing ammable or highly toxic like gasoline, herbicides,

pescides..

• This spray gun was designed and built in accordance with all safety aspects and CE regulaons

• During spraying, due to the speed of ow paint, in parcular situaons may accumulate on the equip-

ment electrostac charges that in discharging phase my generate sparks or ame. Due to this parcular

condion, ensure the proper grounding through a uid feed exible and the pump properly grounded.

Injecon Hazard

High Pressure Painng can cause serious injury if the spray penetrates the skin. Do not point

the gun at anyone or any part of the body. The p guard provides some protecon against

accidental injecon injuries, but is mostly a warning device. Never put your hand, ngers or

body over the spray p. Gloves and clothing do not necessarily oer any protecon either.

Keep the gun trigger safety lever in locked posion when not spraying. Always have the p

guard in place while spraying. In case of penetraon seek medical aid immediately!

Note to physician: Injecon into skin is a serious traumac injury. It is important to treat the injury surgi-

cally as soon as possible. Do not delay treatment to research toxicity. Toxicity is a concern with some exoc

coangs injected into the blood stream. Consultaon with a plasc surgeon or reconstrucve hand surgeon

may be advisable. Be prepared to tell the doctor what uid was injected.

AirCombi Spray Gun

Page 5

OPERATING MANUAL

MAMBA

High Pressure Hazard

This system is capable of producing 200 Bar (2900 PSI). To avoid rupture and injury, do not operate this

pump with components rated less than 200 bar (2900 PSI) working pressure (including but not limited to

spray guns, hose and hose connecons).

Do not spray paints or other inammable uids indoors which have a ash point below 21 degree C, 70

degree F. Keep spray area well venlated. Before spraying, turn o all pilot lights and open

ames.

Warnings for operator

Wear a respirator which is approved for the product being sprayed. Operator must wear

appropriate protecve equipment when operang, servicing or when is in the operang

site in order to prevent serious injury, including eye injury, inhalaon of toxic fumes, burns

and hearing loss. We recommend to wear Protecve eyewear, Clothing and respirator as recommended by

the uid manufacturer, Protecve Gloves, Hearing protecon.

Explosion Hazard

Do not use halogenated hydrocarbon solvents in this system; it contains aluminum parts

and may explode. Cleaning agents, coangs, paints, and adhesives may contain halogenated hydrocarbon

solvents. Don’t take chances, consult your material supplier to be sure. (ex: methylene chloride and 1,1,1 -

Trichlorethane)

Cauon: When a ammable liquid is sprayed there maybe danger of re or explosion especially in a closed

area.

Cauon: Arcing parts. Keep the pump at least 5 mt away from explosive vapors.

Warning: Stac electricity can be developed by airless spraying. Ground unit and object to be sprayed.

On electric units, unit power cord must be connected to a grounded outlet. Use only three wire extension

cords. Stac explosion can occur with ungrounded unit.

AirCombi Spray Gun

MAMBA

Page 6OPERATING MANUAL

3. Introducon

We appreciate your decision to purchase a high quality professional paint spraying system and believe you

will nd it to be the best sprayer you ever owned. Your AirCombi Spray Gun is capable of spraying a wide

variety of latex, oil-based and alkyd paints, as well as stains, preservaves, re-proong, water-proong,

and other many industrial coangs. The material you are spraying will have a direct eect on the amount of

pressure required for the opmum paern and coverage to be obtained. We recommend that before actu-

ally beginning your job, you carefully read this manual and pracce with the sprayer unl you feel comfort-

able using it.

4. Descripon of the equipment

M100 gun is a pneumac operated spray gun used to atomize coangs at high pressure (up to 200 bar).

M100 is operated by hand by operator and can handle coangs like varnishes , enamels, primers, polyure-

thane, solvent based coangs, water based paints. For other coangs we recommend to ask to the manu-

facturer. M100 spray gun is supplied in a cardboard box together with operang instrucons and parts.

ATTENTION: Materials sprayed are varnishes and enamels synthec, varnishes polyu-

rethane, nitro, primers, dyed, water born paints.

For the use of the gun with special products must be obtained approval of manufactur-

er which is not liable for injuries resulng from the equipment by unauthorized person-

nel, unqualied or use it for purposes dierent as menoned above.

It is prohibited from using a spray gun for dispensing ammable or highly toxic like

gasoline, herbicides, pescides.

4.1 Technical data:

Max. Working Fluid Pressure 200 bar (2900 psi)

Max. Working Air Pressure 8 bar (110 psi)

Max. Working Fluid Temperature 43 °C

Fluid Inlet 1/4”

Air Inlet 1/4”

Gun Weight (bare) 400 gr.

Gun Body Forged Aluminum

Weed Parts Stainless Steel, Carbide, PTFE, Cu

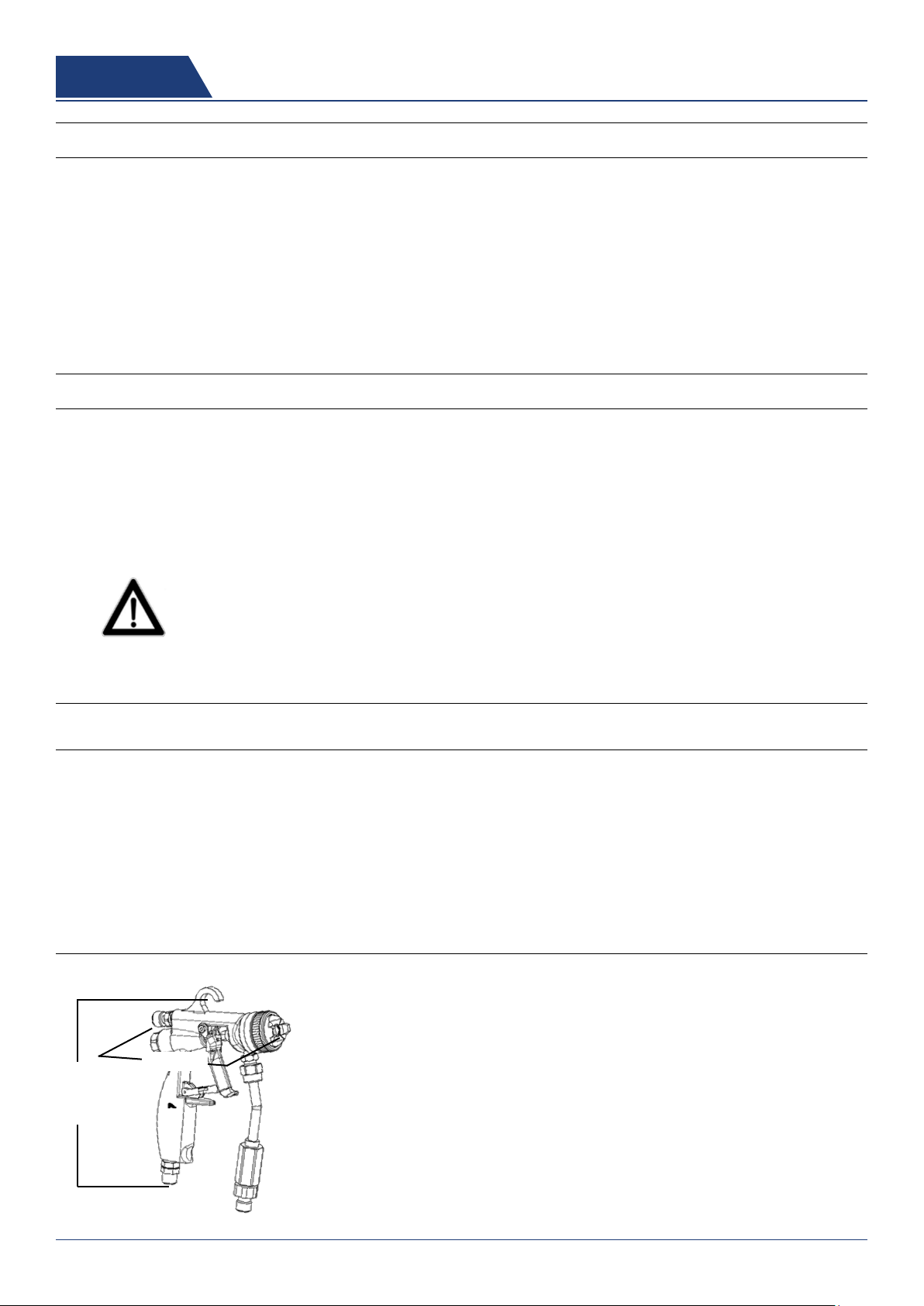

140 mm

160 mm

AirCombi Spray Gun

Page 7

OPERATING MANUAL

MAMBA

4.2 Assembly details

Pos. Descripon

1 AirCap complete

2 Hook

3 Fan regulator set

4 Trigger

5 Trigger lock

6 Filter Holder

7 Fluid connecon

8 Air connecon

AirCombi Spray Gun

MAMBA

Page 8OPERATING MANUAL

5. Set-up

The spray gun is designed specically for AirCombi spraying, i.e. the Spray gun can be used in Airless mode

as well as in Mixed Air mode. The atomizaon is accomplished by the pressure (adjustable from 0 up to 200

Bar) through a pump. The air is used to improve the atomizaon quality and to increase or decrease the fan

size by adjusng the proper fan regulator placed on the spray gun

WARNING: INJECTION HAZARD POSSIBLE. DO NOT SPRAY WITHOUT TIP IN PLACE. AL-

WAYS ENGAGE TRIGGER LOCK BEFORE REMOVING, REPLACING OR CLEANING TIP. NEVER

TRY TO CLEAN THE TIP WITH YOUR FINGERS.

To prevent hazardous concentraon of toxic and/or ammable vapors, spray only in a prop-

erly venlated spray booth. Do not operate the spray gun unless venlaon fans are op-

erang. Check and follow all of the Local and Naonal Codes/Standards regarding exhaust

velocity requirements. Check and follow all local safety and re codes.

5.1. Grouding

Check your local code and pump manual for detailed grounding instrucons. Use only electrically conduc-

ve uid hoses. Ground the spray gun through connecon to a properly grounded uid supply hose and

pump.

5.2. Assembling the spray nozzle

Warning: the proper nozzle size is essenal for a good atomizaon on which depends the nal result. The

nozzle size is determinated by the coangs used and the type of applicaon. Ask to the coangs’ manufac-

turer for the proper p size.

1. Place the trigger lock in horizontal posion in order to prevent accidental injecon

WARNING: Before each nozzle change, assure to release the pressure in the spray gun and disconnect air

supply.

2. Unscrew the nut

3. Remove the air cap

4. Remove the nozzle into the air cap

5. Place the nozzle into the air cap

6. Place the air cap complete with the nozzle into the spray gun

7. Screw the nut onto the spray gun

5.3 Spray Gun Filter

We suggest always to use a Gun Filter, unless the coangs used do not require it. The mesh size of the gun

lter is determinated by the nozzle size. See the table at page 10 for the suggested lter size.

AirCombi Spray Gun

Page 9

OPERATING MANUAL

MAMBA

5.4 Air hose connecon

Aenon: It is suggested to install an air lter on the gun air line to ensure a dry, clean air supply to the

gun. Dirt and moisture can ruin the appearance of your nished worked piece. Install an air pressure reg-

ulator on the gun air line to control air pressure to the gun. Install an air shuto valve on the gun air line

and on the pump air line, to shut o air to the gun. Use a 3/16” (5mm) or even larger air hose to minimize

excessive pressure drop in the hose.

1. Connect the air hose the air inlet placed on the gun.

2. Connect the other end of the air hose to the air pressure regulator placed on the pump

5.5 Material hose connecon

Note: Before connecng the uid line, blow it out with air and ush it with solvent. Use solvent which is

compable with the uid to be sprayed. If beer control of uid pressure is needed, install a uid regulator

on the uid line to beer control uid pressure to the gun.

3. Connect the material hose to material inlet placed on the gun.

4. Connect the other end of the material hose the material outlet placed on the pump.

Note: Only use hoses supplied or approved by the manufacturer

WARNING: Inspect hoses before each use. Never use a damaged hose. High pressure in hoses with wear,

leaks or splits may cause the hose to rupture and cause serious personal injury. Never try to stop or deect

leaks with any part of your body.

AirCombi Spray Gun

MAMBA

Page 10 OPERATING MANUAL

6. Hints for Airless & AirCombi Sprayer

WARNING: DO NOT BEGIN SPRAYING BEFORE READING THIS SECTION AND ALL PREVIOUS SAFETY INFOR-

MATION.

To disengage your trigger lock: Your spray gun is shipped from the factory with the trigger lock in the

engaged posion (horizontal). To disengage, turn the trigger lock down unl it is in a vercal posion. To

engage the trigger lock, turn it back to a horizontal posion.

6.1 Painng and Tip Selecon

Correct adjustment of pressure and proper p selecon are crucial to the

best spray paern....

1. In any situaon, the lowest pressure that gives an adequate spray paern

is the best pressure to use. It will give maximum pump and p life and

produce minimum overspray.

2. Typically, thicker materials require larger ps and higher pressures than

thinner paints do. Some very thick paints may require slight thinning (5-

10%) depending upon pump and p size and applicaon. Generally, thin-

ning is performed when a good spray paern cannot be obtained with an

appropriate p size at maximum pressure.

6.2 Spray Painng Method

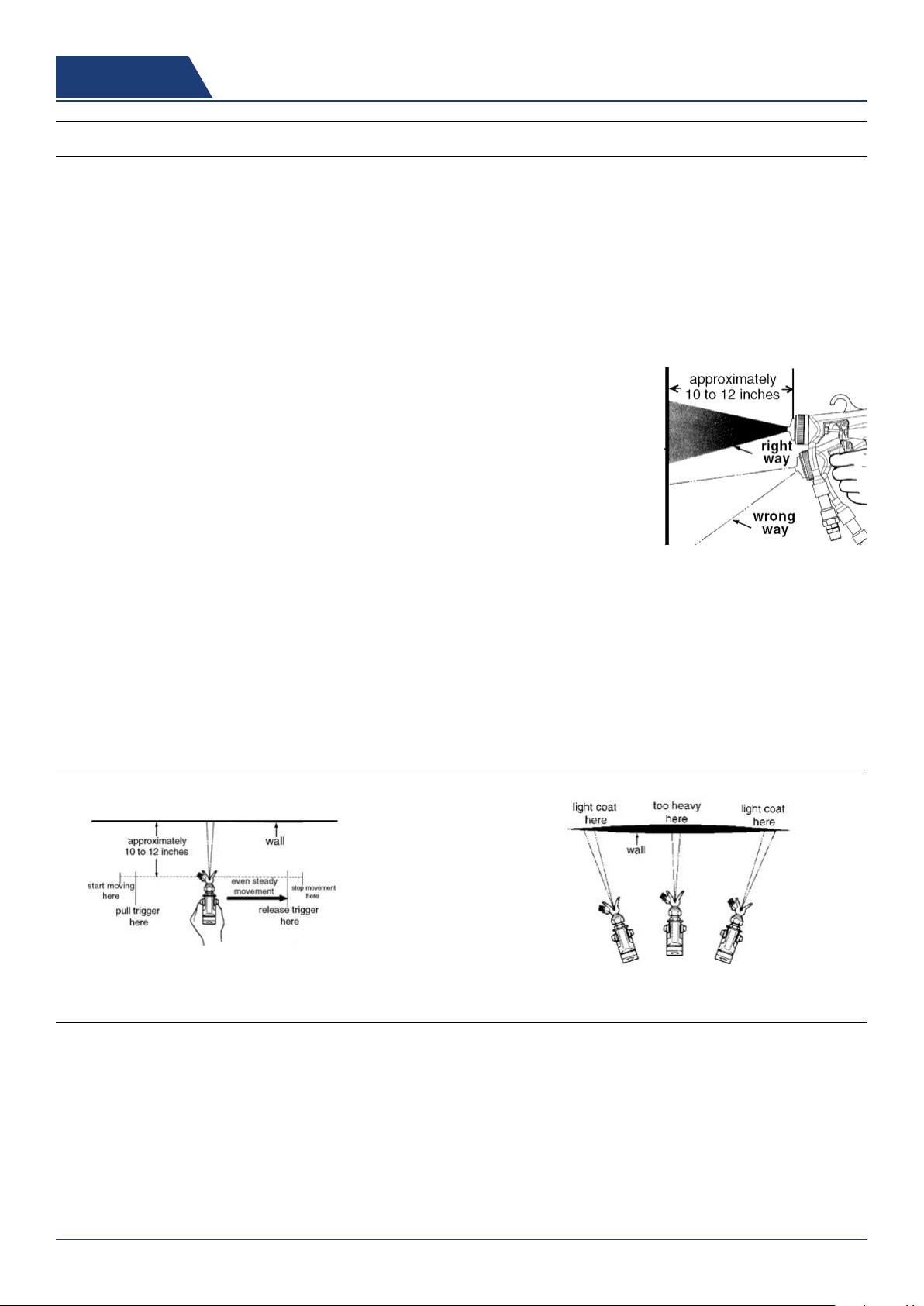

1. Keep the gun perpendicular to the surface. Always hold the gun perpendicular to the surface with the

p approximately 12” from the surface. If held at an angle (up and down or side to side) paint will build

up unevenly and leave the work splotchy.

2. Move with a smooth arm stroke. Move the gun at a steady even pace while keeping the gun perpen-

dicular to the surface. Do not move the gun by exing your wrist. Fanning the gun will cause excessive

overspray and uneven coverage

Proper way to trigger spray gun Result of exing wrist while spraying

3. Start moving the gun before triggering. To get smooth overlap and prevent inial paint buildup, start

our stroke movement before pulling the trigger. At the end of the stroke release the trigger before stop-

ping. NOTE: To assure uniform paint coverage, overlap each stroke by 40% - 50%.

4. Intermient use. If you are spraying and decide to stop for several minutes, lock the spray gun trigger

and submerge the p in a container of the appropriate solvent. This will prevent paint from hardening

in the ny spray opening and clogging the p. Be sure to release the pressure by opening dump valve

and turn o pump.

AirCombi Spray Gun

Page 11

OPERATING MANUAL

MAMBA

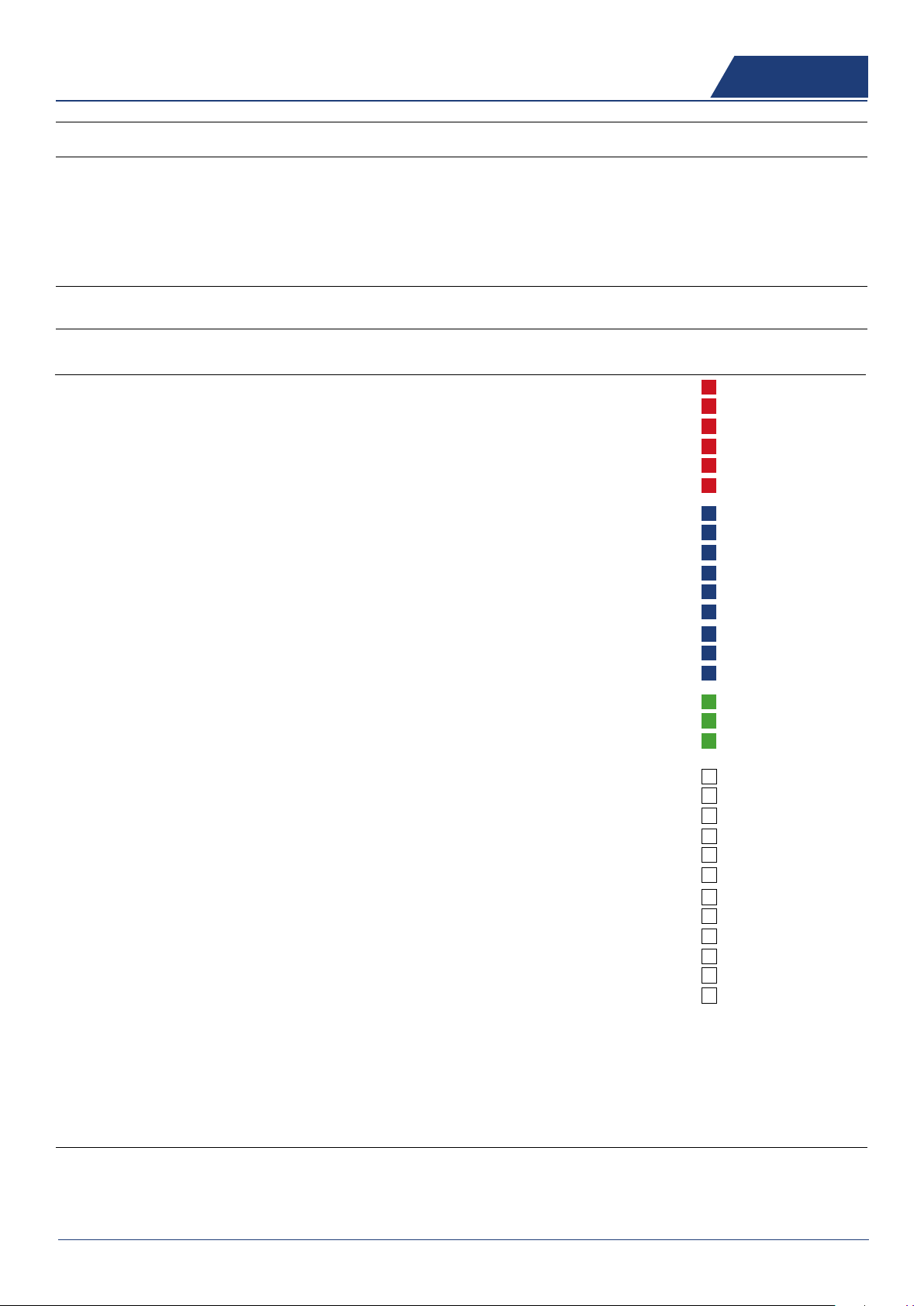

7. How to select p and proper lter

Tip and lter table with specicaons concerning capacity at dierent pressures (lt. minute) with water.

Noce: For each p size please choose between the following fan corners:

0,007 (0,18)

0,007 (0,18)

0,007 (0,18)

0,009 (0,23)

0,009 (0,23)

0,009 (0,23)

0,011 (0,28)

0,011 (0,28)

0,011 (0,28)

0,013 (0,33)

0,013 (0,33)

0,013 (0,33)

0,015 (0,38)

0,015 (0,38)

0,015 (0,38)

0,018 (0,44)

0,018 (0,44)

0,018 (0,44)

0,021 (0,53)

0,021 (0,53)

0,021 (0,53)

0,023 (0,58)

0,023 (0,58)

0,023 (0,58)

0,026 (0,66)

0,026 (0,66)

0,026 (0,66)

0,031 (0,79)

0,031 (0,79)

0,031 (0,79)

0,036 (0,91)

0,036 (0,91)

0,036 (0,91)

20 °

40 °

60 °

20 °

40 °

60 °

20 °

40 °

60 °

20 °

40 °

60 °

20 °

40 °

60 °

20 °

40 °

60 °

20 °

40 °

60 °

20 °

40 °

60 °

20 °

40 °

60 °

20 °

40 °

60 °

20 °

40 °

60 °

0,10

0,10

0,10

0,14

0,14

0,14

0,22

0,22

0,22

0,34

0,34

0,34

0,45

0,45

0,45

0,65

0,65

0,65

0,90

0,90

0,90

1,05

1,05

1,05

1,30

1,30

1,30

2,00

2,00

2,00

2,65

2,65

2,65

0,14

0,14

0,14

0,20

0,20

0,20

0,3

0,3

0,3

0,45

0,45

0,45

0,60

0,60

0,60

0,88

0,88

0,88

1,25

1,25

1,25

1,52

1,52

1,52

1,98

1,98

1,98

2,80

2,80

2,80

3,50

3,50

3,50

0,17

0,17

0,17

0,25

0,25

0,25

0,38

0,38

0,38

0,56

0,56

0,56

0,75

0,75

0,75

1,10

1,10

1,10

1,55

1,55

1,55

1,85

1,85

1,85

2,30

2,30

2,30

3,45

3,45

3,45

3,82

3,82

3,82

0,19

0,19

0,19

0,29

0,29

0,29

0,45

0,45

0,45

0,64

0,64

0,64

0,85

0,85

0,85

1,26

1,26

1,26

1,75

1,75

1,75

2,15

2,15

2,15

2,73

2,73

2,73

4,15

4,15

4,15

4,55

4,55

4,55

Inches (mm) Spray corner 35

Bar

70

Bar

105

Bar

140

Bar

200 Mesh 150 Mesh 100 Mesh 50 Mesh

not reccomended

NOZZLE CAPACITY MEASURED IN LT/MIN.

AT FOLLOWING PRESSURES: SUGGESTED FILTER

AirCombi Spray Gun

MAMBA

Page 12 OPERATING MANUAL

8. Proper system seng

In order to obtain a proper atomizaon and a good nishing, below are the suggested set-up to apply on

the equipment’s sengs and on the AirCombi Spray Gun’s sengs.

1. Set the uid pressure on the pump according to the product’s viscosity (from 0 up to 200 bar)

2. Set the gun air pressure on the pump according the uid to spray

3. Adjust the Fan Regulator Set on the AirCombi gun if it is necessary to increase or decrease the fan width

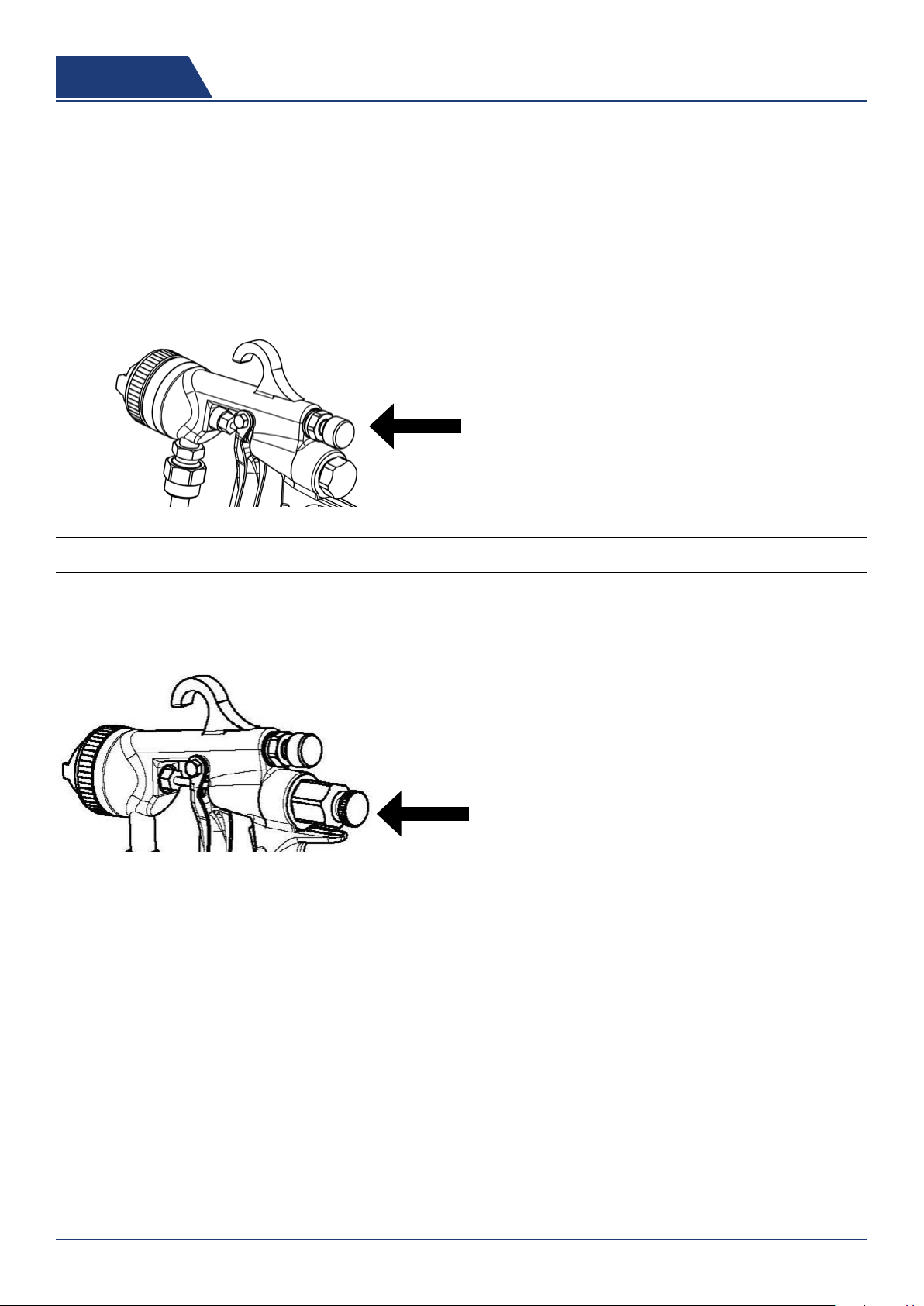

8.1 Spring Tension Adjustment - Only for “A” Versions

Your AirCombi Spray Gun “A” Version is supplied with spring tension closed in order to meet standards for

safety. For a proper spraying it is necessary to set the Spring Tension Adjuster according to the pump pres-

sure (Max. 200 Bar)

By reducing the pressure at the pump allows to open the adjustment screw of trigger tension accordingly.

Lower working pressure at the pump = Turn CCW the screw accordingly

Screw Spring Tension

Adjustment

AirCombi Spray Gun

Page 13

OPERATING MANUAL

MAMBA

9. Cleaning

Your AirCombi Spray Gun must be cleaned properly or it will not operate properly. Clogged nozzle and l-

ters are the most common causes of problems. If followed, these guidelines will insure trouble free perfor-

mance from your sprayer.

WARNING: Flush vigorous immediately aer use or longer work interrupons with solvent

corresponding to the spraying material. Ask to the material’s manufacturer for the proper

cleaning uid.

10. Maintenance

Here below are indicated the procedures to replace the common wear parts.

Warning: Before to intervene on the spray gun, assure to release all the remaining pressure

and disconnect air supply.

Warning: Assure to lock the trigger before to intervene on the spray gun.

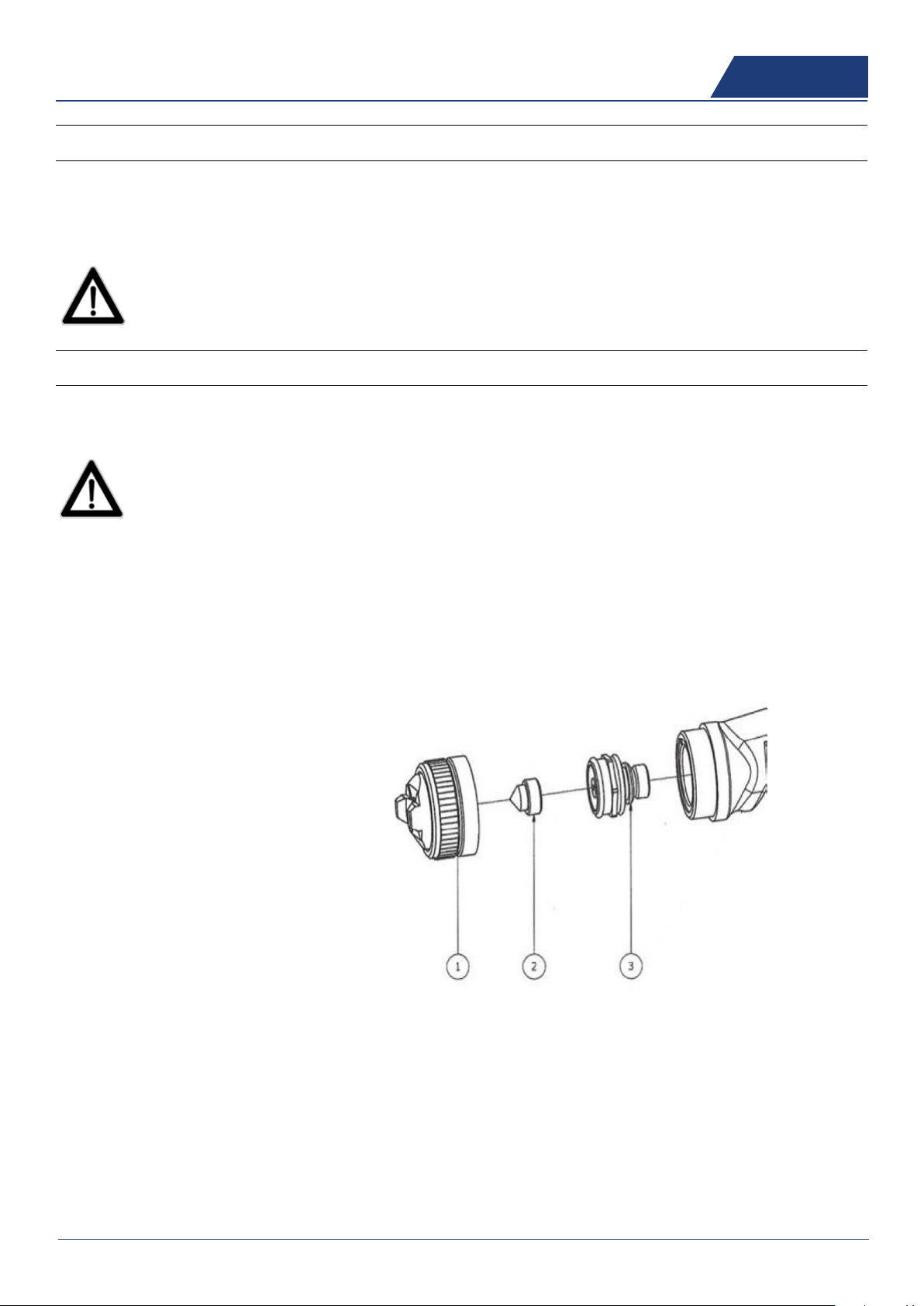

10.1 Nozzle changing

The nozzle is one of the most important element in producing a quality spray job. It requires periodic re-

placement to maintain performance and to prevent overworking of the gun components.

1. Disassemble the AirCap (pos. 1)

2. Remove from the AirCap the Nozzle

(pos. 2)

3. Clean well all parts and holes with a

brush, using the proper cleaner.

4. Replace the worn parts if necessary

AirCombi Spray Gun

MAMBA

Page 14 OPERATING MANUAL

10.2 Gun Filter changing

NOTE: It is important to clean the gun lter regularly in order to minimize p clogging problems. Use the

proper solvent according to the paint used.

1. Unscrew the Filter holder (pos. 6) with the proper wrench

2. Remove the gun lter, clean it or replace if necessary.

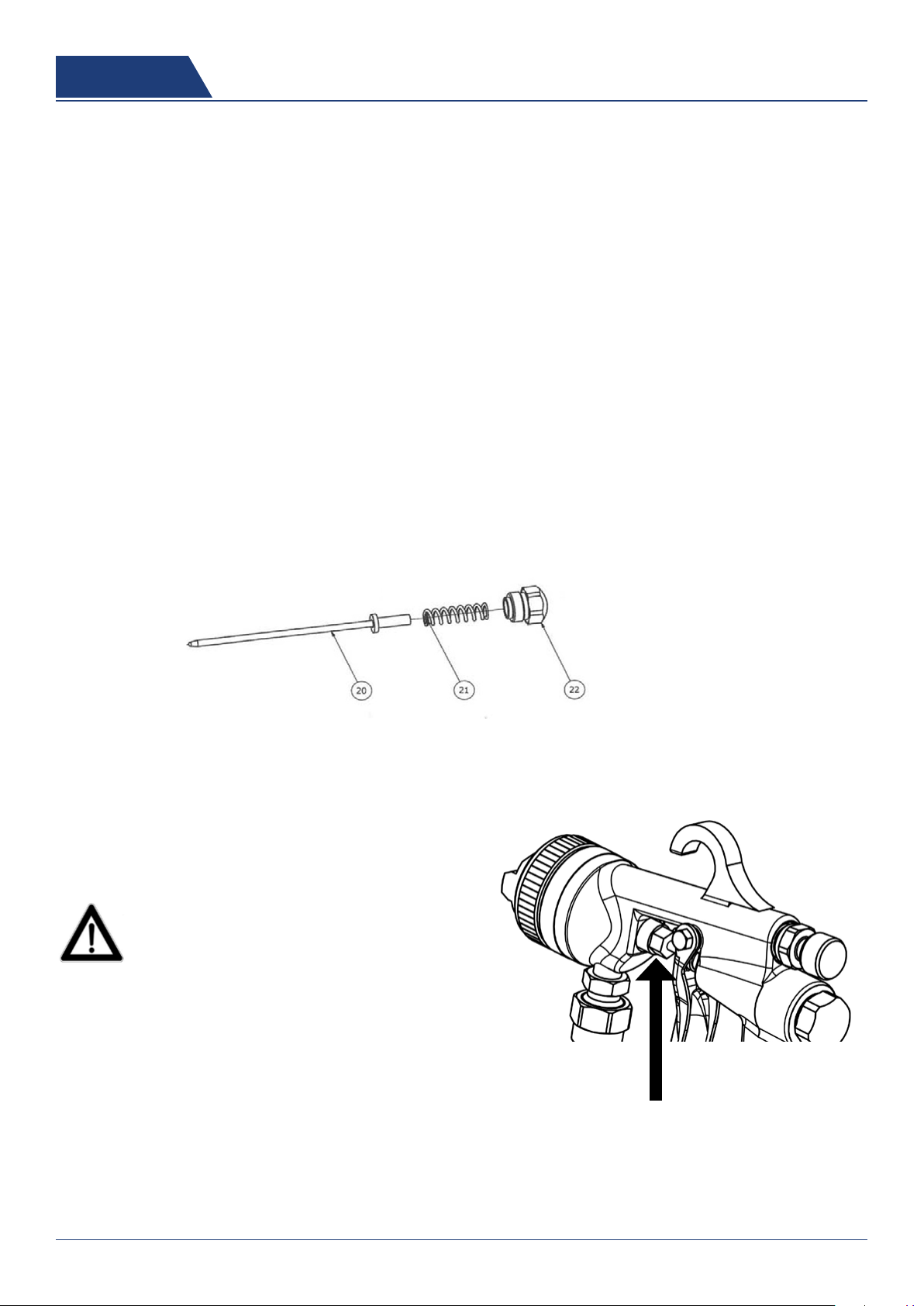

10.3 Needle changing

The components which enter in contact with the material sprayed can require in me to be replaced.

1. Disassemble the AirCap (pos. 1)

2. Remove the Nozzle (pos. 2)

3. Remove the Diusser (pos. 3) with a wrench nr. 22

4. Remove the Rear Cap (pos. 22) with a wrench nr. 17

5. Remove the springs (pos. 21 and 19)

6. By using a pincers remove the needle (pos. 20), clean it or replace if necessary

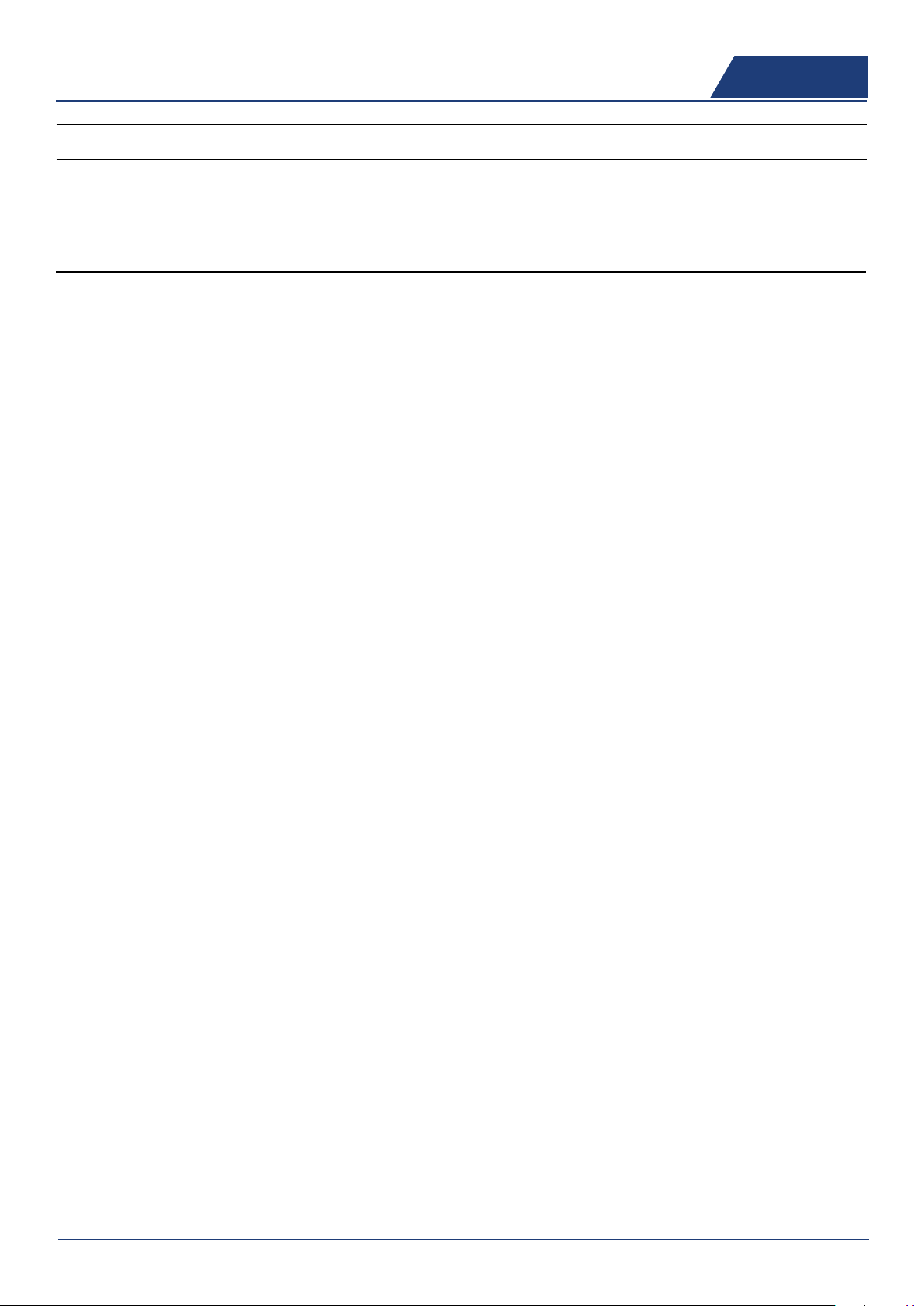

10.4 Packing Adjustment

In case of uid leakage from the seal screw nut it is

enough to screw the Seal screw adjusng nut with

a wrench nr. 7. if leakage persists we suggest to

replace the seal and the pressure washer.

Warning: Before to intervene on

the spray gun, assure to release all

the remaining pressure and discon-

nect air supply.

Warning: Assure to lock the trigger before to inter-

vene on the spray gun.

AirCombi Spray Gun

Page 15

OPERATING MANUAL

MAMBA

PROBLEMS

Low ush of materials

The spraying is not even

Gun leaks

Gun leaks air

Gun do not spray

Spraying not uniform

CAUSES

a. Gun bu lter is clogged

b. Viscosity is too high

c. The nozzle is too big or clogged

d. Working pressure is too low

a. Nozzle is clogged

b. Gun bu lter is clogged

c. The nozzle is too big or clogged

b. Viscosity is too high

e. Atomisaon air is too low

f. Material passages are clogged

g. Compressed air is too high

a. Seal screw is worn or too loose

b. Diuser is worn

c. Needle is worn

a. Air valve set (pos. 18) is worn

a. Filter clogged

b. Material hose clogged

a. Nozzle parally clogged

b. Nozzle worn

REMEDIES

a. Clean it or replace it if necessary

b. Thin the product

c. Replace it with a smaller one

d. Increase the pressure

a. Clean it or replace it if necessary

b. Clean it or replace it if necessary

c. Replace it with a smaller one

d. Thin the product

e. AIncrease the pressure

f. Clean the material passages with a

plasc brush (not in metal)

g. Reduce the pressure from the pump

a. Screw the seal screw adjusng nut

with a wrench nr. 7

b. Clean it or replace if necessary

c. Clean it or replace if necessary

a. Replace it

a. Replace it

b. Replace it

a. Clean with proper tools

b. Replace it

Our products are carefully tested and their quality is excellent, thus the gun-life and its good performance principally

depends on careful cleaning and maintenance.

11. Troubleshoong

Technical data subject to change

Table of contents