#4. START UP

DO NOT HOOK UP SPRAYER TO MACHINE AT THIS TIME.

1. Push the joystick to the LEFT and hold for 15 seconds. This will fill the pump

with chemical. Sprayer should NOT be connected at this point.

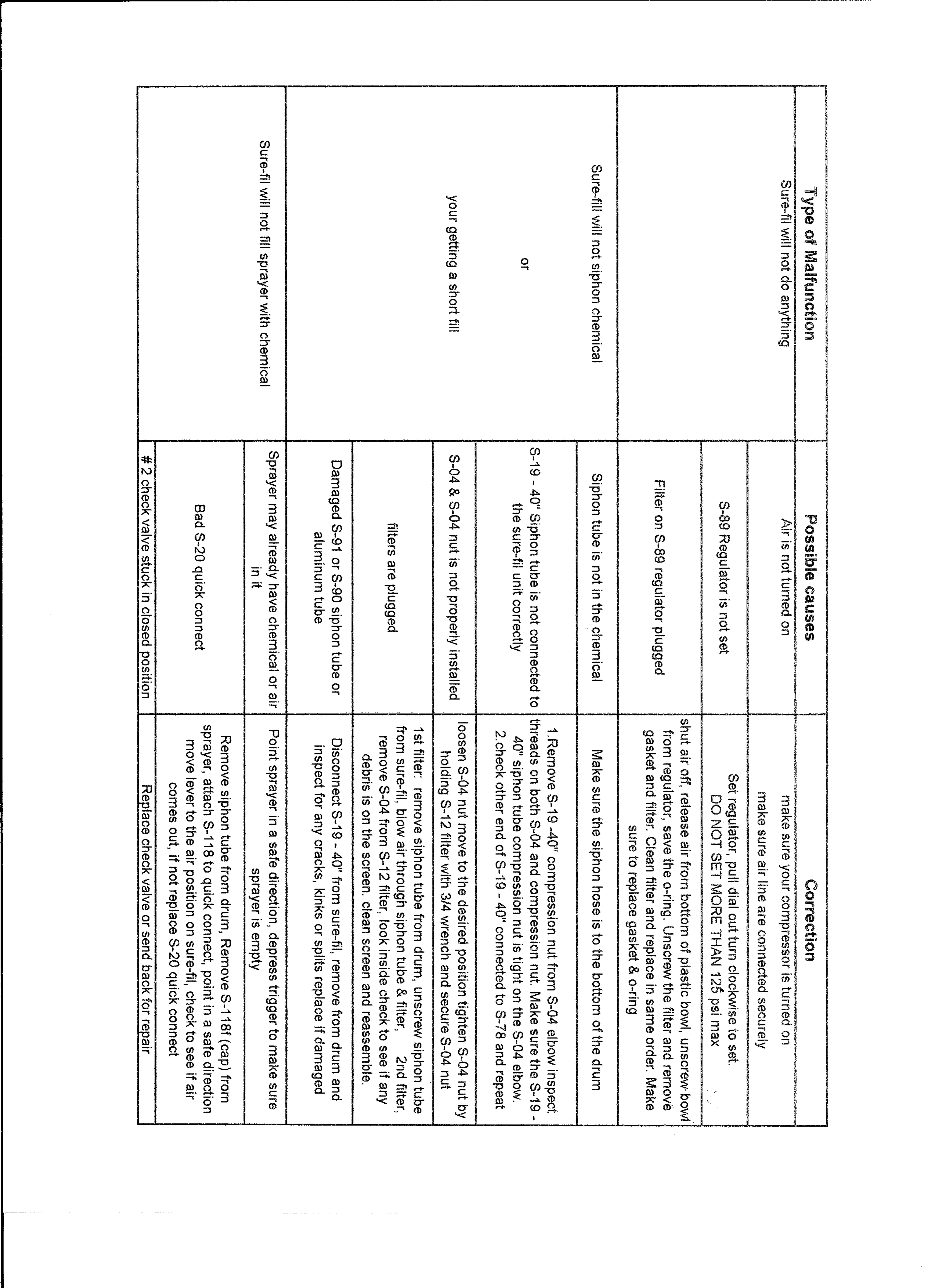

2. When step one has been completed, NOW connect the sprayer to the quick

connect (Diagram #4). Push the joystick to the right (liquid side) of the machine

until the yellow cap on the rod moves all the way to the right (approx. 15 seconds)

and stops. This will fill your sprayer with liquid.

Diagram #4

3. Release the Joystick: make sure it returns to center for approx. 5 seconds, then

push Joystick to the LEFT for air and hold approx. 15 seconds. This will fill the

sprayer with 125 P.S.I. of air AND siphon the chemical back into the pump so

you are ready for the next fill. (If you do not hold the Joystick to the left long

enough, the rod will retract slightly indicating a short fill. If this happens, push

the Joystick back to the left for an additional 5 seconds and release.

4. Disconnect the quick connect from top of sprayer by pulling the outside collar of

the quick connect until it releases. You are ready to spray.

5. Always use the entire product in applicator before you refill as this will

make sure you will have 32 oz on your next fill.

6. You must remove all air from applicator before refilling. You can do this by

holding the canister upside down while depressing the trigger until all the air has

been evacuated. You can also do this by loosening the filler cap/head until all the

air has been evacuated. Retighten when done.