Mammoth COMMERCIAL II Series User manual

INSTRUCTION MANUAL

SKU 211404, 211405, 211406 & 211407

CAUTION

READ INSTRUCTIONS CAREFULLY FOR SAFE

INSTALLATION AND FAN OPERATION.

COMMERCIAL II SERIES

INSTALLATION • OPERATION • MAINTENANCE • WARRANTY INFORMATION

Mammoth Fans COMMERCIAL II SERIES | 3

2

SAFETY PRECAUTIONS

CONGRATULATIONS ON YOUR PURCHASE PARTS LIST

Congratulations on your purchase of a Mammoth Fan. The Mammoth Fans range features world class permanent magnetic

synchronous motor (PMSM) technology and precision-led aeronautical design in mammoth proportions.

With energy efficiency, design, ultimate performance and Australian conditions in mind, Mammoth Fans have been designed as the

latest in high-volume, low-speed (HVLS) ceiling fans for large residential, commercial and industrial spaces.

Their market leading features of supreme efficiency, low noise, minimal maintenance and easy installation are backed by expert

advice and a 5-year warranty. Whether it is a public or commercial space such as a bar, restaurant, gym or hotel, Mammoth Fans

are the perfect solution for your project.

The Mammoth Fan you have purchased is a sophisticated electrical device and all care must be taken to ensure the fan is kept clean

and regularly maintained. Any issues arising from misuse or neglect are not covered by the warranty.

1. General parts

1. Always ensure the power is turned OFF before installing, maintaining, cleaning or adjusting the fan.

2. Must be assembled and installed by a licensed electrician.

3. All wiring and installation of the fan must adhere to the latest local and national wiring rules such as the AS/NZS 3000:2018,

electrical installations.

4. The appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities,

or lack of experience and knowledge, unless they have been given supervision or instruction concerning the use of the

appliance by a person responsible for their safety.

5. Children should be supervised to ensure that they do not play with the appliance.

6. An all-pole disconnection switch must be incorporated into the fixed wiring in accordance with local wiring rules.

7. The structure to which the fan is to be mounted must be capable of supporting 4 times the weight of the product and its own

structural loading. Check with a structural engineer if unsure.

8. Please do not alter the structure of the install site without prior advice from a structural engineer.

9. The fan should be mounted so that the blades are at least 3.5m above the floor.

10. This fan is suitable for covered alfresco use.

11. The fan must be installed with the electrical control box supplied.

12. During installation, adjustment and cleaning ensure the blades are not bent as this will drastically impact the performance of

the fan.

13. Please make sure the fan’s input voltage and supply voltage are the same before operating.

14. Please do not open the electrical control box without first isolating the power as electrical shock may occur.

15. Please do not operate the fan if you notice any damage to or noises from the fan.

16. The control box is a sophisticated controller designed specifically for your Mammoth Fan.

No modifications to the controller are permitted and failure to follow this advice could cause injury or death.

17. Within the electrical control box is a high-voltage storage capacitor. When you operate the fan, please wait for

3 minutes to let the voltage discharge to prevent electric shock.

18. Ensure sufficient clearance around the fan and NO obstructions before starting up the fan. Failure to do so will cause

significant damage and will not be covered under the warranty.

19. Do not cut power to the fan while it is in operation. Please stop the fan first and then isolate the power.

1. Top plate (top connector)

2. Extension tube

3. Fan blade

4. Driving device

5. Integral fan blade connector

6. Fan blade plug

7. Fan blade winglet

3

2

1

4

5

6

7

Mammoth Fans COMMERCIAL II SERIES | 5

4

4. Packing list

PARTS LIST PARTS LIST

3. Control unit

2. Standard component parts

NO. DESCRIPTION NO. DESCRIPTION

1PMS motor 8Top plate

2Fan blade connector 9Screw and fastener package

3Cardan joint 10 Fan hub

4Cardan joint base 11 Motor bottom cover

5Aluminium alloy bushing 12 Blade components

6Coil of wire 13 Extension tube

7Fan controller

CASE NO DIMENSIONS

( LxWxHmm )

Volume

( m3 )

Gross weight

( kg ) Remark

1 1400 x 600 x 310 0.16 70 Main body carton

PACKING SPECIFICATION

1.

Output wiring terminal

LCD screen

RJ45 Ethernet interface

Input wiring terminal

Start /speed regulating switch

Knob master switch

Control box body

7.

4.

3.

13.

2.

8.

12.

9.

Stator shaft

Fasteners

I-beam

Clamp plate

Top plate

Shim

Heat sink

Rotator

Motor cover

Exclusively distributed by Beacon Lighting | 7

6

5. Required installation tools

PARTS LIST

ADJUSTABLE WRENCH

LASER DISTANCE MEASURE

ALLEN KEYS

WIRE-CUTTER

SOCKET WRENCH

LEVEL

MULTIMETER

SCREW GLUE

Mammoth Fans COMMERCIAL II SERIES | 9

8

INSTALLATION REQUIREMENT

3. Concrete structure

(This accessory is sold separately)

4. Steel, concrete or timber beam structure

(This accessory is sold separately)

INSTALLATION REQUIREMENT

1. Roof installation requirement

The Mammoth Fan must be installed in a location where the blades have enough space between the fan and the nearest objects or

walls. (Refer to the below diagram for detailed spacing requirement). Secure the hanging bracket to the ceiling joist or structure with

provided bolts and nuts. Ensure there are 3 - 4 threads left on the bolt after tightening the nut. The structure to which the fan is to

be mounted must be capable of supporting 4 times the weight of the product and its own structural loading. Check with a structural

engineer if unsure.

NOTE: be cautious of items like light fittings which may swing into the

path of the spinning fan, ensure appropriate clearance is maintained.

2. I-beam steel structure

(included as standard)

1. PREPARATION Carefully unload and position the fan on the ground in a location

that won’t be impacted by ladders, scissor lifts or personnel.

2. PLAN Carefully plan and consider the following information

1. Installation point

2. Installation height

3. Whether there are obstacles (such as lights, cables, fire protection, cameras, forklift access, etc.)

4. The position of the control box

5. The input power and design of your electrical layout

6. Traction steel wire position

3. SAFETY Ensure power is isolated to the area that you are working. Ensure safe practices are followed in

regards to working at heights and lifting heavy equipment. Follow appropriate guidelines and

regulations in your region.

4. TOP PLATE Fasten the top plate to the H beam, ensuring a tight connection between the beam and the plate.

Screw glue (Loctite or similar) should be used.

5. EXTENSION TUBE

6. POWER CABLE Ensure you have sufficient length of the cable coming from the extension tube.

7. MAIN BODY

Ensure bolts are horizontal

before tightening the main body

to the extension tube.

8. WIRING Make the appropriate electrical connection to the fan body,

ensure neat and tight connections are completed.

NOTE: This is the

steel wire bracket.

Please make sure it is

installed before installing

the fan motor part to

the extension rod.

Mammoth Fans COMMERCIAL II SERIES | 11

10

FAN INSTALLATIONFAN INSTALLATION

9. STEEL WIRING Important – support wires should be evenly spaced in 4 opposing directions, to evenly

distribute any stress and movement. Wire clamps should be secure and glued with screw

glue (Loctite or similar).

10. POWER CABLE Wiring should follow local regulations.

11. FAN BLADES Fan blades should be mounted one after the other in opposites to each other. Two people

will be required to effectively mount and tighten the fan blades and safety support screws.

This procedure must be done while the fan motor is mounted on the ceiling. Trying to

complete this on the floor then mounting the fan will cause damage to the blades.

12. FAN BLADE TIP

INSTALLATION

Secure fan blade tips to the blades.

13. CONTROL BOX The height from floor to the bottom of the control box should be around 1.2 metres and in

a safe and practical position.

14. WIRING Distinguish the input and output, make sure the ground wire is in place and wire to local

wiring standards.

Fastener

I-beam

Clamp plate

Mammoth Fans COMMERCIAL II SERIES | 13

12

DESCRIPTION OF COMMON PARAMETERS OF CONTROL SYSTEM

USER SETTING INTERFACE DESCRIPTION

FAN INSTALLATION

ELECTRICAL WIRING DIAGRAM

15. DEBUGGING Each Mammoth Fan is tested prior to leaving the factory. If there seems to be a problem

double check all electrical connections, and contact the Mammoth support team.

16. COMMISSIONING Use a spirit level and ensure blades are level before switching on. Run the fan for 15mins

and observe, is it spinning in the correct direction (anti-clockwise for summer), listen for any

abnormal noise, ensure there is no movement in the support cables. Check the current is

within the rated range.

17. HANDOVER Ensure the customer is instructed on how to operate and isolate the fan.

LCD DISPLAY STATUS CONFIRMATION

OPERATING INTERFACE ACCELERATING INTERFACE STANDBY INTERFACE

SETTING INTERFACE DECELERATING INTERFACE FAILURE INTERFACE

FUNCTION CODE DESCRIPTION EXPLANATION

S00 Return Function can be used to return to the main interface. If it doesn’t return by this

function, it will automatically return to the main interface after 10s.

S01

Rotating speed

unlocked/

rotating speed

locked

Once locked, the adjusting knob will not change the given rotating speed to

prevent accidental touching. Select this function again to unlock the rotating

speed.

S02 Motor

self-learning Function can be used to improve motor operation control.

S03 Operation

direction switch

If the motor runs in the wrong direction, the motor direction can be switched

by this function.

After the controller is powered on, when the switch points to ON, the machine is powered on, and the LCD displays: given rotating

speed, operating current, input voltage, operating status, whether “output rotating speed” is locked, failure interface and other

specific interface information as follows. Note: Interface is preset to English.

In the standby state, long press the knob (more than 2 seconds) to enter the ‘setting interface’. The setting interface functions are

as follows:

Mammoth Fans COMMERCIAL II SERIES | 15

14

CLEANING & MAINTENANCE

1. Please read the precautions very carefully before operating.

2. Please confirm the wirings have been connected correctly, then turn the main knob to “ON”. Now it’s powered on.

3. Press the ‘start speed switch’ twice to use the ‘start speed switch’ to control the rotation speed.

4. Press the ‘rotation button’ twice to stop the motor. Then turn the main knob to OFF to completely stop the rotation.

Function description:

1. LCD display: If the interface isn’t used within 1 minute, the LCD screen will turn from bright to dark. The brightness is restored

after input.

2. Main switch: When the switch points to OFF, it is powered off; when the switch points to ON, it is powered on.

3. Rotation speed button: multi-function knob. Please check the below table for details.

Cleaning & maintenance

1. Please ensure the power to your Mammoth Fan is isolated before completing any cleaning and maintenance work.

Also ensure you follow all local regulations in regards to safe working at heights. Periodic cleaning of your ceiling fan

is the only maintenance required. Use a soft brush or lint free cloth to avoid scratching the paint finish.

2. A damp cloth can be used to wipe down the blades, however, ensure that excess water doesn’t enter any wiring

connections as this could damage the fan and cause a safety issue.

3. Ensure that the fitting does not come in contact with any organic solvents or cleaners.

4. The motor has a permanently lubricated ball bearing which does not require maintenance or re-oiling.

OPERATING INSTRUCTIONS

TECHNICAL INFORMATION

SKU# 211404 / 21140 5 2114 0 6 / 2114 07

Model no. SHVLS-D5BAA25 SHVLS-D5BAA30

Diameter 2.5m 3.0m

Rated voltage 220-240V - 50Hz 220-240V - 50Hz

Rated power 150W 200W

Full load current 0.7A 1A

Max. speed 130RPM 110 R P M

Air volume at max. speed 4200m3/min 5150m3/min

Climate class T - Tropical T - Tropical

Weight 41kg 44kg

WARNING

Please read the instruction manual before operation.

Ensure the fan is clear of all obstructions before operation. If the fan is unbalanced or noisy,

immediately shut it down and contact Mammoth Fans support. Ensure the power is isolated

before any maintenance work is carried out on the fan or controller.

NOTE: Always start the fan on low speed.

Function Adjust rotation speed Start, stop button Malfunction reset

Definition

Rotate the rotation speed

button clockwise to increase

speed and anticlockwise

to decrease speed.

Press the rotation

speed button once

to start and stop.

When ‘malfunction’ appears on the LCD display,

press the rotation speed button once to reset it.

If this doesn’t work, contact Mammoth following

the guide shown on screen.

Note:

Short press of the rotation speed button: press for less than 2 seconds

Long press of the rotation speed button: press for more than 2 seconds

Mammoth Fans COMMERCIAL II SERIES | 17

16

TROUBLESHOOTING TROUBLESHOOTING

Common causes of operation malfunction

1. Ensure that the external power supply of the control box is within the range appropriate for the controller.

2. Ensure that there is power to the controller box and turn the speed dial to the minimum setting (Slow). Then turn the control

dial to Run. If this doesn’t work, turn the control dial to Reset, then to Stop and finally to Run.

3. If on startup you notice any unusual sounds coming from the fan or the controller immediately return the control dial to Stop

and contact the Mammoth support team.

4. Equipment damage due to improper use is not covered by the warranty. Mammoth Fans will not be responsible for personal

injuries and equipment damages for failure to comply with the contents of this manual.

Code Desc. Reason Solution

E. Lu

Under

pressure in

operation

Power outages or

instantaneous power outages Check power and reset

Input power lack phase Confirmation of main circuit wiring

Excessive input voltage

fluctuations

Improve the power supply to meet the rated voltage of

the controller. If the main circuit power supply is fine,

check the main circuit side of the electromagnetic con-

tactor to identify the problem

Note: this fault is detected when the bus voltage is lower than the ** voltage protection point (F10.19) when the controller is running.

Code Desc. Reason Solution

E. o Cx x

Mid

acceleration/

mid

acceleration/

mid

speed/

overcurrent

fault

Overload

Reducing load or replacing impulse load of large

capacity controller requires reducing load change

frequency or replacing larger capacity controller

Short circuit to the output

side of the controller Check main circuit, eliminate short circuit

Motor damaged Measure the resistance between the lines of the motor

and replace the motor immediately if conducting

Too short acceleration/

deceleration time

Increase F01.22 (acceleration time 1) increase F01.23

(deceleration time 1) replace bulk control

Overvoltage suppression of

rising frequency may result

in accelerated overcurrent

fault

Decrease overvoltage gain F10.13

Overflow suppression of

frequency reduction

resulting in decelerated

overcurrent fault

Increase overcurrent suppression gain F10.02

Controller output cable

exceeds allowable

maximum

Shorten output cable or add sinusoidal filter

Misoperation caused by

interference

Check the wiring of control circuit, main circuit and

ground, remove interference source

Note: this fault is detected when the output current of the controller exceeds the overcurrent point.

ER Code Description

E. o C1/E. o C2/E. o C3 Acceleration/deceleration/constant speed/overcurrent

E. o U1/E. o U2/E. o U3 Acceleration/deceleration/constant speed/overvoltage

E. Lu Undervoltage during operation

E. o Cx x Mid acceleration/mid acceleration/ mid speed/ overcurrent fault

E . o L1 Motor overload

E. o L2 Controller overload

E. iLF Input phase loss

E. o LFx x U/V/W phase output phase loss

E. o H2 IGBT module over temperature

E. o U x x Mid acceleration/ moderate/ midspeed/ stop/over voltage fault

E. TEx x Self-learning output current exceeds limit

E. SPD Rapid failure

Mammoth Fans COMMERCIAL II SERIES | 19

18

TROUBLESHOOTING TROUBLESHOOTING

Code Desc. Reason Solution

E. iLF

Input

missing

phase

Loosening of main circuit

terminal of controller Tighten the screw and restart

Excessive input voltage

fluctuations

Improve the power supply to meet the rated voltage

of the controller. If the main circuit power supply is

fine, check the main circuit side of the electromagnetic

contactor to identify the problem

Three-phase voltage

imbalance

Confirm if there is a problem with the input voltage

and improve the power imbalance

Code Desc. Reason Solution

E. o LFx x

Output

missing

phase

Controller output side

U/V/W/ phase break

Check that the motor U/V/W/ phase connection is

normal and check that the controller output terminal

screw is not loose

Motor damage Measure the resistance between the motor wires, and

replace the motor immediately if it is connected

Low motor power Reset controller or motor power

Code Desc. Reason Solution

E. o L2 Controller

Overload

Overload

Reduce load

Increase the curve coefficient of overload protection of

motor

Acceleration and deceleration

time too short

Increase F01.22 F01.23 (acceleration and deceleration

time) Decrease F04.01 (torque increase)

Torque lift set too large Decrease F04.01 (torque increase)

V/F curve setting is not

appropriate

To determine the relationship between voltage and

frequency of V/F curve setting, modify F04.00

(VF curve setting) and modify the custom V/F curve

related parameters (F04.10~F04.19)

Abnormal output current due to

input missing phase Check the main loop to remove input phase

Code Desc. Reason Solution

E . o L1 Motor

overload

Overload Reduce the load and increase the curve coefficient of

overload protection

Acceleration and deceleration

time set too small

Increase F01.22,F01.23

(acceleration and deceleration time)

Torque lift set too large Decrease F04.01 (torque increase)

V/F curve setting is not

appropriate

To determine the relationship between voltage and

frequency of V/F curve setting, modify F04.00

(VF curve setting) and modify the custom V/F curve

related parameters (F04.10~F04.19)

The characteristics of

electronic thermal relay are

inconsistent with the

characteristics of motor load.

Use of external thermal relays

Abnormal output current

due to input missing phase Check the main loop to remove input phase

Code Desc. Reason Solution

E. o H2

IGBT

module

overheating

Excessive ambient temperature Reduce the ambient temperature of the controller

Overload Reduce load

Decrease F01.40 (carrier set)

Fan fault Make sure that the fan is running normally.

If not, replace the fan and start up again

Mammoth Fans COMMERCIAL II SERIES | 21

20

TROUBLESHOOTING TROUBLESHOOTING

Code Desc. Reason Solution

E.SPD Rapid failure

Controller application Seek technical support from manufacturer

Improper setting of relevant

parameters for rapid detection

Adjust rapid detection threshold and F10.45

(rapid detection time)

Fan fault Make sure that the fan is running normally.

If not, replace the fan and start up again

Note: the percentage of output motor speed relative to F01.10 (maximum frequency) is greater than F10.44 (rapid detection

threshold), and the fault is reported after continuous F10.45 of rapid detection time. By F10.43 (the rapid protection action),

the fault detection and the motor operation mode can be set when the fault is detected.

Code Desc. Reason Solution

E.TEx x Self-learning

failures

The output current of the

controller exceeds the

upper and lower limits

Check if the motor connection is correct, reset and

retry self-learning. If the error still occurs, contact

the Mammoth Fan support team.

Note: where “xx” is self-learning faults ub code.

Code Desc. Reason Solution

E. o U x x

Mid

acceleration/

moderate/

midspeed/

stop/over

-voltage fault

High voltage Reduce the supply voltage to a specified range

Controller output or motor

short circuit Check main circuit wiring, eliminate short circuit

Too short acceleration/

deceleration time

Determine whether the acceleration stops. The fault

detection increases F01.22 (acceleration time 1)

increases F01.23 (deceleration time 1)

Overvoltage suppression of

frequency rise may result in

accelerated overvoltage fault

Increase overvoltage suppression gain F10.13

Over-current suppression

of frequency-lowering

overvoltage fault

Decrease overcurrent suppression gain

F10.02 and reduce load

Surge voltage mixed

with input voltage Add reactor to input side

Improper setting of speed

tracking parameters Change of speed tracking parameter (F07.25~F07.28)

Note: this fault is detected when the bus voltage exceeds the overvoltage point. Three phase input overvoltage point is 820 V,

single-phase input overvoltage point is 400 V.

Mammoth Fans COMMERCIAL II SERIES | 23

22

WARRANTY WARRANTY

WARRANTY HOTLINE- 1800 602 243 Mammoth Fan WARRANTY INFORMATION

THIS WARRANTY IS VALID IN AUSTRALIA ONLY

In the event of service being required, please call the Mammoth Fans Support Hotline on 1800 602 243 between

9am and 5pm (AEST) Monday to Friday.

Please make sure you have all the Mammoth Fan details filled out at the end of the manual before making the call.

Every Mammoth Fan is thoroughly inspected and tested before being released for sale. In addition to any warranty rights or

conditions under statutory regulations, Mammoth Fans warrant all of its ceiling fans against defective workmanship and faulty

materials for 5 years from the date of purchase. Mammoth Fans undertake, at its option, to repair or replace, free of charge,

each product or part thereof on condition that;

1. The fan or relevant part has not been subjected to misuse, neglect, or been involved in an accident.

2. The repairs are not required as a result of normal wear and tear.

3. The product was installed by a licensed electrical contractor and to the guidelines outlined in the manual.

4. A copy of the original receipt of purchase is presented.

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a

replacement or refund for a major failure and compensation for any other reasonably foreseeable loss or damage. You are

also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not

amount to a major failure.

Mammoth Fans cannot be held responsible for any repair other than those carried out by it or one of its

Authorised Service Agents. Please keep this warranty information in a safe place. This information must be

produced in the event of service being required.

Distributed by:

Beacon Lighting

140 Fulton Drive,

Derrimut, Victoria, 3026,

Australia

Ph 1300 289 808

Email: warranty@beaconlighting.com.au

Mammoth Fans Support Hotline - 1800 602 243

Complete and retain this form for your personal records and warranty purposes.

NAME ___________________________________________________________________________________________________

ADDRESS ________________________________________________________________________________________________

__________________________________________________________________________________________________________

_________________________________________________________________ POSTCODE _____________________________

MODEL NUMBER _________________________________________________________________________________________

(PO# + DATE CODE sticker here)

PO NUMBER or DATECODE ________________________________________________________________________________

DATE OF PURCHASE ______________________________________________________________________________________

INSTALLING LICENSED ELECTRICIAN _______________________________________________________________________

LICENCE No. _____________________________________________________________________________________________

ATTACH PROOF OF PURCHASE HERE

THIS COMPLETED DETAIL PAGE SHOULD BE FILLED IN AND EMAILED TO

THE MAMMOTH FANS SUPPORT WARRANTY TEAM WHEN REQUESTING

WARRANTY SERVICE. APPROVAL FROM MAMMOTH FANS MUST BE

OBTAINED BEFORE WORK IS COMMENCED.

COMMERCIAL II SERIES

This manual suits for next models

6

Table of contents

Other Mammoth Fan manuals

Popular Fan manuals by other brands

Vento

Vento URAGANO Assembly and installation manual

Dometic

Dometic EZ-BREEZE Installation and operating manual

Kathy Ireland

Kathy Ireland CF995BS01 owner's manual

Linea 2000

Linea 2000 Domo DO8146 Instruction booklet

O2cool

O2cool FD05004 quick start guide

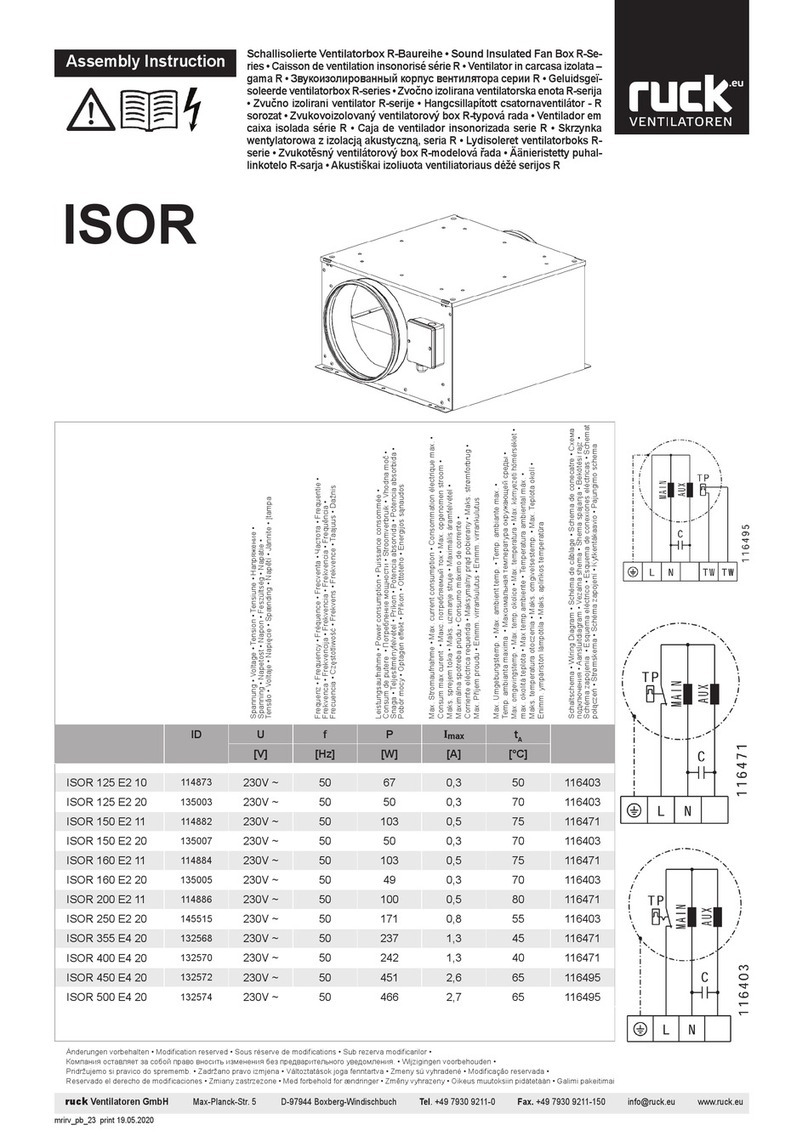

Ruck Ventilatoren

Ruck Ventilatoren ISOR R Series Assembly instruction

Ferroli

Ferroli TOP FAN Technical bulletin

Dimplex

Dimplex DCMIST30 instruction manual

Master

Master CD 5000 operating manual

Fanimation

Fanimation Benito FP8003 220 Series owner's manual

Holmes

Holmes HASF99 owner's guide

LUCCI Air

LUCCI Air Airfusion Moto Installation, operation, maintenance & warranty information