MAN B&W L28/32H User manual

IndexProject Guides

L28/32H

Text Index Drawing No.

Introduction I 00

Introduction to project guide I 00 00 0 1643483-5.2

Key for engine designation I 00 05 0 1609526-0.5

Designation of cylinders I 00 15 0 1607568-0.1

Code identification for instruments I 00 20 0 1609522-3.9

Basic symbols for piping I 00 25 0 1631472-4.1

General information D 10

List of capacities D 10 05 0 1607535-6.6

Engine performance D 10 10 0 1607522-4.1

Heat balance D 10 20 0 1607580-9.2

Description of sound measurements D 10 25 0 1609510-3.3

Sound measurements D 10 25 0 1613431-9.1

Exhaust gas emission D 10 28 0 1624461-6.2

Moment of inertia D 10 30 0 1607592-9.2

Overhaul recommendations D 10 35 0 1624483-2.2

Basic Diesel Engine B 10

General description B 10 01 1 1605544-1.5

Cross section B 10 01 1 1607528-5.2

Main particulars B 10 01 1 1607569-2.5

Dimensions and weights B 10 01 1 1613426-1.5

Centre of gravity B 10 01 1 1631459-4.0

Material specification B 10 01 1 1613480-9.3

Overhaul areas B 10 01 1 1624446-2.5

Low dismantling height B 10 01 1 1631464-1.0

Engine rotation clockwise B 10 11 1 1607566-7.1

Fuel Oil System B 11

Internal fuel oil system B 11 00 0 1607543-9.5

Fuel oil diagram B 11 00 0 1624468-9.4

Fuel oil specification B 11 00 0 1609529-6.3

Fuel oil cleaning recommendations B 11 00 0 1655267-1.3

Specific fuel oil consumption SFOC B 11 01 0 1607587-1.7

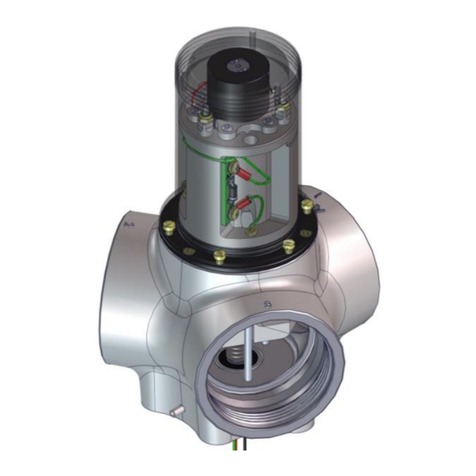

HFO/MDO changing valves (V1 and V2) E 11 10 1 1624467-7.2

Lubrication Oil System B 12

Internal lubricating oil system B 12 00 0 1613544-6.4

Prelubricating pump B 12 07 0 1624477-3.4

Lubricating oil specification B 12 15 0 1609531-8.3

Treatment of lubricating oil B 12 15 0 1643494-3.3

Cooling Water System B 13

Freshwater system treatment B 13 00 0 1609571-3.4

Internal cooling water system B 13 00 0 1613439-3.1

Internal cooling water system 1 B 13 00 0 1613443-9.2

Internal cooling water system 2 B 13 00 0 1613444-0.3

Design data for external cooling water system B 13 00 0 1613545-8.1

External cooling water system B 13 00 0 1613442-7.0

One string central cooling water system B 13 00 0 1624464-1.0

Preheater arrangement in high temperature system B 13 23 1 1613487-1.4

Index Project Guides

L28/32H

Text Index Drawing No.

Compressed Air System B 14

Compressed air system B 14 00 0 1613520-6.4

Compressed air system B 14 00 0 1624476-1.1

Combustion Air System B 15

Combustion air system B 15 00 0 1613523-1.4

Water washing of turbocharger - compressor B 15 05 1 1639499-6.0

Lambda controller B 15 11 1 1639456-5.0

Exhaust Gas System B 16

Exhaust gas system B 16 00 0 1609535-5.1

Water washing of turbocharger - turbine B 16 01 1 1607517-7.4

Dry cleaning of turbocharger - turbine B 16 01 2 1607599-1.3

Position of gas outlet on turbocharger B 16 02 0 1613418-9.3

Silencer without spark arrestor, damping 25 dB (A) E 16 04 2 1609575-0.3

Silencer without spark arrestor, damping 35 dB (A) E 16 04 3 1609578-6.3

Silencer with spark arrestor, damping 25 dB (A) E 16 04 5 1609582-1.3

Silencer with spark arrestor, damping 35 dB (A) E 16 04 6 1609585-7.3

Speed Control System B 17

Starting of engine B 17 00 0 1607583-4.3

Governor B 17 01 1 1639468-5.0

Monitoring Equipment B 18

Standard instrumentation B 18 01 1 1613494-2.3

Standard instrument panel B 18 05 1 1607503-3.2

Safety and Control System B 19

Operation data & set points B 19 00 0 1613514-7.4

Mechanical overspeed B 19 06 1 1643414-2.1

Starting box B 19 10 1 1639469-7.2

Converter for engine rpm signal B 19 13 1 1635436-4.2

Engine control box no 1, safety system E 19 06 4 1631457-0.0

Engine control box no 2, safety- and alarm system E 19 06 6 1643403-4.0

Prelubricating oil pump starting box E 19 11 0 1631477-3.3

High temperature preheater control box E 19 13 0 1631478-5.1

Foundation B 20

Recommendations concerning steel foundations for resilient mounted GenSetsB 20 01 0 1613565-0.2

Resilient mounting of generating sets B 20 01 3 1613527-9.1

Test running B 21

Test running of GenSet on DO B 21 01 1 1356501-5.5

Spare Parts E 23

Weight and dimensions of principal parts E 23 00 0 1613436-8.1

Recommended wearing parts E 23 04 0 1607521-2.6

Standard spare parts P 23 01 1 1613492-9.5

IndexProject Guides

L28/32H

Text Index Drawing No.

Tools P 24

Standard tools for normal maintenance P 24 01 1 1613467-9.4

Tools for reconditioning P 24 02 1 1613460-6.4

Extra tools for low dismantling height P 24 04 1 1613463-1.2

Preservation and Packing B 25

Preservation of diesel engine before dispatch B 25 01 1 1350467-1.2

Preservation of spare parts and tools B 25 01 1 1350473-0.3

Lifting instruction B 25 03 0 1631490-3.0

Alternator G 50

Information from the alternator supplier G 50 02 8 1613538-7.3

Engine / Alternator type G 50 04 0 1613562-5.3

Introduction

I 00

I 00 00 0

Introduction to Project Guide

General

99.33

1643483-5.2

Page 1 (1)

Introduction

WiththisProjectGuidewehopethatwehaveprovidedyouwitha"tool"coveringallnecessaryinformationrequired

forprojectplanningoftheGenSetinstallationandmakingyourdailyworkeasier.Further,ourProjectDepartment

is available with advices on more specific questions concerning the projecting.

Ourproductrangeisconstantlyreviewed,developedandimprovedaccordingtoneedsandconditionsdectated.

Therefore, we reserve the right to make changes in the technical specification and data without prior notice.

Concerningthealternator,thespecificdatadependonthealternatortype.

ProjectrelateddrawingsandinstallationinstructionswillbeforwardedinaProjectSpecificationManual,whenthe

contractdocumentationhasbeencompleted.

TheProjectSpecificationManualwillcompriseallnecessarydrawings,pipingdiagrams,cableplansandspecifi-

cations of our supply.

Code numbers

MAN B&W Holeby Diesel Identification No. X XX XX X

Code letter

Function/system

Sub-function

Choice number

Codeletter: The code letter indicates the contents of the documents:

B: Basic Diesel engine / built-on engine

D: Designationofplant

E: Extrapartsperengine

G: Generator

I: Introduction

P: Extra parts per plant

Function/system number: A distinction is made between the various chapters and systems, e.g.: Fuel oil

system, monitoring equipment, foundation, test running, etc.

Sub-function:This figure varies from 0-99.

Choice number: This figure varies from 0-9:

0 : Generalinformation 1 : Standard

2-8 : Standardoptionals 9 : Optionals

08028-0D\H5250\94.08.12

No. of cylinders

5, 6, 7, 8, 9

12, 16, 18

EngineType

L : In-line

V : V-built

Cyl.diam/stroke

16/24 : 160/240

21/31 : 210/310

23/30 : 225/300

27/38 : 270/380

28/32 : 280/320

32/40 : 320/400

DesignVariant

Rating

MCR : Maximumcontinuousrating

ECR : Economycontinuousrating

1609526-0.5

Page 1 (1) I 00 05 0

Key for Engine Designation

General

Engine Type Identification

The engine types of the MAN B&W Holeby programme are identified by the following figures:

6 L 28/32 HMCR

01.08

Designation of Cylinders

In-Line

98.19

1607568-0.1

Page 1 (1) I 00 15 0

08028-0D\H5250\94.08.12

Code Identification for Instruments

Explanation of Symbols

Measuring device

Local reading

TemperatureIndicator

No. 40 *

Measuring device

Sensor mounted on engine/unit

Reading/identification mounted in a panel on the engine/unit

Pressure Indicator

No. 22 *

Measuring device

Sensor mounted on engine/unit

Reading/identificationoutside the engine/unit

Temperature Alarm High

No. 12 *

Measureingdevice

Sensormountedonengine/unit

Reading/identificationinapanelontheengine/unitandreading/indicationoutside

theengine/unit

PressureTemperature

No. 22 *

* Refer to standard location and text for instruments on the following pages.

Specification of letter code for measuring devices

1st letter Followingletters

F Flow A Alarm

L Level D Differential

P Pressure E Element

S Speed, System H High

T Temperature I Indicating

U Voltage L Low

V Viscosity S Switching, Stop

X Sound T Transmitting

Z Position X Failure

V Valve, Atuator

99.35

TI

40

TAH

12

PI

22

1609522-3.9

Page 1 (2)

General

I 00 20 0

PT

22

08028-0D\H5250\94.08.12

Code Identification for Instruments

Standard Text for Instruments

Diesel Engine/Alternator

LT Water System

01 inlet to air cooler 04 inlet to alternator 07 inlet to lub. oil cooler

02 outlet from air cooler 05 outlet from alternator 08 inlet to fresh water cooler (SW)

03 outlet from lub. oil cooler 06 outlet from fresh water cooler (SW) 09

HT Water System

10 inlet to engine 14 inlet to HT air cooler 17 outlet from fresh water cooler

10A FW inlet to engine 14A FW inlet to air cooler 18 inlet to fresh water cooler

11 outlet from each cylinder 14B FW outlet from air cooler 19 preheater

12 outlet from engine 15 outlet from HT system 19A inlet to prechamber

13 inlet to HT pump 16 outlet from turbocharger 19B outlet from prechamber

Lubricating Oil System

20 inlet to cooler 24 sealing oil - inlet engine 28 level in base frame

21 outlet from cooler / inlet to filter 25 prelubricating 29 main bearings

22 outlet from filter / inlet to engine 26 inlet rocker arms and roller guides

23 inlet to turbocharger 27 intermediate bearing / alternator bearing

Charging Air System

30 inlet to cooler 34 charge air conditioning 38

31 outlet from cooler 35 surplus air inlet 39

32 jet assist system 36 inlet to turbocharger

33 outlet from TC filter / inlet to TC compr. 37 charge air from mixer

Fuel Oil System

40 inlet to engine 44 outlet from sealing oil pump 48

41 outlet from engine 45 fuel-rack position 49

42 leakage 46 inlet to prechamber

43 inlet to filter 47

Cooling Oil System

50 inlet to fuel valves 54 58

51 outlet from fuel valves 55 valve timing 59

52 56 injection timing

53 57

Exhaust Gas System

60 outlet from cylinder 64 68

61 outlet from turbocharger 65 69

62 inlet to turbocharger 66

63 compustion chamber 67

Compressed Air System

70 inlet to engine 74 inlet to reduction valve 78 inlet to sealing oil system

71 inlet to stop cylinder 75 microswitch for turning gear 79

72 inlet to balance arm unit 76 inlet to turning gear

73 control air 77 waste gate pressure

Load Speed

80 overspeed air 84 engine stop 88 index - fuel injection pump

81 overspeed 85 microswitch for overload 89 turbocharger speed

82 emergency stop 86 shutdown 90 engine speed

83 engine start 87 ready to start

Miscellaneous

91 natural gas - inlet to engine 94 cylinder lubricating 97

92 oil mist detector 95 voltage 98 alternator winding

93 knocking sensor 96 switch for operating location 99 common alarm

99.35

1609522-3.9

Page 2 (2)

General

I 00 20 0

08028-0D\H5250\94.08.12

1631472-4.1

Page 1 (3) Basic Symbols for Piping I 00 25 0

General

93.44

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

No. Symbol Symbol designation

1. GENERAL CONVENTIONAL SYMBOLS

2. PIPES AND PIPE JOINTS

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

2.10

2.11

2.12

2.13

2.14

2.15

2.16

2.17

2.18.

2.19

No. Symbol Symbol designation

3. VALVES, GATE VALVES, COCKS AND FLAPS

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

3.10

3.11

3.12

3.13

3.14

3.15

3.16

Pipe

Pipe with indication of flow direction

Valves, gate valves, cocks and flaps

Appliances

Indicating and measuring instruments

High pressured pipe

Tracing

Crossing pipe, not connected

Crossing pipe, connected

Tee pipe

Flexible pipe

Expansion pipe (corrugated) general

Joint, screwed

Joint, flanged

Joint, sleeve

Joint, quick-releasing

Expansion joint with gland

Expansion pipe

Cap nut

Blank flange

Spectacle flange

Orifice

Orifice

Loop expansion joint

Snap-coupling

Pneumatic flow or exhaust to atmosphere

Valve, straight through

Valve, angle

Valve, three-way

Non-return valve (flap), straight

Non-return valve (flap), angle

Non-return valve (flap),

straight screw down

Non-return valve (flap),

angle, screw down

Safety valve

Angle safety valve

Self-closing valve

Quick-opening valve

Quick-closing valve

Regulating valve

Ball valve (-cock)

Butterfly valve

Gate valve

Enclosure for several components as-

sembled in one unit

08028-0D\H5250\94.08.12

I 00 25 0 1631472-4.1

Page 2 (3)

Basic Symbols for Piping

General

93.44

No. Symbol Symbol designation No. Symbol Symbol designation

3.17

3.18

3.19

3.20

3.21

3.22

3.23

3.24

3.25

3.26

3.27

3.28

3.29

3.30

3.31

3.32

3.33

3.34

3.35

3.36

3.37

3.38

3.39

Double-seated change over valve

Suction valve chest

Suction valve chest with non-return valves

Double-seated change over valve, straight

Double-seated change over valve, angle

Cock, straight through

Cock, angle

Cock, three-way, L-port in plug

Cock, three-way T-port in plug

Cock, four-way, straight through in plug

Cock with bottom connect.

Cock, straight through, with bottom conn.

Cock, angle, with bottom connection

Cock, three-way with bottom connection

Thermostatic valve

Valve with test flange

3-way valve with remote control (actuator)

Non-return valve (air)

3/2 spring return valve, normally closed

2/2 spring return valve, normally closed

3/2 spring return valve contr. by solenoid

Reducing valve (adjustable)

4. CONTROL AND REGULATION PARTS

Han-operated

Remote control

Spring

Mass

Float

Piston

Membrane

Electric motor

Electro-magnetic

Manual (at pneumatic valves)

Push button

Spring

Solenoid

Solenoid and pilot directional valve

By plunger or tracer

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

4.10

4.11

4.12

4.13

4.14

4.15

5. APPLIANCES

5.1

5.2

5.3

5.4

5.5

5.6

Mudbox

Filter or strainer

Magnetic filter

Separator

Steam trap

Centrifugal pump

On/off valve controlled by solenoid and

pilot directional valve with spring return

08028-0D\H5250\94.08.12

1631472-4.1

Page 3 (3) Basic Symbols for Piping I 00 25 0

General

93.44

No. Symbol Symbol designation No. Symbol Symbol designation

Gear or screw pump

Hand pump (bucket)

Ejector

Various accessories (text to be added)

Piston pump

Heat exchanger

Electric preheater

Air filter

Air filter with manual control

Air filter with automatic drain

Water trap with manual control

Air lubricator

Silencer

Single acting cylinder with spring returned

Double acting cylinder with spring returned

Steam trap

5.7

5.8

5.9

5.10

5.11

5.12

5.13

5.14

5.15

5.16

5.17

5.18

5.19

5.20

5.21

5.22

5.23

7. READING INSTR. WITH ORDINARY DESIGNATIONS

7.1

7.2

7.3

7.4

7.5

Sight flow indicator

Observation glass

Level indicator

Distance level indicator

Recorder

6. FITTINGS

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6.8

6.9

Funnel / waste tray

Drain

Waste tray

Waste tray with plug

Turbocharger

Fuel oil pump

Bearing

Water jacket

Overspeed device

Fixed capacity penumatic motor with

direction of flow

General information

D 10

This manual suits for next models

5

Table of contents

Other MAN B&W Engine manuals