Introduction

Before use

This product must be handled by qualied personnel with

expert knowledge of electrical and mechanical engineering.

Use the product correctly after thoroughly reading the section

“Safety precautions.”

This product is designed for use as an internal component for

general industrial equipment. Do not use the product for any

other purpose. Oriental Motor shall not be liable whatsoever for

any damage arising from the failure to observe this warning.

Product overview

This product is a 2-phase stepping motor employing a terminal-

block connection method.

This product is recognized by UL and certied by CSA, and

bears the CE Marking (Low Voltage Directive) in compliance

with the EN Standards.

Applicable Standards Certication Body Standards File No.

UL 1004-1, UL 1004-2

CSA C22.2 No.100

CSA C22.2 No.77

UL E64199

EN 60950-1, EN 60034-1

EN 60034-5, EN 60664-1

Conforming to the respective

standards.

Degree of

protection

IP65 (Excluding the gap between the shaft and the

ange)

Operating

environment

Ambient

temperature

−10 to +50 °C (+14 to +122 °F)

(non-freezing)

Humidity 85% or less (non-condensing)

Altitude Up to 1,000 m (3,300 ft.) above sea

level

Ambient

atmosphere Free from corrosive gases

Installation

conditions

Built-in component

Overvoltage category: II

Pollution degree: Class 3 (excluding installation

surface)

Protection against electric shock: Class Iequipment

The user is responsible for conrming the EMC compatibility of

the nal equipment incorporating the motor.

Hazardous substances

The products do not contain the substances exceeding the

restriction values of RoHS Directive (2011/65/EU).

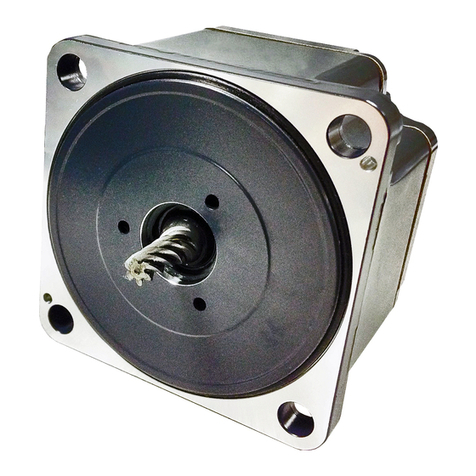

Checking the product

Open the package and conrm that all of the following items

are available. Should you nd any item missing or damaged,

contact the Oriental Motor sales oce where you purchased

the product. Check the model of the motor against the model

number shown on the nameplate.

yMotor................................... 1 unit

yOPERATING MANUAL..... 1 copy

zModel number

Motor identication

A: Single shaft

Motor frame size 6

Motor case length

Blank: 5 terminals (unipolar)

D: 4 terminals (bipolar)

2: 2-phase

HM-7416-4

日本語は、英語の後ろに記載しています。

OPERATING MANUAL

Thank you for purchasing an Oriental Motor product.

This Operating Manual describes product handling procedures and safety precautions.

yPlease read it thoroughly to ensure safe operation.

yAlways keep the manual where it is readily available.

2-Phase Stepping Motor PK Series

Standard Type IP65 rated motor

PK26AT, PK26DAT

zProduct types

PK264AT PK266AT PK268AT

PK264DAT PK266DAT PK268DAT

The connection methods and rated currents are listed below.

Model Connection method Rated current

PK26AT Unipolar connection 2.0 A/phase

PK26DAT Bipolar connection 2.8 A/phase

Safety precautions

The motor is designed for incorporation into industrial

equipment. Touching the motor during operation may result

in bodily injury or property damage, since the output shaft is

rotating and the surface remains very hot. To prevent injury

or damage to the motor, be sure the motor is handled and

operated only by qualied personnel familiar with operations

involving electronic equipment.

Handling the product without observing the instructions that

accompany a“Warning” symbol may result in death or serious

bodily injury.

yDo not use the motor in explosive or corrosive environments,

in the presence of ammable gases, near combustible

materials, or locations subjected to the splashing of oil or

other hazardous liquids. Doing so may result in re, electric

shock or injury.

yTurn o the power before working on the product. Failure to

do so may result in electric shock.

yProvide a measure to retain the position of the movable

part of the equipment when the product is used in a vertical

application. The motor loses its holding torque when the

power is cut o. Without appropriate measures the movable

part will descend, resulting in injury or damage to the

equipment.

yInstall the motor in the enclosure to avoid contact with the

hands, or provide sucient earthing. Failure to do so may

result in electric shock.

yConnect the product correctly and securely according to the

wiring diagram. Failure to do so may result in re or electric

shock.

yAfter connecting the cable, securely x and tighten the

terminal box and cable clamp. Failure to do so may result in

re or electric shock.

yTurn o the power in case of a power failure. Failure to do so

may result in injury or damage to the equipment when the

motor starts suddenly upon the recovery of power.

yDo not disassemble or modify the motor. This may cause

electric shock or injury.

Handling the product without observing the instructions that

accompany a“Caution” symbol may result in bodily injury or

property damage.

yDo not use the motor beyond its specications. Doing so may

result in electric shock, injury or damage to the equipment.

yDo not touch the motor while the motor is conducting

current. Doing so may result in burns.

yUse a round terminal for connection with the protective earth

terminal. Failure to do so may result in re or electric shock.

yDo not carry the motor by its output shaft. Doing so may

result in injury.

ySecurely x the motor to an appropriate metal plate. Failure

to do so may result in injury or damage to the equipment.

yProtect the rotating part of the motor (output shaft) with a

cover. Failure to do so may result in injury.

yConduct the insulation resistance measurement or withstand

voltage test separately on the motor and the driver. Failure to

do so may result in damage to equipment.

yImmediately when trouble has occurred, stop running and

turn o the power. Failure to do so may result in re, electric

shock or injury.

yTo dispose of the motor, disassemble it into parts and

components as much as possible and dispose of individual

parts/components as industrial waste.

yProvide an emergency-stop device or emergency-stop circuit

external to the equipment so that the entire equipment will

operate safely in the event of a system failure or malfunction.

Failure to do so may result in injury.

Precautions for use

•Drive unit

Use a motor driver unit appropriate for the method of motor

connection.

•Connecting the motor

Use a multi-core cable of AWG26 to 16 (0.14 to 1.25 mm2)

[7 to 13 mm (0.28 to 0.51 in.) in outer diameter] for motor

connection. Motor cable (with protective earth conductor) is

available as an option (sold separately). For details, contact your

nearest Oriental Motor oce.

Strip away 40 to 50 mm (1.57 to 1.97 in.) of sheath from the end

of the cable. Stripping the cable sheath by more than 50 mm

(1.97 in.) will reduce the sealing eect of the cable clamp.

•Cable clamp

“Cable clamp” is a section through which a cable passes. The

cable clamp conforms to the IP65 specication and consists of

the cap, gasket and receptacle. To ensure watertightness at the

cable clamp, tighten the cap after conrming that the cover of

the connection cable is securely sealed by the gasket.

•Motor case temperature

The motor is designed to the class B insulation specication.

When operating the motor, keep the motor case temperature to

100 °C (212 °F) or below. Operating the motor at temperatures

above 100 °C (212 °F) will shorten the life of the motor coil and

ball bearing. [The maximum temperature is 75 °C (167 °F) if the

equipment is to receive UL/CSA certication, because the motor

must conform to the class A insulation requirement.]

Installation

Installation requirements

The motor is designed to be a built-in component. It must be

used in an environment conforming to overvoltage category II,

pollution degree of class 3 and protection against electric shock

of class Iequipment.

Degree of protection: IP65 (Excluding the gap between the

shaft and the ange)

Install the motor in a well-ventilated location that provides

easy access for inspection. The locaton must also satisfy the

following conditions:

yInside an enclosure that is installed indoors (provide vent

holes)

yOperating ambient temperature: −10 to +50 °C (+14 to

+122 °F) (non-freezing)

yOperating ambient humidity: 85% or less (non-condensing)

yArea that is free of explosive atmosphere or toxic gas (such as

sulfuric gas) or liquid

yArea not exposed to direct sun

yArea free of excessive salt

yArea not subject to continuous vibration or excessive shocks

yArea free of excessive electromagnetic noise (from welders,

power machinery, etc.)

yArea free of radioactive materials, magnetic elds or vacuum