HM-7422

OPERATING MANUAL

Stepping Motor

PK Series TH

Geared Type

Thank you for purchasing an Oriental Motor product.

This Operating Manual describes product handling procedures and

safety precautions.

• Please read it thoroughly to ensure safe operation.

• Always keep the manual where it is readily available.

Introduction

Before using the motor

Only qualified personnel should work with the product.

Use the product correctly after thoroughly reading the section “Safety

precautions”.

The product described in this manual has been designed and manufactured

for use in general industrial machinery, and must not be used for any other

purpose. For the power supply use a DC power supply with reinforced

insulation on its primary and secondary sides. Oriental Motor Co., Ltd. is not

responsible for any damage caused through failure to observe this warning.

Hazardous substances

RoHS (Directive 2002/95/EC 27Jan.2003) compliant

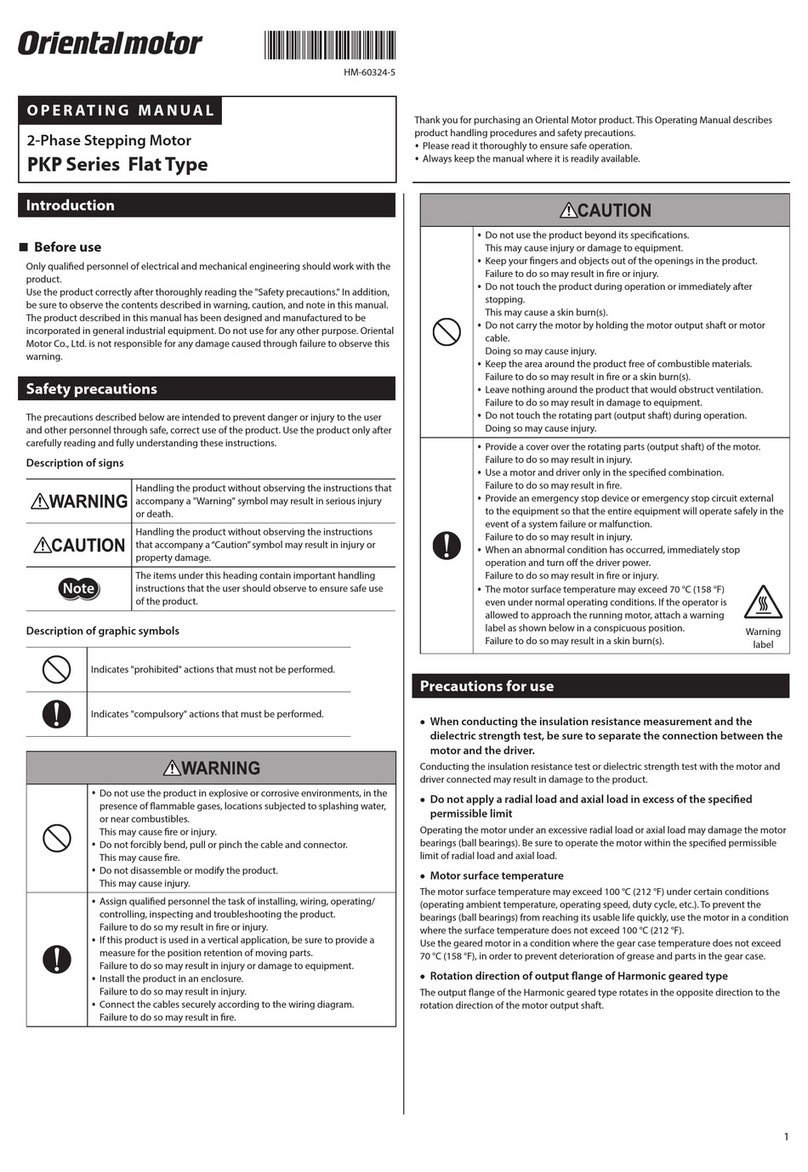

Safety precautions

The precautions described below are intended to prevent danger or injury to

the user and other personnel through safe, correct use of the product. Use the

product only after carefully reading and fully understanding these

instructions.

Handling the product without observing the instructions that accompany a

“Warning” symbol may result in serious injury or death.

• Do not use the product in explosive or corrosive environments, in the

presence of flammable gases, locations subjected to splashing water, or

near combustibles. Doing so may result in fire or injury.

• Assign qualified personnel the task of installing, wiring,

operating/controlling, inspecting and troubleshooting the product. Failure

to do so may result in fire or injury.

• Provide a means to hold moving parts in place for applications involving

vertical travel. The motor loses holding torque when the power is shut off,

allowing the moving parts to fall and possibly causing injury or damage to

equipment.

• Install the motor in an enclosure in order to prevent injury.

• Keep the input-power voltage within the specified range to avoid fire.

• Connect the cables securely according to the wiring diagram in order to

prevent fire.

• Do not forcibly bend or push the connector. Doing so may fire.

• Do not forcibly bend, pull or pinch the cable. Doing so may fire.

• For the power supply use a DC power supply with reinforced insulation on

its primary and secondary sides. Failure to do so may result in electric

shock.

• Turn off the power in the event of a power failure, or the motor will

suddenly start when the power is restored and may cause injury or damage

to equipment.

• Do not disassemble or modify the motor. This may cause injury. Refer all

such internal inspections and repairs to the branch or sales office from

which you purchased the product.

Handling the product without observing the instructions that accompany a

“Caution” symbol may result in injury or property damage.

• Do not use the motor beyond its specifications, or injury or damage to

equipment may result.

• Do not touch the motor during operation or immediately after stopping.

The surface is hot and may cause a skin burn(s).

• Do not hold the motor output shaft or motor cable. This may cause injury.

• Provide an emergency-stop device or emergency-stop circuit external to

the equipment so that the entire equipment will operate safely in the event

of a system failure or malfunction. Failure to do so may result in injury.

• To prevent bodily injury, do not touch the rotating parts (output shaft) of

the motor during operation.

• Immediately when trouble has occurred, stop running and turn off the

driver power. Failure to do so may result in fire or injury.

• To dispose of the motor, disassemble it into parts and components as much

as possible and dispose of individual parts/components as industrial waste.

Precautions for use

• Conduct the insulation resistance measurement or withstand

voltage test separately on the motor and the driver

Conducting the insulation resistance measurement or withstand voltage test

with the motor and driver connected may result in injury or damage to

equipment.

• About grease of geared motor

On rare occasions, a small amount of grease may ooze out from the gearhead.

If there is concern over possible environmental damage resulting from the

leakage of grease, check for grease stains during regular inspections.

Alternatively, install an oil pan or other device to prevent leakage from

causing further damage. Oil leakage may lead to problems in the customer’s

equipment or products.

• Allowable torque

Operate the motor by making sure the sum of the acceleration/deceleration

torque at the starting/stopping of the motor and the load (friction) torque

doesn’t exceed the allowable torque. Operating the motor in excess of the

allowable torque may result in a damaged gear.

• Allowable speed range

Operate the motor at speeds within the allowable range. Operating the motor

at a speed outside the allowable range may result in a shorter gear life.

• Backlash

The gear output shaft is subject to backlash of 10 to 45´. To reduce the effect

of backlash, perform positioning operations from one direction only-either

from the CW direction or the CCW direction.

• Rotating direction of the gear output shaft

Rotating direction of the gear output shaft is identical with that of the motor

shaft in case that the reduction ratio are 3.6:1, 7.2:1 and 10:1, and it is

opposite direction in case that the ratio are 20:1 and 30:1.