CONTENTS

INTRODUCTION ...........................................................................................................3

SAFETY MESSAGES ................................................................................ ..................3

Damage Prevention Messages ..................................................................................3

Safety Information ......................................................................................................3

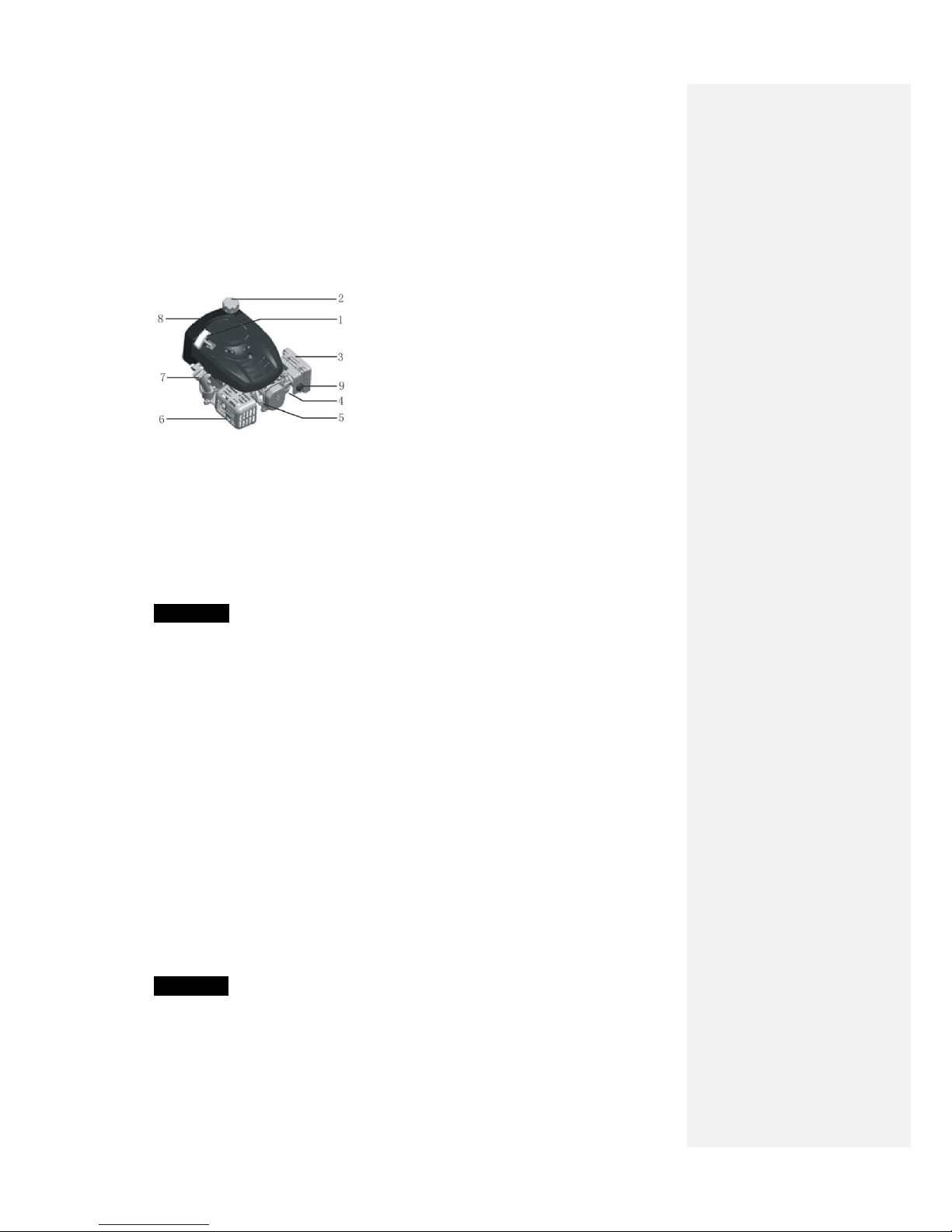

COMPONENT& CONTROL LOCATION .......................................................................4

BEFORE OPERATION CHECKS ..................................................................................4

OPERATION ..................................................................................................................4

Safe Operating Precautions .......................................................................................5

Starting The Engine.....................................................................................................5

Stopping The Engine...................................................................................................5

Specifications..............................................................................................................5

SERVICING YOUR ENGINE ...........................................................................................6

The Importance Of Maintenance .................................................. ..............................6

Maintenance Safety ...................................................................................................6

Safety Precautions......................................................................................................7

Maintenance Schedule............................................................................................... 7

Refueling.....................................................................................................................8

Fuel Recommendations..............................................................................................8

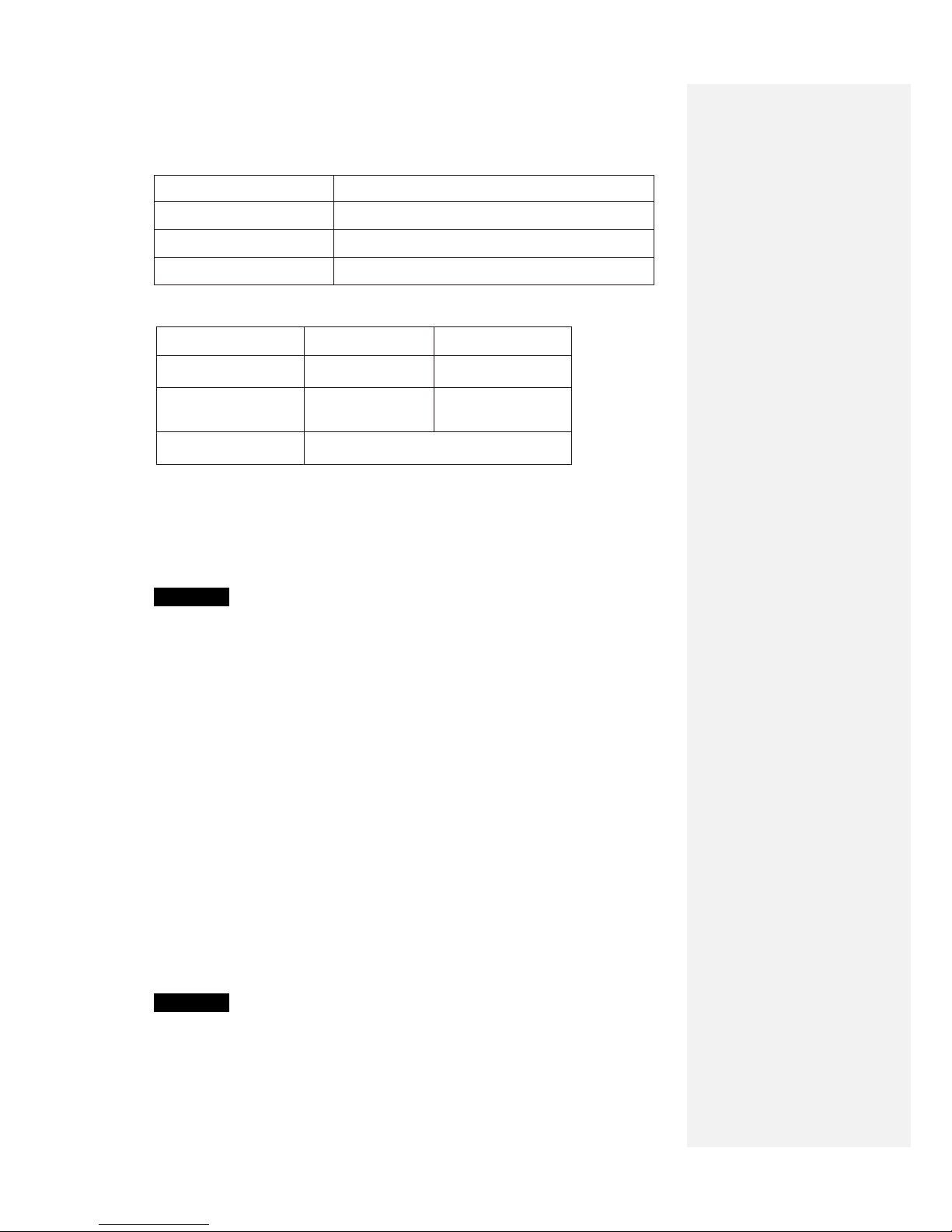

Engine Oil....................................................................................................................9

Air Cleaner.................................................................................................................11

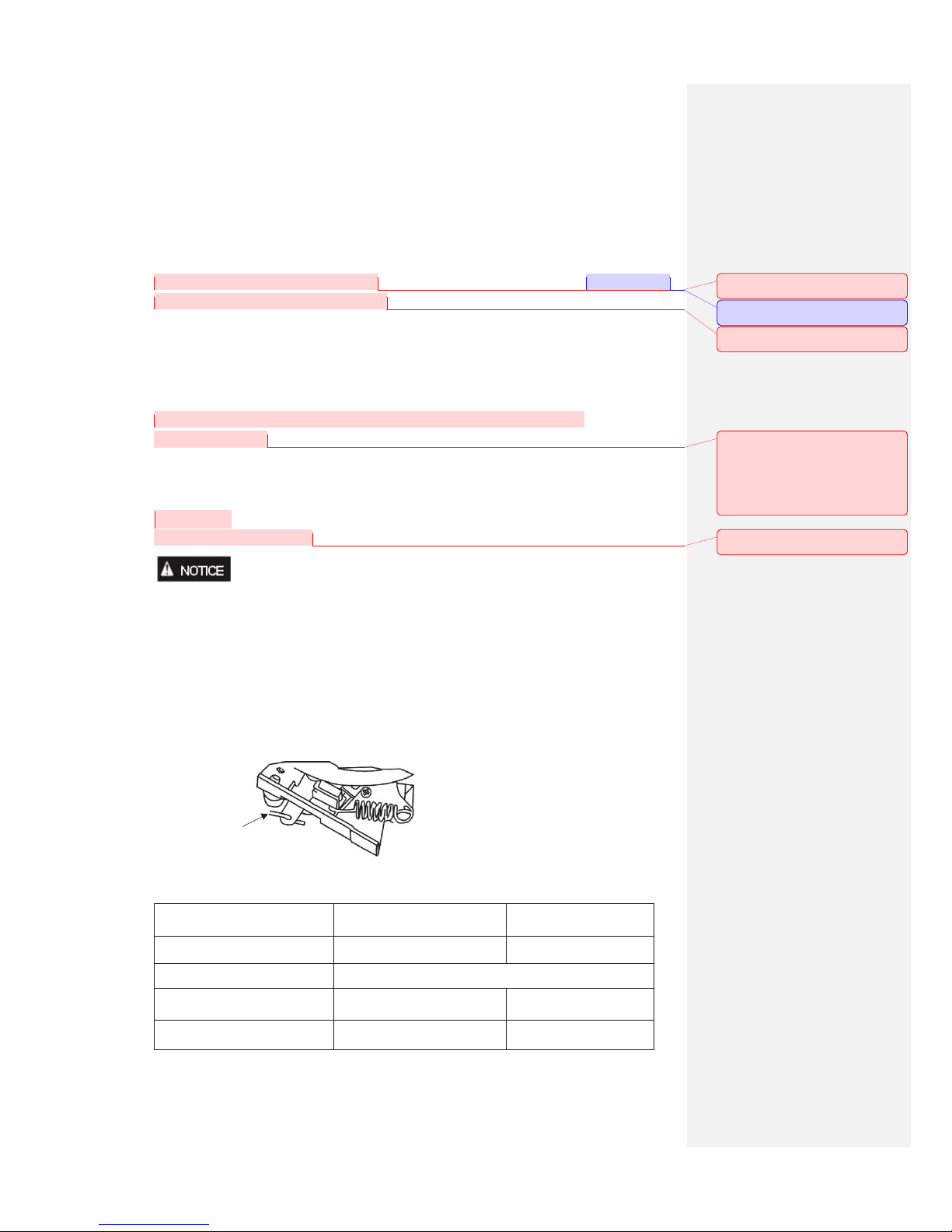

Spark Plug .................................... ...........................................................................11

HELPFUL TIPS& SUGGESTIONS................................................................................13

Storing Your Engine................................................................................... ..............13

Adding A Gasoline Stabilizer To Extend Fuel Storage Life ......................................14

Draining The Fuel TankAnd Carburetor...................................................................14

Clean Fuel Strainer .................................................................................................15

Transporting ............................................................................................................16

TAKING CARE OF UNEXPECTED PROBLEMS...........................................................16

TECHNICAL& CONSUMER INFORMATION

TECHNICAL INFORMATION.........................................................................................17

Serial Number Location.............................................................................................17

High Altitude Operation ..........................................................................................17