Gas hot-air heater MONZUN |instalation, operation instractions and maintenance manual

4 |

EN GENERAL

This manual is an integral part of the product and must be given to the end user together with the equipment.

a) Gas hot-air heaters MONZUN may only be used by a person

who has been instructed in the normal use of the appliance

and who understands the possible dangers.

b) Persons with reduced physical, sensory or mental abilities or

a lack of experience and knowledge may only use the heater

under the supervision of a person trained according to point a).

c) Children cannot use or play with the MONZUN heater.

MONZUN air heaters meet the ecodesign requirements of ErP

2021 according to Commission Regulation (EU) 2016/2281.

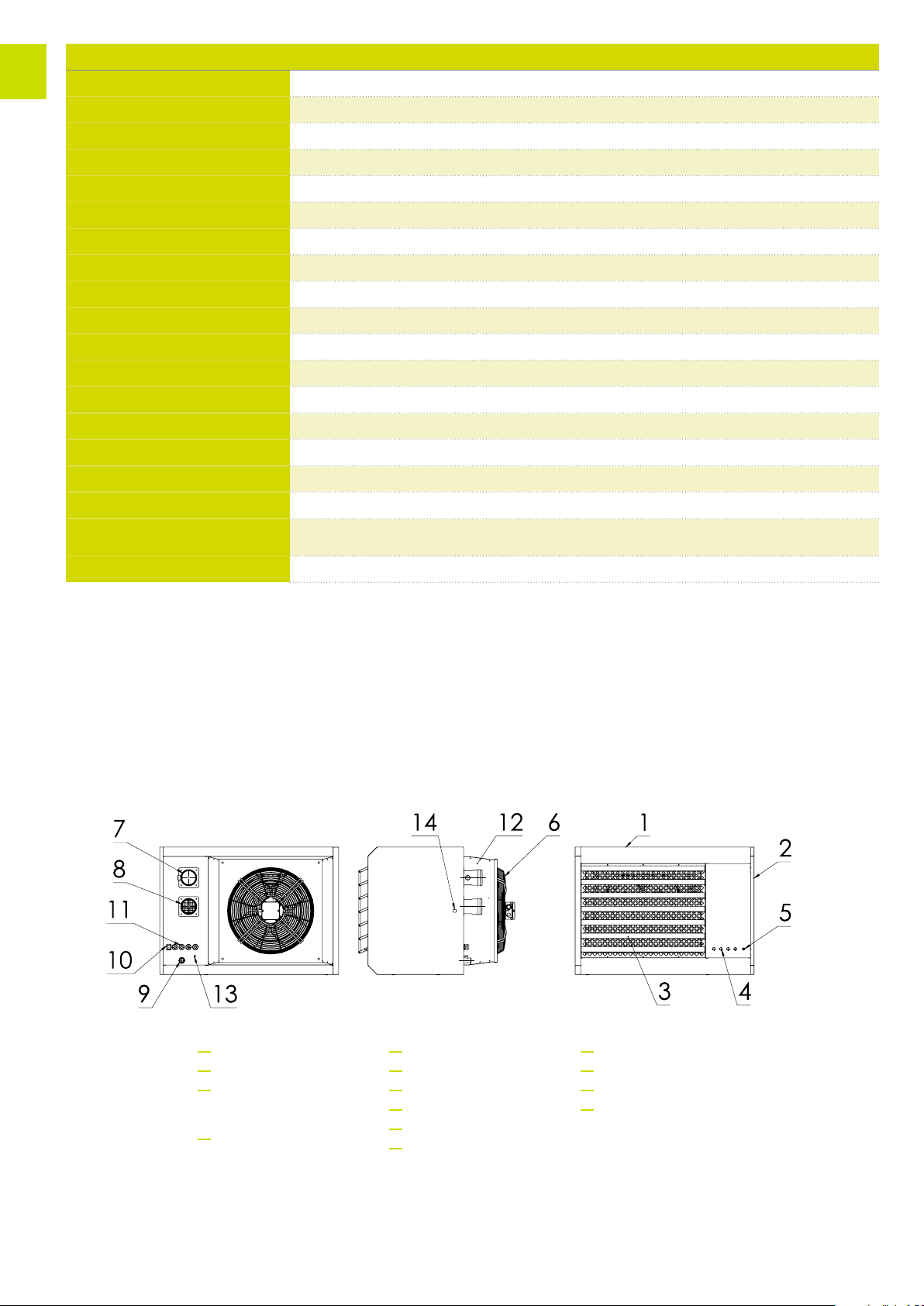

Description of heaters MONZUN

Hot air gas heaters MONZUN are designed for ventilation and ecolog-

ical heating of rooms and halls by heated air. Available versions are

in a power range from 15 kW to 60 kW with an airow from 2,500 to

8,000m/h in size: 15, 20, 30, 40, 50 and 60. In terms of gas extraction

equipment, it is an open or closed appliance with forced exhaust ue

gas.

Appliance categories - II2E3B/P, II2ELL3B/P, design B23, C13, C33, C63

Degree of electrical protection is IP40

Emission value NOxto 70 mg/kWh acc. to commission regulation (EU)

2016/2281 (Ecodesign 2021)

Emission class – NOx5

A common operating fuel for MONZUN units is:

• natural gas – ZP (G20/G25)

• propane-butane – PB (G30/G31)

• propane – P (G31)

The MONZUN heaters are in the standard version intended for instal-

lation in weather-protected environments of class 3K3 according to

EN 60721-3-3 with temperature range from 0° to +35 °C, for spac-

es without explosion hazard according to EN 1127-1. The air pass-

ing through the unit and the combustion air must not contain solid,

brous, sticky or aggressive particles. They cannot be installed in

rooms where there is a risk of re or explosion.

The control of the power output of the MONZUN heaters is continu-

ous from minimum power to rated/maximum power. The heated air

ow is forced by an axial fan.

Due to the high eciency it is necessary to install a condensate drain

from the chimney, unless it is otherwise addressed in special cases.

Description of function

The heater operation is controlled by the control automatics.

After the heater is switched on, the burner fan starts to ventilate and

the exchanger is ventilated with fresh air for 30 s.

After the venting time, starting speed of the burner fan is set by the

control automatics, the burner electrical ignition is triggered and the

electromagnetic gas valve is opened. After the burner is ignited, the

speed of the burner fan is adjusted to the operating speed according

to the required power.

When the heater exchanger is heated to the set temperature, the fan

operating thermostat triggers the axial air fan and the heater starts

to blow heated air.

When the heater is switched o, the control unit automatically closes

the electromagnetic gas valve, the speed of the burner fan is adjust-

ed to the ventilating speed and the exchanger is ventilated with fresh

air. The axial air fan keeps running and ensures that the exchanger

cools down below the set temperature.

The function of the burner fan is monitored by the control automat-

ics with the help of the fan motor speed sensor.

The temperature of the exchanger is monitored by thermostats:

• Operating thermostat of ventilator (switches the axial fan ON and

OFF according to set temperature)

• Burner operating thermostat (checks the correct temperature of

the heat exchanger, if the set temperature is exceeded, its shuts

down the burner operation)

• Emergency thermostat (checks the maximum allowable tempe-

rature of the heat exchanger and when this limit temperature is

reached, shuts down the gas burner and activates the warning

light. Operator intervention is required to unblock the emergency

thermostat. Operator should check the heater and unblock the

emergency thermostat.)

The control of the output power of the hot-air heater is carried out by

the control signal 0–10 V (DC ±) or by Modbus. If the control signal is

not connected, after the heater is switched on by the service switch,

the heater switches to minimum power output.