M&R Sprint 2000 User manual

V.033007 Part #MAN-SPRINT2000

Sprint 2000 Bv1

$45.00 USD

Sprint®2000

WWW.MRPRINT.COM

Toll-Free: 800-736-6431

USA Direct: 630-858-6101

USA Fax: 630-858-6134

Outside USA: +847-967-4461

Outside USA Fax: +847-967-0417

1N 372 Main St. Glen Ellyn, IL 60137 USA

Sprint®2000 V.033007

2M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA

WARNING: For your safety the information in this

manual must be explicitly followed to minimize the

risk of fire or explosion or to prevent property

damage, personal injury or death.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

IF YOU SMELL GAS:

•Do not try to light any appliance

•Do not touch any electrical switch; do not use

any phone in your building

•Clear the room, building or area of all occupants

•Immediately call your gas supplier from a

neighbor’s phone; follow the gas supplier’s

instructions

•If you cannot reach your gas supplier, call the

fire department

Installation must be performed by a qualified

installer, service agency, or the gas supplier.

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

V.033007 Sprint®2000

Table of Contents

1. Safety and Operational Guidelines...........................................................................................................................5

1.1 Management Responsibilities...................................................................................................................................6

1.2 Operator Responsibilities..........................................................................................................................................7

2. General Information....................................................................................................................................................8

2.1 Service and Parts......................................................................................................................................................9

2.2 Defined Purpose .....................................................................................................................................................10

2.3 Warranty..................................................................................................................................................................10

3. Product Specifications.............................................................................................................................................11

4. Assembly and Installation .......................................................................................................................................12

4.1 Assembly.................................................................................................................................................................12

4.2 Installation...............................................................................................................................................................17

5. Operation...................................................................................................................................................................17

5.1 Principles of Operation............................................................................................................................................17

5.1.1 Curing Inks...................................................................................................................................................17

5.2 Control Panel ..........................................................................................................................................................19

5.2.1 Digital Temperature Controller.....................................................................................................................20

5.3 Ignition Sequence ...................................................................................................................................................21

5.4 Dryer Shutdown ......................................................................................................................................................22

5.5 Main Blower Speed Adjustment (Optional).............................................................................................................22

6. Scheduled Maintenance...........................................................................................................................................23

7. Troubleshooting........................................................................................................................................................27

8. Replacement Parts ...................................................................................................................................................28

M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA 3

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

Sprint®2000 V.033007

4M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA

This page intentionally left blank

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

V.033007 Sprint®2000

1. Safety and Operational Guidelines

DANGER

This symbol identifies situations that endanger people, property, and/or equipment. If such

conditions exist, the equipment must be shut down and all energy sources (electrical, gas, and

pneumatic) must be disconnected, purged, and locked out until the problem is resolved.

Never attempt to bypass or defeat any safety device. Do not attempt to operate the equipment if

any safety device is not functioning properly, or if any doubt exists about proper operation of safety

devices.

The product described in this publication may operate at high speed and contain numerous

moving parts. It may employ natural gas or propane, mechanical or pneumatic forces, and/or

hazardous voltages, and may create other conditions that could, through misuse, abuse,

unauthorized alteration or retrofitting, inattention, or lack of understanding, result in injury, death, or

damage to the product or to other equipment. In addition, improper operation may also depreciate

the value of the machine and other assets of the owner, and impair the working efficiency of the

machine.

Energy Sources M&R equipment may use one of more of the following energy sources:

•Compressed Air (Pneumatic Energy)

•Electricity

•Gas (Natural Gas or Propane)

Each form of energy presents its own unique hazards and requires appropriate precautions.

Danger From

Compressed Air

(Pneumatic

Energy)

Only qualified personnel should be allowed to work on pneumatic components or assemblies. Before

work is started on pneumatic components or assemblies, equipment should be disconnected from the

air supply and all pneumatic lines should be purged to prevent accidental operation of pneumatic

assemblies. All pneumatic pipes and hoses should be checked frequently for damage and wear.

Danger From

Electrical

Energy

Only qualified personnel should have access to electrical enclosures or work on electrical systems,

and enclosures should be locked when not in use. Electrical equipment should be checked regularly.

WARNING

Failure to follow safety and maintenance procedures or to take appropriate corrected action when

required can result in severe or fatal personal injuries, property damage, and/or damage to the

equipment.

M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA 5

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

Sprint®2000 V.033007

6M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA

1.1 Management Responsibilities

Management

Responsibilities 1. Ensure that this equipment is used only for the purposes set forth in the “Defined Purpose”

section of this manual.

2. Ensure that all employees involved with the operation of this equipment or working near it read,

understand, and act in accordance with the operational and safety standards set forth in this

manual, including the Operator Responsibilities listed below.

3. Ensure that all recommended preventive maintenance is carried out according to M&R

guidelines.

4. Should any problem arise which compromises the safe operation or normal functioning of this

equipment, ensure that the equipment is immediately shut down, sources of power to the

equipment is shut off and secured, and that personnel not trained to repair – and directly involved

in repairing – the equipment are removed from the immediate area and not allowed to return until

the equipment has been returned to a safe and fully-functional condition.

5. Provide, and compel use of, any personal protection devices that may be required for the safe

operation of this equipment.

6. Make no modification to equipment or equipment software without written approval from M&R.

7. Provide – and support with written documentation – necessary employee training to ensure safe

operation, including but not limited to instruction in:

a. the operation of this machine

b. the use of personal protection devices

c. preventive maintenance procedures

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

V.033007 Sprint®2000

1.2 Operator Responsibilities

Operator

Responsibilities Note: ‘Operator Responsibilities’ pertain to all employees who work on or near the equipment; this includes, but

is not limited to those who clean, maintain and repair the equipment as well as those who operate it. In

general, all those who work on or near the equipment have a duty to use reasonable and ordinary care

for their own safety when in the vicinity of the machine. Failure to use reasonable and ordinary care

subjects people and property to serious personal injury and/or death and to destruction of personal

and/or company property. M&R expressly disclaims any and all liability, whether in contract, tort or by

statute, for damages, whether in the nature of personal injury/death and/or property damage, and

whether direct, indirect, consequential or incidental, as a result of a failure to use reasonable and

ordinary care.

1. Ensure that this equipment is used only for the purposes set forth in the “Defined Purpose”

section of this manual.

2. Read, understand, and act in accordance with the safety and operational standards and

guidelines set forth in this manual.

3. Install and maintain the equipment and safety devices in accordance with this manual; this

includes checking the equipment and safety devices for external or visible damage at least once

per shift, and making sure all safety and danger notices are in place and in readable condition.

4. Make no modification to equipment or equipment software without written approval from M&R.

5. Ensure that all other employees working on or near this equipment are knowledgeable in its safe

operation, and closely supervise inexperienced employees; keep bystanders away from the

equipment.

6. Make sure the area around the equipment is clear and free of obstructions, clean up spills

immediately, and remove ink and other contaminants at the end of each shift.

7. Ensure that any and all safety guards (including but not limited to safety bar, foot switch, yellow

cycle interruption cords, infrared safety beam, yellow floor mats, or hand switches) provided with

this equipment for the purpose of protecting personnel by automatically stopping the equipment

are in place – and are not removed, disabled or rendered ineffective during operation.

8. Wear any personal protection devices required for the safe operation of this equipment.

9. Avoid wearing anything that could become entangled in moving parts; for example, but not by

way of limitation, tie back, pin up, or cover long hair.

10. Do not attempt to operate this equipment if you are sick, fatigued, or under the influence of

alcohol and/or drugs including, but not limited to, prescriptions and over-the-counter medications

that warn against the operation of equipment.

11. Avoid standing on any part of the equipment not intended for that purpose.

12. Immediately shut down the equipment, disconnect and lock out all sources of power (electrical,

gas, and/or pneumatic); and purge all lines under pressure if the equipment fails to be fully

operational or if any safety device fails to operate properly, and ensure that the equipment stays

offline until the safety device is again operational.

13. Perform – and document – preventive maintenance at intervals described in the Operator’s

Manual.

14. Keep this Operator’s Manual in clean, easily readable condition near the equipment at all times

so it can be quickly accessed by operators and maintenance personnel.

M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA 7

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

Sprint®2000 V.033007

8M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA

2. General Information

This Document This document is based on information available at the time of its publication. While every effort has

been made to be accurate, the information contained herein does not purport to cover all details or

variations in hardware, software, features, or specifications, or to provide for every possible

contingency in connection with installation, operation and maintenance. Features may be described

herein which are not present in all models of this product. M&R Printing Equipment, Inc. and its

subsidiaries reserve the right to alter specifications in the manufacture of their products, and they

assume no obligation of notice to holders of this document with respect to changes subsequently

made.

M&R Printing Equipment, Inc. and its subsidiaries make no representation or warranty, expressed or

implied, whether pursuant to statute or case law with respect thereto, and assume no responsibility

for, the accuracy, completeness, sufficiency or usefulness of the information contained herein. No

warranties of merchantability or fitness for a particular purpose shall apply.

This is a publication of M&R Printing Equipment, Inc. and its subsidiaries. All information contained

herein is derived in part from proprietary and patent data of M&R Printing Equipment, Inc., and may

not be copied, electronically reproduced, or transmitted in any form without prior written permission, in

each case made and provided.

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

V.033007 Sprint®2000

2.1 Service and Parts

Manufacturer’s

Rating Plate Most products manufactured by the M&R Companies carry a metal manufacturer’s rating plate similar

to the one shown below. Please use it to fill out the product information below, and be prepared to

provide the identification information when calling. This helps us respond to your needs more quickly.

Model No.

Machine No.

Serial No.

Schematic No.

Date Installed

Installed by

Optional Features and Special Information

Contacting M&R If you need service or have questions about your equipment, call the appropriate number and ask for

Technical Support. If you need parts, ask for the Parts Department.

From the United States & Canada

Monday-Friday between 8:30 AM and 5:00 PM

Central Standard/Daylight Time

800-736-6431

Or

630-858-6101

From all other countries

Monday-Friday between 14:30 and 23:00 Greenwich

Mean Time (GMT) +847-967-4461

Outside Regular Hours Call our Global Hotline:

+630-462-4715

Visit www.mrprint.com for a list of global

contacts www.mrprint.com

M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA 9

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

Sprint®2000 V.033007

10 M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA

2.2 Defined Purpose

Textile Presses Textile Presses are designed to print textile inks on textile substrates, as more fully set forth in the

manual specific to that product. Any other use of this equipment is not permitted.

Textile Dryers Textile Dryers are designed to cure/dry textile inks on textile substrates, as more fully set forth in the

manual specific to that product. Any other use of this equipment is not permitted.

Graphic Presses Graphic Presses are designed to print graphic inks on rigid and semi-rigid flat substrates, as more

fully set forth in the manual specific to that product. Any other use of this equipment is not permitted.

Graphic Dryers Graphic Dryers are designed to cure/dry graphic inks on rigid and semi-rigid flat substrates, as more

fully set forth in the manual specific to that product. Any other use of this equipment is not permitted.

Exposure

Equipment Exposure Equipment is designed to produce photographic printing plates and printing screens, as

more fully set forth in the manual specific to that product. Any other use of this equipment is not

permitted.

Folding and

Packaging

Equipment

Folding and Packaging Equipment is designed to fold, transport, and package textile materials, as

more fully set forth in the manual specific to that product. Any other use of this equipment is not

permitted.

Ancillary

Equipment Ancillary Equipment is designed to perform specific operations related to processing and handling of

substrates, as more fully set forth in the manual specific to that product. Any other use of this

equipment is not permitted.

2.3 Warranty

Limited

Warranty Your Warranty does not apply to damages sustained due to equipment misuse, whether intentional or

negligent, and such misuse may void your warranty. Misuse includes – but is not limited to – the

items listed below. In addition, M&R Printing Equipment, Inc. accepts no responsibility for personal

injury or property damage caused by misuse.

1. Use of the equipment for any non-defined purpose

2. Improper installation or use of the equipment

3. Operation of the equipment with defective safety devices

4. Operation of the equipment with safety devices removed, disabled, not working in whole or in part

or in any manner rendered ineffective for the purpose for which they were designed

5. Failure to comply with instructions for transportation, storage, installation, operation,

maintenance, setup, and take-down of the equipment as described in the Operator’s Manual

6. Unauthorized modification of the equipment or equipment software

7. Failure to replace worn or defective parts

8. Failure to use M&R supplied replacement and repair parts

9. Defective repairs made to the equipment

10. Dangerous conditions which result from improper use of the equipment

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

V.033007 Sprint®2000

3. Product Specifications

Specifications

Sprint 2000-48 Sprint 2000-60 Sprint 2000-72

Belt Width 122 cm (48") 152 cm (60") 183 cm (72")

Burner Width 217 cm (85.5”) 248 cm (97.5”) 278 cm (109.5”)

Heat Chamber Width 160 cm (63") 191 cm (75") 221 cm (87")

Heat Chamber Length 366-610 cm (8'-20’) or more 366-610 cm (8'-20’) or more 366-610 cm (8'-20’) or more

Expansion Head

Modules 61 cm (24") 61 cm (24") 61 cm (24")

Standard Infeed /

Outfeed Length 244 cm (96") 244 cm (96") 244 cm (96")

Overall Length 732-1097 cm (24'-36’) or

more 732-1097 cm (24'-36’) or

more 732-1097 cm (24'-36’) or

more

Exhaust Blower

System2, 3 30 cm (12"): 50 970 l/min

(1800 cfm) @ 6 mm (1/4")330 cm (12"): 50 970 l/min

(1800 cfm) @ 6 mm (1/4")330 cm (12"): 50 970 l/min

(1800 cfm) @ 6 mm (1/4")3

Gas Input Size 2.54 cm (1") 2.54 cm (1") 2.54 cm (1")

LP/Natural Gas Input

Pressure .93-1.49 mm Hg (5"-8” w.c.) .93-1.49 mm Hg (5"-8” w.c.) .93-1.49 mm Hg (5"-8” w.c.)

Burner Input Maximum4300 000 Btu 300 000 Btu 300 000 Btu

Electrical

Requirements1

208/230V, 3 ph, 22/21 A,

50/60 Hz, 5.3 kW 208/230V, 3 ph, 22/21 A,

50/60 Hz, 5.3 kW 208/230V, 3 ph, 22/21 A,

50/60 Hz, 5.3 kW

400V, 3 ph, 16 A, 50 Hz, 5.3

kW 400V, 3 ph, 16 A, 50 Hz, 5.3

kW 400V, 3 ph, 16 A, 50 Hz, 5.3

kW

61 cm (24”) Optional

Radiant Section1

208/230V, 3 ph, 22/21 A,

50/60 Hz, 5.3 kW 208/230V, 3 ph, 22/21 A,

50/60 Hz, 5.3 kW 208/230V, 3 ph, 22/21 A,

50/60 Hz, 5.3 kW

400 V, 3 ph, 16 A, 50 Hz, 5.3

kW 400 V, 3 ph, 16 A, 50 Hz, 5.3

kW

400 V, 3 ph, 16 A, 50 Hz, 5.3

kW

Shipping Weight51678 kg (3700 lb) 1860 kg (4100 lb) 2177 kg (4800 lb)

1If incoming voltage differs from the voltage(s) listed in this brochure, calculate amperage

accordingly. Other electrical configurations are available: Contact M&R for details

2Measured at the Exhaust Discharge Port

3Static pressure

4 Normal usage varies, but is significantly lower than the stated maximum

5Weight applies to models with a 244 cm (96”) heat/expansion chamber

Exhaust Ducts IMPORTANT: Check with your local heating/ventilation Contractor to be sure that exhaust ducts will

meet local building/fire codes and regulations before installation. M&R Printing Equipment does not

specify or recommend materials for the exhaust ducting of this equipment.

IMPORTANT: Do not join the Exhaust Hood ducts with the Main Exhaust duct. This will cause

airflow restrictions and the dryer will not perform properly.

M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA 11

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

Sprint®2000 V.033007

12 M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA

IMPORTANT: To comply with ANSI Standard Z 21.5.2-2001 and CSA Standard 7.2-2001, the dryer

must be installed with a proper exhaust duct connection to the outside. Please disregard all

references in earlier editions of this manual to placing bends in the exhaust ducting. Compliance with

the ANSI Standards in installation of the dryer is in conformance with all M&R ducting

requirements.

Main Exhaust duct size is 12” (30.48 cm) diameter.

Exhaust Hood duct size is 6” (15.24 cm) outside diameter

Main blower cfm is 3000 to 5000

Exhaust blower cfm is 2200 Maximum

Manifold

Pressure IMPORTANT: Manifold pressure is measured at the burner during the initial start up of the dryer.

(Maximum Input Rate)

Air

Displacement IMPORTANT: To comply with ANSI Standard Z 21.5.2-2001 and CSA Standard 7.2-2001, the dryer

must be installed with provisions for adequate combustion and make-up air supply.

Gas Supply IMPORTANT: In order to compensate for variables between the gas supply source and the inlet at

the dryer, the gas supply pipe size must be calculated and provided by a licensed plumber, and then

reduced to 1” (2.54 cm) at the gas inlet to the dryer. Keep all combustible materials at least 3 feet (91

cm) from the dryer operating area.

4. Assembly and Installation

4.1 Assembly

Inspection Carefully inspect for signs of damage in transit. If equipment has been damaged in transit, notify the

Freight Forwarder immediately. M&R is not responsible for damage that occurs during

transportation.

Dryer

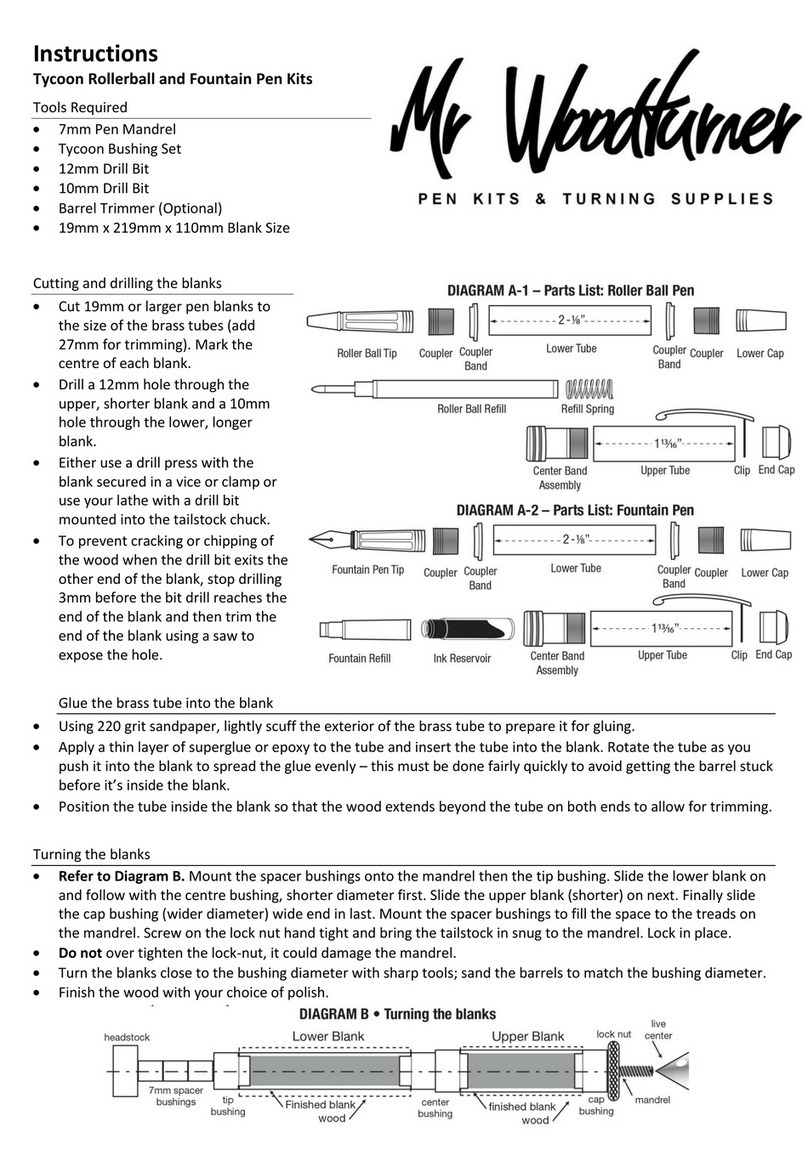

Components The dryer consists of eight basic components. (See Figure 1) Master Heat Chamber (1), Heat

Chamber Extensions (2), Exhaust Hoods (3), Support Rails (4), Support Legs (5), Lower End Caps

(6), Conveyor Support Legs (7) and Conveyor Extension Rails (8).

Figure 1

Hardware and

Tools Included with this dryer is the required assembly hardware. Hardware consists of: No. 10 Self-

Tapping Sheet Metal Screws, 3/8” - 16 X 3/4” Hex Head Bolts, washers, lock washers, nuts, and

5/16” Hex Head Wrench. Additional tools required: 1/2”, 9/16”, and 3/4” Wrenches, Pliers, 5/16” Nut

Driver, and Level.

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

V.033007 Sprint®2000

Step 1 Place Master Heat Chamber (1) in the area where the dryer will be used. Place a level across length

and width of the Master Heat Chamber (1). Adjust for level at all four corners using leveling

bolts/legs provided. Level the Master Heat Chamber (1) from front to rear and side to side.

DANGER: When installing on combustible flooring, the leveling legs must be adjusted for maximum

height. Failure to comply with this instruction may cause a fire hazard.

Step 2 Locate and layout Support Rails (4), Support Legs (5), Exhaust Hoods (3), and Heat Chamber

Extensions (2). Each section is marked with a yellow number tag. Match corresponding numbers.

Step 3 Loosely attach Support Rails (4) and Support Legs (5) to

both ends of Master Heat Chamber (1) using 3/8”-16 X 3/4”

hex head bolts with washer and lock washers provided.

Level the Support Rails by adjusting the feet on the bottom

of the Support Legs. Once level, securely tighten bolts.

Step 4 Heat Chamber Extensions

Heat Chamber Extensions (2) connect to the Master Heat

Chamber (1) with built-in rotary locking mechanisms, and

are secured with No.10 self-tapping sheet metal screws

(included).

Begin by placing the Heat Chamber Extensions (2) on the

Support Rails (4). Next, insert the male bracket of the

rotary locking mechanism into the female bracket.

Each Heat Chamber Extension has six rotary locks: two on

top and two on each side.

Step 5 With the Heat Chamber Extension (2) in alignment with the

Master Heat Chamber (1), lock them together with the

5/16” hex head wrench.

After the chambers have been locked together, secure

them from inside the Heat Chamber Extension with the

No.10 self-tapping sheet metal screws.

Follow the same procedure when connecting additional

Heat Chamber Extensions.

M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA 13

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

Sprint®2000 V.033007

14 M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA

Step 6 Air Plenum End Panels

Each Air Plenum End Panel has a series of screw holes.

Screw the No. 10 self-tapping sheet metal screws through

those holes into to the end Heat Chamber Extensions (2).

Note: End Panels must be installed before Exhaust Hoods.

Step 7 Before installing belt, remove specification tag from belt

flap and place it on the inside cover of this manual for

future reference.

Note: Belt must be inserted from the infeed end of the dryer.

From the infeed side of the dryer, feed the belt (9), flap (11)

down,zipper (10) up, through the End Cap (6).

Step 7a Pull several yards of belt through. Feed the belt through the

dryer until it exits the outfeed end.

Step 7b Install End Cap (6) with rotary cam locks using supplied

hex head wrench.

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

V.033007 Sprint®2000

Step 8 Fasten Exhaust Hoods (3) to Heat Chamber Extensions (2)

with rotary cam locks using supplied hex head wrench.

Step 9 Loosely fasten Conveyor Support Legs (7) and Conveyor

Extension Rails (8) to Heat Chamber Extensions using the

3/8”-16 x 3/4” hex head bolts, washers, lock washers and

nuts provided. Once squarely aligned and leveled to

Master Heat Chamber and Extensions, fasten securely.

Step 10 To complete installation of the Conveyor Belt, use a 3/4”

wrench to move the infeed roller all the way in by turning

the adjustment bolts counterclockwise.

Note: Do not adjust the outfeed roller.

Step 11 Pull the belt out and around the roller (12), and then place

it flat across the top of the rails on the upper portion of the

Conveyor Extension Rails (8). Feed the remainder of the

belt through the dryer and bring the two ends together.

M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA 15

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

Sprint®2000 V.033007

16 M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA

Note the proper routing of Conveyor Belt.

Step 12 Remove metal pin from one end of the metal lacing. Connect both ends of Conveyor Belt by aligning

the metal lacing and re-inserting metal pin.

Step 13

Conveyor Belt Tensioning

Tension the belt by turning both Infeed Roller adjustment bolts an even number of turns clockwise,

until the belt starts to move. Next, place enough garments on the belt to simulate production. Run the

belt and make sure the belt does not slip. If the belt slips, turn both Infeed Roller adjustment bolts

evenly in 1/2 turn increments until the belt starts to move again.

WARNING: Do not over-tension the Conveyor Belt. Over-tensioning puts unnecessary strain on the

Conveyor Drive Motor and shortens Conveyor Belt life. DAMAGE TO THE BELT DUE TO OVER-

TENSIONING IS NOT COVERED BY YOUR WARRANTY!

Conveyor Belt Tracking

IMPORTANT: Do not adjust the Outfeed Roller.

The infeed and outfeed rollers use a “crowned” design, meaning that the roller is thicker in the middle

than it is on the ends. When properly tensioned, this helps the Conveyor Belt track more efficiently.

Use a 3/4” wrench on the Infeed Roller to adjust tracking. Do not adjust the bolts more than 1/2 turn

at a time, and test belt tracking after every adjustment.

Note: To see tracking results faster, set the conveyor speed to its maximum setting.

Turn the left tension bolt counterclockwise if the belt is tracking to the right.

Turn the right tension bolt counterclockwise if the belt is tracking to the left.

IMPORTANT: Upon the initial start up of the dryer you will notice the elasticity of the Conveyor Belt

will change in reaction to exposure in the Heat Chamber. This is a normal condition. For belt

tracking, allow a minimum of four hours running time with both heat and cool down cycles for proper

adjustments. This practice allows a new belt to compensate for expansion during initial adjustment

and dryer operation. Monitor the belt for the first 30 days of operation and make adjustments, as

outlined above, when necessary.

Adjusting Belt

Speed Initial recommended belt speed is 15’ (4.57M) per minute. After starting your dryer, adjust belt speed

accordingly.

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

V.033007 Sprint®2000

4.2 Installation

Safety

Precautions 1. Installation of this appliance must conform with local codes, or in the absence of local codes,

with the National Fuel Gas Code, ANSI-223.1 – Latest Edition.

2. The dryer and shut off valve must be disconnected from the gas supply during pressure testing.

3. The dryer must be isolated from the gas supply piping system by closing its individual manual

shut off valve during any pressure testing of the gas supply piping system at test pressures

equal to or less than 1/2 psig (3.5 kPa).

4. When installed, dryer must be electrically grounded in accordance with local codes or, in the

absence of local codes, with the National Electrical Code ANSI/NFPA 70 - Latest Edition.

5. Dryer must not be installed or stored in an area where it will be exposed to water and/or weather.

6. Clearances from combustible construction as follows: sides (left and right) 36” (91 cm), rear 36”

(91 cm), ceiling 36” (91 cm). When installing on combustible flooring, the leveling legs must be

adjusted for maximum height. Failure to comply with this instruction may cause a fire hazard.

5. Operation

5.1 Principles of Operation

Drying

Principle This dryer is designed for curing/drying plastisol inks.

Plastisol

Heat cures plastisol by creating a chemical bond (crosslink) between plastisol molecules, rather than

by evaporation.

Byproducts of the curing process are vented out the exhaust duct.

IMPORTANT: Always check and confirm cure/dry results before starting a production run.

Due to the variations in garments, inks, and the application process, we disclaim all liability for

damage or loss related to inconsistent printing variables.

5.1.1 Curing Inks

Curing/Drying

Plastisol Inks Plastisol inks will not air dry or permanently adhere to garments unless fused with heat.

Results vary by temperature.

1. 110 degrees F (43.3 degrees C): the fusion process begins

2. 125 degrees F (51.6 degrees C): the ink viscosity will decrease to its lowest point and

the ink surface begins to flow or level

3. 240 degrees F (115.5 degrees C): plastisol begins to gel (this temperature range is

typical for printing transfers)

4. 325 to 350 degrees F (162.7 – 176.6 degrees C): the typical fusion temperature for

plastisol inks (consult your ink manufacturer for more accurate specifications)

Testing

Plastisol for

Proper Cure

When properly cured, plastisol inks produce prints that are extremely durable and wash

resistant. These attributes should be tested when checking for proper cure.

M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA 17

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

Sprint®2000 V.033007

18 M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA

Wash Test The most conclusive method of testing is to subject the print to a series of wash cycles. This

test is time consuming, but offers the most accurate determination of print durability, and

resistance to commonly used soaps, detergents, and bleaches. If the printed garment is

washable, it should be subjected to a minimum of three wash/dry cycles.

Use a phosphate detergent in 180 degrees F (82 degrees C) water. Inspection after testing

should reveal negligible decreases in color intensity and print adhesion. Any noticeable

change may be an indication that the plastisol ink failed to fuse correctly.

Stretch Test A more immediate method of testing plastisol cure is to perform a stretch test of the cured

plastisol print. Although the stretch test results are not as conclusive as the wash test, it

does offer a much quicker indication of the degree of cure.

Properly cured plastisol should stretch as much as 20-30%. If the printed garment is

stretched no more than 20%, and the ink film readily cracks, the ink may be under-cured.

The stretch test should be conducted only after the garment or material has been allowed to

cool to room temperature.

Crock Test The term Crock or Crock Fastness refers to an industry-specific test method designed to

measure the amount of color transferred from the surface of colored textile materials to a

similar—but unprinted—textile material when the two are rubbed together. If the unprinted

material lifts any color from the printed area, it is an indication of an under-cured print. For

more information visit the American Association of Textile Chemists and Colorists at

www.aatcc.org.

A Crock test may be used when curing materials that are not stretchable (ex: canvas), or for

imprints with thin ink deposits (ex: halftones). This test should only be performed after the

garment or material has been allowed to cool to room temperature.

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

V.033007 Sprint®2000

5.2 Control Panel

Number Name Function

1 START DRYER

ON Button The green START DRYER ON button is used to turn on the dryer and activate

the main blower, the exhaust blower, and the Conveyor Belt.

The button lights up when pressed, confirming that electrical power is on.

2 START DRYER

OFF Button The red START DRYER OFF button turns off electrical power to the control

system. The button lights up when pressed, confirming that electrical power has

been disconnected and the shutdown process has begun.

The exhaust blowers and Conveyor Belt drive continue to run until the interior of

the heat chamber reaches 150 F (66 C). At that point the blowers and belt drive

shut down and the red START DRYER OFF button light goes out.

3 Digital

Temperature

Controller

The Digital Temperature Controller includes buttons to input the Set Value

(SV) temperature, and two LED indicators.

The function of the buttons is explained below in Setting the Temperature.

The red indicator on top is the Present Value (PV) indicator. It displays the

temperature in the heat chamber.

The green indicator below displays the Set Value (SV) entered by the operator.

4 BURNER

OPERATION

PURGE Light

The BURNER OPERATION PURGE light remains on during the 60-second

purge cycle portion of the ignition sequence, and turns off when the purge

operation is complete.

5 BURNER

OPERATION

MAIN Light

The green BURNER OPERATION MAIN light turns on when the Burner

Operation Purge light turns off, and remains on as long as the burner is

operating.

6 BURNER

OPERATION

MAIN ON Button

The green BURNER OPERATION MAIN ON button starts the gas burner

ignition sequence. When pressed, the button lights to confirm that the ignition

sequence—including the 60-second Automatic Purge Cycle—has begun.

M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA 19

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

Sprint®2000 V.033007

20 M&R Companies 1N 372 Main St. Glen Ellyn, IL 60137 USA

Number Name Function

7 BURNER

OPERATION

MAIN OFF Button

The red BURNER OPERATION MAIN OFF button initiates burner shutdown.

When pressed, the gas burner shuts down and the green indicator light (5) turns

off.

To completely shut down the dryer, follow the procedure for the START DRYER

OFF button (2).

8 Green Tower

Light When the Present Value (PV) temperature reaches the Set Value (SV), the

green tower light on top of the main control panel turns on.

The Green Tower Light turns off whenever the Present Value (PV) temperature

is above or below the Set Value (SV).

9 EMERGENCY

STOP Button The red EMERGENCY STOP button shuts down the gas burner instantly and

stops all dryer operation.

Press the button in until it remains depressed to activate.

Turn the button slightly clockwise until it pops out to deactivate.

Note: Use the EMERGENCY STOP button only in emergency situations.

10 Audible Alarm

Speaker An audible alarm sounds when the dryer is in Flame Failure mode, when there

is a System Error, when the circulation filter is clogged, or if the Process

Temperature PV) changes plus or minus 5 degrees F (3 degrees C) of the Set

Value (SV).

11 CLEAN FILTER

Light The red CLEAN FILTER light turns on when the stainless steel circulation filter

has become blocked by dirt or lint and needs to be cleaned.

Remove and clean the filter.

12 FAILURE Light The red FAILURE light turns on when there is a Flame Failure or a System

Error.

13 ALARM OFF

Button Press the yellow ALARM OFF button to silence audible alarms.

14 LED CONVEYOR

SPEED Display The CONVEYOR SPEED LED displays conveyor speed in feet per minute or

meters per minute.

15 CONVEYOR

SPEED Knob The CONVEYOR SPEED knob controls Conveyor Belt speed.

Turn the knob clockwise to increase speed.

Turn the knob counterclockwise to decrease speed.

5.2.1 Digital Temperature Controller

Setting the

Temperature Press the Up Arrow or Down Arrow

button to reach the Set Value (SV).

Each time a button is pressed, the Set

Value (SV) increases or decreases by

one degree.

If steady pressure is applied to the

buttons, the Set Value (SV) increases

or decreases rapidly.

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com

Table of contents

Popular Accessories manuals by other brands

Vision-EL

Vision-EL ELV408655 Notice Instructions

DARCHE

DARCHE ECLIPSE T050801794 quick start guide

Honeywell Home

Honeywell Home DC315 Series manual

Libelium

Libelium Smart Cities PRO Technical guide

Focusrite

Focusrite Clarett 8Pre USB user guide

Belden

Belden Hirschmann ELWIKA 5012 PG7 Assembly instructions