SC - 121-00

Dated: 7/1/00

SERVICE COMMUNICATOR

MANITOWOC ICE, INC. +2110 S. 26th ST., PO box 1720, Manitowoc, WI. 54221-1720 USA

(920-682-0161 •Service Fax 920-683-7585 :Web Site - www.manitowocice.com

Subject: QM 20/QM 30 Ice Production, Refrigeration Diagnostics & Charging

The QM 20/QM 30 dice ice cube formation is slightly

different from our previous models. Manitowoc ice

machines have a unique cube shape. It is normal to have a

dimple in the ice cube (a concave indentation in the cube).

Ice cubes from the QM 20/QM 30 may appear to have a

slightly larger dimple than other Manitowoc dice cube

machines. Therefore, cube size for the QM 20/QM 30 is

determined by measuring the slab weight (the combined

weight of all cubes from one harvest cycle). To determine

proper slab weight, follow the instructions listed below.

1. Ensure the air filter, front, and back panels are installed

properly and close the bin door.

2. During the third harvest cycle open the bin door and

catch the entire slab of ice.

3. Weigh the ice slab. The combined weight of all cubes

from one harvest should weigh between 7 - 9 oz

(200 - 270 g). If the slab weight is within this range, the

ice machine is working properly and no further action is

needed. If the slab weight is not within this range or

you desire a slightly thicker or thinner cube, continue to

step four.

4. Remove the air filter.

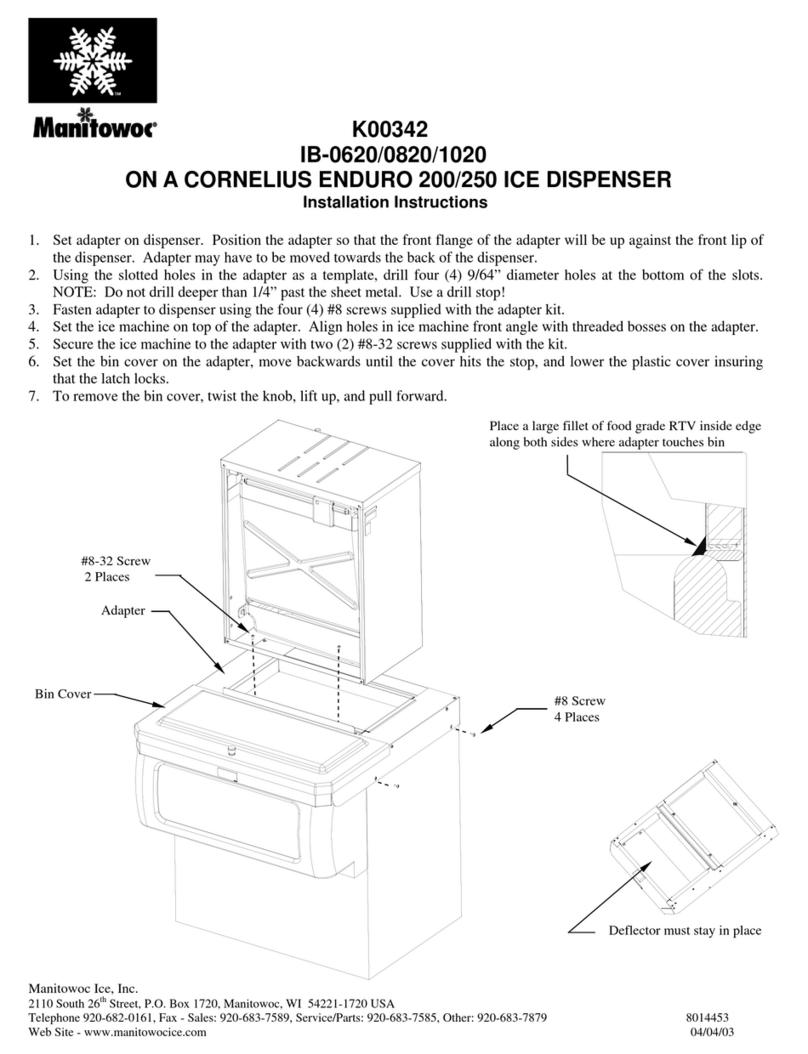

5. Remove the two screws holding the front panel in place

and remove the front cover.

6. Locate the ice thickness control dial on the control

board (see figure). Turn the dial clockwise for a thicker

cube or counter clockwise for a thinner cube.

7. Assure all of the panels and air filter are reinstalled

properly and the bin door is closed. Repeat steps one

through three.

The QM 20/QM 30 ice machines have a very small

refrigerant charge, 4.59 oz. (130 grams) and we do not

recommend diagnosing the ice machine using refrigerant

pressures. For this reason we have not included refrigeration

access fittings.

Verify that your water flow is even across the entire

evaporator before diagnosing the refrigeration system.

Mineral build-up on the evaporator assembly can cause

water tracking and an erratic ice fill pattern. Clean with

Manitowoc Ice Machine cleaner to remove any mineral

build-up before entering the refrigeration system.

The following can be used for diagnostics:

Capillary Tube failures or low refrigerant charge will always

result in a starving evaporator.

Assume 86°F (30°C) air temperature 68°F (20°C) water

temperature.

Suction line temperature at the compressor will range from

86°F (30°C) three minutes into the cycle to 8°F (-13°C) at

the end of the freeze cycle. An obstructed capillary tube or

low refrigerant charge will have a suction line temperature

higher than normal.

Discharge line temperature at the compressor will range

from 168°F (76°C) to140°F (60°C) through the freeze cycle.

An obstructed capillary tube or low refrigerant charge will

have a lower discharge line temperature than normal.

Suction line temperature at the compressor will range from

64°F (18°C) to 111°F (44°C) through the harvest cycle. An

obstructed capillary tube will not affect suction line

temperature range during the harvest cycle. Low refrigerant

charge will have a lower temperature than normal.

Discharge line temperature at the compressor will range

from 180°F (82°C) to 150°F (60°C) through the harvest

cycle. An obstructed capillary tube will not affect discharge

line temperature range during the harvest cycle. Low

refrigerant charge will have a lower temperature than

normal.

Ice fill pattern will vary depending on severity of the

obstruction or refrigeration loss. Ice fill patterns will range

from no ice on the entire evaporator to thin only at the

evaporator outlet (thin at the bottom, thick at the top of the

evaporator).

After completing the procedure above, if you are unable to

obtain a sheet of ice weighing between 7 - 9 oz (200 - 270 g)

contact the Manitowoc Service Department at

1-800-545-5720 for further assistance.

Ice

Thickness

Control

Dial

WARNING

Disconnect electric power to the ice machine at the

electric switch box before proceeding.