Mannesmann MT-CNC User manual

MT-CNC

Quick Reference Guide

Reference Manual

DOK-MT*CNC-REFER*GUIDE-ANW1-EN-P

278478

IAE 74768

QUICK REFERENCE GUIDE

4GX % #$176 6*+5 &1%7/'06 KK

Using This Reference Guide

This document is a quick reference guide for individuals working

with the Indramat MT-CNC. This guide should not be used as a

complete system manual, but as a quick reference guide for plant

floor programming.

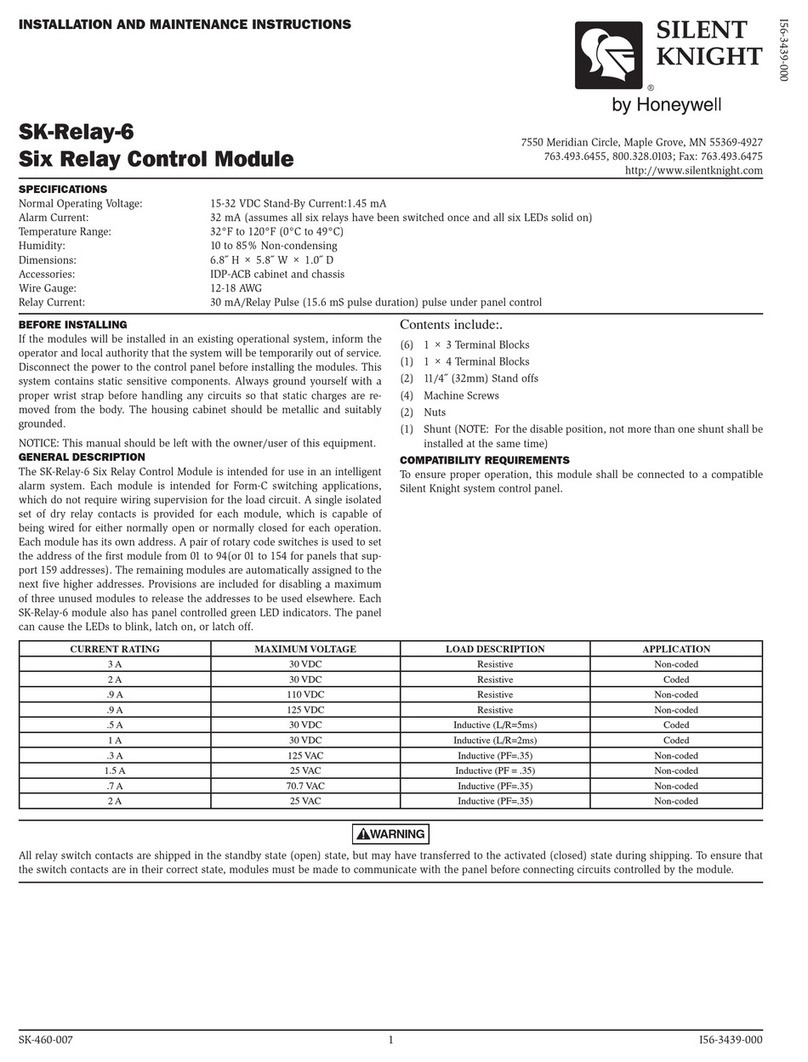

Modules described in this manual include: MT-CNC, TVD power

supplies, DDS drive amplifiers, MDD servo motors, TDA/KDA/RAC

spindle amplifiers, spindle motors.

In this document MUI refers to the MT-CNC User Interface software,

and SPS refers to the PLC programming system.

Hot Key Legend

<A>,<B> : Press key “A” then press key “B”.

<A>+<B>: Press and hold key “A” while pressing key “B”.

<Main Menu>: Always refers to the MT-CNC main Menu.

NOTE:

This reference guide is based on the MT-CNC software version

0x.17/XX.

Later MT-CNC software versions may contain functionality that

deviates from the one described in this manual!

CAUTION:

Life threatening voltages present on amplifier and servo motor

connectors. Do not connect or disconnect while power is on.

Unexpected and dangerous machine movements may result if service is

attempted by unqualified personnel.

IAE 74768

QUICK REFERENCE GUIDE

4GX % (14'914& KKK

FOREWORD

Special Notations:

Special notations are used in this manual to assist the reader in

identifying unique conditions or information that is important.

Three categories of notations are listed below in ascending order

of importance.

Note:

A NOTE is a tip, suggestion or emphasized procedure for

operating the equipment.

Caution:

A CAUTION appears when a condition exists which could

cause operating faults or damage to the equipment.

Warning:

WARNING statements identify conditions which could cause

bodily harm and/or severe damage to the equipment if the operator

is not careful operating the equipment . A WARNING typically

describes the potential hazard, its possible effect, and measures

that must be taken to avoid the hazard.

Please

NOTE: The following notes pertain to the version of

software releases covered in this manual.

No note: valid for all software releases indicated under revisions

(1): MT-CNC software releases 04.11/00 ... 04.13/xx only

(2): MT-CNC software releases 0x.14/xx

(3): MT-CNC software releases 0x.15/xx

(4): MT-CNC software releases 0x.16/xx

(5): MT-CNC software releases 0x.17/00

The Rexroth Corporation

Indramat Division

5150 Prairie Stone Parkway

Hoffman Estates, Illinois 60192

Phone. (847) 645-3600 |FAX (847) 645-6201

IAE 74768

QUICK REFERENCE GUIDE

KX 4'%14& 1( 4'8+5+105 4GX %

RECORD OF REVISIONS

Revision Date Description of Change

Rev A ¦ Jan.1995 ¦ 1st Preliminary Printing, valid for software

¦ ¦ release 0x.11/00 - 0x.13/xx

Rev B ¦ Oct.1995 ¦ Improved, corrected and expanded version per

¦ software releases 0x.11/00 - 0x.15/xx

Rev C ¦ Oct.1997 ¦ Improved, corrected and expanded version per

¦ software releases 0x.16/00 - 0x.17/00

IAE 74768

QUICK REFERENCE GUIDE

4GX % %106'065 X

CONTENTS

FOREWORD................................................................................................................................................................... III

RECORD OF REVISIONS..............................................................................................................................................IV

1. MUI FLOW CHARTS................................................................................................................................................1-1

1.1 MT-CNC USER PROGRAMS & DATA - BACKUP...........................................................................................................1-1

1.2 MT-CNC USER PROGRAMS & DATA - RESTORE .........................................................................................................1-3

1.3 DIGITAL DRIVE PARAMETER (SERVO, SPINDLE) - ARCHIVE.........................................................................................1-5

1.4 ACTIVE USER DATA (EVENTS, VARIABLES, D-CORRECTIONS, ACTIVE TOOL LIST, OFFSET TABLE DATA) - ARCHIVE1-6

1.5 NC PROGRAM (INCLUDING TOOL SETUP LIST) - ARCHIVE..........................................................................................1-7

1.6 MACHINE PARAMETER (SYSTEM, PROCESS, AXIS) - ARCHIVE....................................................................................1-8

1.7 SPS (PLC) PROGRAM - ARCHIVE (1),(2),(3) .....................................................................................................................1-9

1.8 SPS (PLC) PROGRAM - ARCHIVE (4)...........................................................................................................................1-10

1.9 SPS (PLC) PROGRAM - ARCHIVE (5)...........................................................................................................................1-11

1.10 DIGITAL DRIVE PARAMETER (SERVO, SPINDLE) - EDITING ......................................................................................1-12

1.11 MACHINE PARAMETER (SYSTEM, PROCESS, AXIS) - EDITING ..................................................................................1-13

1.12 SPS (PLC) EDITING(1),(2),(3) ......................................................................................................................................1-15

1.13 SPS (PLC) EDITING(4),(5) ..........................................................................................................................................1-16

1.14 USER MESSAGE - EDITING........................................................................................................................................1-17

1.15 DIGITAL DRIVE PARAMETER (SERVO, SPINDLE) - PRINT OUT ..................................................................................1-18

1.16 MACHINE PARAMETER (SYSTEM, PROCESS, AXIS) - PRINT OUT ..............................................................................1-19

1.17 NC PROGRAM - PRINT OUT......................................................................................................................................1-20

1.18 SPS DOCUMENTATION - COMPLETE AND PARTIAL PRINTOUTS(1),(2),(3 ......................................................................1-21

1.19 SPS DOCUMENTATION - COMPLETE AND PARTIAL PRINTOUTS ................................................................................1-22

1.20 GLOBAL DOCUMENTATION - PRINTING USER...........................................................................................................1-23

1.21 FURTHER INFORMATION (HELP) - NC STATUS AND DIAGNOSTICS ...........................................................................1-24

1.22 NC PROGRAM VARIABLES .......................................................................................................................................1-25

1.23 OFFSET TABLE DATA ...............................................................................................................................................1-26

1.24 SPS LOGIC DISPLAY SETUP......................................................................................................................................1-27

1.25 SPS LOGIC ANALYSIS (1),(2),(3) ...................................................................................................................................1-28

1.26 SPS LOGIC ANALYSIS...............................................................................................................................................1-29

1.27 PASSWORD SETUP ( FOR MT-CNC MUI SOFTWARE) ..............................................................................................1-30

1.28 SELECTION OF ONLINE / OFFLINE MODE (FOR MUI SOFTWARE)..............................................................................1-31

1.29 SELECTION OF ONLINE / OFFLINE MODE (FOR MUI SOFTWARE)..............................................................................1-32

1.30 EXITING (FROM ANY SCREEN BACK TO THE MUI MAIN MENU)................................................................................1-33

1.31 OSCILLOSCOPE - SETUP, RECORD, VIEW, SAVE .......................................................................................................1-34

1.32 SOT MESSAGE - DOWNLOADING .............................................................................................................................1-36

1.33 CURRENT NC PROGRAM - VIEWING.........................................................................................................................1-37

2. GUI FLOW CHARTS.................................................................................................................................................2-1

2.1 SETUP, GUI (INDRAMAT DEFAULT)..............................................................................................................................2-2

2.1.1 Online / Off-line Mode, GUI (Indramat default)..................................................................................................2-2

2.1.2 Password Setup, GUI (Indramat default).............................................................................................................2-3

2.1.3 Exiting Menus, GUI (Indramat default) ...............................................................................................................2-4

2.1.4 Load SOT Messages, GUI (Indramat default)......................................................................................................2-5

2.2 BACKUP, GUI (INDRAMAT DEFAULT)........................................................................................................................2-6

2.2.1 Total MT-CNC User Programs & Data Backup, GUI (Indramat default)...........................................................2-6

2.2.2 Digital Drive Parameter Archive, GUI (Indramat default)..................................................................................2-7

2.2.3 Active User Data Archive, GUI (Indramat default)..............................................................................................2-8

2.2.4 SPS (PLC) Project Archive, GUI (1),(2),(3) (Indramat default)................................................................................2-9

IAE 74768

QUICK REFERENCE GUIDE

XK %106'065 4GX %

2.2.5 SPS (PLC) Project Archive, GUI (4) (Indramat default)..................................................................................... 2-10

2.2.6 SPS (PLC) Project Archive, GUI (5) (Indramat default)..................................................................................... 2-11

2.2.7 Machine Parameter Archive, GUI (Indramat default)....................................................................................... 2-12

2.2.8 NC-program (w. Tool Setup List) Archive, GUI (Indramat default).................................................................. 2-13

2.2.9 Tool List Archive, GUI (Indramat default)........................................................................................................ 2-14

2.3 RESTORE, GUI (INDRAMAT DEFAULT)....................................................................................................................... 2-15

2.3.1 Total MT-CNC User Programs & Data Restore, GUI (Indramat default) ........................................................2-15

2.4 TROUBLESHOOTING AND DIAGNOSTICS, GUI (INDRAMAT DEFAULT)........................................................................ 2-16

2.4.1 Further Information to Diagnostics, GUI (Indramat default) ........................................................................... 2-16

2.4.2 Offset Table Data, GUI (Indramat default) ....................................................................................................... 2-17

2.4.3 Active NC-Program, GUI (Indramat default).................................................................................................... 2-18

2.4.4 NC-Variables, GUI (Indramat default).............................................................................................................. 2-19

2.4.5 Oscilloscope, GUI (Indramat default) ............................................................................................................... 2-20

2.4.6 PLC (SPS) Logic Display Setup, GUI (Indramat default) ................................................................................. 2-22

2.4.7 PLC (SPS) Logic Analysis, GUI (1),(2),(3) (Indramat default)............................................................................... 2-23

2.4.8 PLC (SPS) Logic Analysis, GUI (4),(5) (Indramat default) .................................................................................. 2-24

2.5 EDITING, GUI (INDRAMAT DEFAULT)........................................................................................................................ 2-25

2.5.1 Machine Parameter Editing, GUI (Indramat default)....................................................................................... 2-25

2.5.2 Diagnostic Messages Editing, GUI (Indramat default)..................................................................................... 2-27

2.5.3 SPS (PLC) Program Editing, GUI (1),(2),(3) (Indramat default)........................................................................... 2-28

2.5.4 SPS (PLC) Program Editing, GUI (4),(5) (Indramat default)............................................................................... 2-29

2.5.5 Digital Drive Parameter Editing, GUI (Indramat default)................................................................................ 2-30

2.6 DOCUMENTATION, GUI (INDRAMAT DEFAULT)......................................................................................................... 2-31

2.6.1 Global Documentation, GUI (Indramat default)............................................................................................... 2-31

2.6.2 NC-Program Print Out, GUI (Indramat default)............................................................................................... 2-32

2.6.3 Machine Parameter Print Out, GUI (Indramat default).................................................................................... 2-33

2.6.4 Digital Drive Parameter Print Out, GUI (Indramat default) ............................................................................ 2-34

2.6.5 SPS (PLC) Documentation Print Out, GUI (1),(2),(3) (Indramat default).............................................................. 2-35

2.6.6 SPS (PLC) Documentation Print Out, GUI (4),(5) (Indramat default)................................................................. 2-36

3. PARAMETERS .......................................................................................................................................................... 3-1

3.1 SYSTEM PARAMETERS................................................................................................................................................. 3-1

3.2 PROCESS PARAMETERS................................................................................................................................................ 3-2

3.3 AXIS PARAMETERS ...................................................................................................................................................... 3-4

3.3.1 Linear and Rotary Axes ....................................................................................................................................... 3-4

3.3.2 Main Spindle Axis Parameters............................................................................................................................. 3-9

3.3.3 Digital Comb. Turret Axis / Main Spindle, C-Axis Parameters *D................................................................... 3-11

4. NC PROGRAMMING ............................................................................................................................................... 4-1

4.1 NC PROGRAM STRUCTURE.......................................................................................................................................... 4-1

4.2 NC MEMORY............................................................................................................................................................... 4-1

4.3 ADVANCE PROGRAM ................................................................................................................................................... 4-1

4.4 REVERSE PROGRAM..................................................................................................................................................... 4-1

4.5 PART PROGRAM........................................................................................................................................................... 4-2

4.6 PROCESS PROGRAM..................................................................................................................................................... 4-2

4.7 NC-BLOCK ELEMENTS ................................................................................................................................................ 4-2

4.7.1 NC-Block Numbers .............................................................................................................................................. 4-2

4.7.2 NC-block which can be Skipped .......................................................................................................................... 4-2

4.7.3 NC-Labels............................................................................................................................................................ 4-2

4.7.4 NC Message for MUI........................................................................................................................................... 4-2

4.7.5 NC Message for SOT ........................................................................................................................................... 4-3

4.7.6 NC-Block Comment ............................................................................................................................................. 4-3

4.8 G-CODES ..................................................................................................................................................................... 4-3

4.9 AUXILIARY FUNCTIONS ............................................................................................................................................. 4-11

4.10 PROCESS CONTROL COMMANDS.............................................................................................................................. 4-14

IAE 74768

QUICK REFERENCE GUIDE

4GX % %106'065 XKK

4.11 PROGRAM CONTROL NC COMMANDS......................................................................................................................4-15

4.12 SUBROUTINES...........................................................................................................................................................4-16

4.13 REVERSE VECTOR ....................................................................................................................................................4-16

4.14 RE-POSITIONING AND NC-BLOCK RESTART (GUI)....................................................................................................4-17

4.15 5 BRANCH COMMANDS ............................................................................................................................................4-17

4.16 NC-EVENTS..............................................................................................................................................................4-18

4.17 INTERRUPTING NC-EVENTS......................................................................................................................................4-18

4.18 MATHEMATICAL EXPRESSIONS.................................................................................................................................4-19

4.19 NC-FUNCTIONS........................................................................................................................................................4-20

4.20 TIME FUNCTIONS......................................................................................................................................................4-22

4.21 POSITION STROBE.....................................................................................................................................................4-22

4.22 FUNCTIONS FOR DIGITAL DRIVES .............................................................................................................................4-22

4.23 NC-VARIABLES........................................................................................................................................................4-22

4.24 SPINDLE SELECTIONS................................................................................................................................................4-23

4.25 OFFSET TABLES........................................................................................................................................................4-23

4.26 AXIS SWITCHING ......................................................................................................................................................4-24

4.27 PATH ACCELERATION...............................................................................................................................................4-25

4.28 MACHINE DATA .......................................................................................................................................................4-26

4.29 TOOL DATA..............................................................................................................................................................4-27

4.30 MODAL FUNCTIONS..................................................................................................................................................4-27

4.31 NC-BLOCK LOOK AHEAD FUNCTION........................................................................................................................4-27

4.31.1 Global Variable Definitions .............................................................................................................................4-27

5. SPS INSTRUCTION SET...........................................................................................................................................5-1

5.1 ELEMENTARY DATA TYPES..........................................................................................................................................5-1

5.2 DERIVED DATA TYPES .................................................................................................................................................5-1

5.2.1 Structures (STRUCT)............................................................................................................................................5-1

5.2.2 Arrays...................................................................................................................................................................5-1

5.3 INSTRUCTION LIST INSTRUCTIONS................................................................................................................................5-2

5.3.1 Load and save instructions...................................................................................................................................5-2

5.3.2 Set and reset instructions......................................................................................................................................5-2

5.3.3 Logic Instructions.................................................................................................................................................5-3

5.3.4 Jumps, Calls, Return (conditional and unconditional).........................................................................................5-4

5.3.4.1 Return from Function Blocks or Functions.......................................................................................................................5-4

5.3.5 Arithmetic Instructions .........................................................................................................................................5-5

5.3.6 Comparators.........................................................................................................................................................5-7

5.4 LADDER DIAGRAM .......................................................................................................................................................5-9

5.4.1 Basic Elements in the Ladder Diagram..............................................................................................................5-10

5.5 OPERATIONS...............................................................................................................................................................5-11

5.5.1 Logic Bit and Bit String Operations ‘:=‘, ‘AND’, ‘OR’, ‘XOR’.........................................................................5-11

5.5.2 Arithmetic Operations ........................................................................................................................................5-12

5.5.3 Comparators.......................................................................................................................................................5-15

5.6 FUNCTIONS.................................................................................................................................................................5-17

5.6.1 Standard Functions ............................................................................................................................................5-17

5.6.2 Numeric Functions .............................................................................................................................................5-27

5.6.3 Functions for Time-to-Integer Conversion.........................................................................................................5-27

5.6.3.1 Method of operation of the time-to-integer conversion...................................................................................................5-28

5.6.3.2 Error handling of the time-to-integer conversion............................................................................................................5-28

5.6.4 INTEGER-to-TIME Conversion .........................................................................................................................5-29

5.6.5 Bit string functions..............................................................................................................................................5-29

5.6.6 Character String Functions................................................................................................................................5-33

5.7 FIRMWARE FUNCTIONS...............................................................................................................................................5-38

5.8 USER FUNCTIONS .......................................................................................................................................................5-38

5.8.1 Import rules........................................................................................................................................................5-39

5.9 FUNCTION BLOCKS.....................................................................................................................................................5-39

IAE 74768

QUICK REFERENCE GUIDE

XKKK %106'065 4GX %

5.10 STANDARD FUNCTION BLOCKS................................................................................................................................ 5-39

5.10.1 Flip-Flops ........................................................................................................................................................ 5-39

5.10.2 Edge evaluation for rising and falling edges ‘R_TRIG’, ‘F_TRIG’................................................................ 5-40

5.10.3 Up and down counters..................................................................................................................................... 5-41

5.10.4 Time stages for pulses; ON/OFF delay............................................................................................................ 5-43

5.10.5 Function blocks for date and time ................................................................................................................... 5-44

5.10.6 Function blocks for serial interfaces ............................................................................................................... 5-45

5.10.6.1 Standard data type ‘COM’ ............................................................................................................................................5-45

5.10.6.2 Error handling of the function blocks for serial interfaces............................................................................................5-52

5.11 FIRMWARE FUNCTION BLOCKS................................................................................................................................ 5-53

5.12 USER FUNCTION BLOCKS......................................................................................................................................... 5-53

5.12.1 Import rules...................................................................................................................................................... 5-53

5.13 ERROR HANDLING ................................................................................................................................................... 5-54

5.13.1 Basics of the Error Handling Concept............................................................................................................. 5-54

5.13.2 Error Handling Sequence................................................................................................................................ 5-55

5.13.3 Error Handling of Multiple Errors.................................................................................................................. 5-56

5.13.4 Error Handling in User Files........................................................................................................................... 5-56

5.13.5 Overview of Possible Errors and Their Causes............................................................................................... 5-56

5.13.6 Errors in functions and function blocks........................................................................................................... 5-57

5.13.7 Errors in operations and IL instructions ......................................................................................................... 5-62

5.13.8 Errors in exceptional REAL operations........................................................................................................... 5-64

6. GATEWAY SIGNALS............................................................................................................................................... 6-1

6.1 INTRODUCTION TO CNC⇔SPS GATEWAY SIGNALS.................................................................................................... 6-1

6.2 DECLARING GATEWAYS IN SPS................................................................................................................................... 6-1

6.3 PROCESS SIGNALS........................................................................................................................................................ 6-2

6.4 POWER ON CONTROL .................................................................................................................................................. 6-4

6.5 CNC OPERATING MODES ............................................................................................................................................ 6-5

6.5.1 AUTOMATIC MODE........................................................................................................................................... 6-6

6.5.2 SEMI-AUTOMATIC MODE................................................................................................................................ 6-7

6.5.3 MANUAL MODE (Setup)..................................................................................................................................... 6-8

6.6 NC-PROGRAM SELECTION......................................................................................................................................... 6-10

6.7 PROCESS CONTROL SIGNALS (SPS⇒CNC) ............................................................................................................... 6-11

6.8 PROCESS STATUS SIGNALS (CNC⇒SPS) .................................................................................................................. 6-14

6.9 FEED AND SPINDLE OVERRIDE (SPS⇒CNC)............................................................................................................. 6-18

6.10 PROCESS / PART PROGRAM SYNCHRONIZATION ...................................................................................................... 6-19

6.11 SPINDLE CONTROL (SPS⇒CNC)............................................................................................................................. 6-23

6.12 SYNCHRONOUS AXES .............................................................................................................................................. 6-24

6.13 MECHANISM CONTROL SIGNALS.............................................................................................................................. 6-26

6.14 MECHANISM STATUS SIGNALS................................................................................................................................. 6-26

6.15 AXIS SIGNALS.......................................................................................................................................................... 6-27

6.15.1 Axes Hardware Limits (SPS

⇒

CNC)................................................................................................................ 6-27

6.15.2 Axis Control Signals (SPS

⇒

CNC)................................................................................................................... 6-28

6.15.3 Axis Status Signals (CNC

⇒

SPS)..................................................................................................................... 6-36

6.16 MT-CNC SPECIFIC APR PARAMETERS.................................................................................................................... 6-39

6.16.1 SCARA Robots ................................................................................................................................................. 6-39

6.16.2 DDS as Spindle Drive...................................................................................................................................... 6-41

6.16.3 Gear Change.................................................................................................................................................... 6-42

6.16.4 Torque Reduction............................................................................................................................................. 6-43

6.16.5 Filter ................................................................................................................................................................ 6-43

6.16.6 Synchronous Axis............................................................................................................................................. 6-44

6.16.7 Measuring Function Torque / Lag Error......................................................................................................... 6-46

6.16.8 Combined Spindle / Turret Axis....................................................................................................................... 6-47

6.16.9 General ............................................................................................................................................................ 6-47

IAE 74768

QUICK REFERENCE GUIDE

4GX % %106'065 KZ

6.17 GATEWAY SIGNAL LISTING (STRUCTURED DATA TYPE)...........................................................................................6-52

6.17.1 Axis Status Signals (iAXIS)...............................................................................................................................6-52

6.17.2 Process Status Signals (iPROC).......................................................................................................................6-52

6.17.3 Local Inputs Signals (iDEA).............................................................................................................................6-53

6.17.4 External Mechanism Status Signals (iMECH)..................................................................................................6-54

6.17.5 Axis Control Signals (qAXIS) ...........................................................................................................................6-55

6.17.6 Process Control Signals (qPROC) ...................................................................................................................6-55

6.17.7 Local Output Signals (qDEA)...........................................................................................................................6-56

6.17.8 External Mechanism Control Signals (qMECH)..............................................................................................6-56

7. TOOL MANAGEMENT.............................................................................................................................................7-1

7.1 INTRODUCTION TO TOOL MANAGEMENT......................................................................................................................7-1

7.2 TOOL SETUP LIST .........................................................................................................................................................7-1

7.2.1 Tool Lists and Setup Lists.....................................................................................................................................7-1

7.2.2 Basic Tool Data of Setup List...............................................................................................................................7-1

7.2.2.1 Tool Name (ID).................................................................................................................................................................7-1

7.2.2.2 T-Number (T)....................................................................................................................................................................7-1

7.2.2.3 Amount of Tool Edges ......................................................................................................................................................7-1

7.2.2.4 Time Unit ..........................................................................................................................................................................7-2

7.2.2.5 Length Unit .......................................................................................................................................................................7-2

7.2.2.6 Comment...........................................................................................................................................................................7-2

7.2.3 Tool Edge Data.....................................................................................................................................................7-2

7.2.3.1 Tool Edge Orientation.......................................................................................................................................................7-2

7.2.3.2 Maximum Tool Life ..........................................................................................................................................................7-2

7.2.3.3 Tool Life............................................................................................................................................................................7-2

7.2.3.4 Maximum and Minimum Tool Length..............................................................................................................................7-2

7.2.3.5 Maximum and Minimum Tool Radius ..............................................................................................................................7-2

7.2.3.6 Length Tool Wear Factor (L1, L2, L3)..............................................................................................................................7-3

7.2.3.7 Radius Tool Wear Factor ..................................................................................................................................................7-3

7.2.4 Setup List Organization........................................................................................................................................7-3

7.2.5 Setup List Within the MT-CNC.............................................................................................................................7-3

7.3 TOOL LIST ....................................................................................................................................................................7-4

7.3.1 Tool List Data.......................................................................................................................................................7-4

7.3.2 Basic Tool Data of Setup List...............................................................................................................................7-4

7.3.2.1 Tool Name.........................................................................................................................................................................7-4

7.3.2.2 Tool Storage......................................................................................................................................................................7-4

7.3.2.3 Tool Location....................................................................................................................................................................7-4

7.3.2.4 Tool Index.........................................................................................................................................................................7-4

7.3.2.5 Tool Correction Type........................................................................................................................................................7-5

7.3.2.6 Amount of Tool Edges ......................................................................................................................................................7-5

7.3.2.7 Half Pocket Overlap..........................................................................................................................................................7-5

7.3.2.8 Old Location......................................................................................................................................................................7-5

7.3.2.9 Length Unit .......................................................................................................................................................................7-6

7.3.2.10 User Tool Data (1...9)......................................................................................................................................................7-6

7.3.3 Tool Edge Data.....................................................................................................................................................7-6

7.3.3.1 Tool Edge Orientation.......................................................................................................................................................7-6

7.3.3.2 Remaining Tool Life .........................................................................................................................................................7-6

7.3.3.3 Warning Limit...................................................................................................................................................................7-6

7.3.3.4 Geometric Data..................................................................................................................................................................7-7

7.3.3.5 Tool Length Correction.....................................................................................................................................................7-7

7.3.3.6 Tool Radius Correction.....................................................................................................................................................7-7

7.3.3.7 User Edge Data..................................................................................................................................................................7-7

7.3.4 Tool List within the Control System......................................................................................................................7-7

7.4 ACTIVE TOOL LIST .......................................................................................................................................................7-8

7.4.1 Data of the Active Tool List..................................................................................................................................7-8

7.4.2 Tool Edge Status Bits..........................................................................................................................................7-13

7.5 TOOL MANAGEMENT PARAMETERS ...........................................................................................................................7-14

7.5.1 System Parameters .............................................................................................................................................7-14

IAE 74768

QUICK REFERENCE GUIDE

Z %106'065 4GX %

7.6 NC TOOL MANAGEMENT CONTROL FUNCTIONS ....................................................................................................... 7-18

7.6.1 Requirements ..................................................................................................................................................... 7-18

7.6.1.1 Defined Plane..................................................................................................................................................................7-18

7.6.1.2 Tool Selection.................................................................................................................................................................7-19

7.6.1.3 Tool Edge Selection (E)..................................................................................................................................................7-19

7.6.1.4 Tool Change....................................................................................................................................................................7-20

7.6.1.5 Spindle Selection for Tool Mgmt....................................................................................................................................7-20

7.6.2 Tool Storage Movement NC-commands ............................................................................................................ 7-20

7.6.3 Tool Change NC-commands.............................................................................................................................. 7-23

7.7 SPS TOOL MANAGEMENT CONTROL FUNCTIONS ...................................................................................................... 7-26

7.7.1 Standard Data Types ......................................................................................................................................... 7-26

7.7.2 Tool Storage Reference...................................................................................................................................... 7-27

7.7.3 Position Tool Storage ........................................................................................................................................ 7-28

7.7.4 Standard Tool Change FUNCTIONs................................................................................................................. 7-29

7.7.5 Tool Change Between Magazine and Spindle.................................................................................................... 7-30

7.7.6 Tool Transfer FUNCTIONs ............................................................................................................................... 7-32

7.7.7 Tool Transfer FUNCTION Overview................................................................................................................. 7-35

7.7.8 Combined Spindle / Turret Axis......................................................................................................................... 7-37

7.7.9 Standard FUNCTION_BLOCKS for Tool Management.................................................................................... 7-40

7.7.9.1 Standard FUNCTION_BLOCKS for Basic Tool Data....................................................................................................7-40

7.7.9.2 Standard FUNCTION_BLOCKS for Tool Edge Data....................................................................................................7-41

7.7.9.3 Standard FUNCTION_BLOCKS for Tool Data .............................................................................................................7-42

7.7.9.4 Standard FUNCTION_BLOCK for D-Corrections.........................................................................................................7-44

7.8 TOOL MANAGEMENT GATEWAY SIGNALS ................................................................................................................. 7-44

7.8.1 Tool Management Control Signals (SPS

⇒

CNC) .............................................................................................. 7-44

7.8.2 Tool Management Status Signals (CNC

⇒

SPS)................................................................................................. 7-46

8. STATUS, DIAGNOSTICS AND SETUP.................................................................................................................. 8-1

8.1 NC STATUS AND DIAGNOSTICS.................................................................................................................................... 8-1

8.2 FAULT LIST.................................................................................................................................................................. 8-2

8.3 HARDWARE AND SOFTWARE REQUIREMENTS.............................................................................................................. 8-2

8.3.1 Computer Requirements (PC).............................................................................................................................. 8-2

8.3.2 MS-DOS Software Configuration Recommendations for compatible PCs .......................................................... 8-3

8.3.2.1 Example of the CONFIG.SYS file of compatible PCs.......................................................................................................8-3

8.3.2.2 The CONFIG.SYS file for Indramat’s BTV 01..................................................................................................................8-3

8.3.2.3 Example of the AUTOEXEC.BAT File for compatible PCs.............................................................................................8-4

8.3.2.4 The AUTOEXEC.BAT File of Indramat’s BTV 01..........................................................................................................8-4

8.4 MT-RUN.BAT FILE.................................................................................................................................................... 8-5

8.4.1 Software Options Which Can Appended to (TSRPG25I) Line of MT-RUN.BAT................................................. 8-5

8.4.2 Software Options Which Can be Appended to the MT-CNC Line of MT-RUN.BAT............................................ 8-6

8.5 HOT KEYS ................................................................................................................................................................... 8-6

8.6 WINDOWS NT3.51 SOFTWARE CONFIGURATION RECOMMENDATIONS FOR COMPATIBLE PCS..................................... 8-6

8.6.1 Windows NT Interface Drivers............................................................................................................................. 8-7

8.6.2 Windows NT Task Response Time........................................................................................................................ 8-8

8.6.3 PIF File Setting for the Window NT MS DOS Window ...................................................................................... 8-9

8.6.4 Batch File to Call Up the MT-CNC User Interface Software............................................................................ 8-11

8.6.5 Create MT-CNC User Interface Program Icon ................................................................................................. 8-12

8.7 DDE SERVER DEPLOYMENT CONDITIONS ................................................................................................................. 8-13

8.7.1 Required Software for the DDE Server.............................................................................................................. 8-13

8.7.2 Cooperation with other Software Components.................................................................................................. 8-13

8.8 GENERAL................................................................................................................................................................... 8-14

8.9 PROGRAM CALL......................................................................................................................................................... 8-14

8.10 PASSWORD ADMINISTRATION.................................................................................................................................. 8-15

8.10.1 First Execution of Password Administration................................................................................................... 8-15

8.10.2 Register New User ........................................................................................................................................... 8-16

8.11 DDE CLIENT CONNECT TO INDRAMAT’S DDE SERVER .......................................................................................... 8-16

IAE 74768

QUICK REFERENCE GUIDE

4GX % %106'065 ZK

8.11.1 Automatic Start.................................................................................................................................................8-16

8.11.2 Data Access Function Commands....................................................................................................................8-17

IAE 74768

QUICK REFERENCE GUIDE

%106'065 4GX %

List Of Appendices

Appendix A: MT-CNC Control system

Appendix B:

this appendix is left intentionally blank

Appendix CD: MT-CNC Module Rack MTCB

Appendix E: Central Processor module CPUB

Appendix F: SPS Module PLCB

Appendix G: Axis Processor Module APRB

Appendix H: Input/Output Module DEAB

Appendix IJ:

this appendix is left intentionally blank

Appendix K: Operating, Programming and Visualizing Terminal BTV01.3

Appendix L: Configurable Operator Panel BTM13

Appendix M: Configurable Operator Panel BTM03

Appendix NO: Configurable Operator Panel BTM04

Appendix PQ: Station Operator Terminal SOT02

Appendix R: Remote I/O Rack RECO

Appendix S: Remote I/O Rack RECO02

Appendix Sch: Fiber Optic Repeater/Switcher LWR01

Appendix St: Firmware and Software selection for the MT-CNC Control System

Appendix T-V: Power Switching in E-Stop Chain

Appendix W: Hand Terminal BTC05

Appendix X: Master Index for Chapters 1 - 8

IAE 74768

QUICK REFERENCE GUIDE

Rev C, 10/97 MUI Flow Charts 1-1

1. MUI FLOW CHARTS

This chapter contains flowcharts to perform commonly used functions with the standard Indramat

softkey menu of the MT-CNC Machine User Interface Software

1.1 MT-CNC User Programs & Data - Backup

Figure 1-1: MT-CNC User Programs & Data - Backup (Sheet 1 of 2)

Main Menu

Do

y

ou want to include the

Di

g

ital Drive

(

Servo & Spindle

)

parameters on this backup? refer tp

'Di

g

ital Drive Parameter Archive'

chart.

return from

'Di

g

ital Drive Parameter Archive'

refer to

'Active Users Data Archive'

chart.

return from

'Active User Data Archive'

chart.

<F3> MT-CNC Archive

Insert empt

y

formatted diskette

in the appropriate drive and

<ENTER> to select BACKUP option

select desired disk drive and

<ENTER>

<F1> Archive Administration

No

No

Do

y

ou want to include

Active User Data

on this backup?

[

Ex., SPS retentative data, NC Events,

NC Variables, D-Corrections,

Offset table data

]

.

A

Yes

Yes

IAE 74768

QUICK REFERENCE GUIDE

1-2 MUI Flow Charts Rev C, 10/97

Figure 1-2 MT-CNC User Programs & Data - Backup (Sheet 2 of 2)

A

MUI Main Menu

<F8> To Main Menu

press any key to continue with BACKUP

or

<ESC> to abort

an estimated number of diskettes will be displayed

IAE 74768

QUICK REFERENCE GUIDE

Rev C, 10/97 MUI Flow Charts 1-3

1.2 MT-CNC User Programs & Data - Restore

Figure 1-3 MT-CNC User Programs & Data - Restore - (Sheet 1 of 2)

<Shift><F1> Setu

p

<F2> En

g

lish Lan

g

ua

g

e

<Down cursor>MT-CNC Definition List

<ENTER> to select

<F2> Define MT-CNC

follow instructions at bottom

of screen to define Slave MT-CNC's.

<F8> Setu

p

Menu

<Up cursor> Exit Setup

<ENTER>

G

<F3> MT-CNC Archive

Insert BACKUP diskette

in the appropriate drive and

did

y

ou have Slave MT-CNC's

defined on the backup?

Main Menu

No

<Ri

g

ht cursor> to RESTORE

<ENTER> to select RESTORE option

<F1> Archive Administration

WARNING

appears alertin

g

that all existin

g

pro

g

rams and date on the harddrive will be overwritten!

<ESC> to ABORT

or

<Y> to continue

Yes

IAE 74768

QUICK REFERENCE GUIDE

1-4 MUI Flow Charts Rev C, 10/97

Figure 1-4 MT-CNC User Programs & Data - Restore - (Sheet 2 of 2)

G

MUI Main Menu

<F8> To Main Menu

the RESTORE begins

select desired disk drive and

<ENTER>

press any key when RESTORE is complete

IAE 74768

QUICK REFERENCE GUIDE

Rev C, 10/97 MUI Flow Charts 1-5

1.3 Digital Drive Parameter (Servo, Spindle) - Archive

Figure 1-5 Digital Drive Parameter (Servo, Spindle) - Archive

<F5> Machine Parameter Administration

MUI Main Menu

<F5> Drive Param

move pointer to the desired Drive

<ENTER> to select.

<F7> File Service

follow instructions at bottom of screen

<F1> Save Param

archive another axis?

MUI Main Menu

No

Yes

MUI Main Menu

<F10>

or

<F8>, <F8>

the option to save only current drive data or all drive data will be given

NOTE: Saving all drive data gathers data from all drives and saves it

to one file.

All drives must connected when downloading file back to drives.

IAE 74768

QUICK REFERENCE GUIDE

1-6 MUI Flow Charts Rev C, 10/97

1.4 Active User Data (Events, Variables, D-Corrections, Active Tool List, Offset Table Data) - Archive

Figure 1-6 Active User Data (Events, Variables, D-Corrections, Active Tool List, Offset Table

Data) - Archive

MUI Main Menu

<F1> Archives Administration

<F8> To Main Menu

MUI Main Menu

(must be ONLINE for this option to appear)

<CTRL><F6> MT-CNC to NC-Data

follow instruction at bottom of screen

the following data will be archived:

NC-Event Status

NC-Variable Contents

D-Correction

Active Tool List(s)

Offset Table Data

IAE 74768

QUICK REFERENCE GUIDE

Rev C, 10/97 MUI Flow Charts 1-7

1.5 NC Program (Including Tool Setup List) - Archive

Figure 1-7 NC Program (Including Tool Setup List) - Archive

MUI Main Menu

<F1> Archives Administration

<F2> Store NC Prog.

move pointer to desired program slot

<ENTER>

follow instructions at bottom of screen

when archive is complete

press any key to continue

MUI Main Menu

<F1> NC-Archive

<F8> Archive Main Menu

<F8> To Main Menu

- select drive to archive to -

<F2> Ext. Arch Drive a

or

<F4> Int. Arch H. Disk C

Table of contents

Popular Control Unit manuals by other brands

SABAF

SABAF 46 TECHNICAL CHARACTERISTICS INSTRUCTIONS FOR USE, ASSEMBLY INSTRUCTIONS, MAINTENANCE INSTRUCTIONS

Asco

Asco 8316 Series operating manual

Vescent

Vescent D2-210 quick start guide

Siemens

Siemens SINAMICS S120 manual

PDi

PDi PD295-001 Installation and operating instructions

Siemens

Siemens OZW771 installation instructions