Manostar MS99 User manual

RoHS

READ THE INSTRUCTION MANUAL BEFORE USING

INSTRUCTION MANUAL

MANOSTAR SWITCH

MS99

No. TR-MS99-E02

1-2-3,Nishi-shiriike-cho,Nagata-ku,Kobe,Hyogo 653-0031 JAPAN

TEL. +81-78-631-6000 FAX. +81-78-631-6020

TABLE OF CONTENTS

PAGE

INTRODUCTION .............................................................................................................................. 1

Ⅰ.PRECAUTIONS ....................................................................................................................... 1

Ⅱ.THE NAME OF EACH PART ........................................................................................... 2

Ⅲ.INSTALLATION

1. Caution of service condition .................................................................................... 2

2. Installation of MS99 ....................................................................................................... 2

3. Installation position ........................................................................................................ 3

4. Wiring material ................................................................................................................... 3

5. Accessory for MS99 ...................................................................................................... 3

6. Accessory for type C ................................................................................................... 4

7. About an exchange of type C piping connector. ......................................... 5

8. Pressure of measurement and connection of piping ................................. 5

Ⅳ.SETTING OF PRESSURE

1. Switch contact configuration ................................................................................... 6

2. Setting of upper limit/ lower limit ........................................................................ 6

3. Setting the dial .................................................................................................................. 7

4. Reset time ........................................................................................................................... 7

Ⅴ.ABOUT BUILT-IN SWITCH

1. Material of contact ......................................................................................................... 8

2. About measured gas and contact failure .......................................................... 8

3. Protection of contact of switch ............................................................................. 9

Ⅵ.GENERAL PRECAUTIONS

1. Prohibition of common piping .............................................................................. 10

2. Prevention of clogged piping due to drain .................................................... 10

3. Measurement of high temperature gases ..................................................... 10

4. Errors caused by long distance piping ........................................................... 10

Ⅶ.PERIODIC INSPECTION ............................................................................................ 11

Ⅷ.PRODUCT WARRANTY ............................................................................................. 11

1

INTRODUCTION

Thank you very much for purchasing of "MANOSTAR SWITCH MS99".

△

!

Caution

To ensure your safety in using this instrument :

・Be sure to read the instruction manual carefully before using the instrument so that you

can use it properly.

Wrong use may result in failure of the instrument and lead to its damage and accident. This

manual should be kept in a proper place so that you can refer to it any time you need.

Ⅰ.PRECAUTIONS

△

!Warning

・Do not use the instrument where flammable gas is present.

The instrument is not explosion-proof. Do not use instruments in the circumstance where flammable gas is present. It

may cause explosion.

・Do not use the instrument at the place where corrosive gas is present.

The instrument is not corrosion resistance construction. Measuring corrosive gas may corrode the receiving element

and housing material of the instrument. It is expected that corrosive gas leaked out of the instrument will harm a

person.

・Do not apply the pressure to the instrument more than it can withstand.

The diaphragm and the retainer are broken and cause of injury or accident, etc. disaster if the pressure exceeding

withstanding pressure of the pressure receiving element is applied to the instrument. The case body and the

transparent cover of the instrument are broken and cause of injury or accident, etc. disaster if the pressure exceeding

withstanding pressure of the instrument body is applied to the instrument.

・The instrument is measurable for air and non-corrosive gas only.

The machine is exclusive use of dry air (90%RH or less). Using measuring the water or oil it may be damaged and

causes the accident.

・Avoid using where the instrument is subject to many vibration and impact.

Using the instrument where intensified vibration and impact may be damaged the instrument. It is expected that gas

leaks of the instrument which harms a parson.

・Do not exceed rated surrounding temperature, humidity and altitude in use.

Using the instrument by exceeding rated surrounding temperature and humidity and altitude it may be damaged and

cause the accident.

・Do not disassemble or reconstruct the instrument.

It may void the warranty.

・Do not exceed rated voltage in using

Using the instrument by exceeding rated voltage may cause fire or electric shock.

・Wire correctly.

Incorrect wiring may cause fire.

△

!Caution

・As to where to install and how to install this instrument, be sure to follow the instruction manual provided

so as to ensure a proper method.

・Use the instrument indoors.

・In case of not being installed in dry and well-kept clean locations, the instrument must be enclosed in box.

・Do not use organic solvent for cleaning.

Use a cloth soaked with water-diluted neutral detergent to wipe the surface of a product. Using of organic solvent

causes damage on the surface.

・Dropping the product.

Product is a precision instrument. If you drop the product, there is a possibility that the exterior, also the interior

mechanism damage.

・Removal of the piping

Please do not pull the pipe with a strong force. There is a possibility that the pipe cap is broken.

・MS99 acquires UL-approved as an open type enclosure.

For UL listing application, install MS99 in the system, and configure so that the entire system will be UL-approved.

2

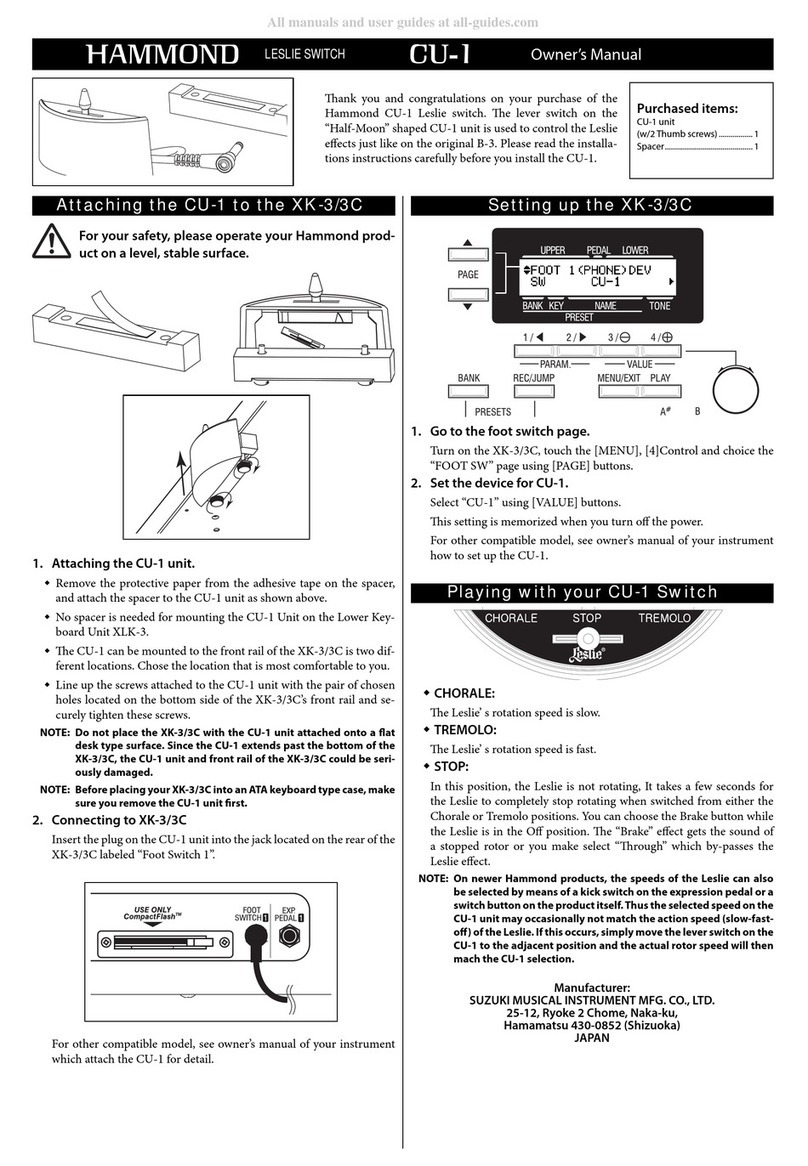

Ⅱ.THE NAME OF EACH PART

・Type V ・Type C

(All except for the piping connector part is

common with type V)

Ⅲ.INSTALLATION

Before using this instrument, make sure if it is the type that you requested and meets the demand of the

environment, pressure and piping conditions where it is used, by specification.

1. Caution of service condition

a) Do not use the instrument in a place subjected to direct sunlight, vibration or shock, or excessive

moisture. In particular, vibration and shock to the instrument should shorten its life.

b) Use under the medium and ambient temperature from - 10 to + 50 ℃.

c) The instrument is not waterproof. Do not use it in a place subjected to rain, or other splashing water.

The product is equivalent to the protection class IP54, when mounted as below.

1)Use the cable clamp which matches the wire diameter of the wiring.

2)Please install it so that a gap doesn't occur between a cover and the body by a screw for cover

installation of an accessory.

※Please refer to the item of p.3 "5. Accessory for MS99" about cable clamp.

d) In installing the instrument, select the place where the ground is smooth and flat.

2. Installation of MS99

Panel cut size

△

!

Caution

・The tightening torque of the screw is 1 N・m.

・Do not apply excessive torque more than

stipulated value, otherwise it will damage the

body of the instrument.

Cover

Installation screw

for cover

Terminal screws

Pointer

Dial

Cable clamp holder

Installation plate

High pressure

side tube tap

Low pressure

side tube tap

(Interchangeable)

(Interchangeable)

High pressure

side piping

connector

Low pressure

side piping connector

2×φ5 or M4

90±0.3

3. Inst

a

M

u

A

f

4. Wiri

n

C

h

s

c

te

w

h

c

a

F

u

b

e

5. Acc

e

Used w

i

Ca

b

n

Use the

protecti

o

※When

C, it

c

inter

v

a

llation posi

t

ust be specif

i

f

ter inspectio

n

n

g material

h

oose the wi

r

c

rew of the

rmination of

h

ich matches

a

n be change

d

u

rther, an att

e

chosen fro

m

e

ssory for

M

In

aluminum,

i

th the install

b

le clamp (prod

u

ylon66,polypr

o

O

O

O

cable clamp be

o

n class IP54.

taking wiring

o

c

an't be install

e

v

ene.

△

!

Caution

U

t

ion

i

ed at time of

n

and adjust

m

r

ing material

d

product is

the crimpin

g

the general

M

d

by changing

achment poi

n

m

2 points.

M

S99

stallation pla

t

copper made

[

ation of the i

n

u

ced by OHM E

L

o

pylene,NBR

Product code

O

A-W15M-0

4

O

A-W15M-0

5

O

A-W15M-0

7

low so as to m

a

o

ut in the conn

e

e

d for a conne

c

se of in a po

s

5

°

Vertic

order.

m

ent in accor

d

d

epending on

M4. Wire

b

g

terminal (

O

M

4 screws.)

T

the directio

n

n

t of the cabl

e

t

e

[

installed ]

Product

c

ADPL99

n

strument bo

L

ECTRIC CO., L

T

made [ option

Suitable

diame

t

4

φ2

~

5

φ3

~

7

φ5

~

a

ke it equivale

n

e

ctor direction

c

tor and cable

c

s

ition other t

h

°

5°

0

°

90°

al plane

Vertica

l

3

d

ance with th

the load. Te

b

y performin

O

.D. less tha

T

he wiring dir

n

of the cove

r

e

clamp recei

p

c

ode

9

-01

dy.

T

D.)

]

wire

t

e

r

~

4

~

5

~

7

n

t to the

by type

c

lamp to

h

an the spec

1.

R

5°

5°

°

Horizo

n

l

Hor

pla

n

e specified in

rminal

g the

n φ8

e

ction

r

.

p

t can

p

o

ified is out o

f

Th

e

(W

h

in

s

R

emove the l

o

locknut is not

install the inst

r

n

tal

izontal

n

e

<Installation

>

s

tallation pos

C

o

o

lycarbonate-

m

f

accuracy w

a

e

wiring directi

o

h

en cable clam

s

talled.)

o

cknut. The

n

ecessary to

r

ument.

On installati

o

position is a

>

s

ition, and sh

i

o

ve

r

m

ade [ installe

d

a

rranty.

on

m

p, which is sol

d

2.The cable

c

by hand. A

t

the cable c

l

and, parts

a

(without a

g

may be da

m

tightening.

o

npanel,follo

w

vailable.

O

-

Cable cl

a

i

pped.

d

]

Product cod

e

TCA-99

d

separately, i

s

lamp screwed

t

t

that time, O-

l

amp is compr

e

a

re in contact

g

ap). Caution,

m

aged if too m

u

w

ing

-

ring

a

mp holder

e

s

t

o it,

ring o

f

e

ssed,

parts

u

ch

6. Accesso

Be sure

Howeve

r

pressur

e

instrum

e

These c

o

connect

e

The join

t

tube or

t

This is

c

(O.D.6

±

You nee

d

connect

o

△

!

Cauti

o

ry for type

C

VT connect

reny

to use I.D.6 a

n

r

, the vinyl or

r

e

(including va

c

e

nt range or th

e

VR connec

t

bra

s

o

nnectors are

r

e

d to vinyl or

r

PT con

n

PBT,

b

t

installed tub

e

t

he applicable

t

M

stainles

s

H

KG

A

c

onnector can

b

±

0.1).

Inner sle

e

polypro

p

d this to conn

e

o

rs for metal t

u

△

o

n

Comme

r

Please

b

C

or for vinyl or

-made [ instal

l

n

d thickness o

f

r

ubber tube wi

t

c

uum pressure)

e

line pressure

t

or for vinyl or

s

s-made [ opti

o

Pro

d

High pressure

KGA81VR-H

r

otary elbow t

y

r

ubber tube of

I

n

ector for plas

t

b

rass-made [ o

Pro

d

High pressure

KGA81PT-H

e

is push-in ty

p

t

ube (JIS B838

M

TW connecto

r

s

steel-made [

Prod

u

H

igh pressure

A

81MTW-H-

S

b

e connected t

e

ve set for pla

p

ylene-made [

e

ct plastic tub

e

u

be. (the follo

w

r

cial products

b

e sure to use

Inner(resin)

Sleeve(r

e

Pla

s

rubber tube

l

ed ]

Product

c

KGA99

V

f

1mm or more.

h enough with

s

is required wh

is higher than

rubber tube

o

n ]

d

uct code

Low pres

KGA81V

y

pe and can be

I

.D. 6.

t

ic tube

ption ]

d

uct code

Low pres

KGA81P

p

e. Use the op

t

1-1).

r

option ]

u

ct code

Low pres

s

S

KGA81MT

W

o stainless tub

e

s

tic tube

option ]

Produc

t

XIN

6

e

(O.D.6, I.D.4

w

ing figure)

(

connectors e

t

a connector

m

e

sin)

s

tic tube

4

c

ode

V

T

s

tanding

h

en the

50 kPa.

sure

V

R-L

sure

P

T-L

t

ional

sure

W

-L-S

e

t

code

6

X4

4

) to the

t

c.) can’

t

be u

s

m

entioned abo

v

This connecto

r

±0.1) made f

r

When this con

I.D.4), remov

e

inner sleeve s

e

(Please use th

e

pipe)

This connecto

r

to the metal t

u

on). Applicabl

e

connector.

The joint inst

a

Applicable pip

i

When using a

r

difference in l

e

(the following

f

s

ed, because t

h

v

e.

MT connector

brass-mad

High

p

KGA

8

r

can be conne

om copper, al

u

n

ector is conn

e

the brass-ma

d

e

t (XIN6×4) th

a

e

type MTW c

o

MR connecto

r

brass-mad

High

p

KGA

8

r

is rotary elbo

u

be (made fro

m

e

piping materi

a

P

R connector

PBT, brass-

m

High

p

KGA

8

lled tube is pu

s

i

ng material is

t

Piping adapto

r

brass-mad

High

p

KGA8

r

evolving conn

e

e

vel so as not t

f

igure)

h

e structure is

Pipin

g

r

for metal tub

e

d

e [ option ]

Product c

o

p

ressure

L

8

1MT-H

K

e

cted to the m

e

u

minum and so

e

cted to plasti

c

d

e sleeve and

u

a

t is sold sepa

r

o

nnector for th

r

for metal tub

e

d

e [ option ]

Product c

o

p

ressure

L

8

1MR-H

K

o

w type and ca

n

m

copper and al

al is the same

a

for plastic tub

m

ade [ option ]

Product c

o

p

ressure

L

8

1PR-H

K

sh-in and rota

r

the same as P

T

r on back vie

w

d

e [ option ]

Product c

o

p

ressure

L

8

1FBA-H K

ector, it's pos

s

t

o interfere ea

c

different.

g

adaptor on bac

k

e

o

de

L

ow pressure

K

GA81MT-L

e

tal tube (O.D.

on.

c

tube (O.D.6,

u

se the resino

u

r

ately

e stainless ste

e

e

o

de

L

ow pressure

K

GA81MR-L

n

be connecte

d

uminum and s

o

a

s MT

e

o

de

L

ow pressure

K

GA81PR-H

r

y elbow type.

T

connector.

w

o

de

L

ow pressure

G

A81FBA-L

s

ible to make

c

h pipe.

k

view

6

u

s

e

l

d

o

7. Abo

u

W

ty

8. Pre

s

a)

b)

c)

△

!

Caut

i

u

t an excha

n

W

hen exchangi

pe C".

The exampl

e

VR co

n

s

sure of me

a

Measureme

n

Connect t

h

The lowe

r

Measureme

n

Connect t

h

opened to

a

Measureme

n

Connect t

h

low pressu

r

△

i

on

・Even

pres

s

・The

p

・Tigh

t

The

p

instr

u

by O

-

met

e

so pl

e

・Tigh

t

Alwa

y

conn

met

a

tight

e

n

ge of type

ng a connect

o

e

on which a

c

n

necto

r

a

surement

a

n

t of positive

h

e tube to th

e

r

pressure po

r

n

t of negative

h

e tube to th

e

a

tmosphere,

b

n

t of differen

t

h

e tube from

t

r

e piping con

n

if this appli

a

s

ure side can

'

p

art of conne

c

t

ening torque

p

lug sealing

b

u

ment, the pi

p

-

rings. The ti

e

r body is da

m

e

ase be care

f

t

ening with lo

c

y

s use lockin

g

ectors (for

m

a

l tube) and

M

e

ning torque

C piping co

n

o

r, remove a

c

c

onnector wa

MT con

n

a

nd connect

i

pressure

e

high pressu

r

r

t (L) should

o

pressure

e

low pressur

e

b

ut do not re

m

t

ial pressure

t

he high pres

s

n

ector to the

a

nce replace

s

'

t be change

d

c

tor piping is

b

etween the

p

p

ing connect

o

ghtening tor

q

m

aged for fas

t

f

ul.

c

king spanne

r

g

spanner to

etal tube), M

M

TW connect

o

d

irectly to th

5

n

nector.

c

ap, and plea

s

a

s loaded

n

ecto

r

ion of pipin

g

r

e side piping

opened to at

m

e

side piping

c

move the pip

i

s

ure piping c

o

low pressure

s

a connecto

r

d

.

marking“ H”

o

p

iping connec

o

r, and the s

e

q

ue of the co

n

t

ening beyon

d

r

tighten the r

i

R connector

s

o

rs. Be caref

u

e instrument

s

e install a ca

MTW conn

e

g

connector (

H

m

osphere, bu

t

c

onnector (L

)

i

ng connecto

r

o

nnector to t

h

port (L).

r

, the polarit

y

o

n high pres

s

t

or port of t

h

e

aling plug is

a

n

nector is 1

N

d

the stipulat

e

i

ng joints for

s

(rotating ty

p

u

l not to appl

y

body.

p

of mentioni

n

e

ctor

H

).

t

do not rem

o

)

. The high p

r

r

.

h

e high press

u

y

in a high p

r

ure side and

“

e

a

chieved

m. The

e

d value,

MT

p

e for

y

the

n

g in p.4 "6.

A

PT connect

o

o

ve the pipin

g

r

essure port

(

u

re port (H)

a

r

essure side

a

“

L” on low pr

Locking spanner

A

ccessary fo

r

or

g

connector.

(

H) should be

a

nd from the

a

nd the low

essure side.

Cap nut

Spanner for

tightening

r

6

Ⅳ.SETTING OF PRESSURE

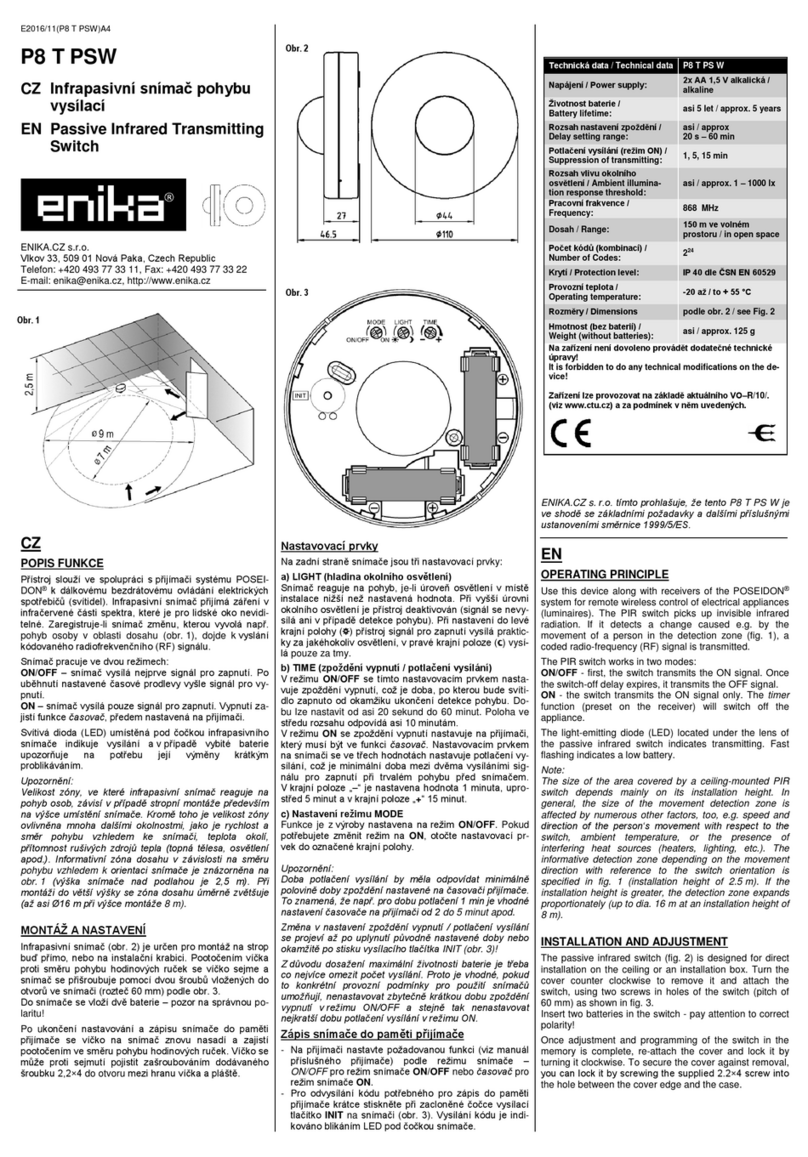

1. Switch contact configuration

・Composition of contact of this instrument is as shown on the right.

・If the instrument is not applied by differential pressure we call such “normal condition”.

・At normal condition, the contact between 1(COM.) and 2(N.C.)

is closed, and between 1(COM.) and 3(N.O.) is open.

・With increase of differential pressure and reaching the

actuation pressure, the contact will be changed over ;

between 1(COM.) and 2(N.C.) is opened and between

1(COM.) and 3(N.O.) is closed.

2. Setting of upper limit/ lower limit

・When differential pressure applied to the instrument is

increased starting from zero and changes over the electric

contact from N.C. (normal close) to N.O. (normal open), the

pressure at this moment is called “actuation pressure”.

・When this differential pressure decreases from the pressure

higher than this actuation pressure activating electrical

contact and returning the contact from N.O. (normal open) to

N.C. (normal close), the pressure at this moment is called

“reset pressure”.

・There is certain difference between actuation pressure and reset pressure and this is called “dead band”.

・There are two types of the instrument. One is called “upper limit setting type”type (H) whose scale of

setting knob is adjusted on actuation pressure, the other is called “lower limit setting type”type (L)

which is adjusted on reset pressure.

・Depending on the purpose of use, choose the instrument either “upper limit setting type”or “lower limit setting type”

Please confirm the following table about the respective movement.

In case of 1-10 kPa range with set value 1 kPa. (dead band is 0.7 kPa)

Setting of scale Adjusting of scale Movement of contact

Upper limit

setting type Adjusted in activating pressure

When the differential pressure increases, the circuit is

closed between N.O. and COM. at 1 kPa.

Then as the differential pressure decreases, the circuit is

opened between N.O. and COM. at 0.3 kPa.

Lower limit

setting type Adjusted in reset pressure

When the differential pressure increases, the circuit is

closed between N.O. and COM. at 1.6 kPa.

Then as the differential pressure decreases, the circuit is

opened between N.O. and COM. at 1 kPa.

△

!

Caution

It can't be changed from the lower limit setting to the upper limit setting or vice versa.

Differential

pressure

Actuation pressure

Reset pressure

Dead band

Time

2(N.C.)

1(COM.) 3(N.O.)

Increase of

differential

pressure

7

3.Setting the dial

Use the dial and pointer, when you set the “Activating pressure” or “Reset pressure”.

Set the "Activating pressure" for the upper limit setting.

Set the "Reset pressure" for the lower limit setting.

Set the tip of the pointer to the pressure you desire by knobbing the outer periphery of the dial to rotate the

dial. Turning the pointer from the lower side (anti-clockwise) is recommended to set accurately with good

reproducibility. Turning the pointer from the lower side (anti-clockwise) is recommended to set accurately

with good reproducibility.

4. Reset time

The reset time means the time needed for the differential pressure to decline to the reset pressure from the

activating pressure (i.e., the electrical contact is reset) when the differential pressure is sharply reduced to

zero. It is about three seconds at 20 Pa, and one second at more than 50 Pa for Manostar switches. (This

value is only for the instrument itself and does not include the effect of piping.) Therefore, a response

quicker than this value is not possible.

△

!

Caution

Do not turn the dial too much exceeding the upper bound or the lower bound of the scale.

It causes performance deterioration and the failure.

Pointer[fixed]

Dial(color:white)[movable]

Dial cover(color:black)[fixed]

200

180

160

140

120

100

80

60

40

20

8

Ⅴ.ABOUT BUILT-IN SWITCH

1. Material of contact

The product has been plated a gold layer on the point of contact to get the contact reliability of the point on

the low electrical load.

The gold film is damaged when using by general use.

△

!

Caution

Once the product has been used for general load, it cannot be used for low electrical load.

2. About measured gas and contact failure

a) Corrosive gas

If the gas to be measured contains corrosive gases (nitric acid, hydrogen sulfide, sulfurous acid,

ammonia, chlorine, and so on), they may cause electrical contact failure or corrosion of internal

mechanism, which leads to malfunction of the switch. Do not use the switch for the gases containing

high humid air because in such gases, the arc generated by opening/ closing the contact produces nitric

acid, and it may also cause electrical contact failure or malfunction of switches.

b) Silicone gas

If the gas to be measured contains silicon produced from silicon (contained in oil, grease, filling agent,

and so on), the gas produced by arc, generates by opening/ closing the contact, accumulates on the

contact surface and causes contact failure. Take corrective measures such as the removal of the gas

source or arc suppression.

c) Dust and organic gas

The film can be made to the switch part by the composition of the gas. In addition, the dust contained in

the gas to be measured can adhere to the contact surface and be changed into carbide caused the

contact failure by the arc generated when the contact is opened or closed. Therefore, pay attention to

the measurement environment as well.

(Even with gold alloy contact, be careful about the dust.)

△

!

Caution

As the opening/ closing frequency of the contact increases, wear dust from the

contact increases. This wear dust accumulates between the contacts to increase the

contact resistance and causes the malfunction in the load circuit.

In particular, the surrounding where there exists continuous vibration and impact will be

most likely to cause contact failure due to worn powder.

9

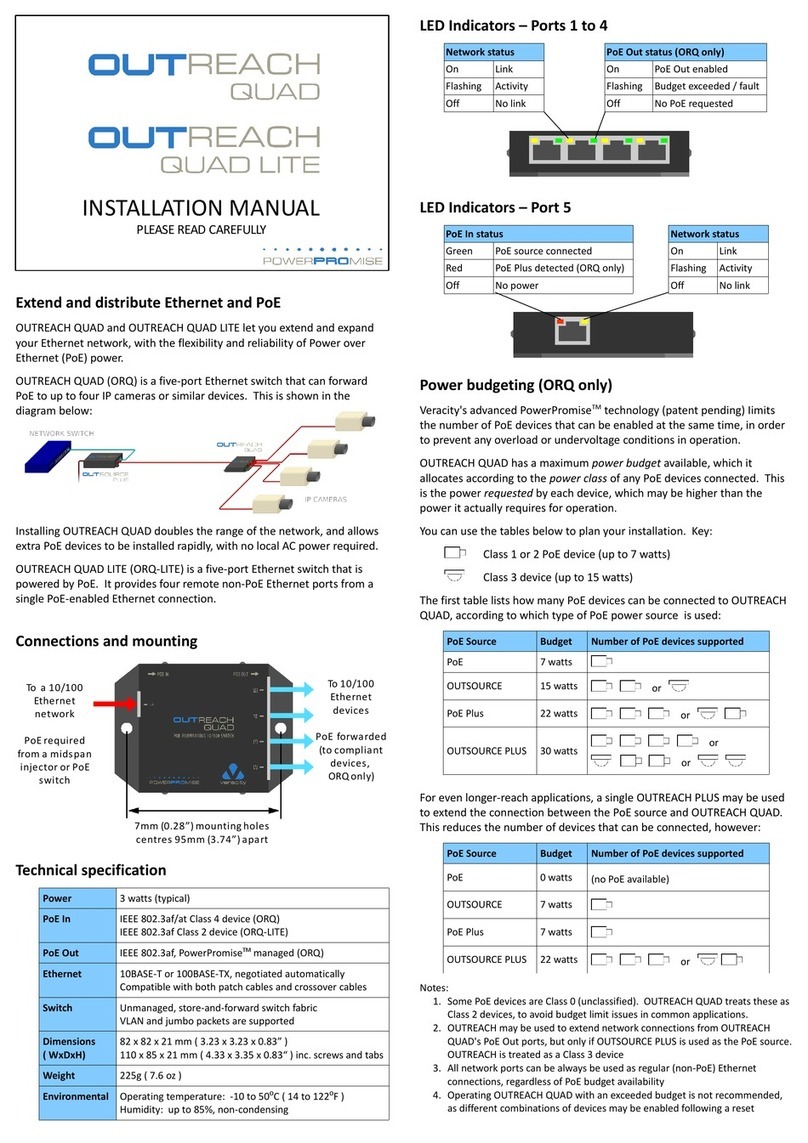

3. Protection of contact of switch

・Contact protection circuit is used to extend the service life of contact. It reduces generation of noise at

the time of switching on and off. It also minimizes carbide and nitric acid gas generated by arc. Use this

circuit correctly, otherwise it will cause reverse effect, making the matter worse.

・In case of using contact protection circuit, pay attention the operating time is possibility of delaying a little.

The following are typical examples of contact protection circuit.

a) Typical example of protective circuit

Example of circuit Special remarks for application and selection

Varistor

method

This method is intended not to apply voltage beyond limit of

varistor to in between contacts. It delays a little time to

return inductive load such as relay.

Select the most conformed rated model in terms of power

supply voltage and load capacity in selected article by

varistor maker.

C・R

method

It delays a little time to activate or return inductive load

such as relay.

As for CR value, to contact current and contact voltage, the

estimate value is C : 0.5 μ F / A, R : 1.0 Ω / V.

However, it differs according to the characteristics of load,

therefore, be sure to confirm to select by experiment.

Diode

method

This method is intended to consume counter electromotive

force of inductive load by diode and avoid to apply high

voltage to in between the contacts.

This method makes the return time of inductive load

slower. Choose the diode rated current is more than load

current and counter withstand voltage more than 10 times

of power supply voltage.

Diode+

Zener diode

method

Diode method proves to be effective when the return time

takes too long for inductive load such as relay. When you

choose zener voltage of zener diode, choose base on power

supply voltage. Be careful with limitations having this

method. Because load is too big, larger capacity zener

diode is needed for reverse surge power.

P.S. : Power supply, I.L. : Inductive load

b) Example of wrong protection circuit

Condenser method

This is very effective to remove arc at the time of

off-contact, but this is likely to run charged current to

condenser leading to contact sticking and short service life

at the time on-contact.

This is very effective to remove arc at the time of

off-contact, but this is likely to run short circuit current

accumulated in the condenser leading to contact sticking

on contacting.

This is likely to short service life at the time on-contact.

P.S. : Power supply, I.L. : Inductive load

If the load is larger than the specified contact capacity, use a secondary relay. In general, the load voltage and

the current is too less to the life of contact is longer. However, this does not expect for a low electrical load.

Manostar switches cannot directly shut off the circuit of 250 V AC or more.

U

I.L.

P.S.

R

C

I.L.

P.S.

I.L.

P.S.

I.L.

P.S.

CP.S. I.L.

CI.L.

P.S.

10

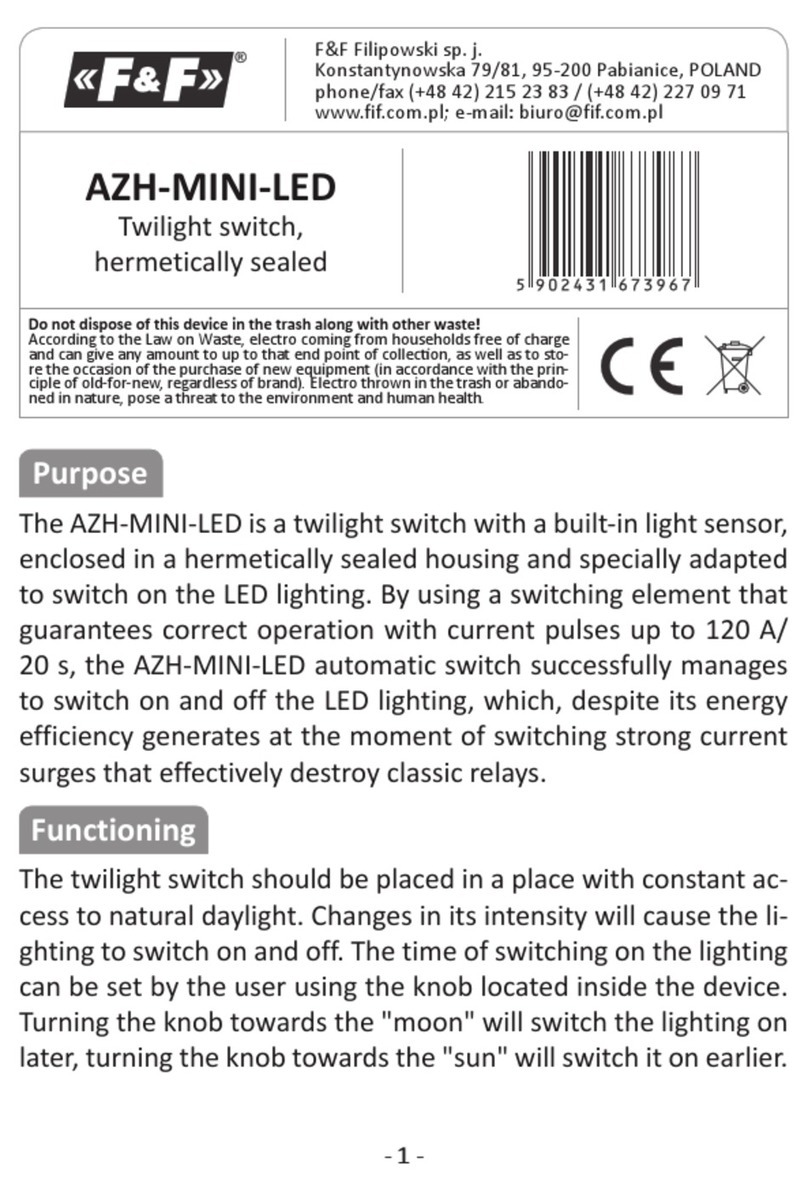

Ⅵ.GENERAL PRECAUTIONS

1. Prohibition of common piping

Piping each of pressure detectors and pressure receiving

instruments tube exclusively dedicated for it, and do not

connect the piping commonly with the adjacent system as

shown in the right figure.

Common piping causes measurement error because the

pressure of each system interferes.

2. Prevention of clogged piping due to drain

If drain remains within the line, it causes measurement error. Be

sure to install the pressure receiving instrument above the

pressure outlet port of the pressure detector and arrange the line

so that the drain water should not remain in the slack piping.

If the arrangement mentioned above in not possible, install a drain

tank within the line as shown in the right figure and clean it once in

a while. After the cleaning of the tank, check that the air tightness

is fully kept.

3. Measurement of high temperature gases

In the pressure measurement of high temperature gas, use the

pressure detector (pitot tube) made of the heat-proof metal (such

as stainless steel), and connect it with the pressure receiving

instrument through a metal tube which is long enough to cool down

the high temperature gas.

4.Errors caused by long distance piping

The speed of response is delayed when the product is used for

remote monitoring.

In such application, the I.D. of the connection tube should be as large as

possible.

The time constant is almost inversely proportional to the inner cross

sectional area of the piping. (refer to the diagram below)

If the piping conditions of the high and low pressure side are significantly

different, the difference in the piping resistance between high and low

pressure side causes the difference in pressure transmission time, and

the measurement becomes inaccurate.

Piping length

Instrument

body

Installation diagram of drain tank

Switch

Drain

Drain

tank

MS99 MS99 MS99

MS99

Independent piping○

Passageway

Passageway

Room BRoom A Room BRoom A

Common piping×

11

Ⅶ.PERIODIC INSPECTION

Generally speaking, it is important not to exert external stress to keep life and reliability of the instrument for a

long time.

Proper use of this instrument will ensure its faultless service over many years without any necessity of periodic

lubrication.

However, it is recommended that it is subjected to periodic inspection (calibration) once a year.

Ⅷ.PRODUCT WARRANTY

Warranty Period

This product warranty is valid for one year from the date of delivery to a place specified by an ordering party who

has transacted directly with Yamamoto Electric Works Co., Ltd.

Coverage

If a product breaks down due to a reason for which we are responsible during the warranty period and you return

the product to us, we will either repair or replace the product free of charge.

This warranty does not cover:

(1) Usage of the product under any inappropriate conditions or environment contrary to what is described in our

product catalog, specifications or manual.

Handling or usage of the product other than as described in our product catalog, specifications or manual.

(2) Breakdown due to a reason other than a fault within our product.

(3) Any product that has been modified or repaired by a party other than us.

(4) Any breakdown due to a reason that was not foreseeable based on scientific and technical standards applied at

the time of shipment.

(5) Any breakdown due to a reason not attributable to us such as a natural calamity or other disaster.

These terms of warranty represent our entire liability with respect to the product, and we shall have no liability

for any other loss arising in connection with a breakdown of the product.

*This product warranty is only valid within Japan.

This document is a translation from the original Japanese version, and the original Japanese version has priority

over this translation.

Be sure to refer to the original Japanese for the details of this warranty.

<Prior notice>

The specifications and description of the product explained in this instruction manual may be subject to change

without prior notice because of modification and the like.

Table of contents

Other Manostar Switch manuals