Mantall XE65N User manual

CE

Operator’s Manual

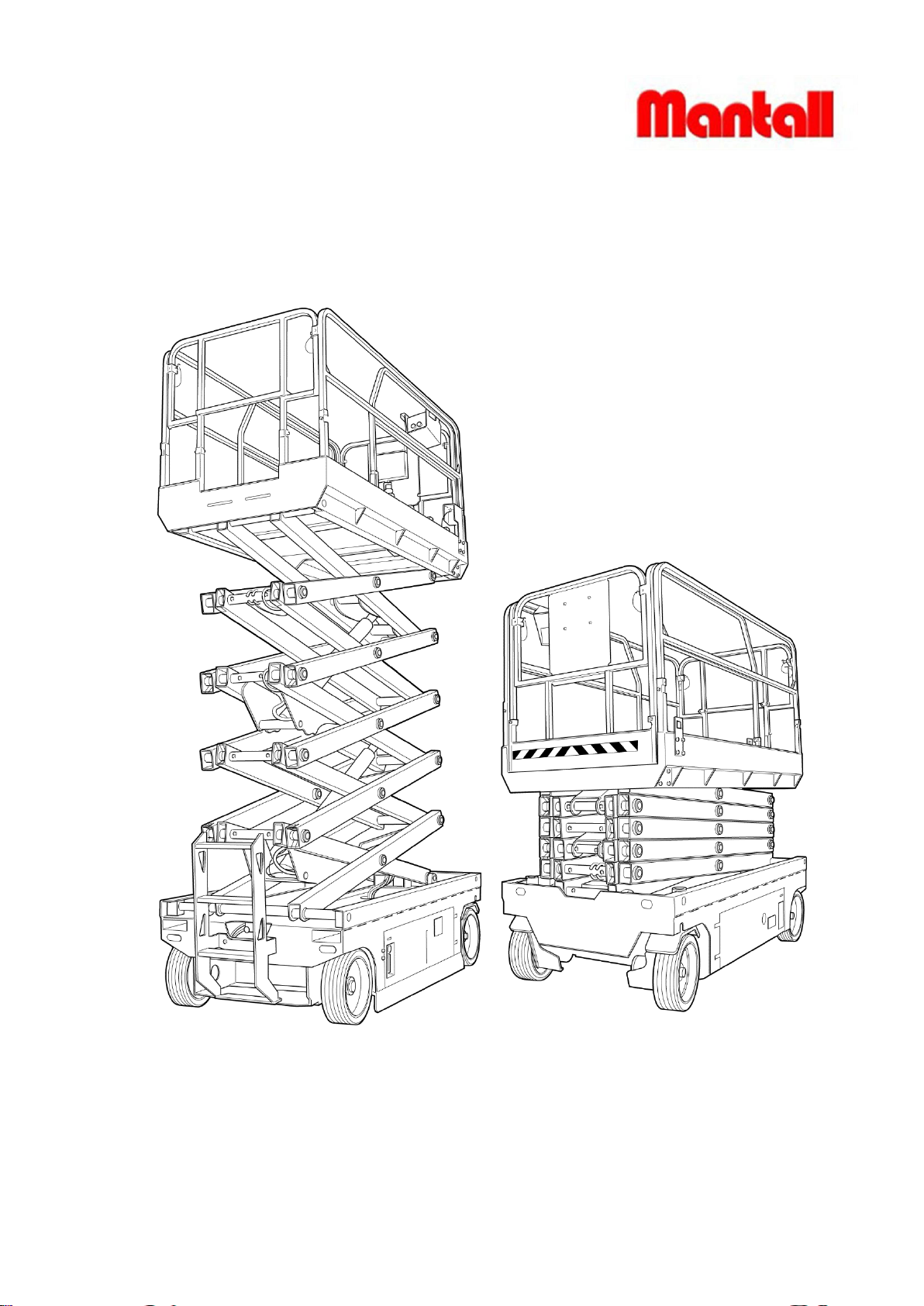

Self-Propelled Scissor Lift

XE65N / XE80N / XE80C / XE80W / XE100C / XE100W

XE120W / XE140W / XE160W

Original Instructions

Second Edition

Copyright © Mantall 2016

Operator’s Manual

Self-Propelled Scissor Lift

Version1

2

1 Contents

2Introduction ....................................................................................................................................4

2.1 Hazard Classification .................................................................................................................4

2.2 Intended Use..............................................................................................................................4

2.3 Declaration of Conformity ..........................................................................................................5

2.4 Safety Sign Maintenance...........................................................................................................6

3Safety...............................................................................................................................................6

3.1 Personal Safety..........................................................................................................................6

3.1.1 Personal Fall Protection.......................................................................................................6

3.2 Work Area Safety.......................................................................................................................6

3.2.1 Electrocution Hazards..........................................................................................................6

3.2.2 Tip-Over Hazards.................................................................................................................7

3.2.3 Operation on Slopes Hazards..............................................................................................8

3.2.4 Fall Hazards.........................................................................................................................9

3.2.5 Collision Hazards.................................................................................................................9

3.2.6 Bodily Injury Hazards.........................................................................................................10

3.2.7 Component Damage Hazards...........................................................................................10

3.2.8 Explosion and Fire Hazards...............................................................................................10

3.2.9 Damaged Machine Hazards..............................................................................................11

3.2.10 Crushing Hazards..............................................................................................................11

3.3 Battery Safety...........................................................................................................................11

3.3.1 Burn Hazards.....................................................................................................................11

3.3.2 Explosion Hazards.............................................................................................................12

3.3.3 Component Damage Hazards...........................................................................................12

3.3.4 Electrocution Hazards........................................................................................................12

3.3.5 Tip-Over Hazards...............................................................................................................12

3.3.6 Lifting Hazards...................................................................................................................12

4Machine Identification .................................................................................................................13

5Controls.........................................................................................................................................14

5.1 Ground Control Panel..............................................................................................................14

5.1.1 Identification.......................................................................................................................14

5.1.2 Functionalities....................................................................................................................15

5.2 Type A Platform Controller......................................................................................................16

5.2.1 Identification.......................................................................................................................16

5.2.2 Functionalities....................................................................................................................17

5.3 Type B Platform Controller.......................................................................................................18

5.3.1 Identification.......................................................................................................................18

5.3.2 Functionalities....................................................................................................................19

6Inspections ...................................................................................................................................20

6.1 Pre-Operation Inspection.........................................................................................................20

6.1.1 Fundamentals....................................................................................................................20

6.1.2 Inspection...........................................................................................................................20

6.2 Function Tests..........................................................................................................................22

6.2.1 Fundamentals....................................................................................................................22

6.2.2 Tests ..................................................................................................................................22

6.3 Work Place Inspection.............................................................................................................28

6.3.1 Fundamentals ....................................................................................................................28

Operator’s Manual

Self-Propelled Scissor Lift

Version 1

3

6.3.2 Inspection ..........................................................................................................................28

7Operating Instructions ................................................................................................................29

7.1 Fundamentals..........................................................................................................................29

7.2 Emergency Stop......................................................................................................................29

7.3 Emergency Lowering...............................................................................................................29

7.4 Operation From the Ground ....................................................................................................30

7.5 Operation From the Platform...................................................................................................30

7.6 Extend and Retract the Platform .............................................................................................32

7.7 Operation From Ground with Platform Controller....................................................................33

7.8 After Each Use.........................................................................................................................33

7.9 Fold Down of the Platform Guard Rails...................................................................................33

7.10 Battery and Charger Instructions .....................................................................................34

7.10.1 To Charge Battery .............................................................................................................34

7.10.2 Dry Battery Filling and Charging Instructions....................................................................34

8Error Codes (Only for Type B Platform Controller)..................................................................35

9Lifting Instructions ......................................................................................................................36

9.1 Lifting with Forklift....................................................................................................................36

9.2 Lifting with Crane.....................................................................................................................36

10 Transport Instructions.................................................................................................................37

10.1 Towing the Machine (Only for Hydraulically Driven Machines) .......................................37

10.2 Securing the Machine to a Transport Vehicle..................................................................38

11 Maintenance .................................................................................................................................38

11.1 Check the Hydraulic Oil Level..........................................................................................38

11.2 Add Hydraulic Oil..............................................................................................................38

11.3 Check the Batteries..........................................................................................................39

11.4 Lubrication Locations .......................................................................................................39

12 Specifications...............................................................................................................................40

12.1 Narrow / Compact Models................................................................................................40

12.2 Wide Models.....................................................................................................................41

Operator’s Manual

Self-Propelled Scissor Lift

Version1

4

Important

Read, understand and obey these safety rules and operating instructions before operating this

machine. Only trained and authorized personnel shall be permitted to operate this machine. This

Operator’s Manual should be considered a permanent part of your machine and should remain with

the machine at all times.

2 Introduction

DANGER

Failure to obey the instructions and safety rules in this Operator’s Manual will result

in serious injury or death.

Do Not Operate Unless:

•You learn and practice the principles of safe machine operation contained in this

Operator’s Manual.

1. Avoid hazardous situations.

Know and understand the safety rules before going on to the next section.

2. Always perform a pre-operation inspection.

3. Always perform function tests prior to use.

4. Inspect the workplace.

5. Only use the machine as it was intended.

•You read, understand and obey the manufacturer’s instructions and safety rules,

Operator’s Manual and machine decals.

•You read, understand and obey employer’s safety rules and worksite regulations.

•You read, understand and obey all applicable governmental regulations.

•You are properly trained to safely operate the machine.

2.1 Hazard Classification

DANGER

Indicates a hazardous situation which, if not avoided, will result in serious injury or death.

WARNING

Indicates a hazardous situation which, if not avoided, could result in serious injury or

death.

CAUTION

Indicates a hazardous situation which, if not avoided, could result in minor or moderate

injury.

2.2 Intended Use

This machine is intended to be used only to lift personnel, along with their tools and materials to an

aerial work site.

Operator’s Manual

Self-Propelled Scissor Lift

Version 1

5

2.3 Declaration of Conformity

2.4 Safety Sign Maintenance

Replace any missing or damaged safety signs. Keep operator safety in mind at all times. Use mild

soap and water to clean safety signs. Do not use solvent-based cleaners because they may damage

the safety sign material.

This manual suits for next models

8

Table of contents