Maple Armor FW562-A User manual

DOC-FW562-UM-R1.0

INSTALLATION MANUAL

© 2021. MAPLE ARMOR FIRE ALARM DEVICE CO., LTD.

8866, boulevard du Quartier, Brossard, Quebec, Canada, J4Y 0R2

All rights reserved. www.maplearmor.com

Page 1of 5

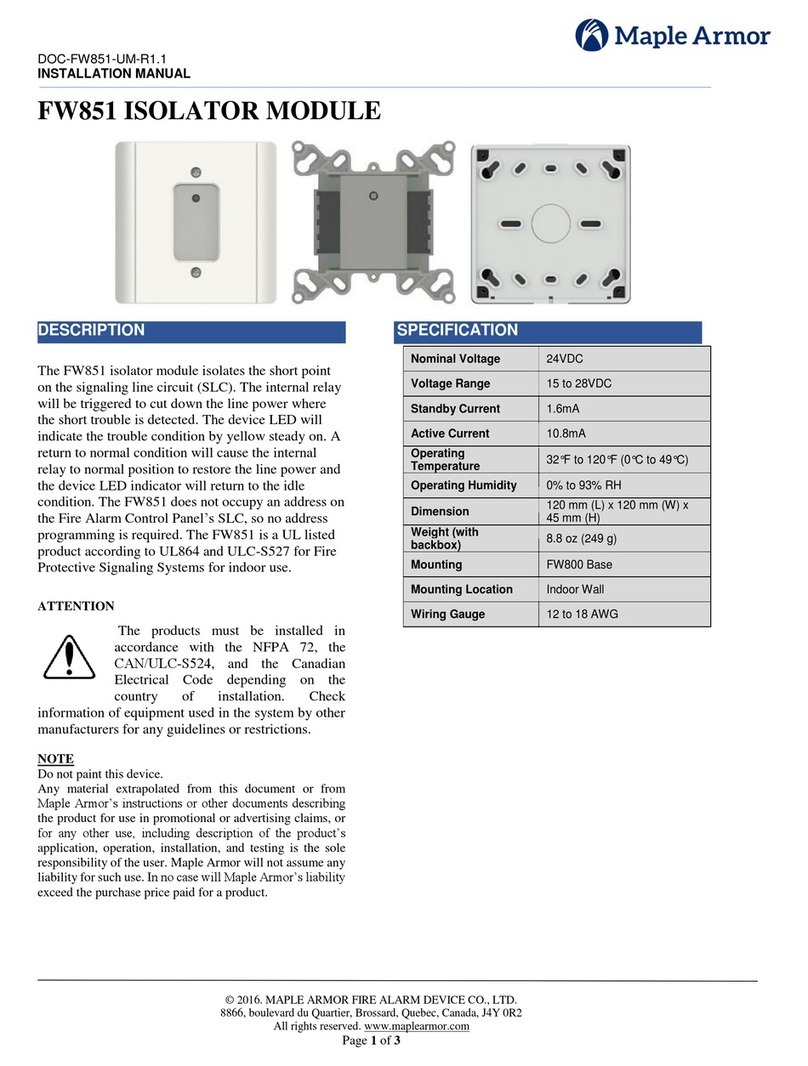

FW562-A/B/C, FW562C-A/B/C TWO-WIRE DUCT DETECTOR

DESCRIPTION

The FW562-A/B/C and FW562C-A/B/C models are

ventilation duct detectors smart designed FOR USE

WITH MODEL FW511A DETECTOR HEADS. FW562-

A/B/C are UL-listed devices according to UL 268A,

and FW562C-A/B/C are ULC listed according to ULC-

S529 for fire protection systems. Equipped with a

photoelectric smoke detector, the units will signal

the presence of a dangerous amount of combustion

product in the ventilation system. They are

compatible with Maple Armor’s control panel model

FW106, FW106C, FW106S, FW106SC.

Note: These detectors are not designed to be used in

open areas.

ATTENTION

The products must be installed in accordance with

NFPA 72, CAN/ULC-S524, and/or Canadian

Electrical Code depending on the country of

installation. Check information of equipment

used in the system by other manufacturers for any

guidelines or restrictions.

The detector should never be installed in the following

locations: areas with excessive exhaust fumes, kitchen

areas, near fireplaces, furnace rooms, etc. Smoke

detectors are not to be used with detector guards

unless the combination has been evaluated and found

suitable for that purpose.

NOTE

Do not paint this device.

Any material extrapolated from this document or from

Maple Armor’s instructions or other documents

describing the product for use in promotional or

advertising claims, or for any other use, including a

description of the product’s application, operation,

installation, and testing is the sole responsibility of the

user. Maple Armor will not assume any liability for such

use. In no case will Maple Armor’s liability exceed the

purchase price paid for a product.

SPECIFICATION

Nominal Voltage

24V dc

SLC Voltage Range

17.6 to 28V dc

Standby Current

0.35 mA

Alarm Current

2 mA

Operating

Temperature

32°F to 100°F (0°C to 38°C)

Operating Humidity

0% to 93% RH

Dimension

329(W) x 114(H) x 51(D) mm

(13 1/8 x 4 x 2) in.

Weight (with base)

4.6 oz (132 g)

Mounting location

Side and top

SPECIFICATIONS

Duct Detector models

a. Applicable to ULC listing required area

Model

Air Velocity

Contents

FW562C-A

2000 to 4000 FPM

(ft/min)

10.2 to 20.3 (m/s)

⚫Duct detector assembly

⚫One exhaust tube

⚫One detector headcover

⚫One φ5 * 2 hole sampling

tube (order separately)

FW562C-B

700 to 2000 FPM

(ft/min)

3.6 to 10.2 (m/s)

⚫Duct detector assembly

⚫One exhaust tube

⚫One detector headcover

⚫One φ5 * 4 hole sampling

tube (order separately)

FW562C-C

300 to 700 FPM

(ft/min)

1.5 to 3.6 (m/s)

⚫Duct detector assembly

⚫One exhaust tube

⚫One φ5 * 4 hole sampling

tube (order separately)

b. Applicable to UL listing required area

Model

Air Velocity

Contents

FW562-A

2000 to 4000 ft/min

10.2 to 20.3 (m/s)

⚫Duct detector assembly

⚫One exhaust tube

⚫One detector headcover

⚫One φ5 * 4 hole sampling

tube (order separately)

FW562-B

1000 to 2000 ft/min

5.1 to 10.2 (m/s)

⚫Duct detector assembly

⚫One exhaust tube

⚫One φ5 * 4 hole sampling

tube (order separately)

FW562-C

300 to 1000 ft/min

1.5 to 5.2 (m/s)

⚫Duct detector assembly

⚫One exhaust tube

⚫One detector head baffle

⚫One φ5 * 2 hole sampling

tube (order separately)

DOC-FW562-UM-R1.0

INSTALLATION MANUAL

© 2021. MAPLE ARMOR FIRE ALARM DEVICE CO., LTD.

8866, boulevard du Quartier, Brossard, Quebec, Canada, J4Y 0R2

All rights reserved. www.maplearmor.com

Page 2of 5

Sampling tubes selection

Note: To fit different duct widths, 12, 18, 24, 36, 42

inches length sampling tubes are optional. If you

need a longer length, you can combine shorter

ones with the tube connector.

Model

Description

FW561-ST-12

12 inch’s Air Sampling Inlet Tube

FW561-ST-18

18 inch’s Air Sampling Inlet Tube

FW561-ST-24

24 inch’s Air Sampling Inlet Tube

FW561-ST-36

36 inch’s Air Sampling Inlet Tube

FW561-ST-42

42 inch’s Air Sampling Inlet Tube

Pre-Installation

IMPORTANT: Technicians will have to be

certified by Maple Armor on the installation of

the Maple Armor duct detector before they

can verify & certify them.

Step 1

We recommend that the duct detector assembly be

installed 6 duct widths from any bends or inlets. This

is to maximize the sensor efficacy. There will be less

air turbulence and if smoke is present, the air and

smoke will be better mixed. See Figure 1

Figure 1

Step 2

The duct detector assembly must be installed on the

supply side of the air handling unit.

Step 3

Located assembly upstream of air humidifiers and

cooling coils.

Step 4

A duct detector can be mounted on a round duct

detector, as long as the diameter is 12 inches or

more.

Step 5

If possible try to install the duct detector in an

accessible location.

Step 6

If the duct detector is hidden in a ceiling, you will

need to install a remote indicating light in the ceiling

under the detector to show the location.

Step 7

It can be installed horizontally on a duct as

narrow as 6 inches and vertically on a duct as

wide as 16 inches.

Step 8

For more help on model FW562C you can consult

CAN/ULC-S524-06 section 5.8 & Figure 24 & 25;

for model FW562 you can consult NFPA 90A.

To install the duct detector:

1. Tape the template to the duct housing and drill

(or punch) the mounting holes at the desired

mounting location as indicated in Figure 2.

Figure 2 Mounting Hole Illustration

2. Slide the sampling tube into the duct detector

housing assembly. Note: The sampling tube

must be installed with the air inlet holes facing

the airflow, check duct housing surface for any

indication of airflow, or ask the HVAC installer.

3. Mount the duct smoke detector on the HVAC

duct and secure it using four sheet metal screws

provided.

If using 2 lengths of air sampling tube, drill a

1/2-inch hole on the opposite side of the duct

for the tube to pass through and cut the tube so

that approximately one inch of the tube extends

through the duct. Plug the third and fourth

holes using the rubber stopper provided, for

models FW562C-A and FW562-C.

Figure 3 sampling tube installation

The sampling tubes should be supported at both

ends of the duct as shown in figure 4.

DOC-FW562-UM-R1.0

INSTALLATION MANUAL

© 2021. MAPLE ARMOR FIRE ALARM DEVICE CO., LTD.

8866, boulevard du Quartier, Brossard, Quebec, Canada, J4Y 0R2

All rights reserved. www.maplearmor.com

Page 3of 5

Figure 4 Duct Detector Installation

4. Remove any rough edges from the holes.

5. Seal the opening around the tube with an

approved duct sealant.

6. Verify that all field wiring is free of opens, shorts,

and ground faults.

7. Make all wiring connections as shown in Figure

5.

L1 L2 (N/A) KEY

IN KEY

TEST LED- LED+

(N/A)(N/A)(N/A)(N/A)(N/A)(N/A)(N/A)

Figure 5 Wiring Diagram

8. Set the internal smoke detector address via the

handheld programmer FW412 or via panel

FW106. Refer to individual manuals for details.

Note: The duct FW562-A/B/C/ or FW562C-A/B/C

share the same address with the smoke

detector model FW511.

9. You must perform an air differential pressure

test by using an Air Velocity Meter ex: Dwyer

model 460 or Reed R3001 or equivalent. Wright

down the air pressure differential value, next

you must select the appropriate model that falls

in the specified operating range.

10. Duct detector assembly contains all 3 models in

a kit, the technician must set up the duct

detector per 1 of 3 figures. See below for proper

operation and certification.

11. The FW562-A/B/C can be configured in 3 ways.

For model, FW562-A see figure 6, for model

FW562-B see figure 7 and for model FW562-C

see figure 8; the FW562C-A/B/C can be

configured 3 ways also, for model FW562C-A see

figure 9, for model FW562C-B see figure 10 and

for the model, FW562C-C see figure 11.

Figure 6

Figure 7

DOC-FW562-UM-R1.0

INSTALLATION MANUAL

© 2021. MAPLE ARMOR FIRE ALARM DEVICE CO., LTD.

8866, boulevard du Quartier, Brossard, Quebec, Canada, J4Y 0R2

All rights reserved. www.maplearmor.com

Page 4of 5

Figure 8

Figure 9

Figure 10

Figure 11

When the part number is determined, use the

blank sticker to cover the additional part

numbers shown on the label. See Figure 12.

DOC-FW562-UM-R1.0

INSTALLATION MANUAL

© 2021. MAPLE ARMOR FIRE ALARM DEVICE CO., LTD.

8866, boulevard du Quartier, Brossard, Quebec, Canada, J4Y 0R2

All rights reserved. www.maplearmor.com

Page 5of 5

Figure 12 Label check

12. To verify the air pressure differential

To verify air pressure differential, air must be moving

through the HVAC system.

Connect a suitable air pressure differential

meter model Reed R3001 or equivalent to the

sampling tube and exhaust tube openings as shown

in Figure 13.

Figure 13 Air Pressure measure

13. Verify that the air pressure differential

measured falls within the specified

operating range of the detector.

Model

Air pressure

FW562C-A

0.36 to 1.53 iwg (inches of water)

90 to 380 Pa (Pascals)

FW562C-B

0.04 to 0.4 iwg (inches of water)

9 to 100 Pa (Pascals)

FW562C-C

0.004 to 0.06 iwg (inches of water)

1 to 15 Pa (Pascals)

FW562-A

0.32 to 1.41 iwg (inches of water)

80 to 350 Pa (Pascals)

FW562-B

0.1 to 0.4 iwg (inches of water)

25 to 100 Pa (Pascals)

FW562-C

0.004 to 0.14 iwg (inches of water)

1 to 35 Pa (Pascals)

14. If the air pressure differential measured

does not fall within the specified operating

range of the detector, make sure the

sampling tube air holes are not obstructed

and are facing the HVAC system airflow.

15. After completing the installation of the duct

smoke detector, test the detector to ensure it is

operating correctly.

Main function

Models FW562-A/B/C and FW562C-A/B/C Duct

Smoke Detectors utilize photoelectric smoke

detectors for the detection of smoke. When

sufficient smoke is sensed, an alarm signal is

initiated.

Test function

⚫Alarm simulation: Pressing the TEST SW can

simulate an alarm condition.

⚫Cover tightness monitor: When the JUMPER

switch is on the NORMAL side, a trouble event

will be annunciated when the cover is not

secured properly. When the JUMPER switch is

on the TEST side, this feature will be bypassed.

Note the TEST mode should only be used in

installation and field testing.

To clean the duct smoke detector

1. Disable the detector/zone to prevent false

alarms.

2. Remove the detector’s cover then power down

the detector by disconnecting the SLC wiring.

3. Using a vacuum cleaner, or clean compressed air,

with a soft bristle brush, remove loose dirt and

debris from inside the detector housing and

cover.

4. Remove dirt and other contaminants from the

gasket on the detector’s cover using isopropyl

alcohol and a lint-free cloth.

5. Squeeze the retainer clips on both sides of the

optic housing then lift the housing away from

the printed circuit board.

6. Gently remove dirt and debris from around the

optic plate and inside the optic housing.

7. Replace the optic housing and detector cover,

and then connect the SLC wiring.

Return the product for reparation if it fails to flash or

alarm during testing. Do not disassemble the

product without permission.

This manual suits for next models

5

Table of contents

Other Maple Armor Security Sensor manuals

Popular Security Sensor manuals by other brands

United Technologies

United Technologies Interlogix RF430I4 Installation sheet

SKF

SKF TKED 1 Instructions for use

Optex

Optex SL-100 TNR installation instructions

AGCO

AGCO HayBoss 700A installation manual

Det-Tronics

Det-Tronics Eagle Quantum EQ2200UVHT installation guide

CoCo

CoCo APIR-2150 Quick installation guide