Maquet Servo ventilator 900 C User manual

Service Manual

SERVO VENTILATOR 900 C/D/E

2

Contents

Introduction . . . . . . . . . . . . . . . . . . 4

Principle diagram. . . . . . . . . . . . . . . . 6

Pneumatic unit

Gas flow through the ventilator . . . . . . . . . 8

Gas supply . . . . . . . . . . . . . . . . . 9

Bellows and spring assembly. . . . . . . . . . 10

Gas supply unit . . . . . . . . . . . . . . . 11

O

2cell . . . . . . . . . . . . . . . . . . . 12

Relief/safety valve and working

pressure manometer . . . . . . . . . . . . . 12

Flow transducer . . . . . . . . . . . . . . . 14

Pressure transducer . . . . . . . . . . . . . 15

Inspiratory valve and step motor . . . . . . . . 16

Expiratory valve and pull magnet . . . . . . . . 17

Non-return valve . . . . . . . . . . . . . . . 17

Transducer interface . . . . . . . . . . . . . . 18

Electronic unit

Principle of operation . . . . . . . . . . . . . 19

Reference level generation . . . . . . . . . . . 20

Regulation of inspiration. . . . . . . . . . . . 23

Timing. . . . . . . . . . . . . . . . . . . 28

Monitoring . . . . . . . . . . . . . . . . . 33

Regulation of expiration . . . . . . . . . . . . 39

Voltage supply . . . . . . . . . . . . . . . 41

Input/output . . . . . . . . . . . . . . . . 42

Disassembling

Disassembling the pneumatic unit . . . . . . . . 44

Disassembling the electronic unit. . . . . . . . . 44

Replacement of step motor assembly

and pull magnet . . . . . . . . . . . . . . . 45

Replacem

ent o

f power supply unit . . . . . . . 45

Replacement of safety catches . . . . . . . . . 45

Replacement of flow transducer . . . . . . . . 46

Adjustments

Adjustment of meters Z1 and Z2 . . . . . . . . 46

Adjustment of valve arm. . . . . . . . . . . . 46

Replacement and adjustment of R5 . . . . . . . 47

Removing the front panel knobs . . . . . . . . 47

Front panel potentiometer adjustments. . . . . .

48

Troubleshooting . . . . . . . . . . . . . . . . 49

Index . . . . . . . . . . . . . . . . . . . . 52

Block diagram . . . . . . . . . . . . . . . . . 56

Contents

To the responsible service personnel

The contents of this document are not binding.

If any significant difference is found between

the product and this document, please contact

MAQUET for further information.

We reserve the right to modify products without

amending this document or advising the user.

We recommend using MAQUET authorized

personnel for all service and repairs and the

use of MAQUET exchange parts or genuine

spare parts. MAQUET will not otherwise assume

responsibility for the materials used, the work

performed or any possible consequences of

same.

The Servo Ventilator 900 was orginally

manufactured and sold by Siemens. Responsibility

for the product was assumed by MAQUET Critical

Care in 2003. Manufacturing of the product was

discontinued in 2004.

Please note that this Service Manual has only

been re-labeled from Siemens to MAQUET. No

further significant changes are made. Thus,

some information in the Service Manual may be

outdated.

In case of questions, please contact your local

MAQUET representative

Your local MAQUET representative supplies factory

calibrated and tested plug-in circuit boards as well

as other spare parts indicated in the spare parts

list. When exchanging spare parts, always state

serial number of the apparatus and fault-symptom.

Note that the Operating Manual is an indis-

pensable complement to the Service Manual for

proper servicing.

About this manual

This Service Manual is intended for Servo Ventilator 900 C,

D and E. When reading the manual, please note:

SV 900 C SV 900 D SV 900 E

Read all

information

Do not read

information out-

lined in red

Do not read

information in

shaded areas

3

Product information program

This Service Manual is a part of a comprehensive in-

formation program for Servo Ventilator 900 C/D/E.

The program is planned to contain the following:

Promotional and Scientific Publications

Operating and Service Instructions

Product Training Material

Brochure Servo Ventilator

Concept

Application

Brochures:

Intensive Care,

Anesthesia,

Transportation

Operating

Manual

Brief Operating

Instructions

Training

Instructions

Front Panel

Flip-chart

Advisory

Booklet for

Instructors

Panel Block

Wall Diagram

for Cleaning

Slide Series

including

Textbook

Trainee’s Set

Product Leaflet

“I am breathing

through a

ventilator”

Film and

Booklet

Video

programs,

Video guide,

Video news

Reprints

Circuit Diagram

The Patient’s

ABSee@

Cards and

Poster

Service Manual

4

Introduction

Principle of operation

The Servo Ventilator 900 C/D/E consists of two sepa-

rate units.

The pneumatic unit comprises the gas conduction

system with two pressure transducers, two flow

transducers and two servo valves.

Each transducer, continuously delivers its actual value

to the electronic unit.

The servo valves are used as CONTROLLING

ELEMENTS for the control of inspiratory and expiratory

gas conduction.

The electronic unit comprises three controlling

systems, two for regulation of inspiration and one for

regulation of expiration.

The three controlling systems will be in use, one at a

time, depending on the TIMING control and the selected

ventilation MODE.

Pneumatic unit

Electronic unit SV 900 C

Electronic unit SV 900 D

Electronic unit SV 900 E

5

Introduction

Feedback control

(= regulation system)

Each of the controlling systems comprises its PID-

controller, (P=Proportional action, I=Integral action and

D=Derivative action), as shown in the picture.

The CONTROLLING ELEMENT will be positioned by

the PID-CONTROLLER (output).

P-action gives a continuous basic positioning.

(Thereby the ACTUAL VALUE will correspond to the

DESIRED VALUE).

I-action gives a slowly varying positioning com-

pensation for small long time error (in the ACTUAL

VALUE).

D-action gives a speed-up positioning reaction at fast

changes (in the ACTUAL VALUE).

The actual value from the TRANSDUCER in use is

compared with the desired value from REFERENCE

LEVEL. The difference between the ACTUAL VALUE

and the DESIRED VALUE results in an ERROR SIGNAL,

which is converted to a positioning signal for the

CONTROLLING ELEMENT (inspiratory and expiratory

valve respectively). The valve in use will then be moved

into such a position that the error will be corrected. In this

way, the desired value is maintained independently of

changes in the airways and the lungs.

6

!

Reference level

The main block REFERENCE LEVEL generates the

DESIRED VALUE for each regulating system, corre-

sponding to the settings on the front panel.

@

Regulation of inspiration

The regulation of inspiration is done by means of the FLOW

SERVO LOOP in the following modes: VOL. CONTR. VOL.

CONTR. + SIGH. MAN., each mandatory inspiration during

SIMV + PRESS. SUPPORT and each mandatory inspiration

during SIMV.

The actual value for the controller in this loop comes

from the FLOW TRANSDUCER in the inspiratory channel.

The regulation of inspiration is done by means of the

PRESSURE SERVO LOOP in the following modes: PRESS

SUPPORT. PRESS. CONTR., CPAP, each spontaneous

inspiration during SIMV + PRESS.SUPPORT and each

spontaneous inspiration during SIMV.

The actual value for the controller in this loop comes

from the PRESSURE TRANSDUCER in the inspiratory

channel.

The ERROR SIGNAL from the controller in use (flow

or pressure), is fed to a converter, common to both

inspiratory servo loops, which delivers the valve

control signal to the inspiratory valve (positioning).

For both servo loops, the inspiratory valve is the

controlling element in regulation of inspiration.

#

Timing

Reference timing pulses (START SIMV CYCLE, CLOCK,

INSP.TIME and EXP.TIME) are generated in this main block.

The TIMING gets some command variables from the

front panel settings.

$

Monitoring

The monitoring of all values that are displayed on the panel

meters and the digital display takes place in this main

block.

Some of the readings are compared with preset alarm

limits and visual and audible alarms are activated if the

preset limits are exceeded.

The monitoring system is independent of the

regulating systems.

The pressure limiting system is included in this

main block.

%

Regulation of expiration

The regulation of expiration is done by means of the

PRESSURE SERVO LOOP during expiration in all modes

when using PEEP.

The actual value for the controller in this loop comes

from the PRESSURE TRANSDUCER in the expiratory

channel.

The error signal from the controller is fed to a con-

verter which delivers the valve control signals for the

expiratory valve (positioning).

The expiratory valve is the controlling element in

regulation of expiration.

^

Power supply

The four regulated supply voltages are; +5V, ±15V and

+24V.

&

Input/output

Output signals are buffered in this main block.

Some of the functions of the ventilator can be

externally controlled via inputs in this block.

= Not valid for SV 900 D = Not valid for SV 900 E

Principle diagram

7

Principle diagram

= Not valid for SV 900 E

= Not valid for SV 900 D

!@

#

$%

^

&

8

Pneumatic unit

The flap valve prevents

back flow of gases in

the expiratory tubing.

It is essential for the

trig function

The working pressure is

mechanically adjusted

Gas flow through the ventilator

The gas flow to the patient

is measured

The safety valve opens if the

bellows is overfilled or if the

pressure in the bellows exceeds

approximately 120 cm H

2

O

The airway pressure is measured

The gas conduction from the

patient is regulated

From patient

The gas flow from the

patient is measured

To patient

The gas is filtered

O

2

concentration in the gas is

measured

The gas supply is regulated so

that a constant filling volume is

maintained in the bellows

Gas inlets

A more detailed description of the pneumatic

unit is found in the Training Instructions

The working pressure is shown

on a manometer

The gas conduction to the patient

is regulated

9

Gas supply

The lower gas inlet is used for high pressure gases 250-

700 kPa). The inlet can be connected either via a gas mixer

or directly to the hospital central gas supply, to gas bottles

or to a compressor.

The upper gas inlet is used for low pressure gases,

e.g. from an anesthesia circuit or a flowmeter. Normally,

only one of the two inlets is used at a time.

In any case, the gases pass a one-way valve, an

O2cell and a bacteria filter. The bacteria filter removes

99.998% of all particles down to a size of 0.3 microns.

When an anesthesia vaporizer is used, the gas supply

unit has a different construction with three nipples. For

further information, see the Operating Manual for the

vaporizers.

When the gas is supplied via the high pressure inlet,

a constant filling volume is obtained in the bellows by

means of the gas inlet regulatory function of a controlled

inlet valve. A constant working pressure is obtained by

the action of the spring assembly.

Pneumatic unit

10

Pneumatic unit

Bellows and spring assembly

The bellows are placed in a double coil spring set between

two metal plates. The lower plate is movable and spring

tensioned. The upper plate acts as a lid, which is firmly

positioned above the bellows.

A double coil spring set is arranged to give a constant

pressure to the bellows, independent of the plate position.

The pressure is set by the adjustment handle PRESET

WORKING PRESSURE.

Coil springs

11

Pneumatic unit

Gas supply unit

The gas supply unit contains an on-demand valve for the

high pressure gas, a controlled inlet valve, two one-way

valves, the O2cell holder and a bacteria filter.

Normally, the high pressure inlet is used and the

bellows are filled through the controlled inlet valve, a one-

way valve and the bacteria filter.

Mechanically actuated gas supply unit

The pressure plate acts upon the controlled inlet valve

via the lever arm. Before connecting the gas supply, the

bellows are empty, the pressure plate in top position and

the controlled inlet valve open. When connecting high

pressure gas, the bellows fills, the actuating tab on the

right edge of the pressure plate goes down against the

lever arm until the controlled inlet valve has closed. The

pressure plate is then in its regulating position, which

means that during inspiration, gas is continuously fed to

the bellows. Thus a constant gas volume is kept in the

bellows when using the high pressure inlet.

When a constant gas flow (from a flowmeter) is

supplied via the low pressure inlet, excess gas will be let

out from the bellows by the relief valve (surplus function).

Gas supply unit for Vaporizer with magnets

When using Vaporizer 950, 951 or 952, a gas supply

unit with three gas inlets has to be used and the

actuating tab on the pressure plate must be replace by

a magnet kit.

Electronic gas supply unit for vaporizer

The gas is normally supplied via a gas mixer at the

lower gas inlet. This inlet is controlled by a 24 V

electromagnetic inlet valve.

The built-in PC-board has two Hall-sensors,

sensing the position of the pressure plate magnet.

When the magnet reaches up to the upper Hall-

sensor, the inlet valve will open. When the magnet

reaches down to the lower Hall-sensor, the inlet valve

will close.

Also when there is no power, the inlet valve is kept

closed.

= Not valid for SV 900 E

12

Pneumatic unit

O2cell

The O2cell used in the ventilator gives an output voltage

proportional to the partial pressure of O2at the cell. At

constant sum of barometric pressure and WORKING

PRESSURE (and constant temperature), the output voltage

is proportional to the relative O2CONCENTRATION.

For each O2cell, the variable output will stay at

a fairly constant level during the life time of the cell

(approximately 800 000 %xhours).

The output voltage level from the cell is usually within

7-15 mV in normal air.

Relief/safety valve and working

pressure manometer

The working pressure manometer is connected to the

safety valve via a plastic tube. A bacteria filter protects the

manometer from contamination.

13

Safety function

Pneumatic unit

Relief/safety valve for gas

evacuation

A special reief/safety valve has to be used for gas

evacuation.

For detalíls, see corresponding Operating Manual.

The relief/safety valve may be opened in two ways. Firstly,

if the bellows tend to overfill, a metal rod will push the lever

to let out excess volume (surplus function). Secondly, if the

working pressure exceeds approximately 120 cm H2O, the

valve will let out excess pressure (safety function).

= Not valid for SV 900 E

14

Pneumatic unit

Flow transducer

The inspiratory and expiratory flow transducers have

the same construction. The gas flows through the flow

transducer in two parallel channels, one large main

channel, and one small measuring channel.

The main channel is fitted with a wire mesh net, the

resistance of which causes a certain proportion of the

gas to flow through the measuring channel.

The flow through, and the differential pressure

across, the measuring channel acts on a small metal

disc (“flag”), which, via a metal pin presses on a small

semiconductor strain gauge. This consists of diffused

resistors on both sides of an elastic silicone rod. The

resistors are connected as a part of a Wheatstone bridge,

the other part of which is situated on the TRANSDUCER

INTERFACE board (PC 765).

The more flow in the channel, the higher the pres-

sure on the strain gauge. The change in resistance in

the Wheatstone bridge, is converted to a corresponding

signal voltage.

The output signal from the flow preamplifier is a non-

linear function of the flow. The flow preamplifier signals

are linearized on PC board 5 (inspiration) and on PC

board 4 (expiration), respectively.

A resistor, 220 Ohms, 6W, is moulded into the

transducer and is used for heating of the expiratory flow

transducer. The transducer is heated to approximately

60°C (140°F) to prevent condensation of water vapour.

The inspiratory flow transducer has the same resistor,

but since it is not connected to any voltage, it will not be

heated.

If water should condense in the expiratory flow

transducer, the resistance of the wire mesh net increases.

Thus the output signal will increase. This can be seen on

the meter EXPIRED MINUTE VOLUME, or on the digital

display, as an increased reading. The accumulation of

medicaments, mucus and secretions in the expiratory

flow transducer gives the same result.

For details on cleaning and calibration of the flow

transducer, see the chapters Routine cleaning and

Calibration in the Operating Manual.

15

Pneumatic unit

Pressure transducer

The pressure transducers in the inspiratory and expiratory

channels are of the same type.

The gas pressure acts upon a silicone rubber mem-

brane into which is moulded a strain gauge of the

same type as in the flow transducers. The strain gauge

resistors are connected as a part of a Wheatstone bridge,

the other part of which is situated on the TRANSDUCER

INTERFACE board (PC 765).

The output signal voltage from the pressure amplifier

is proportional to the gas pressure.

When replacing the pressure transducers, the

preamplifier zero and gain have to be adjusted. For

details, see the chapter Calibration in the Operating

Manual.

Each pressure transducer is connected to its channel

via a plastic tube and a bacteria filter. The bacteria filter

and the plastic tube for the inspiratory channel should be

replaced after every 1000 hours of operation.

The bacteria filter and the plastic tube for the ex-

piratory channel should be replaced after every patient.

16

Pneumatic unit

Inspiratory valve and step

motor

The inspiratory valve is operated by the step motor via the

logarithmically slotted cam and the lever arm.

When the step motor is in operation, a ball bearing at

the end of the lever arm travels in the slot.

The lever arm squeezes the inspiratory valve

tube against a fixed arm. The change in the flow is

approximately 10% for each step of the step motor,

independent of the motor position as long as the airway

pressure is unchanged.

The step motor has four coils which are fed with

positioning signals from PC board 6 in the electronic unit.

When the mains voltage is switched off (or at mains

voltage failure) the step motor will always end up with the

inspiratory valve in fully opened position.

The maximum speed of the step motor is about 480

steps/second and the time elapsing from fully open to

fully closed position is approximately 0.1 second.

The plastic case contains two PC boards, one with

two miniature lamps and the other with two photo

detectors. When the step motor reaches either end

position of the cam slot, the light beam between the lamp

and the photo detector is interrupted by the cam screen.

This will generate an end position signal for the electronic

circuits on PC board 6.

The position of the lamps in relation to the screen is of

the utmost importance. If the lamps by any chance come

out of position, this will cause the step motor to “rattle”

because end positions are not properly indicated. The

same symptom occurs if a lamp is damaged.

17

Pneumatic unit

Expiratory valve and pull

magnet

The expiratory valve comprises a pull magnet acting on

a lever arm which squeezes a silicone rubber valve tube

against a fixed arm. The valve will close when the magnet

is activated. When the supply current to the magnet is

removed, the valve will open fully because of the spring.

This ensures that the patient can always exhale through

the ventilator at voltage failure.

The expiratory valve is controlled by the signals from

the electronic unit. At a PEEP setting, the information

from the pressure transducer in the expiratory channel

regulates the valve position during expiration.

Non-return valve

The purpose of the flap valve is to prevent air from entering

the patient circuit through the expiratory channel.

The valve is a vital part of the triggering function

since a patient trig is sensed in the expiratory channel

(pressure drop).

➡

18

This PC board comprises the preamplifiers for INSP. FLOW

and EXP. FLOW, the amplifiers for AIRWAY PRESSURE (I),

AIRWAY PRESSURE (E) and O2CONCENTRATION.

The INSP.FLOW WORKING POINT INDICATOR,

EXP.FLOW WORKING POINT INDICATOR and the 6.8V

REGULATOR and its 6.8V REGULATOR MONITOR are

also included on this PC board.

The CALIBRATION POTENTIOMETERS and the

CALIBRATION SWITCH are situated on this PC board.

On failure in the 6.8V REGULATOR indicated by the

6.8V REGULATOR MONITOR block, the block AIRWAY

PRESSURE (I) AMPLIFIER will be influenced to generate

a high AIRWAY PRESSURE (I) signal which will result in

UPPER PRESSURE ALARM condition.

Transducer interface

(PC board no 11)

Pneumatic unit

19

The electronic unit contains the various electronic circuits

for regulation and monitoring. A general description is

found in chapter Introduction and the following chapter

comprises a detailed description of the PC boards

included in the electronic unit.

Electronic unit – Principle of operation

20

Electronic unit – Reference level generation

General

The front panel settings are converted to reference level

signals for the regulating systems.

This manual suits for next models

5

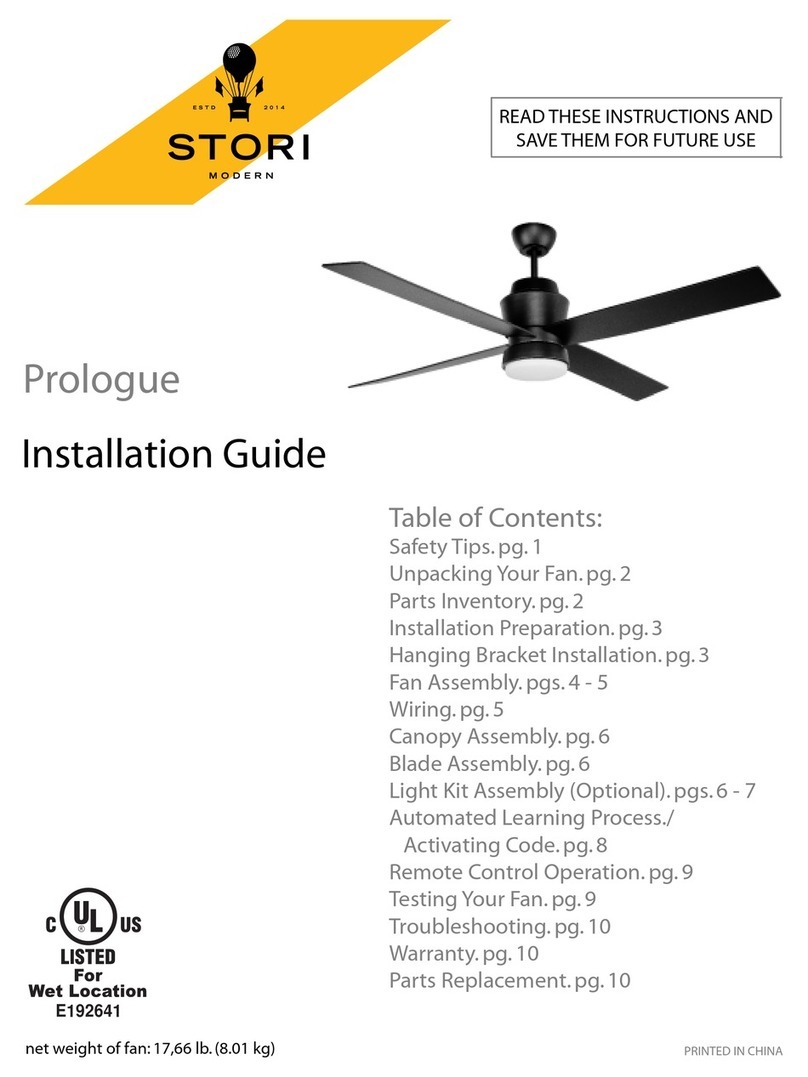

Table of contents

Other Maquet Fan manuals

Popular Fan manuals by other brands

S&P

S&P HR100V Homeowner's guide

Adler Europe

Adler Europe AD 7326 user manual

Home Decorators Collection

Home Decorators Collection HAVERBROOK AM634-PN Use and care guide

Hunter

Hunter Castleton 55043 Manual de instrucciones

Dimplex

Dimplex DCTF117NL instruction manual

Broan

Broan AI Series User's and installer's manual