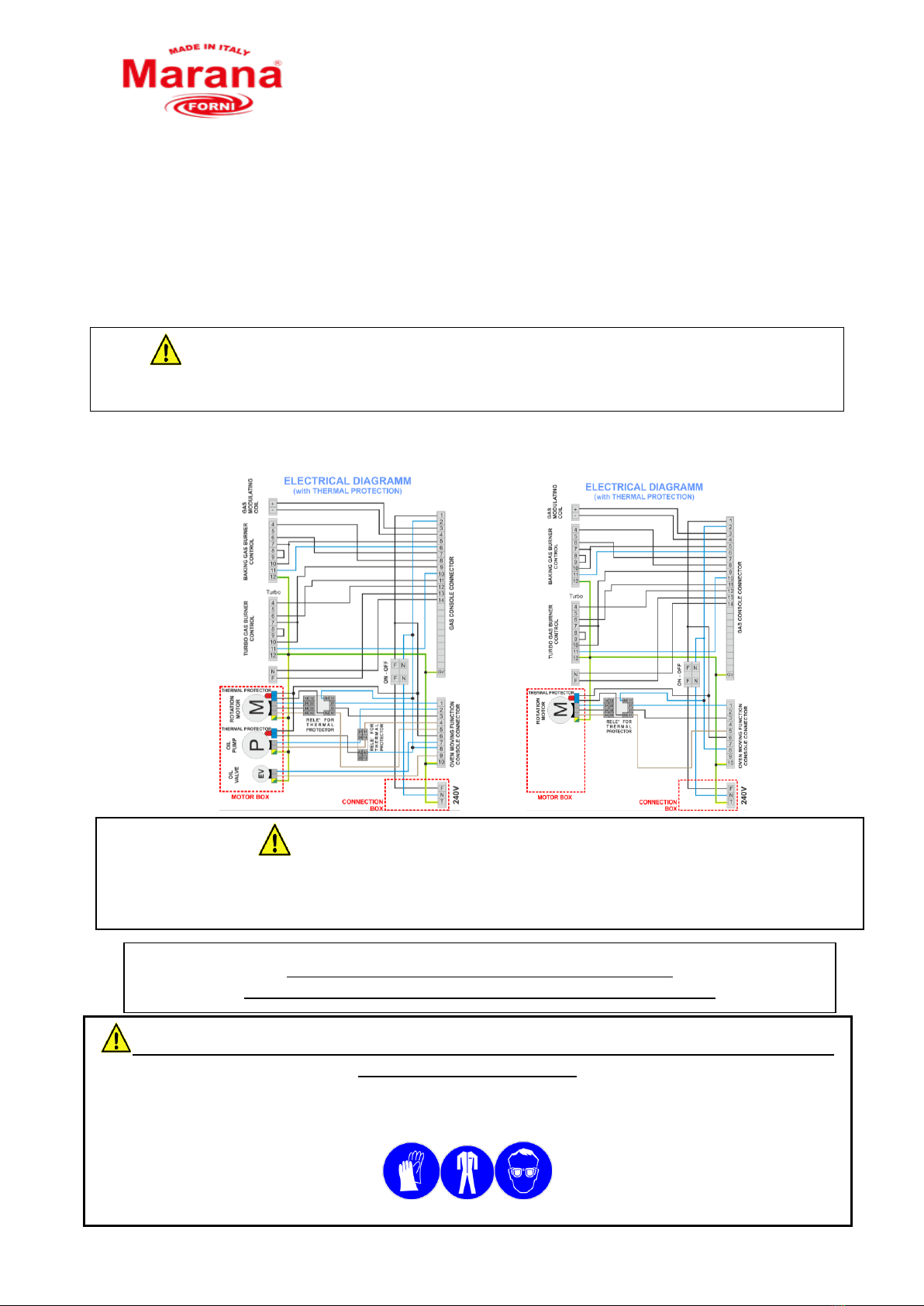

GAS SPECIFICATIONS

Installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1/NFPA 54, or the Natural Gas and Propane Installation Code, CSA B149.1, as applicable,

including:

1.The appliance and its individual shutoff valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of ½ psi (3.5 kPa).

2.The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply piping system at test pressures equal or less than ½ psi

(3.5 kPa).

The appliance, when installed, must be electrically grounded in accordance whit local codes, or in absence of

local codes, with the National Electrical Code, ANSI/NFPA 70, or the Canadian Electrical Code, CSA C22.2,

as applicable.

The supply line must be equipped with a manual shutoff valve. This valve should be located in the same room

but external to the range. It should be in a location that allows ease of opening and closing.

DO NOT BLOCK ACCESS TO SHUTOFF VALVE.

The vent line from the gas appliance pressure regulator shall be installed to the outdoors in accordance with

local codes or, in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1/NFPA 54, or the

Natural Gas and Propane Installation Code, CSA B149.1, as applicable.

DO NOT OBSTRUCT THE FLOW OF COMBUSTION AND VENTILATION AIR

Maranaforni Gas Ovens are equipped with gas connection. Have a licensed gas installer provide to

hook-up and test all fittings and pipe connections for leaks. Use approved gas leak detectors (soap

solutions or equivalent) over and around the fittings and pipe connections.

DO NOT USE FLAME TO TEST FOR LEAKS!

Exhaust hood must be installed by a qualified mechanical engineer in accordance with the hood

manufacturer’s instructions and all relevant Local and Natural Codes. Maranaforni recommends to submit your

venting plants to local code authorities before proceeding with installation.

Marana Forni recommends direct venting.