1

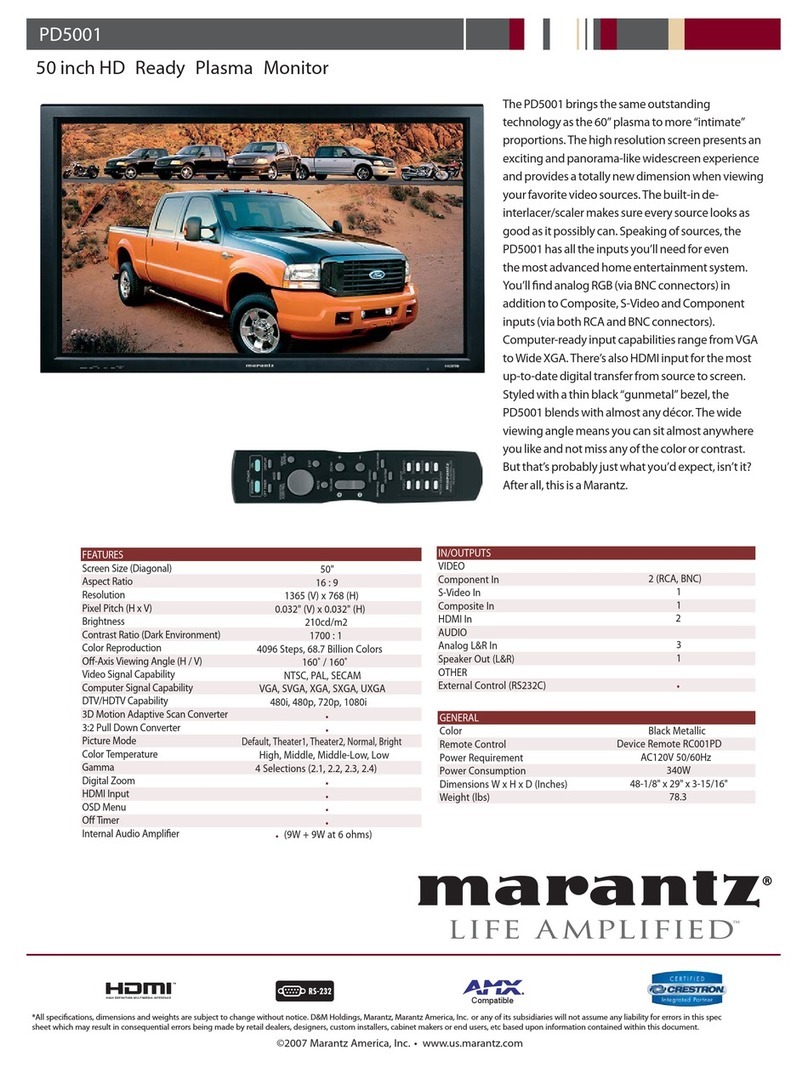

TECHNICAL SPECIFICATIONS

Screen Size 43.5"(H)⳯24.5"(V) inches

1106(H)⳯622(V) mm

diagonal 50"

Aspect Ratio 16 : 9

Resolution 1365(H)⳯768(V) pixels

Pixel Pitch 0.032"(H)⳯0.032"(V) inches

0.81(H)⳯0.81(V) mm

Color Processing 4,096 steps, 68.7 billion colors

Signals

Synchronization Range Horizontal : 15.5 to 110 kHz

(automatic : step scan)

Vertical : 50.0 to 120 Hz

(automatic : step scan)

Input Signals RGB, NTSC (3.58/4.43), PAL (B,G,M,N),

PAL60, SECAM, HD*1, DVD*1, DTV*1

Input Terminals

RGB

Visual 1 (Analog) mini D-sub 15-pin⳯1

Visual 2 (Analog) BNC (R, G, B, H/CS, V)⳯1*2

Visual 3 (Digital) HDMI⳯1*3

Video

Visual 1 BNC⳯1

Visual 2 RCA-pin⳯1

Visual 3 S-Video: DIN 4-pin⳯1

DVD/HD/DTV

Visual 1 RCA-pin (Y, PB[CB], PR[CR])⳯1*1

Visual 2 BNC (Y, PB[CB], PR[CR])⳯1*1, *2

Visual 3 HDMI⳯1*3

Audio Stereo RCA⳯3 (Selectable)

External Control D-sub 9-pin⳯1 (RS-232C)

Sound output 9W+9W at 6 ohm

Power Supply AC100-240V 50/60Hz

Current Rating 7.6A (maximum)

Power Consumption 435W (typical)

Dimensions 48.1 (W)⳯30 (H)⳯3.8 (D) inches

1222 (W)⳯736 (H)⳯96(D) mm

Weight 98.1 lbs / 44.5 kg (without stand)

Environmental Considerations

Operating Temperature 0°C to 40°C / 32°F to 104°F

Humidity 20 to 80% (no condensation)

Altitude 0 to 9180 feet / 0 to 2800 m

Storage Temperature -10°C to 50°C / 14°F to 122°F

Humidity 10 to 90% (no condensation)

Altitude 0 to 9840 feet / 0 to 3000 m

Front Panel User Controls Power on/off, Input source select,

Volume up/down/ OSM control

Remote Control Functions

Power on/off, Input source select, OSM

control,Volume up/down, Cursor (UP,

DOWN,LEFT, RIGHT), Zoom up/down,

Split screen buttons

OSM Functions PICTURE (PICTURE MEMORY/CONTRAST/

BRIGHTNESS/SHARPNESS/COLOR/TINT/NR/

COLOR TEMP./WHITE BALANCE/GAMMA/

LOW TONE/SET UP LEVEL/COLOR TUNE/

CINEMA MODE/PICTURE MODE), AUDIO

(BASS/TREBLE/BALANCE/AUDIO INPUT1/

AUDIO INPUT2/AUDIO INPUT3), IMAGE

ADJUST (ASPECT MODE/V-POSITION/H-

POSITION/V-HEIGHT/H-WIDTH/AUTO

PICTURE/FINE PICTURE/PICTURE ADJ.),

SET UP (LANGUAGE*/BNC INPUT/D-SUB

INPUT/HD SELECT/RGB SELECT/HDMI SET

UP/COLOR SYSTEM/BACK GROUND/GRAY

LEVEL/S1/S2/DISPLAY OSM/OSM ADJ./ALL

RESET), FUNCTION (POWER MGT./INPUT

SKIP/SUB. P DETECT/ZOOM NAV/PICTURE

FREEZE/PDP SAVER [PEAK BRIGHT /

ORBITER / INVERSE/WHITE / SCREEN WIPER

/ SOFT FOCUS / OSM ORBITER / OSM

CONTRAST]/CLOSED CAPTION/CAPTION

CONT), SIGNAL INFO.

The features and specifications may be subject to change without

notice.

*1HD/DVD/DTV input signals supported on this system

480P (60 Hz) 480I (60 Hz) 525P (60 Hz)

525I (60 Hz) 576P (50 Hz) 576I (50 Hz)

625P (50 Hz) 625I (50 Hz) 720P (60 Hz)

1035I (60 Hz) 1080I (50 Hz) 1080I (60 Hz)

*2The 5-BNC connectors are used as RGB/PC2 and HD/DVD2 input.

Select one of them under “BNC INPUT”.

*3Compatible with HDCP.

Supported Signals

• 640ⴒ480P @ 59.94/60Hz • 1920ⴒ1080I @ 50Hz

• 1280ⴒ720P @ 59.94/60Hz • 720ⴒ576P @ 50Hz

• 1920ⴒ1080I @ 59.94/60Hz • 1440 (720)ⴒ576P @ 50Hz

• 720ⴒ480P @ 59.94/60Hz

• 1440 (720)ⴒ480I @ 59.94/60Hz

Note: In some cases a signal on the plasma monitor may not be displayed

properly. The problem may be an inconsistency with standards from

the source equipment (DVD, Set-top box, etc...). If you do experience

such a problem please contact NEC Solutions (America), Inc. and also

the manufacturer of the source equipment.

Units are in inch

(mm)

3.8"

(96)

1.5"

(38) 2.3"

(58)

48.1" (1222)

30" (736)

43.5" (1106)

24.5" (622)

*English, German, French, Italian, Spanish, Swedish,

Chinese, Russian

Other Features Motion compensated 3D Scan Converter (NTSC,

PAL, 480I, 576I, 525I, 625I, 1035I, 1080I), 2-3

pull down Converter (NTSC, 480I, 525I, 1035I,

1080I (60Hz)), 2-2 pull down Converter (PAL,

576I, 625I, NTSC, 480I, 525I), Digital Zoom

Function (100-900% Selectable), Self Diagnosis,

Image Burn reduction tools (PEAK BRIGHT,

INVERSE, WHITE, ORBITER, SCREEN

WIPER), Color Temperature select (high/middle/

middle low/low, user has 4 memories), Auto

Picture, Input Skip, Color Tune, Low Tone (3

mode), Gamma Correction (4 mode), Plug and

play (DDC1, DDC2b, RGB3: DDC2b only),

Split screen operations

Accessories Remote control with two AAA batteries, Power

cord, User Guide, Safety metal fittings, Ferrite

cores, Bands, Cable clamps

Regulations UL approved (UL60950, UL6500, CSA C22.2

No.60950-00, CAN/CSA-E60065-00)

SEMKO Approved (EN60950, EN60065,

IEC60950, IEC60065)

Meets FCC Part 15 Class B

DOC Canada requirements

Meets AS/NZS CISPR 22:2002 Class B

OPTION STAND AS4250

Bezel color is silver.