Marathon TS 910 User manual

9087A – 198th Street, Langley, BC Canada V1M 3B1 Telephone (604) 888-0110

Telefax (604) 888-3381 E-Mail: info@thomsontechnology.com www.thomsontechnology.com

TS 910

AUTOMATIC TRANSFER SWITCHES

OWNERS MANUAL

INSTALLATION, OPERATING &

SERVICE

PM140 Rev 214/01/23

TS 910 TRANSFER SWITCH

PM140 REV 214/01/23 1Thomson Power Systems

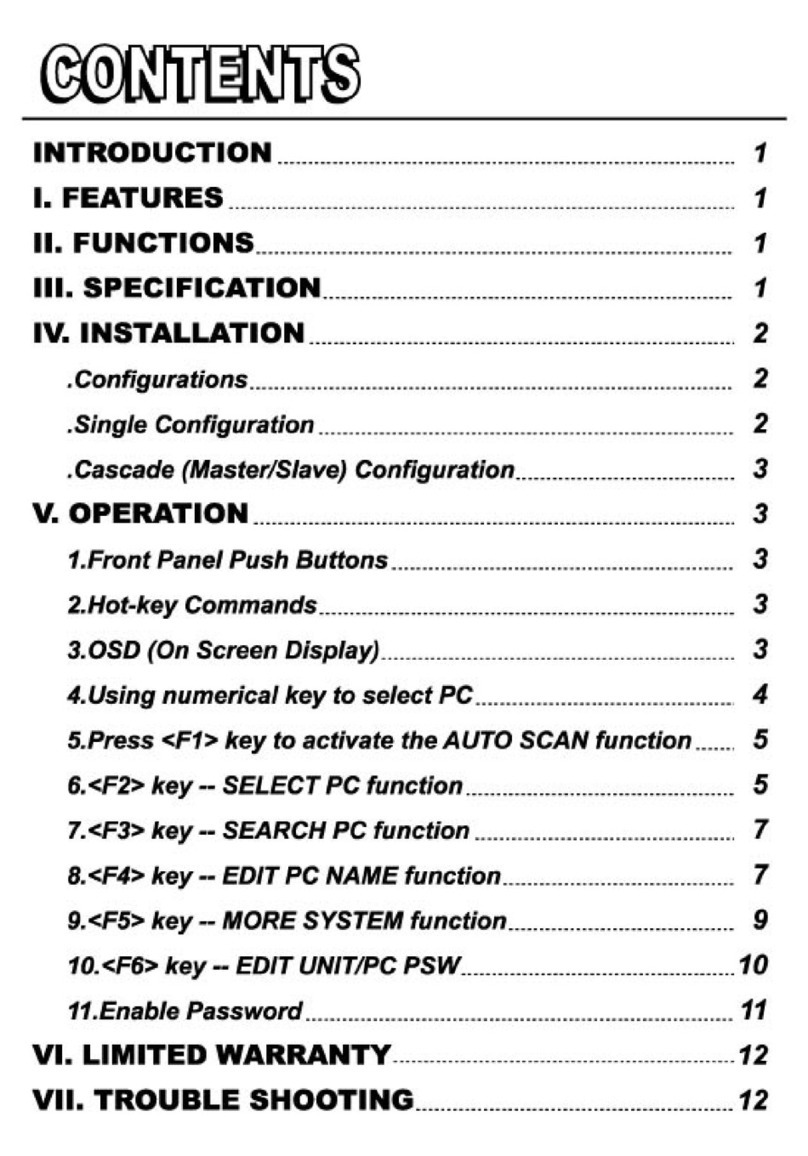

TABLE OF CONTENTS

1PRODUCT REVISION HISTORY 1

2EQUIPMENT STORAGE 1

3NOTES TO INSTALLER 2

3.1 APPLICATION 2

3.2 CHECK EQUIPMENT DELIVERY 2

3.3 CHECK LINE VOLTAGE/AMPERAGE 2

3.4 INSTALLATION REQUIREMENTS 3

3.5 DIELECTRIC TESTING 6

3.6 SERVICE DISCONNECT ATS CONFIGURATION 7

4GENERAL DESCRIPTION 8

4.1 PRODUCT MODEL CODE 9

4.2 TS 910 OPTIONAL ACCESSORIES 10

4.3 TYPICAL COMMISSIONING PROCEDURES 10

5GENERAL THEORY OF OPERATION 11

5.1 AUTOMATIC SEQUENCE OF OPERATION 11

5.2 SERVICE ENTRANCE AUTOMATIC TRANSFER SWITCH OPERATION 11

6OVER CURRENT PROTECTION 14

6.1 STANDARD TS 910 AUTOMATIC TRANSFER SWITCH 14

6.2 SERVICE ENTRANCE RATED TS 910 AUTOMATIC TRANSFER SWITCH 14

7GENERAL NOTES ON SERVICING TRANSFER SWITCH MECHANISM 14

8TRANSFER SWITCH MECHANISM OPERATION 15

8.1 AUTOMATIC OPERATION 15

8.2 MANUAL OPERATION 15

9RECOMMENDED MAINTENANCE 17

10 FRONT INTERIOR VIEW (100A STANDARD ATS) 18

TS 910 TRANSFER SWITCH

PM140 REV 214/01/23 2Thomson Power Systems

11 FRONT INTERIOR VIEW (100A SERVICE ENTRANCE ATS) 19

12 FRONT INTERIOR VIEW (200A STANDARD ATS) 20

13 FRONT INTERIOR VIEW (200A SERVICE ENTRANCE ATS) 21

14 FRONT INTERIOR VIEW (400A STANDARD ATS) 22

15 FRONT INTERIOR VIEW (400A SERVICE ENTRANCE ATS) 23

16 ENCLOSURE DIMENSIONS/CABLE TERMINALS 24

17 REQUIREMENTS FOR UPSTREAM CIRCUIT PROTECTIVE DEVICES 25

17.1 100A, 2P TRANSFER SWITCH UPSTREAM CIRCUIT PROTECTIVE DEVICES 26

17.2 100A, 3P TRANSFER SWITCH UPSTREAM CIRCUIT PROTECTIVE DEVICES 26

17.3 200A, 2P TRANSFER SWITCH UPSTREAM CIRCUIT PROTECTIVE DEVICES 27

17.4 200A, 3P TRANSFER SWITCH UPSTREAM CIRCUIT PROTECTIVE DEVICES 27

17.5 400A, 2P TRANSFER SWITCH UPSTREAM CIRCUIT PROTECTIVE DEVICES 28

17.6 400A, 3P TRANSFER SWITCH UPSTREAM CIRCUIT PROTECTIVE DEVICES 28

18 TSC 9 TRANSFER SWITCH CONTROLLER 29

18.1 DESCRIPTION 29

18.2 ELECTROSTATIC DISCHARGE PRECAUTIONS 30

18.3 DIELECTRIC TESTING 30

18.4 TSC 9 FACEPLATE 31

18.5 TSC 9 FACEPLATE LIGHTS AND PUSHBUTTON OPERATION 32

18.6 TSC 9 PRINTED CIRCUIT BOARD 33

18.7 TSC 9 OPERATING INSTRUCTIONS 37

18.8 TSC 9 OPERATING MODE DESCRIPTIONS 38

18.9 TEST MODES 40

18.10 TRANSFER FAIL FAULT RESET 42

18.11 LAMP TEST 43

18.12 TIMER BYPASS 43

18.13 TSC 9 VOLTAGE SENSING 43

TS 910 TRANSFER SWITCH

PM140 REV 214/01/23 3Thomson Power Systems

18.14 TSC 9 GENERATOR FREQUENCY SENSING 43

18.15 TSC 9 CONFIGURATION INSTRUCTIONS 44

18.16 LOAD SHED 49

19 TS 910 SCHEMATIC DIAGRAM 51

20 TROUBLESHOOTING 52

21 REPLACEMENT PARTS 53

22 PRODUCT RETURN POLICY 55

23 NOTES 56

24 APPENDIX A – TYPICAL AUTOMATIC TRANSFER SWITCH COMMISSIONING

PRIOCEDURES 57

a) PRE-ENERGIZATION CHECKS 57

b) EQUIPMENT ENERGIZATION 58

TS 910 TRANSFER SWITCH

PM140 REV 214/01/23 1Thomson Power Systems

1 PRODUCT REVISION HISTORY

The following information provides an historical summary of changes made to this product since the

original release.

Owners Manual Version

Rev 0 12/02/09 Original release

Rev 1 12/08/28Added 3 Phase Product Information

Contact Thomson Power Systems, to obtain applicable instruction manuals or if in doubt

about any matter relating to installation, operation or maintenance. Soft copy of the most

current version is available at www.thomsontechnology.com.

NOTE: All information contained in this manual is for reference only and is subject

to change without notice.

2 EQUIPMENT STORAGE

The following procedures are required for correct storage of the transfer switch prior to installation.

CAUTION!!!

Failure to store equipment under the specified environmental conditions may cause

equipment damage and void warranty.

The transfer switch shall be stored in an environment with a temperature range not exceeding -4° to

+158° Fahrenheit (-20° to +70° Celsius) and a humidity range not exceeding 5%-95% non-

condensing. Before storing, unpack sufficiently to check for concealed damage. If concealed

damage is found, notify the ATS supplier and the Carrier immediately. Repack the transfer switch

with the original packing material (or equivalent). Protect from physical damage. Do not stack. Store

indoors in a clean, dry, well ventilated area free of corrosive agents including fumes, salt and

concrete/cement dust. Apply heat as necessary to prevent condensation.

TS 910 TRANSFER SWITCH

PM140 REV 214/01/23 2Thomson Power Systems

3 NOTES TO INSTALLER

DANGER!!!!

Arc Flash and Shock Hazard. Will cause severe injury or death.

Do not open equipment until ALL power sources are disconnected

This equipment must be installed and serviced only by qualified electrical

personnel utilizing safe work practices and appropriate Personal Protective

Equipment (PPE). Failure to do so may cause personal injury or death

3.1 APPLICATION

The TS 910 Transfer Switch is designed and is Listed by Underwriters Laboratories (UL) to

Safety Standard UL 1008 for Transfer Switches for Optional Standby applications only. This

product is not intended for installation or operation on legally required standby

applications for emergency power systems as defined by the National Electrical Code.

3.2 CHECK EQUIPMENT DELIVERY

Upon delivery of the transfer switch, remove the product packaging and verify the product

has not been damaged.

WARNING: Damaged Transfer Switch equipment: Do not install or operate the transfer

switch if it appears damaged. Failure to follow these instructions can result in death,

serious injury, or equipment damage.

Check that the model number printed on the inside cover of the transfer switch is the same

as on the delivery note corresponding to the purchase order.

3.3 CHECK LINE VOLTAGE/AMPERAGE

The transfer Switch is designed for a maximum voltage of 120/240V, Single Phase 3 wire

with neutral or 120/208V, three phase 4 wire with neutral. Verify the line voltage and

amperage of the transfer switch matches the site requirements. Note: The transfer switch

can be configured for operation on 208V sources by way of configuration jumper. Refer to

Section 18.15 CONFIGURATION JUMPERS of this manual for further information.

TS 910 TRANSFER SWITCH

PM140 REV 214/01/23 3Thomson Power Systems

WARNING: Do not install the transfer switch if either voltage or amperage does not match.

Failure to follow these instructions can result in death, serious injury, or equipment

damage.

3.4 INSTALLATION REQUIREMENTS

Before installing the transfer switch, review the following requirements:

3.4.1 Installation Codes/Permits and ATS Sizing

Suitable permits are typically required by local jurisdictions having authority prior to

installing standby generator sets and automatic transfer switches. Per NEC Article

702, Automatic transfer switches shall be sized for either a) entire load whole house,

load calculation per NEC 220, or b) Pre-selected “EM” panel(s) of load being served

or optional standby panel and transfer switch, or c) automatic load shedding feature

to reduce total load imposed on the generator, not to exceed the capacity of the

generator. The TS 910 transfer switch has automatic load shedding capabilities built-

in when load shedding control contact is connected. Refer to Load Shedding section

of this manual for further details.

3.4.2 Installation Location

The standard TS 910 transfer switch is designed for indoor wall mounting. For

applications requiring outdoor wall mounting, a NEMA 3R door kit is optionally

available. The transfer switch must be installed in an environment where the

temperature range is within +5° to +122° Fahrenheit (-15° to +50° Celsius) and

humidity range not exceeding 5%-95% non-condensing.

3.4.3 Power Cabling

All power cabling entering/exiting the enclosure must be installed in suitably sized

conduit per NEC requirements. Ampacity, type and voltage rating of current carrying

conductors must also comply with NEC requirements and local jurisdictions having

authority.

Refer to Section 16 ENCLOSURE DIMENSIONS/CABLE TERMINALS of this

manual for further details.

3.4.4 SYSTEM PHASING-HIGH LEG DELTA SYSTEMS

When the transfer switch is connected to 3 phase 4 wire delta systems, the “High” leg, must

be connected to Phase B of the Utility and/or Generator supply inputs to the ATS (Phase B,

TS 910 TRANSFER SWITCH

PM140 REV 214/01/23 4Thomson Power Systems

colored Orange per “NEC 384-3(e)” identified as the leg with highest potential with reference

to ground). This will ensure the ATS control power that is internally connected between

phase A and neutral is maintained at 120VAC. Refer to figure below for further details.

WARNING

Failure to match correct system phasing will result in serious

damage to the Transfer Switch.

208V

B

(Orange)

(High Leg)

C

(Yellow)

A

(Red)

N

(White)

PH A

(UA)

Automatic Transfer

Switch (Utility Supply)

PH B

(UB) PH C

(UC) Neural

(N)

120V 120V

240V 240V

Note: For correct voltage sensing operation on High Leg Delta systems, the TSC 9

controller must have the configuration jumpers set at “240V” and “3PH” settings.

Refer to Section 18.15 TSC 9 CONFIGURATION INSTRUCTIONS of this manual

for further details.

3.4.5 Control Wiring

All control wiring for engine start, load shed, alarm and remote test must be installed

in separate conduits from all power cabling and must utilize suitably sized conduits

per NEC requirements. All control wiring shall be sized for minimum #14 AWG.

TS 910 TRANSFER SWITCH

PM140 REV 214/01/23 5Thomson Power Systems

Control wiring type and voltage rating must also comply with NEC requirements and

local jurisdictions having authority.

3.4.6 Generator Set Automatic Operation

The standard TS 910 transfer switch operates in conjunction with any generator set

with remote automatic starting capabilities utilizing a 2 wire, remote start control

contact input. A dry contact is provided for remote generator starting control (contact

closes to start generator and opens to stop generator).

Optionally available is a Universal Generator Interface kit (UGI) which allows the TS

910 transfer switch to be applied to multiple types of generator sets utilizing 240V

remote starting control systems. Additional information on the Universal Generator

Interface kit can be obtained from our Website (www.thomsontechnology.com).

3.4.7 Upstream Overcurrent Protection (Non-Service Entrance Rated TS 910)

Non-Service Entrance Rated TS 910 transfer switch models do not contain any

integral over current protection and require upstream over current protection devices

for both Utility and Generator sources. The standard TS 910 series Automatic

Transfer Switch is rated for 100% system load and is suitable for control of motors,

electric discharge lamps, tungsten filament lamps, and electric heating equipment

where the sum of motor full-load ampere ratings and the ampere ratings of other

loads do not exceed the ampere rating of the switch and the tungsten load does not

exceed 30 percent of the switch rating. Refer to Section 17 REQUIREMENTS FOR

UPSTREAM CIRCUIT PROTECTIVE DEVICES of this manual for further details.

3.4.8 Upstream Overcurrent Protection (Service Entrance Rated TS 910)

Service Entrance rated TS 910 transfer switch models contain integral over current

protection for the Utility source as standard. Service Entrance rated TS 910 transfer

switches do not contain any integral over current protection for the generator source

and requires upstream generator source over current protection. The Service

Entrance rated TS 910 is rated for 80% maximum continuous loading of all load

types. Refer to Section 17 REQUIREMENTS FOR UPSTREAM CIRCUIT

PROTECTIVE DEVICES of this manual for further details.

3.4.9 Withstand/Interrupting Current Ratings

Refer to electrical ratings table shown below for withstand/Interrupting current ratings.

Withstand/Interrupting short circuit current ratings shown require use of specific

types/manufacturers of upstream molded case circuit breakers. Refer to Section 17

TS 910 TRANSFER SWITCH

PM140 REV 214/01/23 6Thomson Power Systems

REQUIREMENTS FOR UPSTREAM CIRCUIT PROTECTIVE DEVICES of this

manual for further details. Short circuit currents listed for Standard type ATS are

Withstand ratings. Short circuit currents listed for Service Entrance type ATS are

Interrupting ratings based on the ratings of the supplied utility service disconnect

circuit breaker utilized.

WARNING: Do not install the transfer switch on systems with higher available short

circuit current levels than listed below Failure to follow these instructions can

result in death, serious injury, or equipment damage.

MODEL ATS TYPE POLES MAX

VOLTAGE AMPERAGE SHORT

CIRCUIT

CURRENT 1

TS912A0100A

STANDARD

2

240V

100A

10kA

TS912A0100B

SERVICE

ENTRANCE

2 240V 100A 10kA

TS912A0200A

STANDARD

2

240V

200A

10kA

TS912A0200B

SERVICE

ENTRANCE

2 240V 200A 10kA

TS912A0400A

STANDARD

2

240V

400A

25kA

TS912A0400B

SERVICE

ENTRANCE

2 240V 400A 25kA

TS913A0100A STANDARD 3 240V 100A 22kA

TS913A0100B

SERVICE

ENTRANCE

3 240V 100A 10kA

TS913A0200A STANDARD 3 240V 200A 25kA

TS913A0200B

SERVICE

ENTRANCE

3 240V 200A 10kA

TS913A0400A STANDARD 3 240V 400A 50kA

TS913A0400B

SERVICE

ENTRANCE

3 240V 400A 25kA

1 AMPS RMS Symmetrical

3.5 DIELECTRIC TESTING

Do not perform any high voltage dielectric testing on the transfer switch with the TSC

9 controller connected into the circuit as serious damage will occur to the controller.

The control circuit isolation plug connected to the TSC 9 must be removed if high

voltage dielectric testing is performed on the transfer switch.

TS 910 TRANSFER SWITCH

PM140 REV 214/01/23 7Thomson Power Systems

3.6 SERVICE DISCONNECT ATS CONFIGURATION

If the transfer switch is ordered with Service Entrance rating type and is to be used as

Service Equipment, following the procedure described below:

WARNING: The transfer switch must be de-energized prior to opening the enclosure

to access Neutral Bonding strap. Failure to follow these instructions can result in

death or serious injury.

1. Connect the Bonding Strap

to Neutral

2. Apply the Service Disconnect

label supplied with the ATS to the

front of the door under the circuit

breaker toggle

TS 910 TRANSFER SWITCH

PM140 REV 214/01/23 8Thomson Power Systems

4 GENERAL DESCRIPTION

TS 910 Automatic Transfer Switches employ a power contactor switching unit with a microprocessor

based controller to automatically start a generator and transfer system load to a generator supply in

the event of a utility supply failure. System load is automatically re-transferred back to the utility

supply following restoration of the utility power source to within normal operating limits. All load

transfer sequences are “Open Transition” (i.e. “break-before-make”) utilizing an in-phase transfer

detection control sequence.

The TS 910 series transfer switches use a type TSC 9 microprocessor based controller. All

necessary control functions for fully automatic operation are provided by the TSC 9 transfer

controller. The TSC 9 controller is mounted inside the transfer switch enclosure and operating

status is provided via LED indicators that are visible though a front panel opening on NEMA 1 rated

enclosures. For detailed information on the TSC 9 Transfer Switch controller, refer to Section 18 of

this manual.

The standard TS 910 series Automatic Transfer Switch is rated for 100% system load and is suitable

for control of motors, electric discharge lamps, tungsten filament lamps, and electric heating

equipment where the sum of motor full-load ampere ratings and the ampere ratings of other loads do

not exceed the ampere rating of the switch and the tungsten load does not exceed 30 percent of the

switch rating.

Service Entrance Rated TS 910 Automatic Transfer Switch models are supplied with a utility supply

circuit breaker with over current protection. Refer to Section 17 of this manual for detailed

information on over current protection.

TS 910 TRANSFER SWITCH

PM140 REV 214/01/23 9Thomson Power Systems

4.1 PRODUCT MODEL CODE

The type of TS 910 series transfer switch supplied is identified by way of a 11 digit product

code which appears on the equipment rating plate (MODEL) on the inside of the door of the

transfer switch.

*Configurable for 120/208V System Voltages

TS 910 TRANSFER SWITCH

PM140 REV 214/01/23 10 Thomson Power Systems

4.2 TS 910 OPTIONAL ACCESSORIES

The following optional accessories may be ordered as field installable kits.

Model Code

Description

TS910-HTR

Enclosure Heater, 120VAC Fused, supplied from ATS

Load Bus

TS910-SPD1PH

Surge Protective Device, Single Phase Class 1,

120/240V

TS910-SPD3PH

Surge Protective Device, Three Phase Class 1,

120/208V

TS910-KWLS1PH2

kW Load Shed Control output contact, Single Phase,

One Stage, 0-200A Current Transformers connected to

ATS Load Bus

TS910-KWLS1PH4

kW Load Shed Control output contact, Single Phase,

One Stage, 0-400A Current Transformers connected to

ATS Load Bus

TS910-KWLS3PH2

kW Load Shed Control output contact, Three Phase,

One Stage, 0-200A Current Transformers connected to

ATS Load Bus

TS910-KWLS3PH4

kW Load Shed Control output contact, Three Phase,

One Stage, 0-400A Current Transformers connected to

ATS Load Bus

TS910-WMS

Wireless Remote Alarm Messaging Module

TS910-N3R100A

TS910-N3R100B

TS910-N3R200A

TS910-N3R200B

TS913-N3R200A

TS913-N3R200B

TS910-N3R400A

TS910-N3R400B

NEMA 3R Door, External Door Mountable to NEMA 1

ATS Enclosure (Specify matching ATS model number)

TS910-UGI

Universal Generator Interface Start Kit

Additional information on TS 910 optional accessories can be obtained from our Website

(www.thomsontechnology.com).

4.3 TYPICAL COMMISSIONING PROCEDURES

CAUTION:

Commissioning procedures must be performed by qualified

personnel only.

Note: The TYPICAL AUTOMATIC TRANSFER SWITCH COMMISSIONING PROCEDURES

MODEL SERIES TS 910 (attached as “Appendix A”) is provided for general information only

TS 910 TRANSFER SWITCH

PM140 REV 214/01/23 11 Thomson Power Systems

pertaining to typical site installations and applications. Contact Thomson Power Systems for

further information as may be required.

5 GENERAL THEORY OF OPERATION

5.1 AUTOMATIC SEQUENCE OF OPERATION

Note: Time delays indicated below are factory default settings only. Refer to Section 18.15 of this

manual for alternate time delay settings available on TSC 9 Controller

UTILITY POWER FAIL When voltage drops on any phase of the utility supply below

70% of rat

ed voltage, a generator start sequence will be

initiated.

GEN START The generator will start following expiry of the 3 second Gen

Start timer.

GEN WARM-UP A generator warm-up period will be initiated once the generator

starts and reaches 80% rated voltage and 90% rated frequency.

TRANSFER TO GEN The load will transfer to the generator supply following expiry of

the 10 second Gen Warm-up timer.

LOAD SHED ACTIVATE All non-essential loads connected to Load Shed control circuit

will be de-energized once generator transfers on load (If kW

Load Shed option is installed, refer to Section 18.16 of this

manual for further details).

UTILITY POWER RETURN When utility power is restored to above 80% rated voltage on all

phases, a utility power return sequence will be initiated.

TRANSFER TO UTILITY The load will transfer from generator to utility power following

expiry of the 120 second Utility Return

timer, provided both

generator and utility voltages are in-phase at time of transfer.

LOAD SHED RESET All non-essential loads connected to Load Shed control circuit

will be re-energized once load transfers to utility power.

GEN COOL DOWN The generator will automatically stop following expiry of the 2

minute Gen Cool Down timer.

5.2 SERVICE ENTRANCE AUTOMATIC TRANSFER SWITCH OPERATION

5.2.1 OVER CURRENT TRIP

Should the utility breaker trip open due to an over current condition, TSC 9 transfer

controller will initiate an engine start signal and will permit transfer of the load to the

generator supply. The utility source will be locked out and the load will remain on the

generator supply until the Utility Service Entrance breaker is manually reset.

5.2.2 SERVICE DISCONNECT PROCEDURE

To initiate a Utility Supply Service Disconnect, follow procedure shown below:

TS 910 TRANSFER SWITCH

PM140 REV 214/01/23 12 Thomson Power Systems

5.2.2.1 TURN OFF GEN STARTING CONTROL: At the generator set, turn it’s automatic starting

control to OFF position to prevent generator set from automatically starting when the Utility

Service disconnect breaker is opened.

5.2.2.2 LOCK OPEN GENERATOR CIRCUIT BREAKER: At the generator set, OPEN its main

generator output power circuit breaker. Attach safety lockout padlock to the circuit breaker

to prevent unauthorized change in operating condition.

WARNING!

Failure to lock open the main generator output

circuit breaker may result in serious personal

injury or death due to electrical shock.

5.2.2.3 LOCK OPEN UTILTY SERVICE DISCONNECT BREAKER: At the transfer switch, OPEN

the Utility Service disconnect circuit breaker. Attach safety lockout padlock directly onto the

Service Disconnect Utility circuit breaker toggle hasp provided to prevent unauthorized

change in operating condition.

NOTE!

On NEMA 3R rated Transfer Switches, A door

locking Padlock hasp is also provided in cases

where the padlock does not fit behind the

NEMA 3R door when closed.

WARNING!

Failure to lock open the Utility Service

disconnect circuit breaker may result in serious

personal injury or death due to electrical shock.

DANGER!!!!

Arc Flash and Shock Hazard. Will cause severe injury or death.

TS 910 TRANSFER SWITCH

PM140 REV 214/01/23 13 Thomson Power Systems

Do not open equipment until ALL power sources are disconnected

This equipment must be installed and serviced only by qualified electrical

personnel utilizing safe work practices and appropriate Personal Protective

Equipment (PPE). Failure to do so may cause personal injury or death

5.2.3 RETURN FROM SERVICE DISCONNECT MODE

To return the system back to automatic operation following a Service Disconnect

mode, follow procedure shown below:

5.2.3.1 CLOSE ATS ENCLOSURE DOOR: Prior to Load re-energization, ensure the transfer

switch enclosure door/front cover is adequately closed with all provided fasteners.

5.2.3.2 CLOSE UITLITY SERVICE DISCONNECT BREAKER: To re-energize the load, remove the

padlock(s) from the Utility Service Disconnect Circuit Breaker and or ATS door, and move

the circuit breaker to the CLOSED position. The Load will be re-energized and the transfer

switch will remain in the utility supply position.

5.2.3.3 CLOSE GENERATOR CIRCUIT BREAKER: At the generator set, re-close the main

generator output power circuit breaker.

5.2.3.4 RE-ENABLE AUTOMATIC GEN STARTING CONTROL: At the generator set, turn its

automatic starting control back to the AUTOMATIC position to return the system back to

fully automatic operation.

TS 910 TRANSFER SWITCH

PM140 REV 214/01/23 14 Thomson Power Systems

6 OVER CURRENT PROTECTION

6.1 STANDARD TS 910 AUTOMATIC TRANSFER SWITCH

The standard TS 910 Automatic Transfer Switch does not contain any integral over current

protection and requires upstream over current protection devices for both Utility and

Generator sources. The Standard TS 910 is rated for 100% continuous loading and can

withstand a maximum short circuit fault current as noted in Section 17 of this manual. The

standard TS 910 transfer switch model without integral over current protection is identified in

the product model code. Refer to Section 4.1 of this manual for further details on model

coding.

6.2 SERVICE ENTRANCE RATED TS 910 AUTOMATIC TRANSFER SWITCH

TS 910 transfer switches have integral over current protection supplied on the Utility source

as standard. For transfer switches rated 100A through 400A, over current protection is non-

adjustable thermal-magnetic type.

7 GENERAL NOTES ON SERVICING TRANSFER SWITCH MECHANISM

DANGER!!!!

Arc Flash and Shock Hazard. Will cause severe injury or death.

Do not open equipment until ALL power sources are disconnected

This equipment must be installed and serviced only by qualified electrical

personnel utilizing safe work practices and appropriate Personal Protective

Equipment (PPE). Failure to do so may cause personal injury or death

Only qualified personnel should undertake Service work. Failure to correctly maintain an

automatic transfer switch may present a hazard to life and equipment. Full operational

testing must be done prior to placing a transfer switch in service subsequent to any

maintenance or repair. Any service work involving electrical components requires high-

potential testing to ensure that required insulation levels have been maintained.

When performing any service work on the transfer mechanism, it is imperative that the

following be observed:

To maintain mechanical integrity, ensure that:

•All fasteners are adequately tightened.

Table of contents

Other Marathon Switch manuals

Popular Switch manuals by other brands

Transition Networks

Transition Networks E-PSW-TX-02 user guide

Patton electronics

Patton electronics SmartNode 4650 Series quick start guide

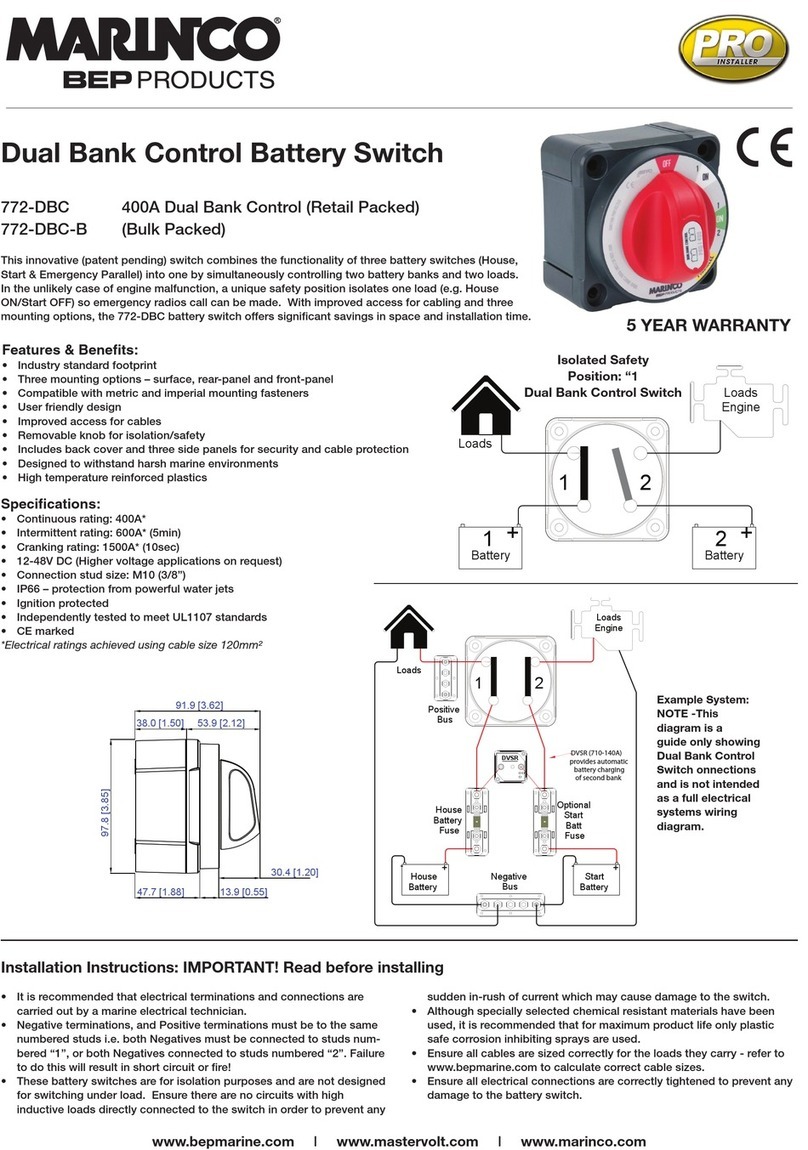

marinco

marinco 772-DBC installation instructions

IVT

IVT FS-01 operating instructions

SMC Networks

SMC Networks 8024L2 - FICHE TECHNIQUE overview

Asante

Asante IntraCore 35516 Series user manual

JETWAY

JETWAY JRL116M-2F-M user guide

Grandbeing

Grandbeing SW0401-N073-000 user manual

NETGEAR

NETGEAR MS108EUP Hardware installation guide

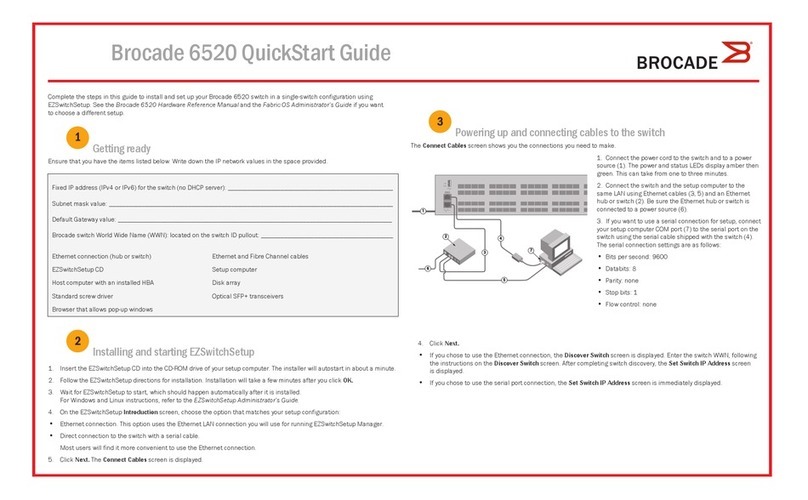

Brocade Communications Systems

Brocade Communications Systems Brocade 6520 quick start guide

D-Link

D-Link DGS-1510-28XMP Getting started guide

Edimax

Edimax EK-16RE Quick install guide