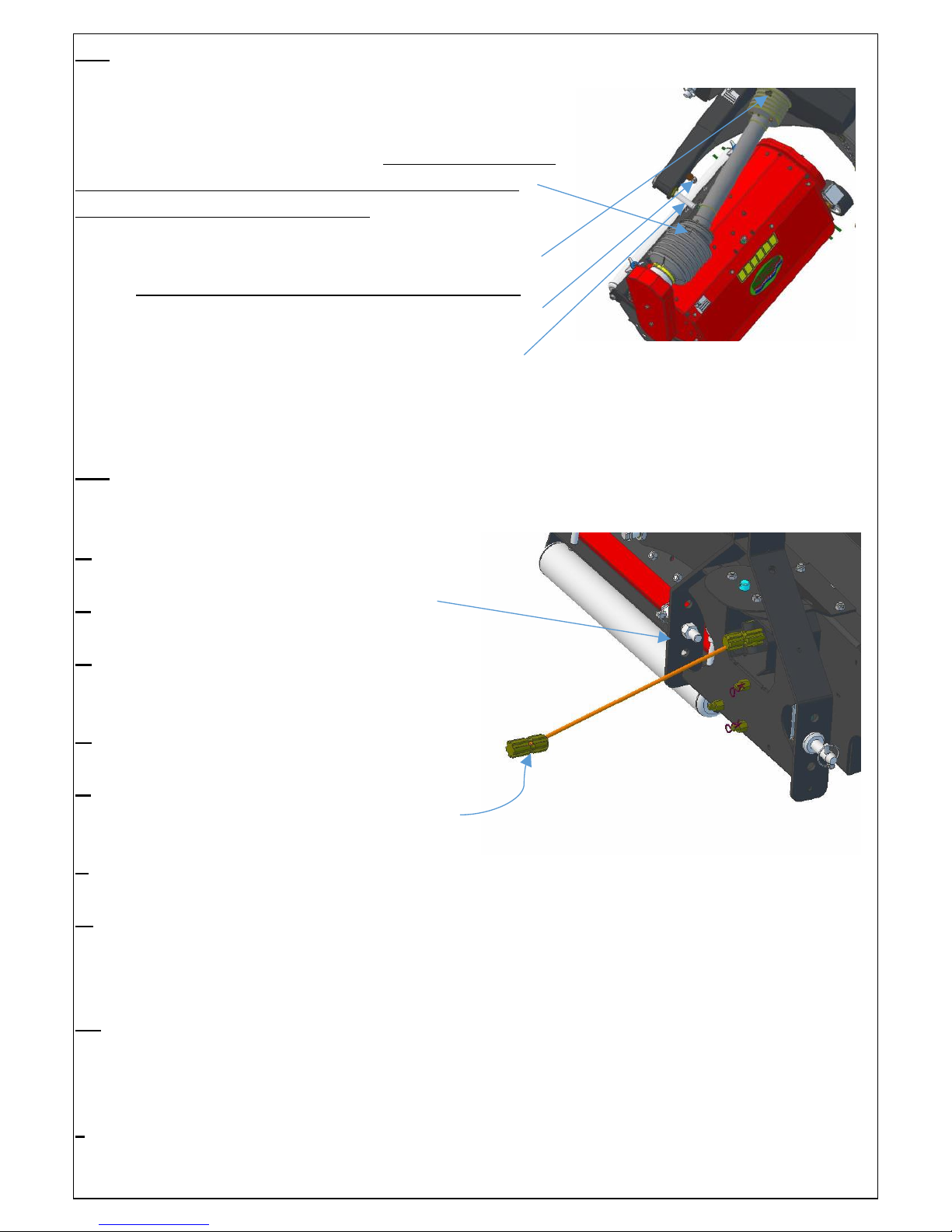

6.2 DEPTH SETTING.

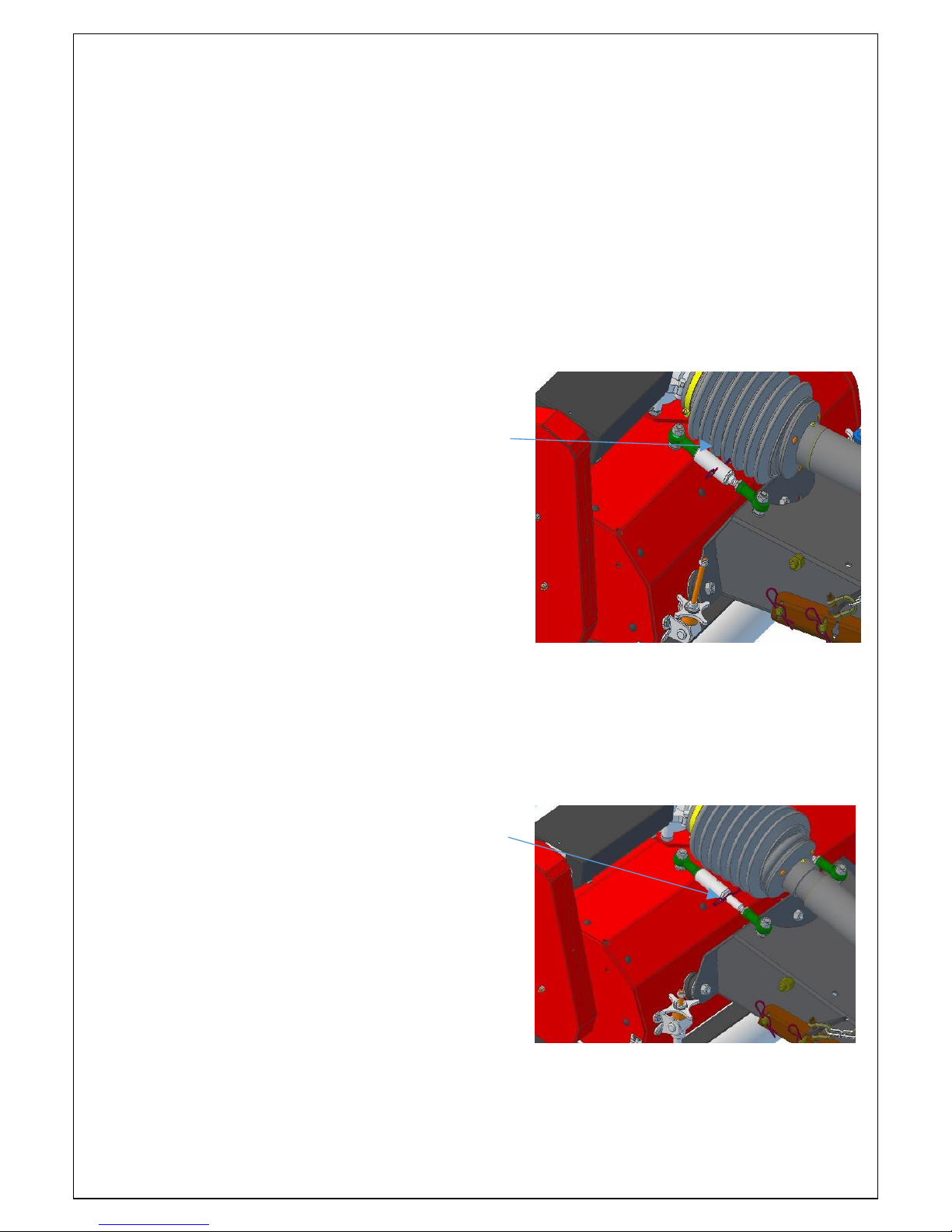

There are two depth adjusters per head. They can be adjusted by hand. Unscrew the

top secure nut (blue) first. Next the second spoke-nut can be turned. The front roller

will move up and down. At the decall you can read

the (theoretical) depth setting. Some NOTES:

A- The theoretical depth setting is not the same as

the actual cutting depth. This depends on the

“softness” of the turf and how much the roller +

wheels are pushed into the turf. This deviation can

be corrected by moving the distance washes to the

top or bottom position.

B- Set both sides at the same depth.

C- Do NOT adjust one side more than 10 mm/ ½”

before compensating the other side.

D- If the (blue) lock nut is tight, “unscrew” it by

turning the big nut first.

E- After the depth setting is done, tighten the (blue) top nut to secure the setting.

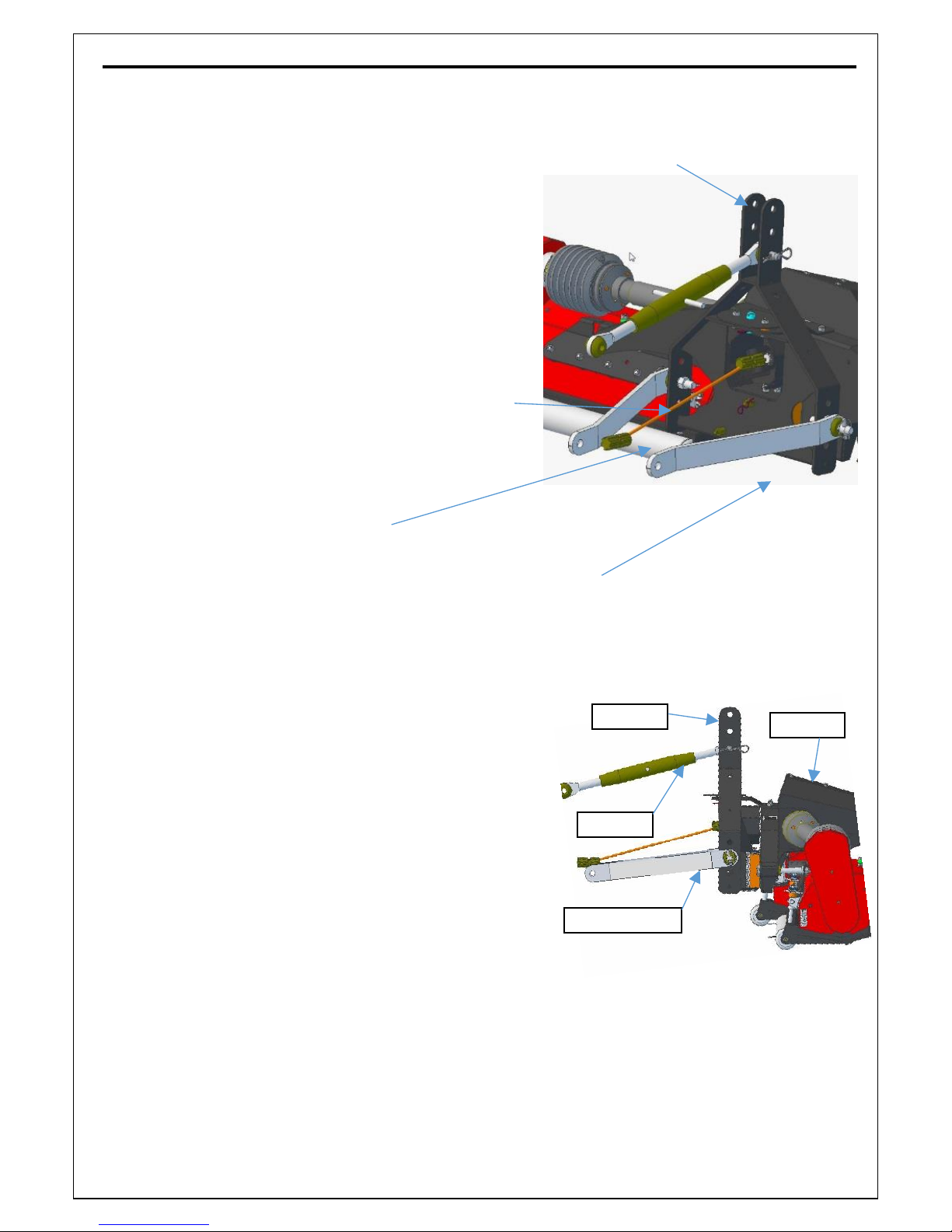

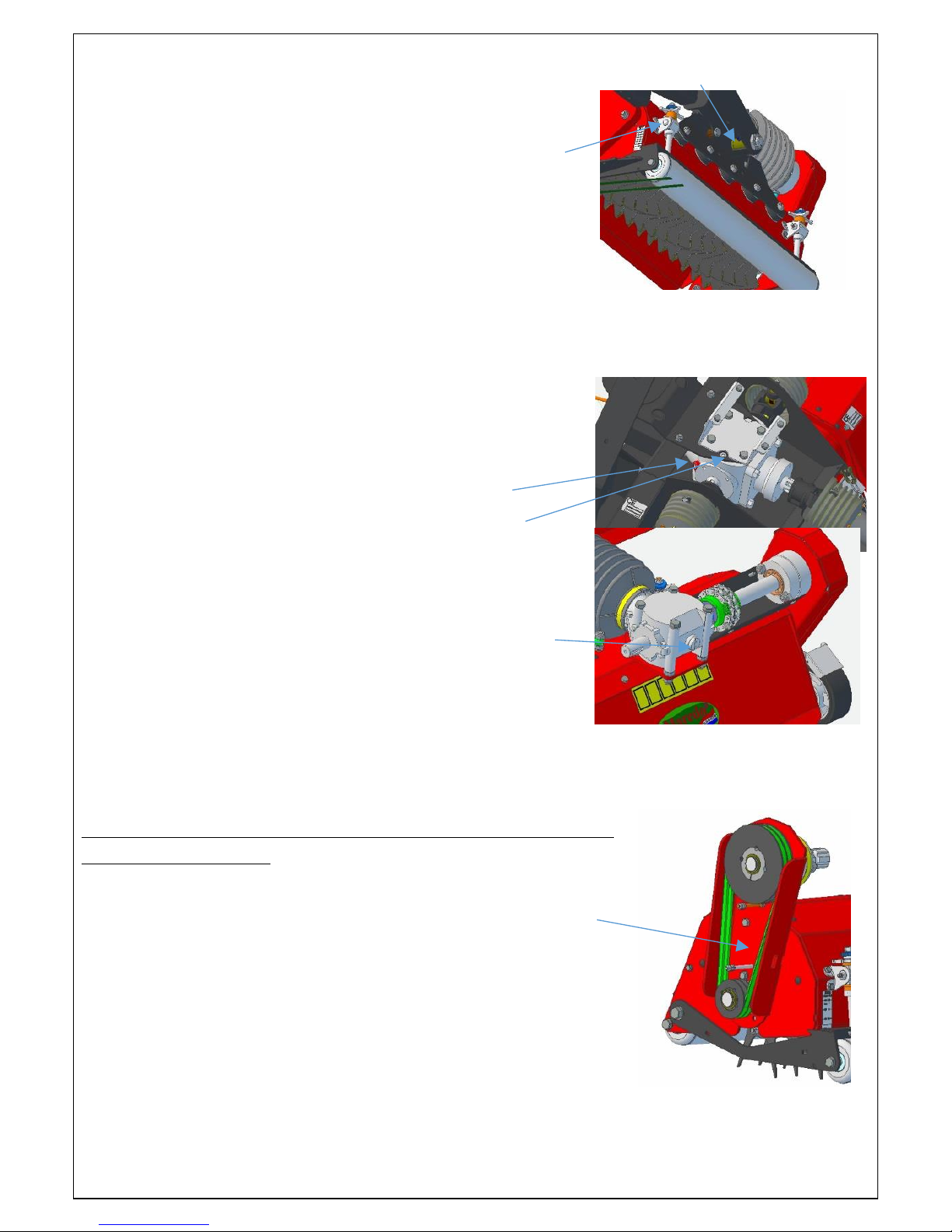

6.3. UNLOCKING THE AFRAME.

By removing the pin in the centre of the Aframe, the

A frame is unlocked from the main chassis and the

machine is ready to make curves during work.

For long transport travels, it is essential to put the

lock pin back in position, so the Maredo MT210

machine does not swing behind the tractor.

When unlocked put the pin in the storage hole, so

you can easily see if the machine is locked or not.

6.4. START EN STOP PROCEDURES.

6.4.1 Inspect the area that you want to treat.

Remove loose objects. DON’T USE the machine in the dark, in heavy rains, on

frozen grounds, stony conditions and on slopes steeper than 30 degrees.

6.4.2 Gently drop the Maredo MT210 machine all the way down till the spikes hit

the surface. Make sure the hitch control lever is in the lowest position.

6.4.3 Next start driving forward and engage the PTO and increase the engine revs till

the PTO runs appr. 540 revs.

6.4.4 The ground speed depends on the depth setting and the ground conditions. Start

with appr. 5 km/h (3 mph). Max speed is 10 km/h (6 mph) or till one of the heads get

unstable. Reduce the groundspeed at that moment immediately.

6.4.5 You can make curves, as long as they aren’t tighter than a radius=2.00 mtr./ 6’.

6.4.6 Important: Make sure the PTO is always switched off before lifting the MT210.

Running the PTO with a lifted MT210 may cause serious damage to the machine.