2

Mareli Systems

Observing the prescriptions of the present manual is in the user’s favour and is one of

the warranty conditions. Compliance with this instruction is in the interest of the con-

sumer and one of the warranty terms.

• is appliance is not intended for use by people (including children) with limited physical, senso-

ry or mental abilities or lack of experience and knowledge. e installation must be performed by

a qualied expert in the eld of heating installations or authorized by “Marelli Systems’ service. e

place and way of connecting the stove should be selected carefully in accord with the safety instruc-

tions. Install away from ammable objects!

• Before starting any operation, the user must read and fully understand the contents of this in-

struction manual. Incorrect setup may cause hazardous conditions and / or incorrect function of

the stove;

• Do not wash the stove with water. Water can get inside the replace and damage the electronics

and cause an electric shock;

• Do not put clothes to dry on the stove. Any clothes hangers and other objects must be located

within a reasonable distance from the replace. Fire hazard;

• e user is fully responsible for the proper use of the product which exempts the company from

liability of any users errors or misbehaviour or omissions;

• Any intervention or replacement that is made by unauthorized people or using non original spare

parts for the product can be risky for the user and release the company from all liability;

• Most surfaces of the stove are extremely hot (the door handle, glass, ue pipe, etc.). Avoid contact

with these parts before assuring yourself that you us temperature resistant gloves as well as suitable

temperature resistant instruments;

• Under no circumstances should the re be ignited with the door open or broken glass;

• e product must be electrically connected to a system equipped with an eective earth conduc-

tor. (Must be grounded);

• Turn o the stove in case of failure or malfunction;

• All unburned pellets in the burner aer each unsuccessful attempt ignition must be removed

before a new ignition;

• When installing the product all re safety requirements must be respected

If there is a re in the ue pipe, extinguish the stove, disconnect the power cord and never open the

door. Call competent authorized service technicians;

• Do not light the stove with ammable materials if the ignition system failed;

• Periodically check and clean the smoke outlet ducts of the stove (connection to the ue pipe);

• Pellet stove is not a cooker;

• Always keep the cover closed;

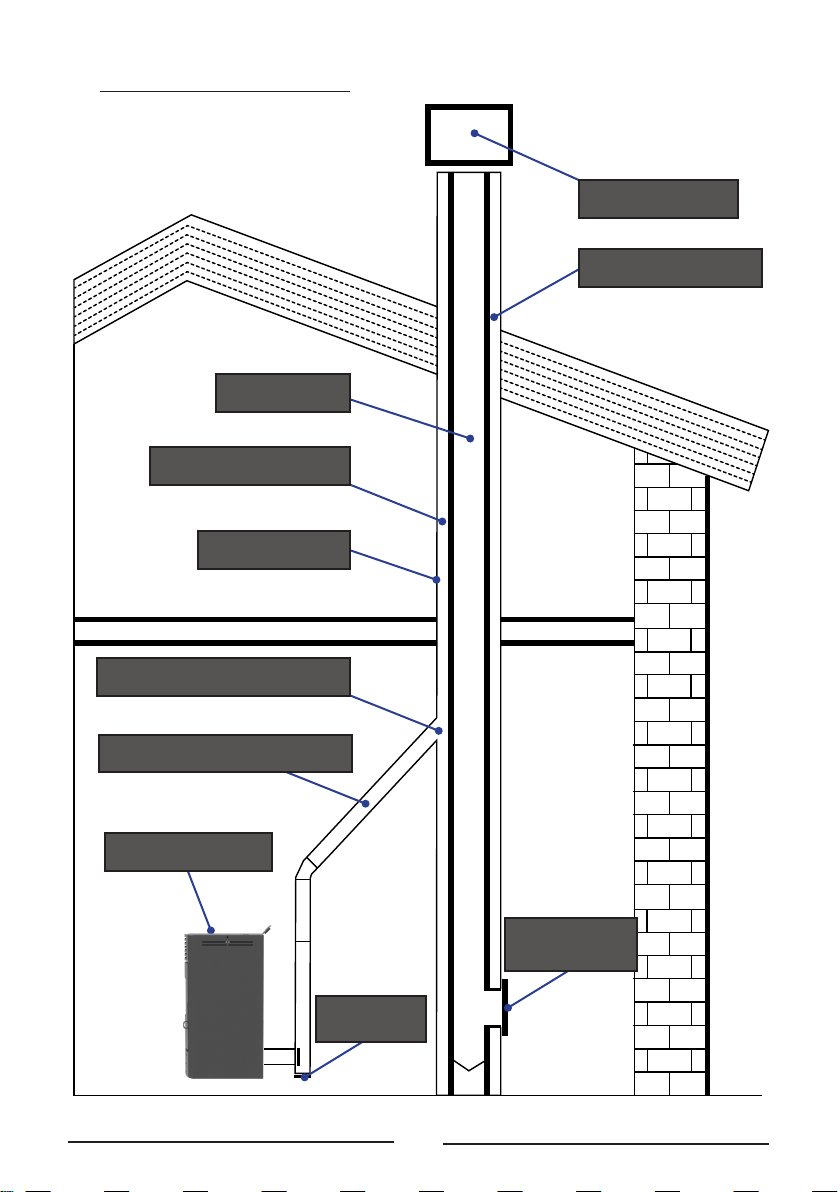

SAFE DISTANCES:

When installing the product a safe distance of at least 600 mm must be respected. is

distance applies to the product located near materials of B or C ammability level. e

safe distance is doubled if the product is close to materials of C3 combustion level.

INSTRUCTIONS FOR SECURITY: