Congratulations on choosing the new "JPROP" propeller !

We are pleased to give you some general information and the

technical instructions for its assembly, use and servicing.

• "JPROP" has been created by the twenty-years experience of

Cober, a precision mechanical industry which as come famous

in its field. Every detail is built with the best materials and

processed on CNC working centre.

• Thanks to its vast range of sizes and to its innovative and

patented technical solutions, "JPROP" can satisfy most of the

requirements of its most exacting customers.

Designed to measure for the sailing world, "JPROP" has been

made to be safe, simple and always efficient:

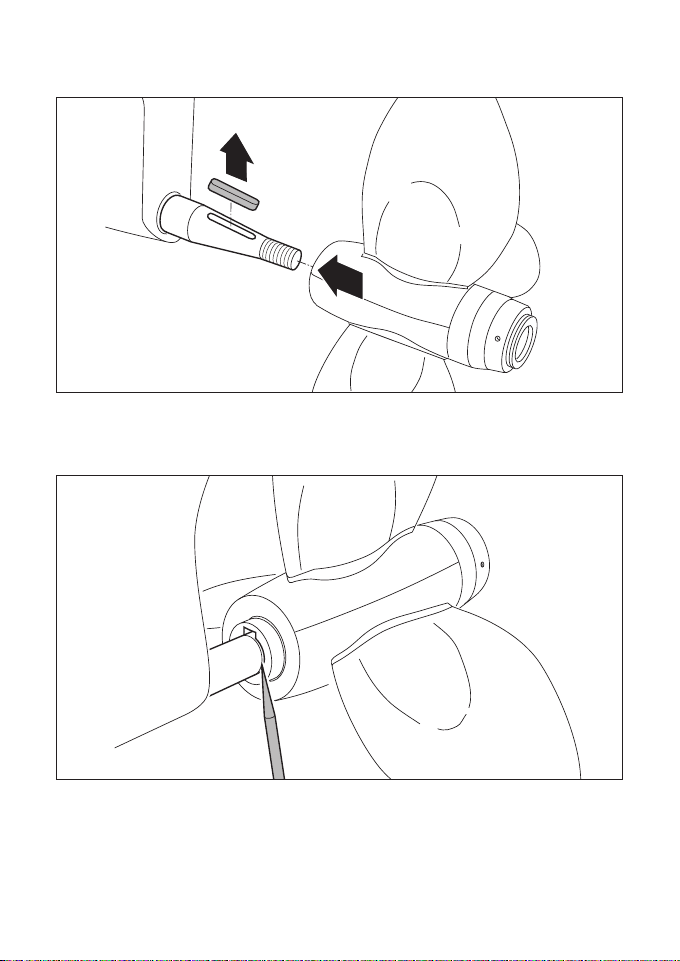

- it can be assembled as easily as a fixed-blade propeller;

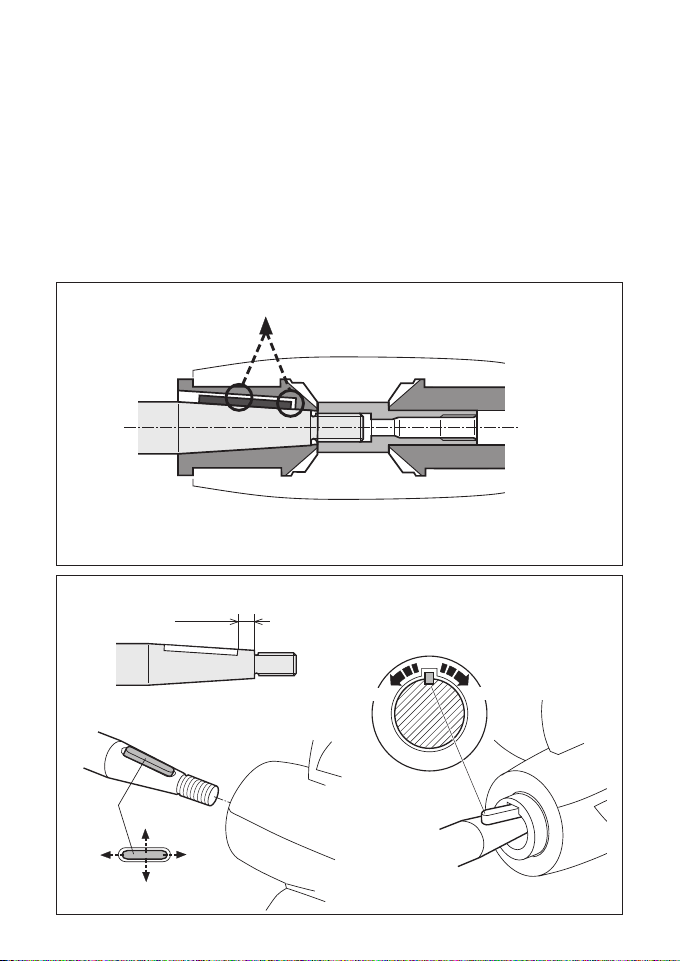

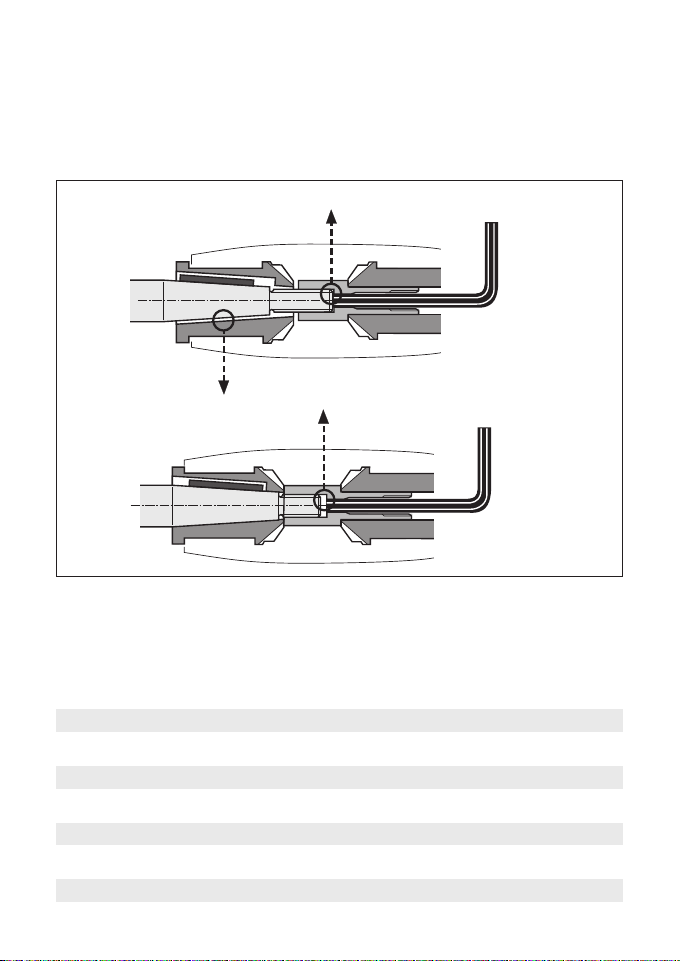

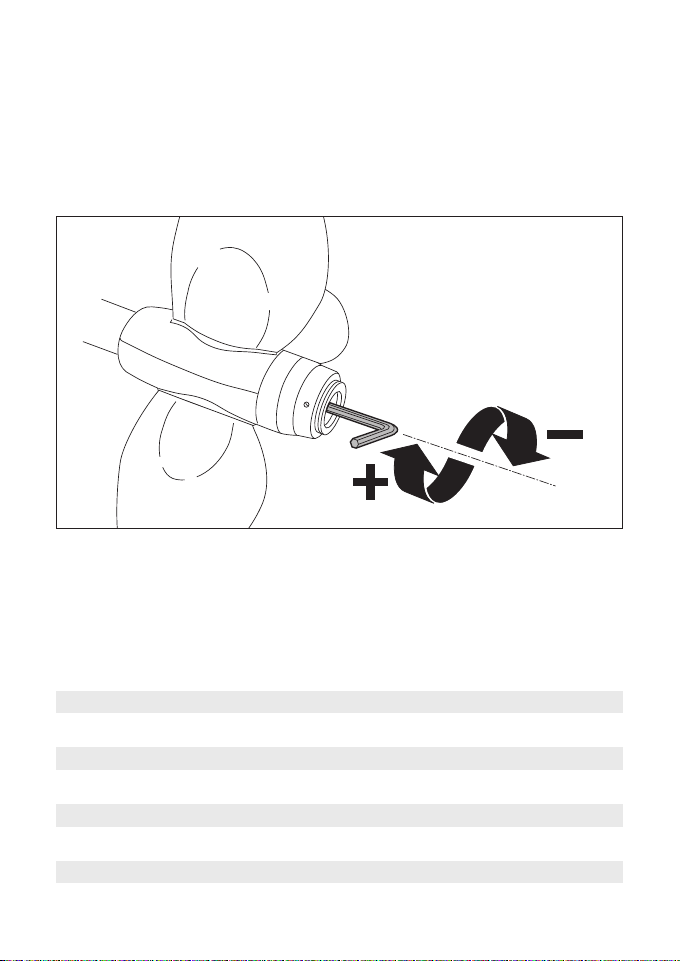

- its pitch can be regulated with simple actions without

dismantling the propeller;

- it avoids the accidental loss of the propeller thanks to simple

and effective solutions;

- the normal servicing just consists of applying some grease

through the nipple provided;

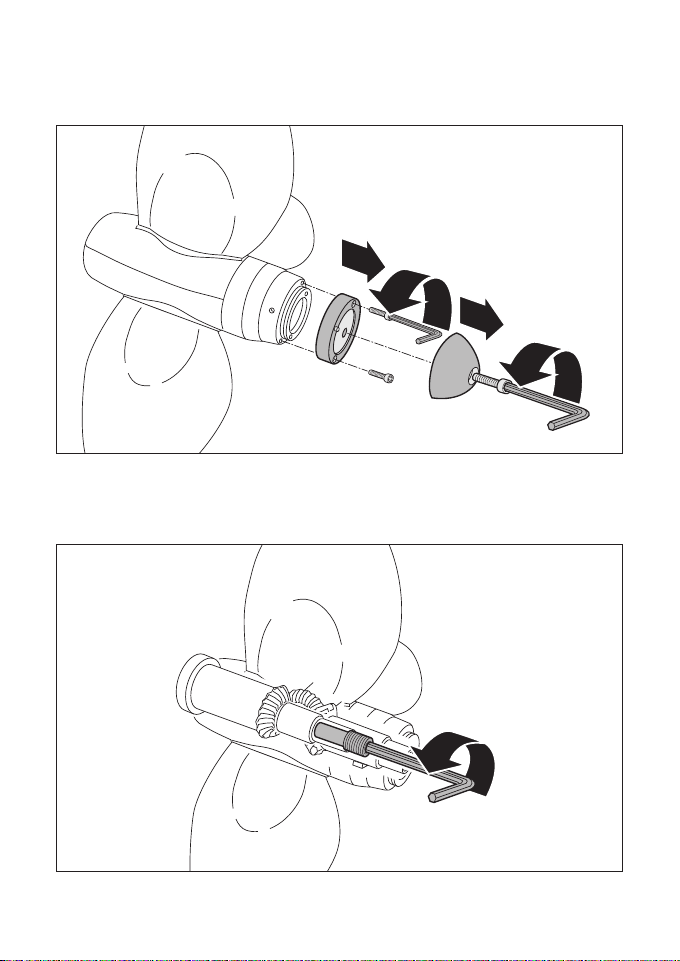

- the servicing of the propeller shaft has been made extremely

easy: the "JPROP" propeller can be dismantled without extractor

by exploiting the features of the fixing nut.

• Our technician choose the "JPROP" propeller suitable for your

boat on the basis of the data communicated through your

order.

J PROP

Variable pitch propeller

s.r.l.