ITIONS AFFECTING

OPERATION

WEIGHTDISTRIBUTION

Positioning of we~yht(passengers and

gear) inside the boat has the following

effects:

A

SIi~ft~ngwrryht

to

rear (stern)

@

Generally Incredses speed and englne

RPM

@

At extremes, can cause boat to por

-

poise

@

Causesbowtobounce ~nchoppy water

(1

Increases danger of thefollow~ng-wave

splash~ngInto boat when comlng off

plane

B.

Shift~ngweight to front (bow)

lmproves ease of planing off

e

Improves rough water ride

0

At extremes, can cause boat to veer

back and forth(bowsteer).

BOTTOM OF BOAT

To maintain maxlmumspeed the follow

-

ing cond~tionsof the boat bottom should

beobserved:

A. Clean, free of barnacles and marine

growth.

B. Free of distortion, nearly flat where ft

contacts the water.

C. Straight and smooth, fore andaft.

L

RECOMMENDATIONS

Any

leaded or unleaded (lead

-

free) gaso

-

line,that willsatisfactorily operateanauto

-

mobile engine is suitable for use in these

model outboard motors.

However, gasolines containing alcohol.

e~thermethyl alcohol (methanol)or ethyl

(ethanol)may cause increased:

s

Corrosion of metal parts.

c

Deteriorat~onof elastomer and plastic

parts.

s

Fuel permeation through flexible fuel

lines

Wear and damage of internal engine

parts.

Stiirting and

operating

diff~cult~es.

Some of these adverse effects are due to

thetendency of gasolinescontaining alco

-

holtoabsorb rnoisturefromthe air, result

-

ing in a phase of water and alcohol

separating from the gasoline in the fuel

tank.

The adverse affects of alcohol are more

severe with methyl alcohol (methanol)

and arc worsu w~thIncreasing alcohol

content.

A

WARNING

FIREANDEXPLOSIONHAZARD:Fuel

leakagefromanypartofthefuelsystem

canbeafireandexplosionhazardwhich

cancauseseriousbodilyinjuryordeath.

Carefulperiodicinspection oftheentire

fuel system is mandatory, particularly

after storage. All fuel components in

-

cluding fuel tanks, whether plastic,

metal or fiberglass, fuel lines, primer

bulbs, fittings, fuel filters and car

-

buretors should be inspected for leak

-

age, softening, hardening, swelling or

corrosion. Any sign of leakage or de

-

teriorationnecessitates replacementbe

-

fore further engine operation.

Because ofthe possible adverse effects

ofalcoholingasoline,

it

isrecommended

that only alcohol

-

free gasoline beused

where possible. If only alcohol-con-

tainingfuelisavailable, orifthepresence

of alcohol is unknown, then increased

inspection frequency for leaks and ab

-

normalities is required.

FUEL

RECOMMENDATIONS

(Continued)

A

wmN1w

USECAREwhentransportingfuelcon

-

tainer, whether in a boat or car. DO

NOT fill fuel container to maximum

capacity. Gasoline willexpandconsider

-

ably as

it

warms up and can build up

pressure inthe fuelcontainer. This can

cause fuel leakage and a potential fire

hazard.

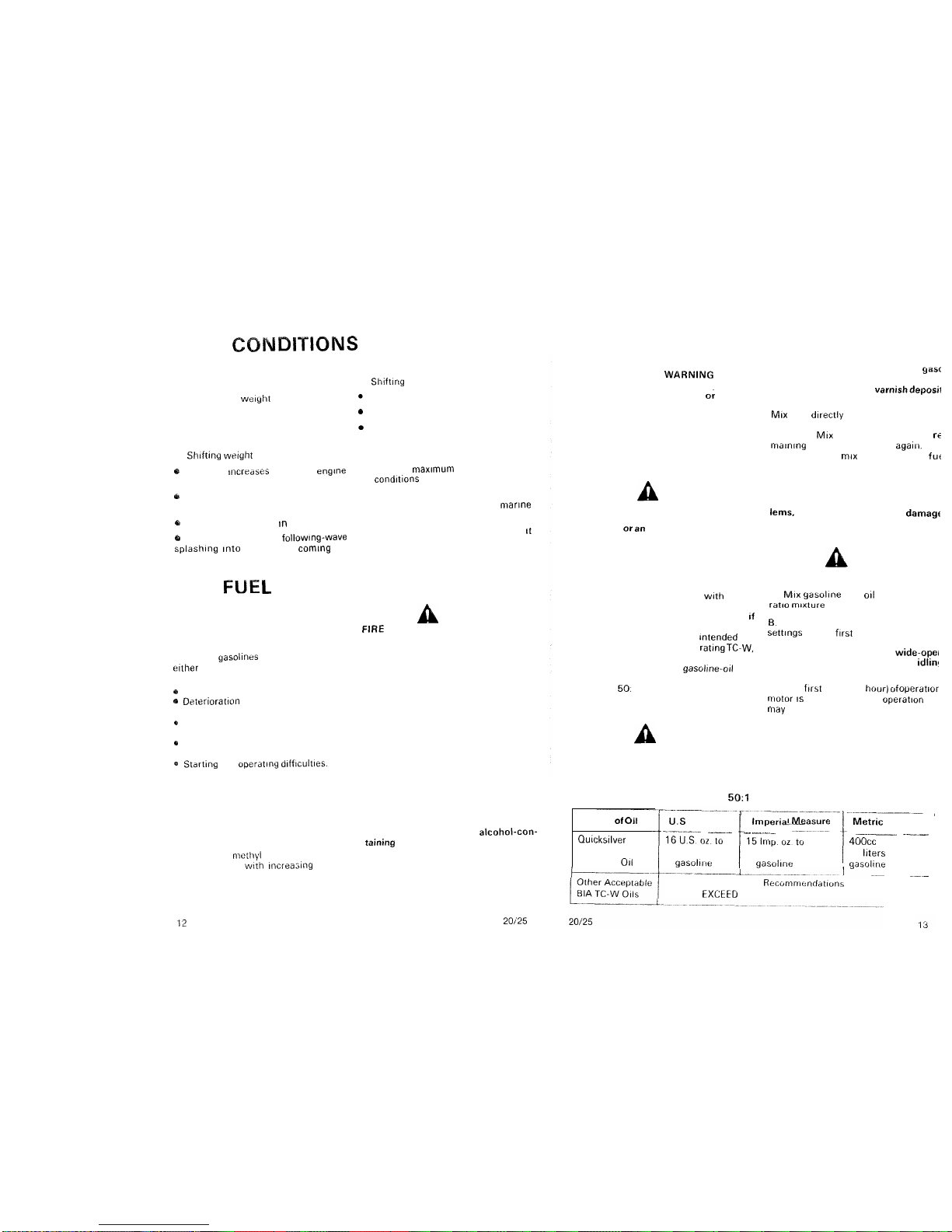

OILRECOMMENDATIONS

A

CAUTION

The use of other than recommended

gasoline and Quicksilver 2

-

Cycle Out

-

boardOiloranacceptableBIATC

-

Woil

maycausepistonscoring, bearingfailure

or both. DO NOT, under any circum

-

stances. usemulti

-

gradeorotherhighly

detergent automobileoils or oils which

contain metallic additives.

Mix recommended gasoline w~thQuick

-

silver 2

-

CycleOutboardOilinratioshown

inthefollowingchart.Inanemergency, ~f

this is not available, substitute a high

quality 2

-

cycle

oil

that is Intended for

outboarduseandmeetsBIA ratingTC-W,

shownonoilcontainer.Usetheoilmanu

-

facturer's recommended gasol~ne-oilmix

-

ture as shown on the label (NOT TO

EXCEED 50:

1

RATIO).

MIXINGINSTRUCTIONS

A

WARNING

Observe fire prevention rules, particu

-

larly NOSMOKING. Mix fueloutdoors

or inwell ventilated location.

IMPORTANT: Always use fresh

yasc

line. Gasoline whichis keptintank to

longwillformgumand

varnishdeposil

whichmaycausetrouble.

MIX fuel d~rectlyinto remote tank. P

OL

small, equal amounts

of

gasoline ando

into tank. MIX thoroughly, then add re

ma~n~ngoilandgasoline.Mix agai~r.Kee

fuel clean and mlx each batch of fuf

exactly the same way.

IMPORTANT: Use recommende

amount of2

-

cycleoil. Toomuchorto

little oil can cause performance prot

lems. aswellasseriousenginedamagf

MOTOR BREAK

-

IN PROCEDURE

A

CAUTION

Follow break

-

inprocedurecarefully.

A

MIX gasohne and 011at normal 50

ratlo mlxture

B.

Operate new motor at varied throttl

sett~ngsfor the fwst hour (one hour).

IMPORTANT: Avoid both wide-ope1

throttle operation andprolonged idlin!

during first hour.

C

After f~rsthour(onehour)ofoperatlor

motor

IS

ready for normal

operation

an

may he runat any speed

A

CAUTION

DONOTEXCEED thefullthrottle RPN

range. See SPECIFICATIONS for RPN

range.

NORMAL

50:l

FUELMIXTURE

Type of Oil

/

U.I Measure

/

lmper~al

---

Measur.

1

Metr~cMeasure

-

Quicks~lver 16USozto 15lmpozto 400cc to each

2

-

Cycle each 6 gallons each

5

Imp gallons 20 l~tersof

Outboard

011

of gasol~~te of gasol~r~e aasol~ne

--

-

Use at Manufacturer's Recummenddtlons

DO NOT EXCtED

50

1