3

MAINBURNERADJUSTMENTS

Satisfactoryovenperformanceandburnerlifearedependentoncorrectburneradjustment.Before

shipment,burnershavebeenadjustedforproperoperationwiththetypespecifiedontheratingplate

locatedinsidethecontrolcompartmentabovethelightswitch.Iffurtheradjustmentisnecessaryproceed

asfollows:

Adjustprimaryairshutteratthefrontoftheburnercompartmenttoobtainastableandquiet

flame.

Iftoomuchprimaryairispresent,flameswillliftfromtheburnerparts.Areductionin

primaryairwillcorrectthiscondition.

Toolittleprimaryairwillcauseyellowtippingoranentireyellowflametoappear.This

conditionindicatesincompletecombustionandmaycausecarbonsootingtoappearonmetal

partsneartheflame.

Whenaflameraisesofftheburneritisimportanttodetermineifitisa“liftingflame”ora

“floatingflame”:

o“Liftingflames”risefromtheportstoburnsomedistanceabovetheports.Insome

casestheseflameswilldropbacktotheportandliftagainintermittently.Theyare

causedbytoomuchprimaryair.Decreasingtheshutteropeningwillstoplifting

flames.

o“Floatingflames”arelongandlazyinappearance,poorlydefined,quietflames

whichrollaroundthecombustionchambersometimescompletelyofftheports.

Floatingflamesresultfromtoolittlesecondaryair.Lackofsecondaryairiscaused

byincorrectventing,cloggedflueways,blockedsecondaryairinletopenings,orlack

ofnaturalroommakeupairtotheoven.

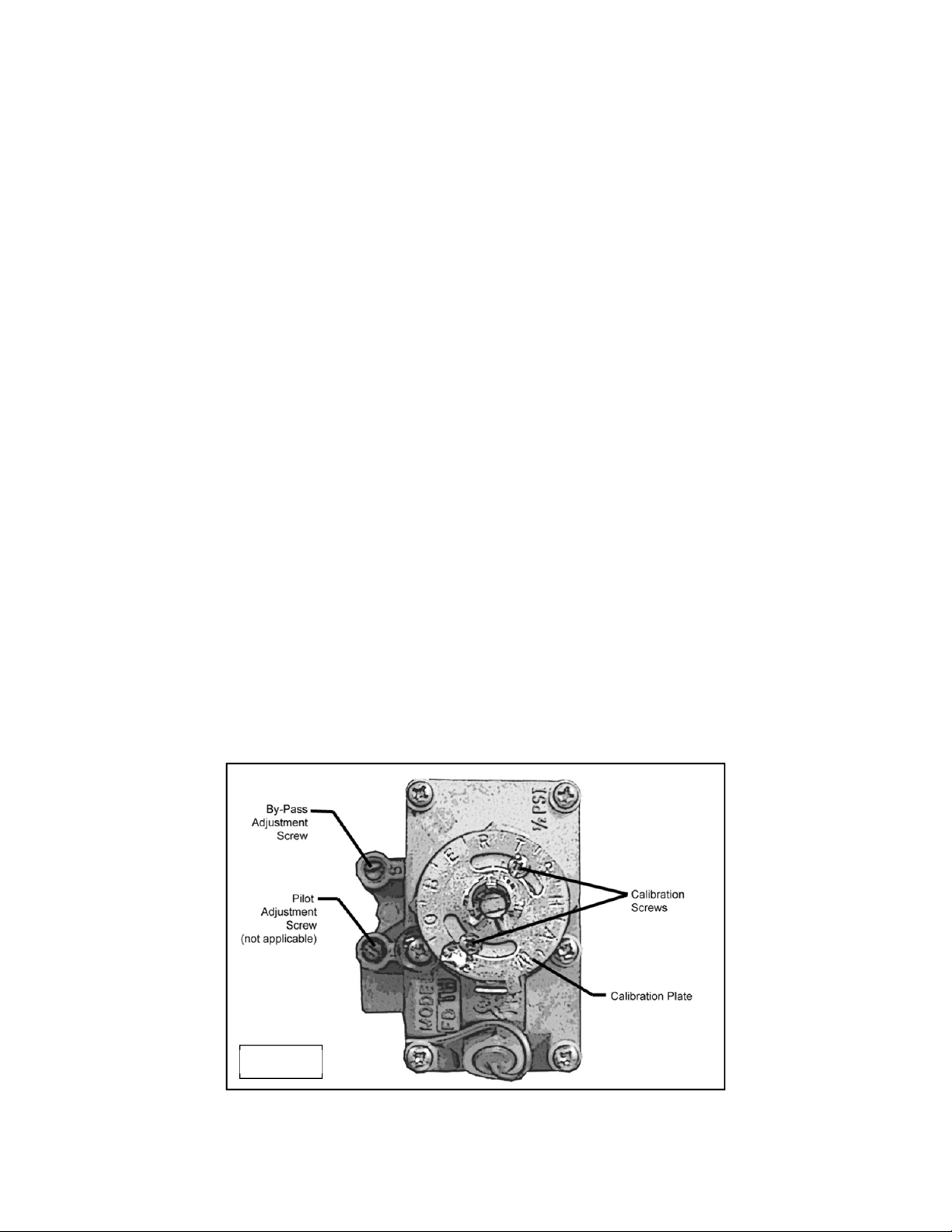

BYPASS(MINIMUMBURNERFLAME)ADJUSTMENTS

ARobertshawFDTH300°‐650°F(149°‐343°C)typethermostatisused.Thisisathrottlingtypegas

thermostatwithbypassflameadjustmentcontrol.Forbypassadjustmentproceedasfollows:

1. Preheatovento500°F(260°C).Whenthermostathasthrottledtobypasstheglameonthe

mainburnershouldhavedecreasedtoaflamenolargerthan1/8”(6mm)

2. Ifflameistoohigh,removedial,insertscrewdriverinscrewmarked“B”onthethermostatand

turnscrewclockwisetolowerflame.

3. Ifflameistoolow,removedial,insertscrewdriverinscrewmarked“B”onthethermostatand

turnscrewcounterclockwisetoincreaseflame.