Table of Content

SAFETY PRECAUTIONS....................................................................................................3

FEATURES OF DEVICES...................................................................................................4

EXPLODED VIEW............................................................................................................5

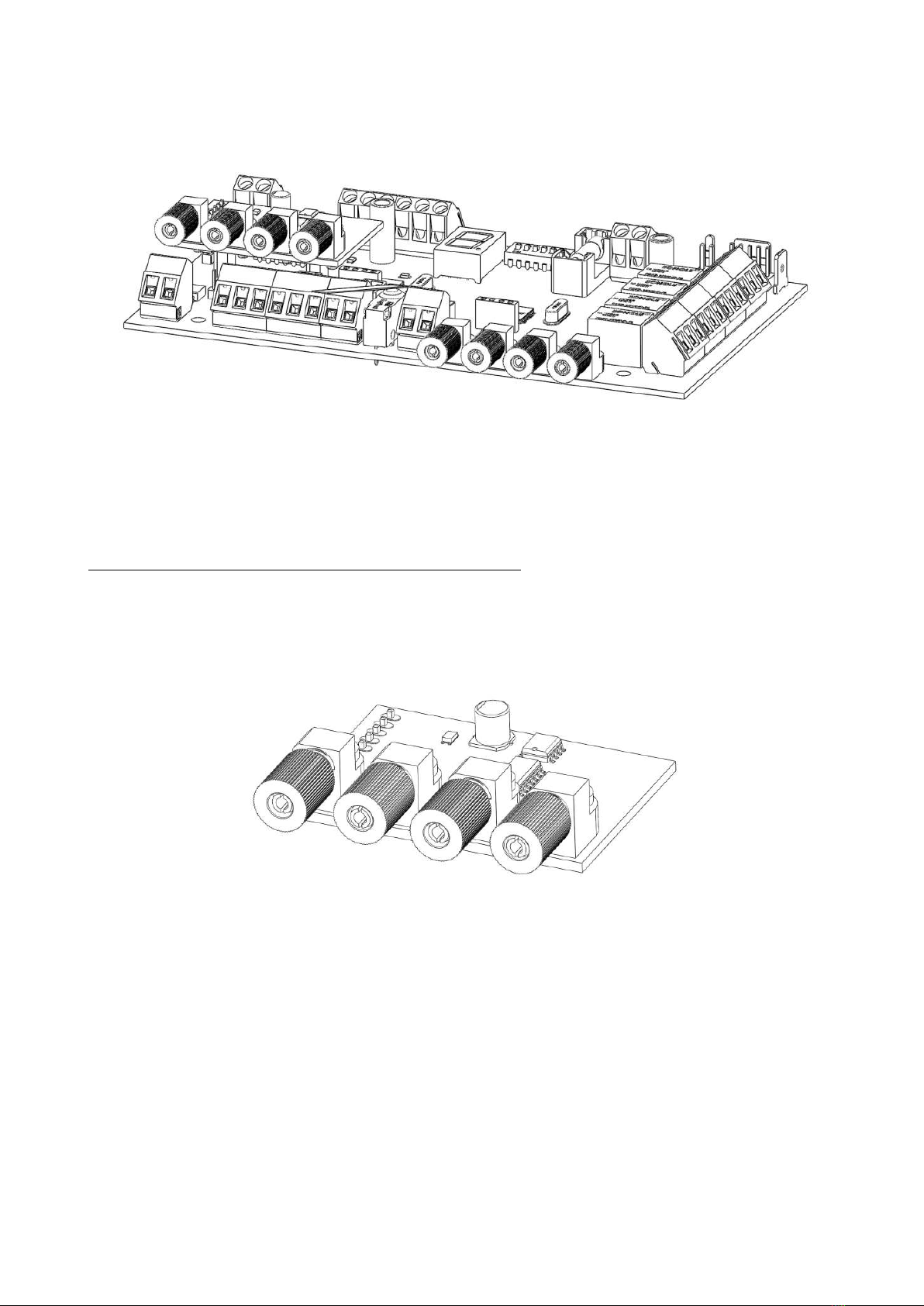

Concentrator module for fiber-optic Solar Defender (model ALM-6 14/6 15).........................6

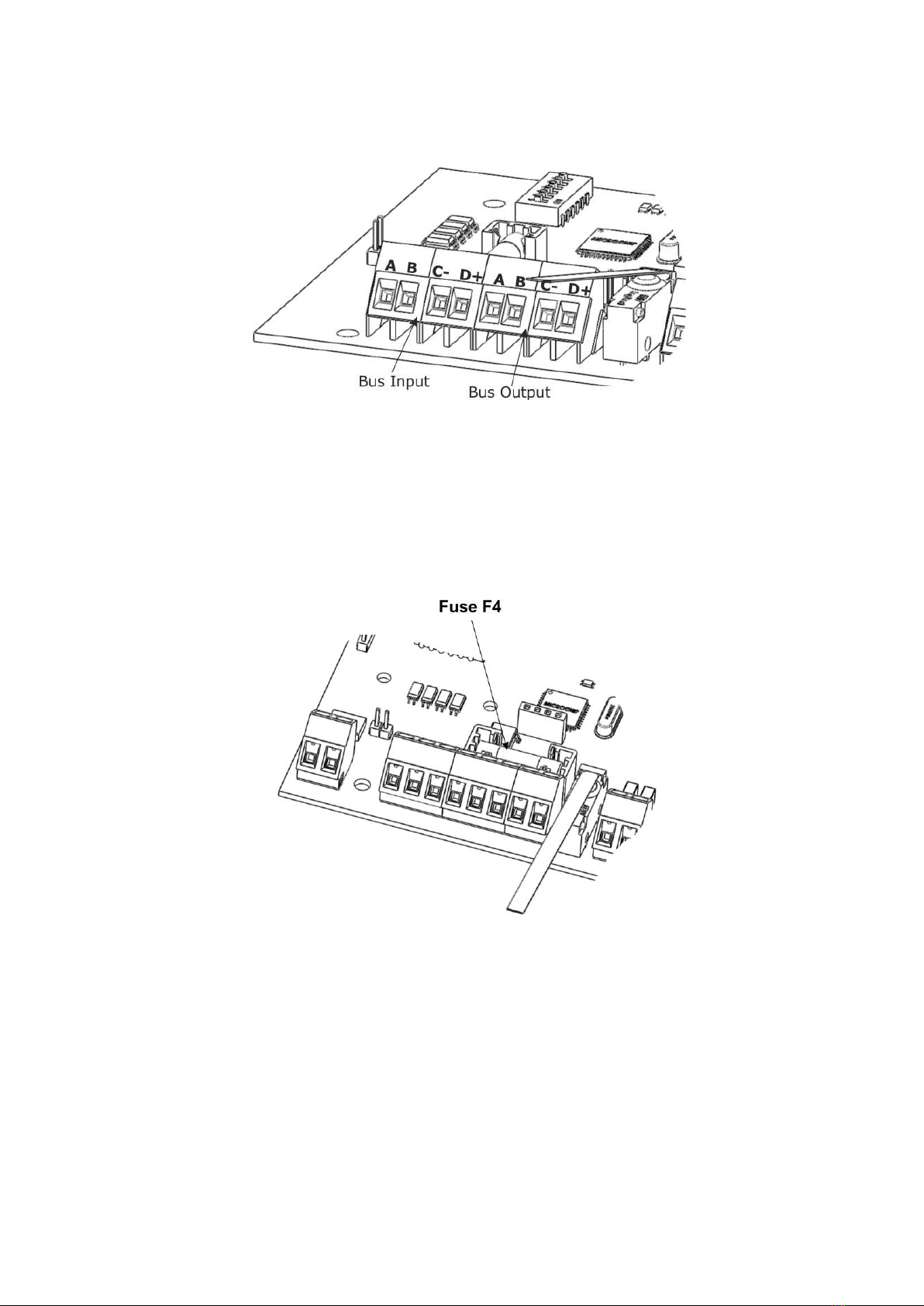

Description of the concentrator module.............................................................................7

Bus Input A B C D terminal block.................................................................................

Bus Output A B C D terminal block...............................................................................

Fuse F4.....................................................................................................................9

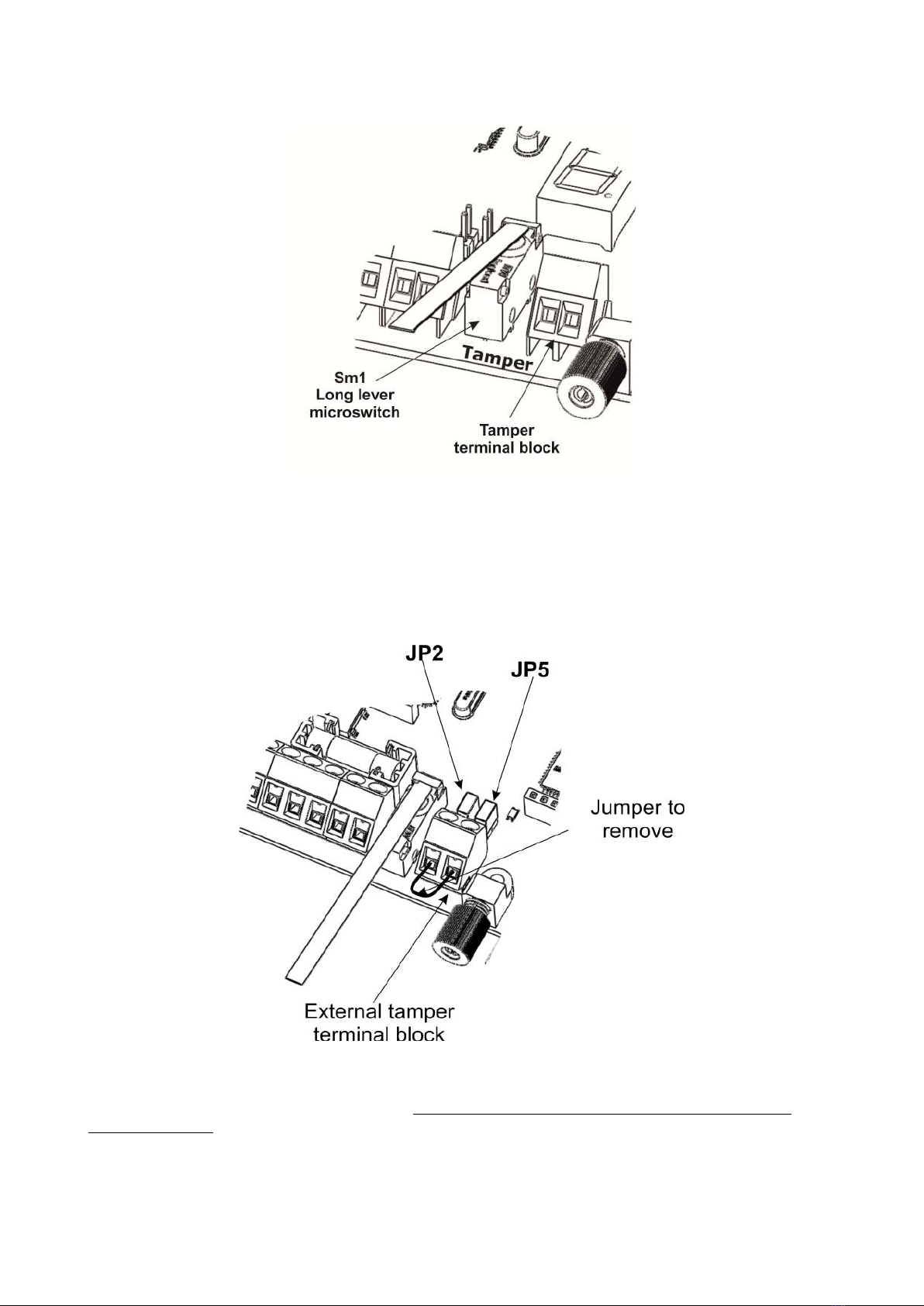

Tamper terminal block.................................................................................................9

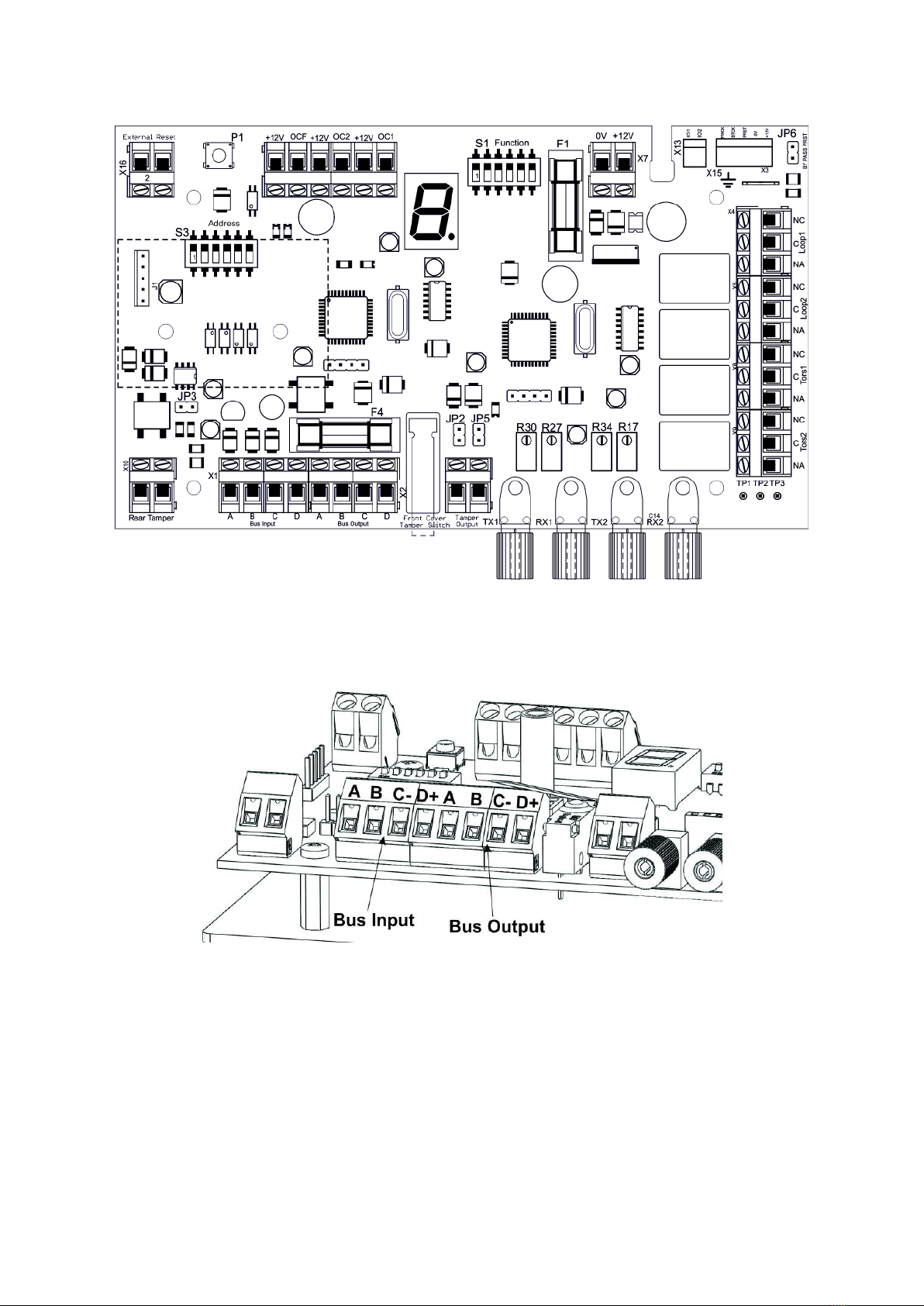

Fiber Optic TX and RX...............................................................................................10

Cutting and torsion fiber signalling relay......................................................................11

Reset button and External Reset terminal block............................................................12

Open Collector OC1, OC2 and OCF outputs..................................................................12

Using the OCF Open Collector output......................................................................13

Use first mode..................................................................................................13

Use second mode.............................................................................................14

Use third mode.................................................................................................15

Auxiliary power supply X7 terminal block.....................................................................16

Fuse F1...................................................................................................................16

JP6 e JP3 Jumpers....................................................................................................16

Dip-switch SW2 Function...........................................................................................17

Loop fiber adjustment ALM-6 15 and ALM-6 14...............................................................1

Fiber loop calibration.................................................................................................19

Primary calibration................................................................................................19

Fine calibration.....................................................................................................19

Dip-switch S3 Address...............................................................................................22

Addressing operation................................................................................................23

Jumper JP3..............................................................................................................24

Seven Segments Display...........................................................................................24

Wiring inside the container ...........................................................................................24

Cable gland on the container .....................................................................................25

Connection and passing of the optical fiber .................................................................26

Minimum curvature of the fiber..............................................................................2

Power Supply features...................................................................................................2

Terminal blocks on power supply module.....................................................................29

Autonomy of operation with battery backup.....................................................................30

TECHNICAL SPECIFICATIONS.........................................................................................31

Note:..........................................................................................................................32

Declaration of Confirmity...............................................................................................35

Installation and Programming Manual V1.2 3