2H REFRIGERANT

Charging the system

The charging of refrigerant section of the risk assessment template or equivalent should be carried out before

commencing refrigerant charging.

1. Evacuate the system and interconnecting pipework ensuring the service valves are fully open.

2. Allow the evacuated system to draw in the majority of the refrigerant charge.

3. The final charge should be adjusted with the system running.

4. All units are fitted with head pressure control. The link wire across the orange terminals allows the fan to operate at full

speed. THIS SHOULD BE REMOVED AFTER CHARGING

5. A random start delay of up to 1 minute occurs when mains is first applied. A 3 minute delay occurs between successive

compressor operations on all systems.

6. Refrigerant and polyolester oil should be introduced through the Schrader valve the service port on the suction service

valve on the outdoor unit. Ensure the refrigerant is the correct type, as shown on the rating plate. R454C must

always be added in the liquid state.

7. Run the system for a few minutes to allow it to stabilize. Check suction and head pressures.

8. Systems should not be overcharged, to avoid liquid return to the compressor

9. HEAD PRESSURE CONTROL ALCO (FSY-42S) & SAGINOMIYA (XGE-4C)

The head pressure controller is factory set to suit the refrigerant. It may be necessary to adjust this to suit site conditions,

to raise or lower the nominal head pressure.

ALCO (FSY-42S)

a. With the system switched off, connect a high pressure gauge to the liquid line service valve.

b. Switch on the system and run for a few minutes to stabilise.

c. The head pressure should be approximately:

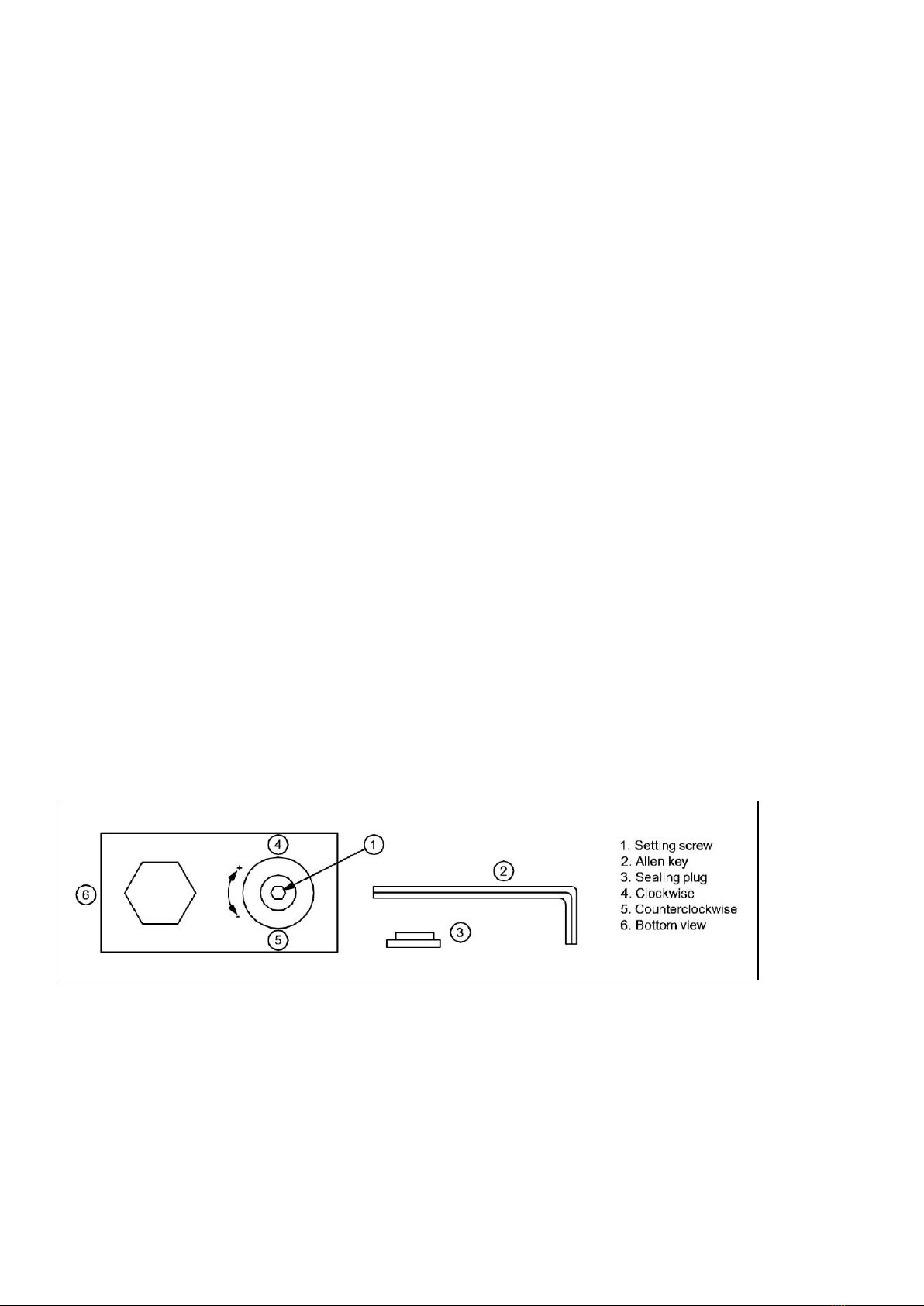

R454C: 210-220 psig (14.0-15.2barg) to achieve this remove sealing plug and insert 2mm or 5/64”

allen key into setting screw. Turn allen key clockwise (+) or counter clockwise (-) to readjust the setting.

NOTE: The condenser fan may stop if the operating pressure drops below 200 psig (13.8 barg)

Do not turn setting screw more than 3 turns clockwise (+3).

Pressure changes per turn of adjusting screw:

Pressure change: 9.2 … 21.2 bar:

Clockwise ~ +2,5 bar, counter clockwise ~ -2,5 bar

After adjustment, re-insert sealing plug and make sure that it is properly fitted. IP65 protection

requires firmly sealed plug

NOTES:

Tolerances for condensing temperatures setpoint: ±2K