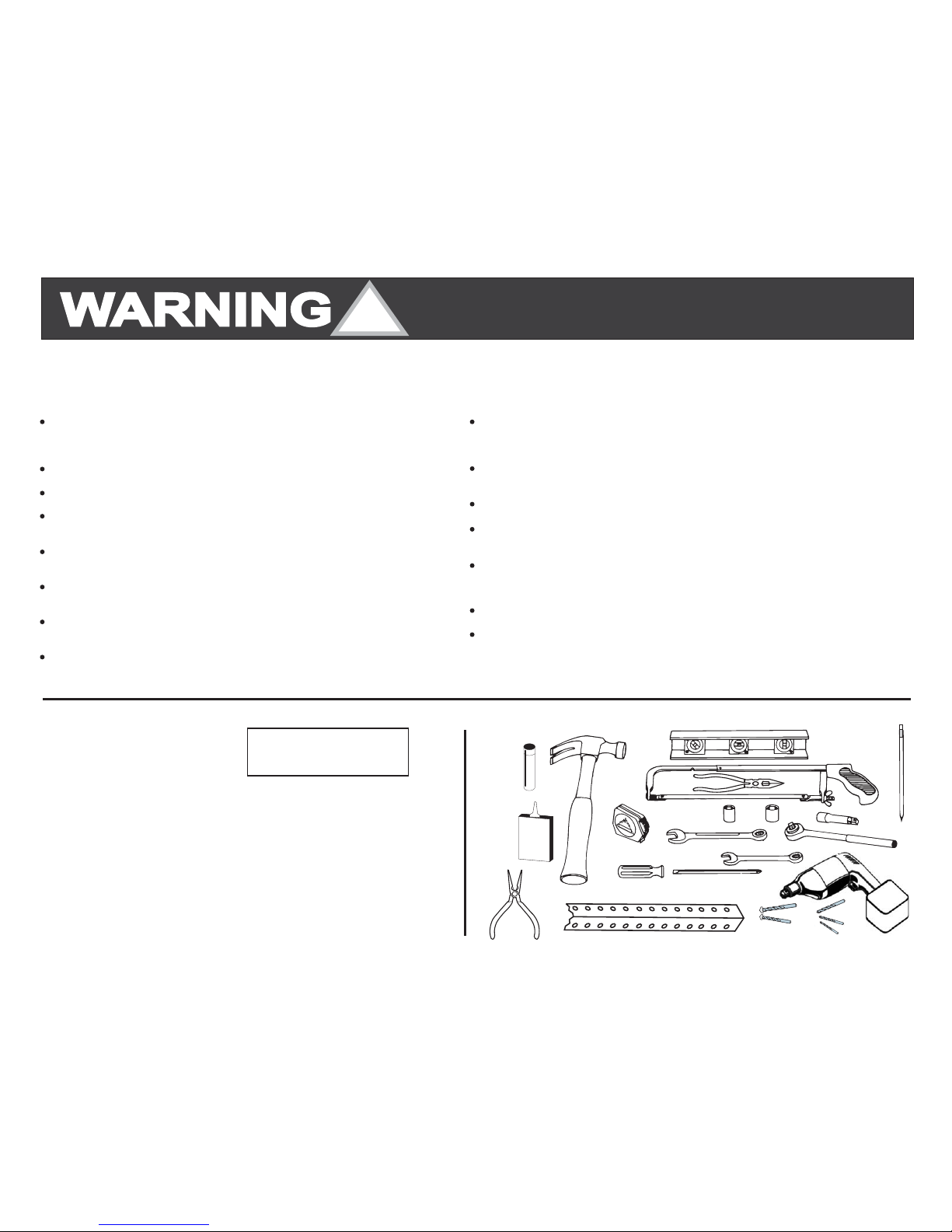

THE FOLLOWING ITEMS ARE HELPFUL TO COMPLETE A SATISFACTORY MARTIN GARAGE DOOR AND OPENER INSTALLATION:

Hammer

Level (magnetic)

Hacksaw

Wire Cutters

18’ (5.5) measuring tape

Socket wrench set for 7/16“ (11), and 9/16” (14) with 3“ (76) extension

Regular and phillips screwdriver

End wrench set for 7/16“ (11), and 9/16” (14)

10/40 motor oil lubricant

Wax lubricant (paraffin, candle, etc.)

Cordless drill with 1/8“ (3), 13/64” (5), 1/4” (6) bits

plus 1/4” and 3/8” (6 and 10) masonry bits

Step ladder (not shown)

Pencil

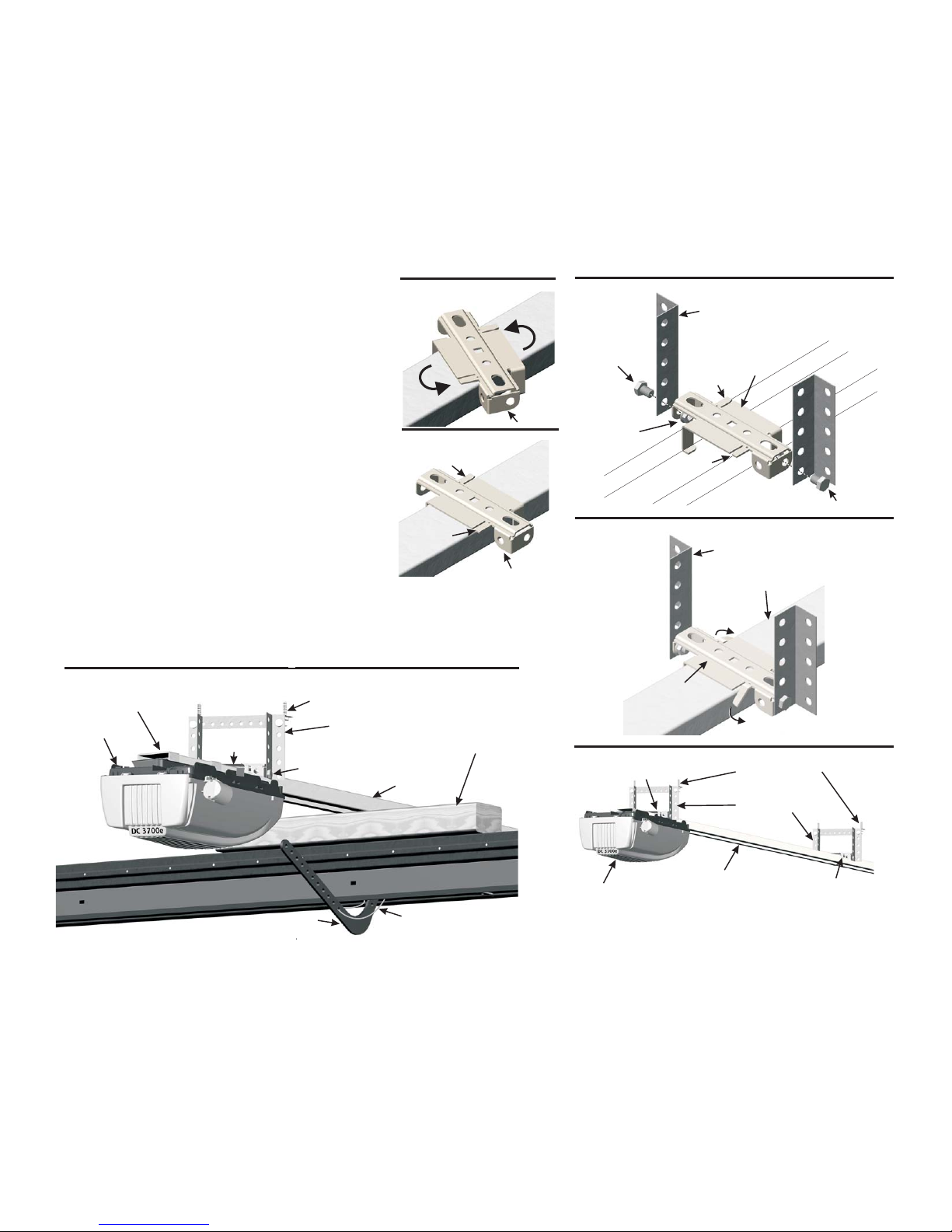

Punched angle opener hanger: 8' X 1-1/4" X 1-1/4" (2440 X 32 X 32)

Needle nose piler and wire stripper.

NOTE: Bolts, lock nuts and lag screws for fastening the punched angle are

furnished with the door opener hardware fasteners.

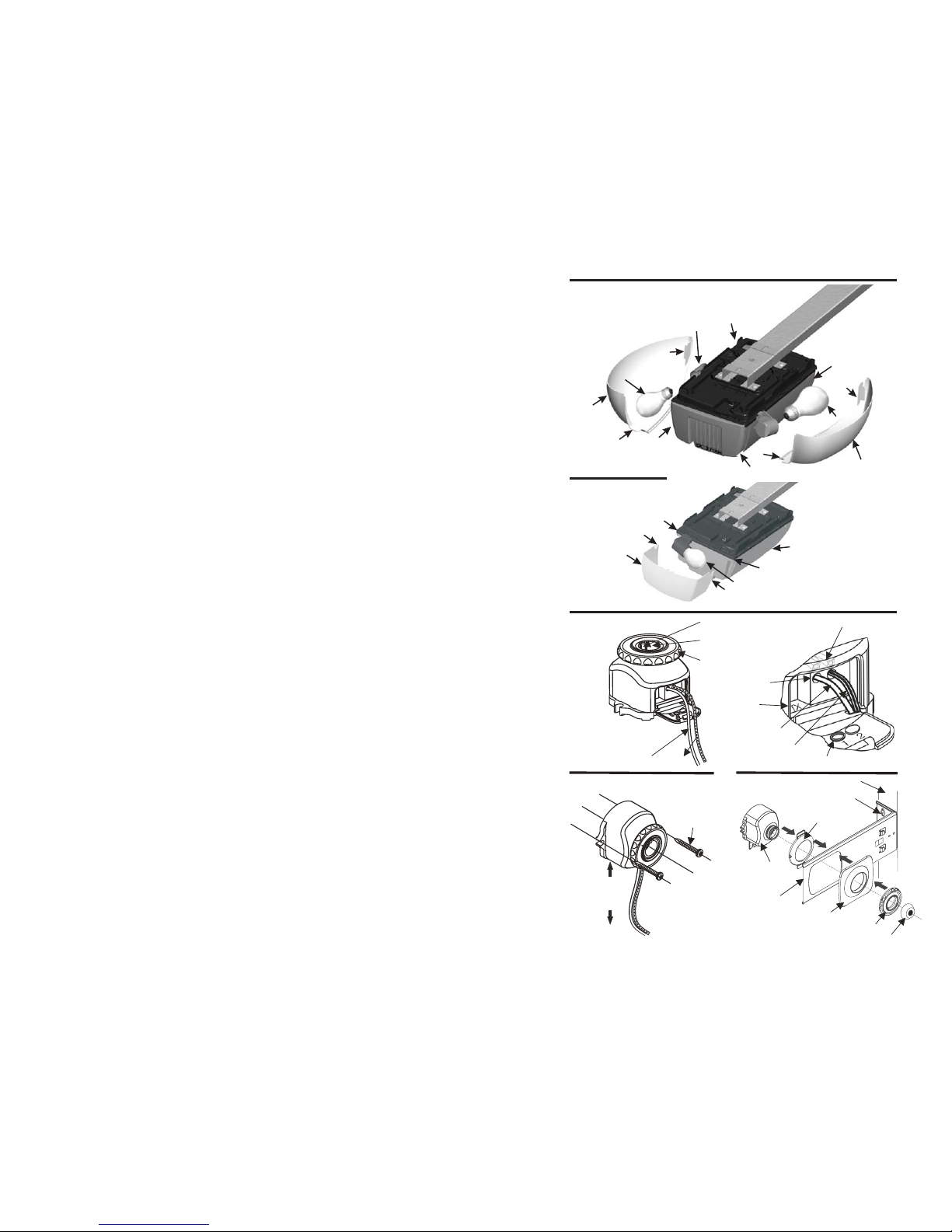

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

2.

3.

6.

9.

WAX LUBE

10/40

MOTOR

OIL

11.

10. 4.

1.

7.

TM

GARAGE DOORS

ARTI

MN

14.

8.

6.

5.

13.

ALL MEASUREMENTS IN

PARENTHESIS ( ) ARE

MILLIMETERS IN THIS

INSTRUCTION MANUAL.

!

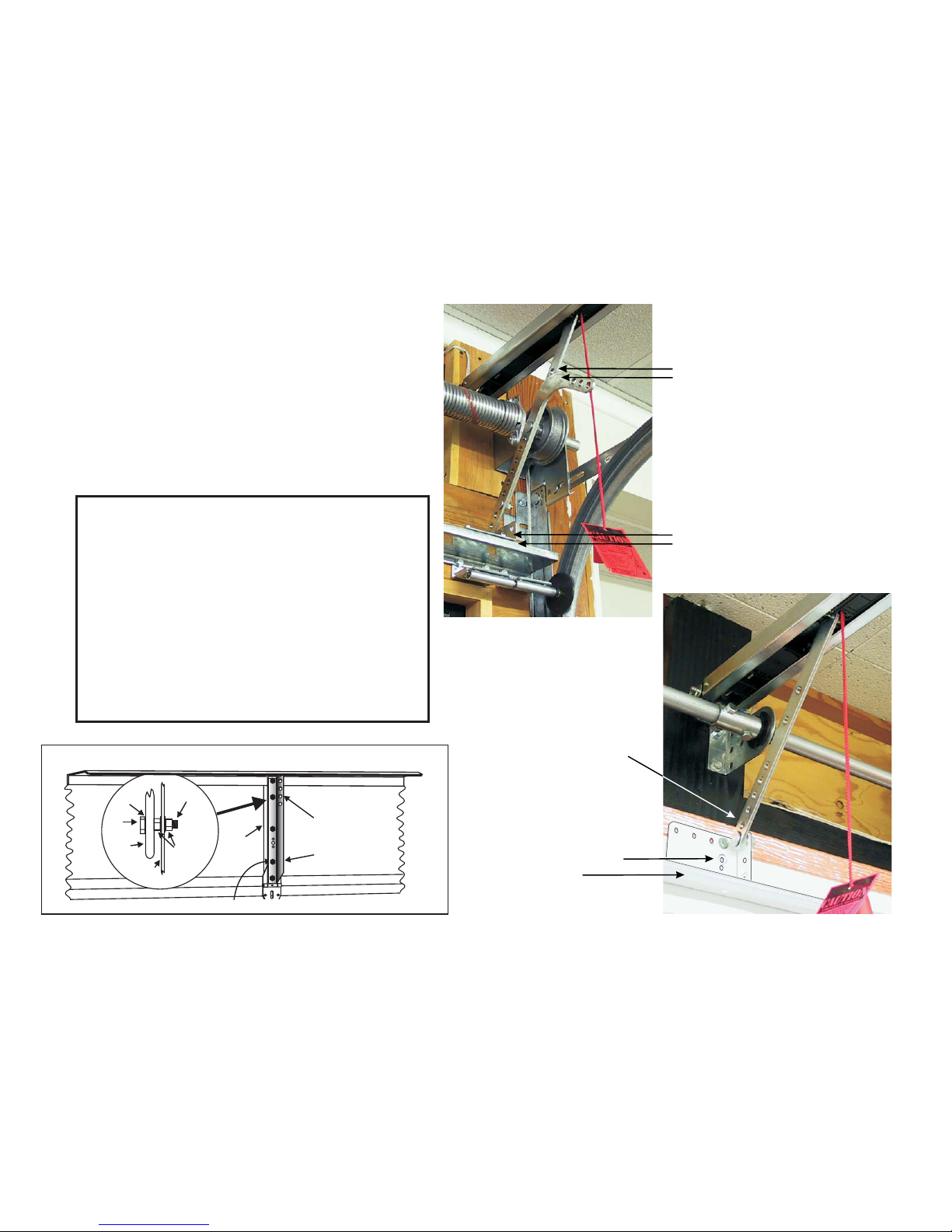

Do not install this opener or any other opener on "HIGH RISK" garage doors that may cause severe injury, entrapment or death!

See back page for serious injuries which may occur if “HIGH RISK” areas are left uncorrected. Martin Garage Doors are “Low Risk”.

Untrained or Negligent

Garage door

Locks

Locate

Emergency release tag

Risk of electrical shock

Entrapment and warning labels

Where possible

Installing, Adjusting and Servicing can be Dangerous! The

garage door springs and related parts can cause serious injury or death! IF YOU ARE

UNSURE, CALLA TRAINED MARTIN DOOR DEALER!

should be balanced and easy to open and close by hand.

should be disabled and pull down ropes should be removed.

wall control/push button within sight of door, at min. height of 5' (1520) so

small children cannot reach it, and away from all moving parts of door. See Step 8.

should be installed above knob and adjusted to about

6' (1830) above the floor.

is explained in Step10. Do not connect opener to source

of power until instructed to do so.

should be installed next to the wall control/push

button as explained in Step 14.

, install the door opener 7’ (2130) or more above the floor.

IMPORTANT INSTALLATION, MAINTENANCE & SAFETY INSTRUCTIONS

Monthly,

Always

NEVER

Do not allow children

The emergency release

Monthly

If the Safety Reverse

check the opener's down cycle safety reverse. The door must reverse when it

contacts a 1 1/2" (38) high object (or a 2X4 board laid flat) on the floor, in line with the door

opener. A closing door must also reverse if the photo eyes are interrupted. See Steps 12,13.

keep the moving door in sight and away from people and objects until it is

completely closed. NO ONE SHOULD CROSS THE PATH OF THE MOVING DOOR.

GO UNDER A STOPPED, PARTIALLY OPEN DOOR

to operate or play with the garage door opener controls. Keep all

remote controls away from children.

should only be used when garage door is in the closed position.

Weak or broken springs may cause door to fall if released in the open position, increasing

the risk of severe injury or death. Use caution when using the release with door open.

visually check the lift cables, spring assembly, hardware, etc. for wear and stability.

or any other part of the garage door and opener system do not work

properly, or if you do not understand, call a trained Martin Door Dealer.

TO REDUCE THE RISK OF SEVERE INJURY OR

DEATH, READ AND FOLLOW ALL INSTRUCTIONS

TO REDUCE THE RISK OF SEVERE INJURY OR

DEATH, READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE IMPORTANT INSTRUCTIONS

COPYRIGHT © 2007 MARTIN DOOR 5

15.