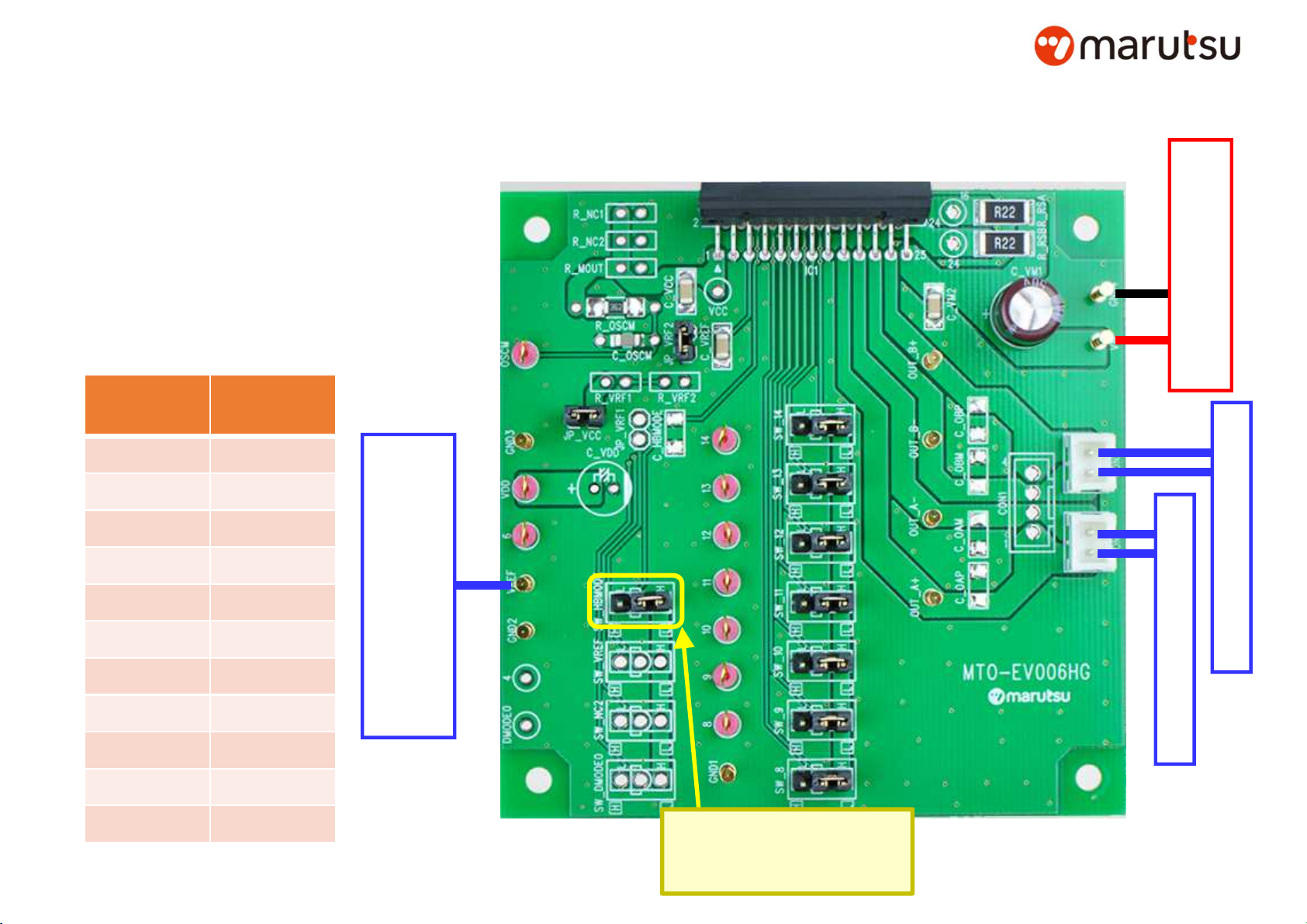

Connection of Evaluation Board 2

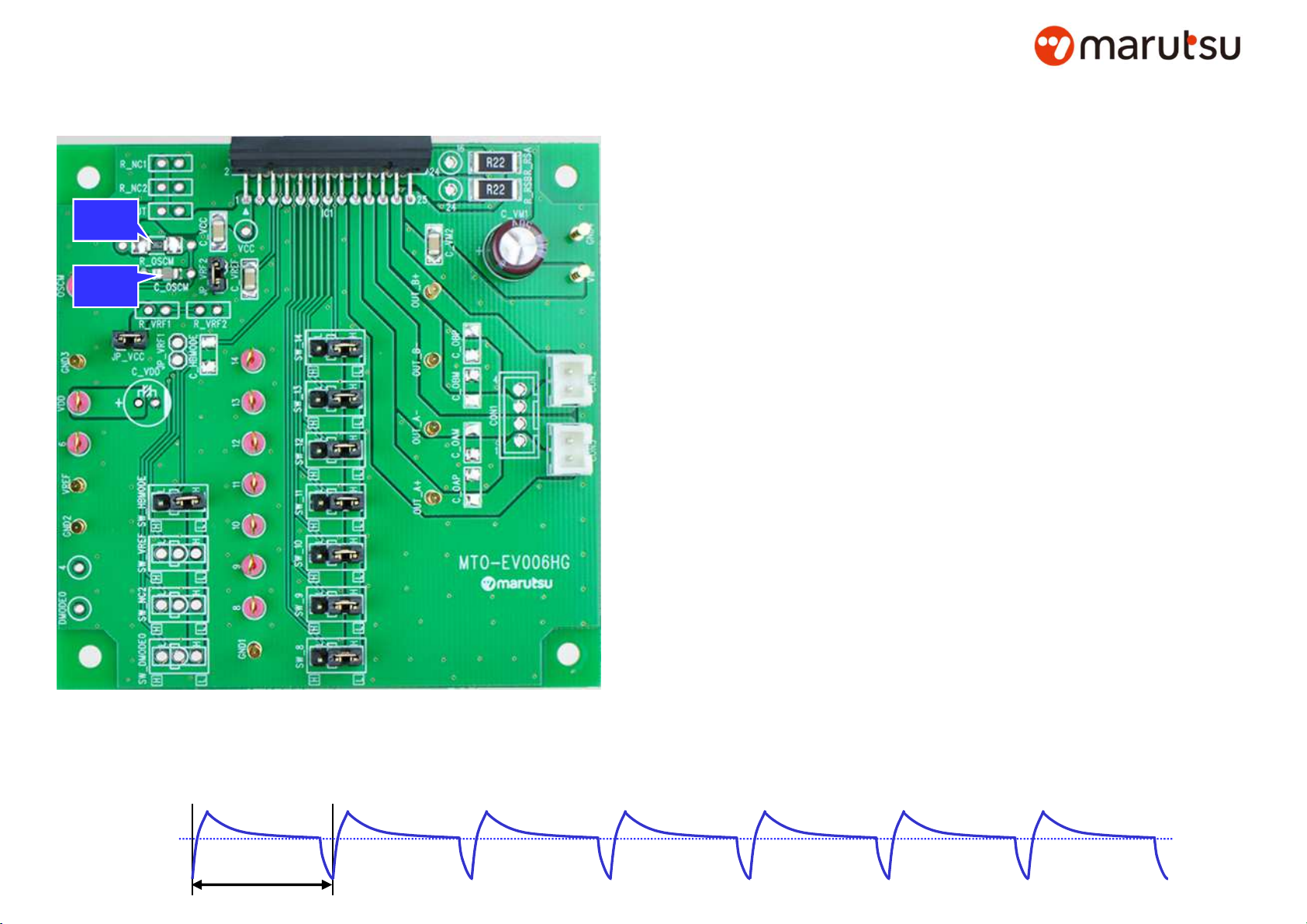

In use of Large Mode

③

③③

③

①

①①

①

④

④④

④

②

②②

②

⑤

⑤⑤

⑤

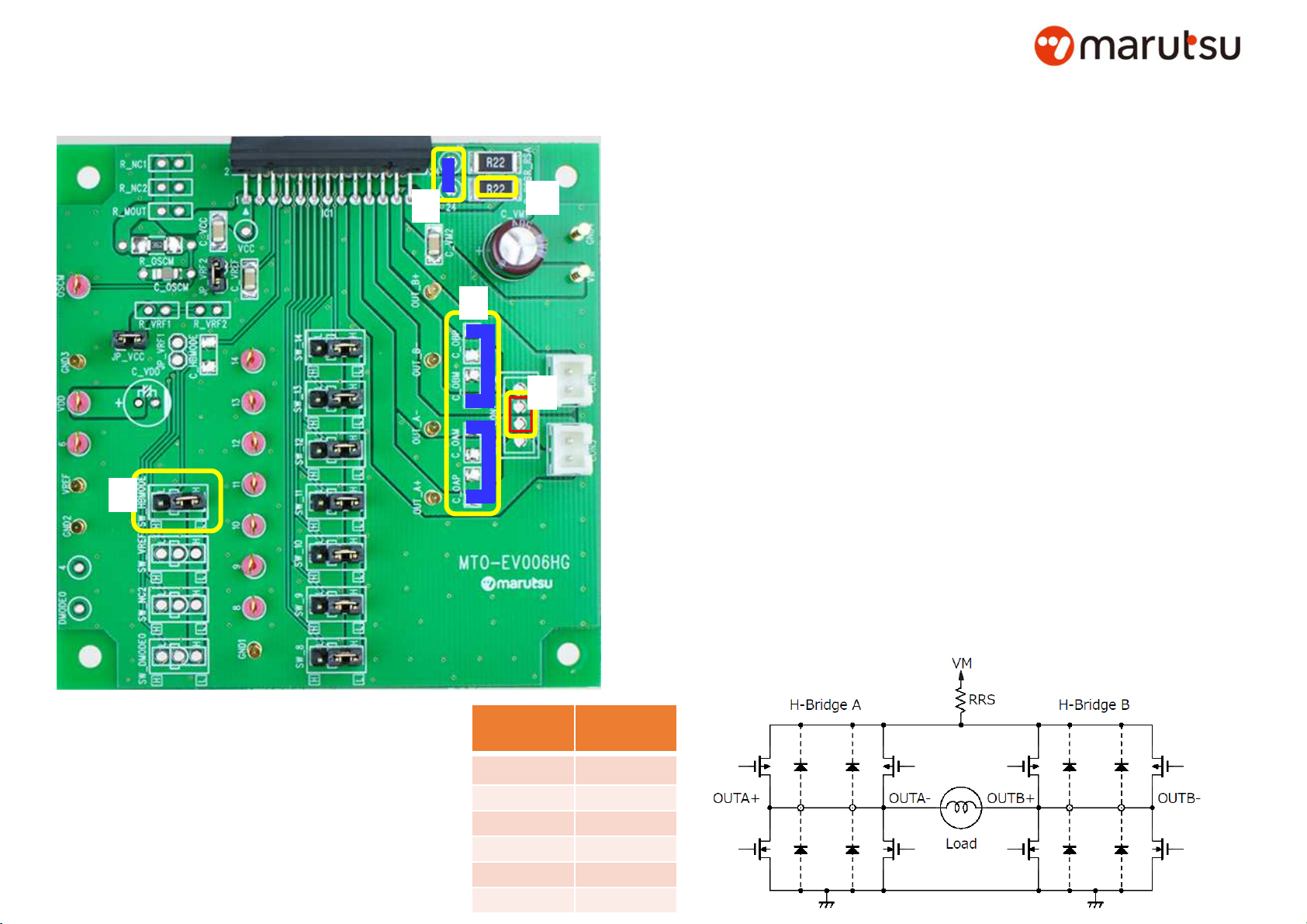

HBMODE

Large Mode is a parallel control function of the output

part, OUTA+ and OUTA-, OUTB+ and OUTB- are tied

in cascade as shown in the circuit diagram below.

n that case, the current balance of A-ch and B-ch

becomes important in operation due to high current.

n use of this mode please make the following changes.

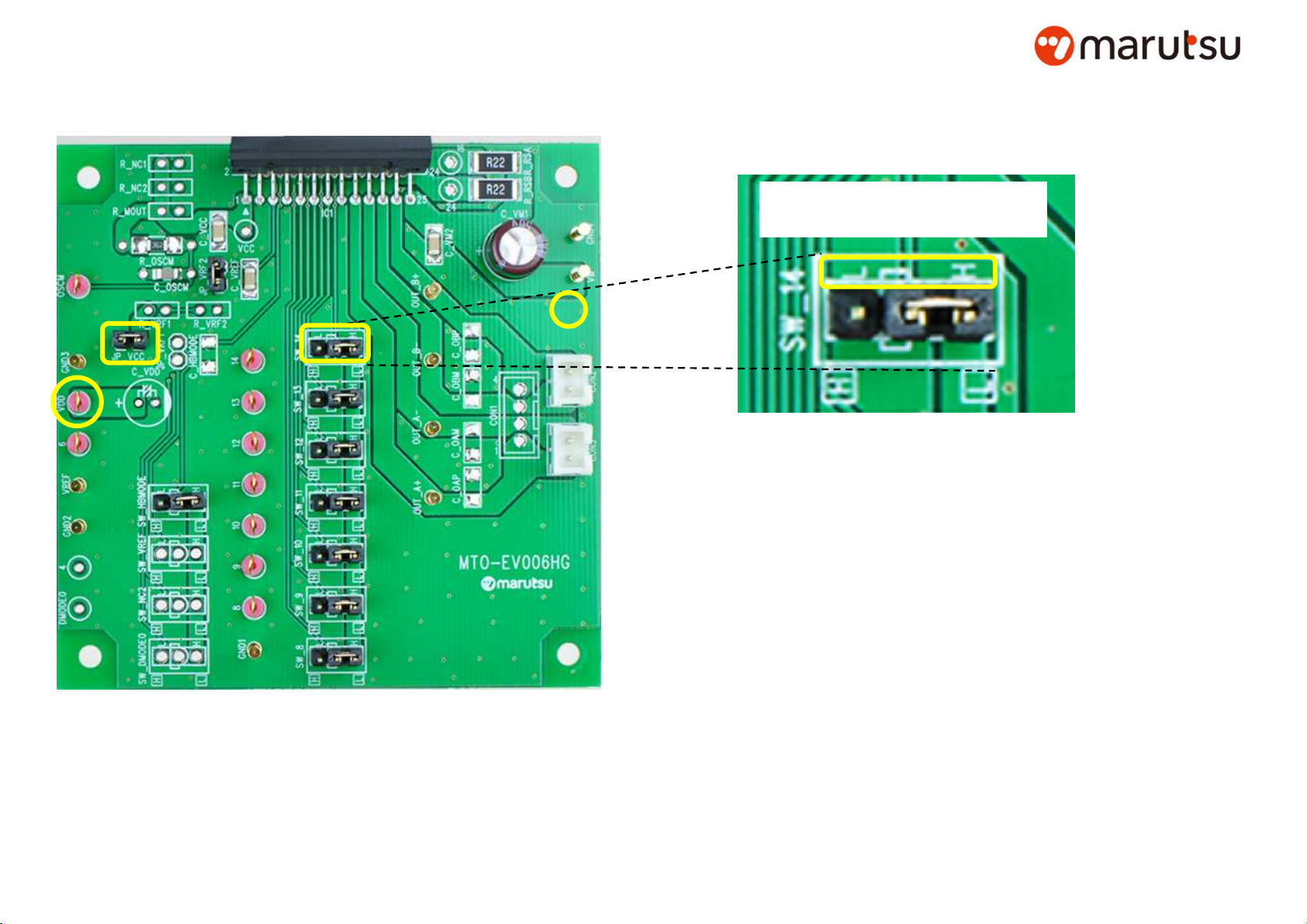

①Mounting the motor connector

Please mount a connector at the two pins in the middle.

②Shorting of RSA terminal and RSB terminal

By using the holes for check pin mounting, RSA terminal and

RSB terminal are shorted with wiring.

Mounting of 0 Ω resistor (short resistor)

To commonize RSS, by utilizing the rounds for C_OAM, C_OAP

and C_OBM, C_OBP, OUTA+ and OUTA-, OUTB- and OUTB+

are shorted with wiring etc.

④Removal of resistor R_RSB

The resistor R_RSA becomes RRS in the circuit diagram below.

The constant current control value is set according to the input

voltage Vref.

⑤Set HBMODE to "H" level

In order to input "H“ level, please set a short pin to "H“ side.

【Changed unction of Terminal 】

n Large Mode, the functions of

each terminal are changed as

shown in the table on the right.

Silk

name

Signal

name

8 IN1

9 IN2

10 PWM

11 Non use

12 Non use

13 Non use 1 Large DC Motor operation

A-ch and B-ch are connected

in parallel to form one H-Bridge,

and it drives one motor.