-6-EN

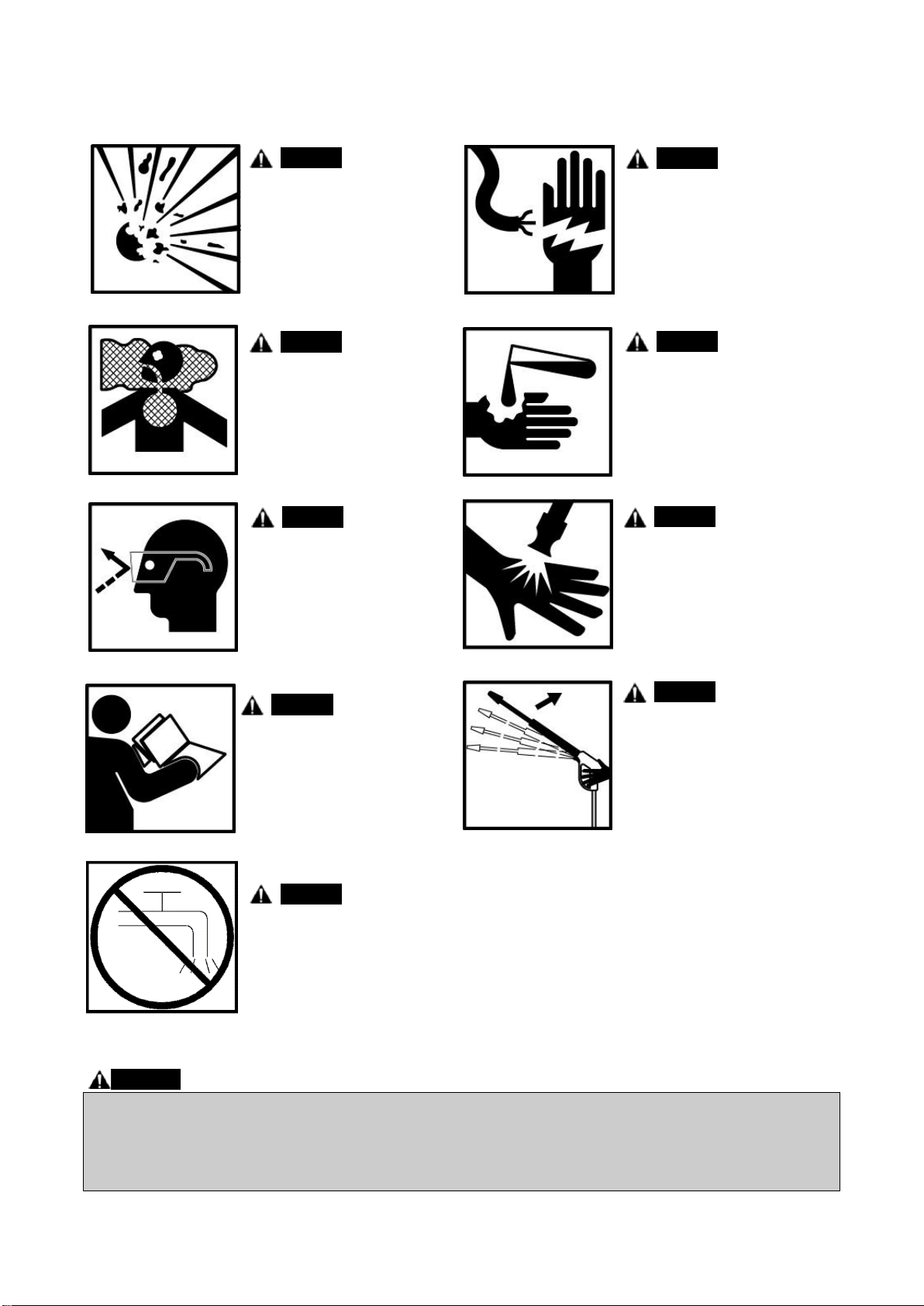

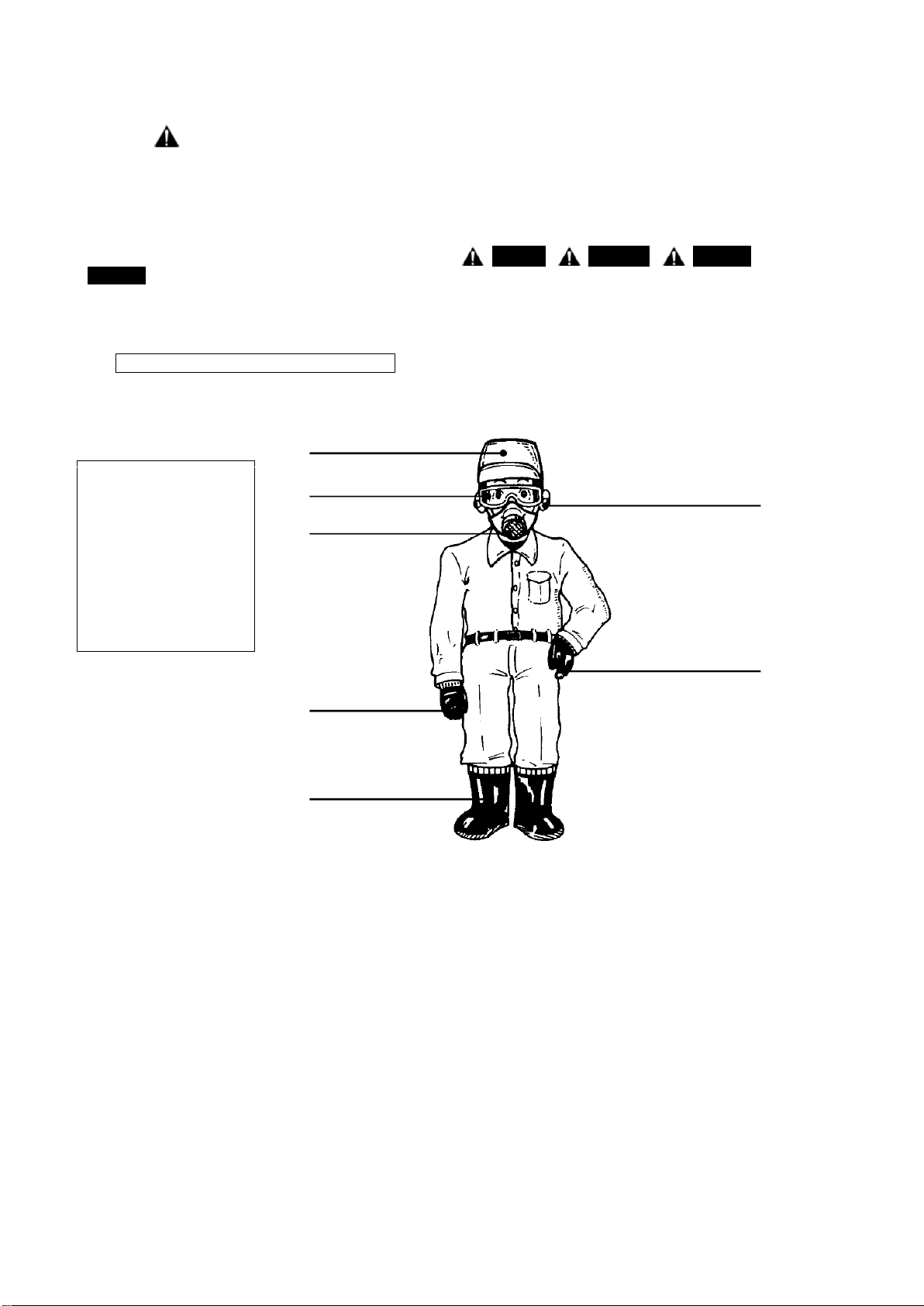

Do not touch with bare hands any of the male threads connecting the water suction hose, high-pressure

hose, spray wand and spray gun. Doing so may result in injuries. Wear protective gloves when

connecting these components.

Do not attempt to modify this product or create accessories not recommended for use with this product.

Any such alteration or modification is misuse and could result in a hazardous condition leading to

possible serious personal injury.

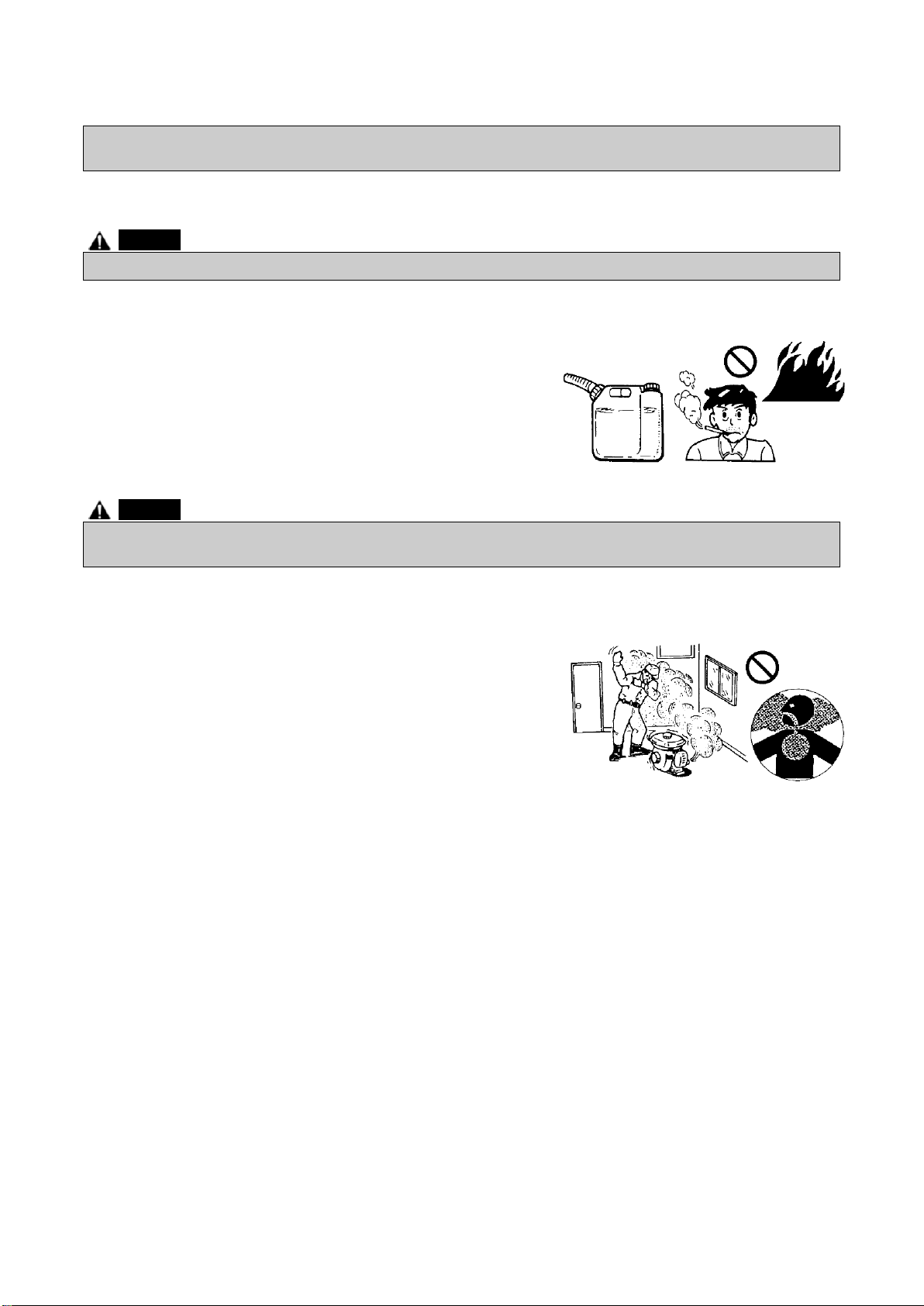

Do not use acids, alkalis, solvents, flammable material, bleaches, or industrial grade solutions in this

product. These fluids can cause chemical injuries to the operator and serious damage to the machine.

Precautions on moving

Do not move the machine while in operation. Stop the engine and wait for it to cool sufficiently before

moving the machine. Failure to do so may result in fire or burns.

This machine is heavy. To avoid back injury, lift the machine with your legs, not your back, and get help

when needed.

Do not tilt the machine more than necessary or take your hands off the machine while moving. The

machine may tip over and cause injuries.

When moving the machine with vehicle, drain fuel and secure the machine on the vehicle. Failure to do

so may cause of accidents caused by rollover or moving the machine.

Precautions on installation

Do not block the muffler side of the engine, when installing the machine. Failure to do so may result in

fire due to the heat of the exhaust gas, and can cause carbon monoxide poisoning by exhaust gas.

Exhaust port of the muffler must be directed to a well-ventilated open area.

Keep the machine free of grass, leaves, twigs, cloth rags, or grease to avoid a fire hazard.

Must be installed to be able to manipulate the machine easily. It may cause a delay in an emergency

response.

Install the machine on a horizontal, flat surface in a place not subject to water and droplets during work,

by keeping a sufficient distance away from the object to be cleaned. If the machine is used while tilted,

fuel spillage may result and the machine may move or tip over due to vibration. To avoid a hazardous

environment, do not install the machine into any muddy location or near objects that may fall.

Precautions pre-operation

Be sure to inspect the machine before operation to prevent potential dangers and problems during

work.

Check the high-pressure hose before connecting it and confirm that it is not damaged.

Check if the high-pressure hose and spray gun and spray wand are connected properly. Loose

connection may cause pressure to leak or the spray wand to come off and fly off, resulting in injuries.

Check bolts and nuts for looseness before each use. A loose bolt or nut may cause serious machine

problems.

Check for fuel and oil leaks. It may cause fire.

Precautions on cleaning operation

Keep children and visitors away from work area. All the assistants should wear safety goggles and be

kept a safe distance from work area.

Do not overreach or stand on unstable support. Keep proper footing and balance at all times.

Choose a working location as flat as possible and clear away unnecessary objects nearby. Exercise

caution to avoid slipping or falling.

If necessary, cover around the cleaning target with sheets to

protect the building, etc., from water droplets.

Precautions during operation

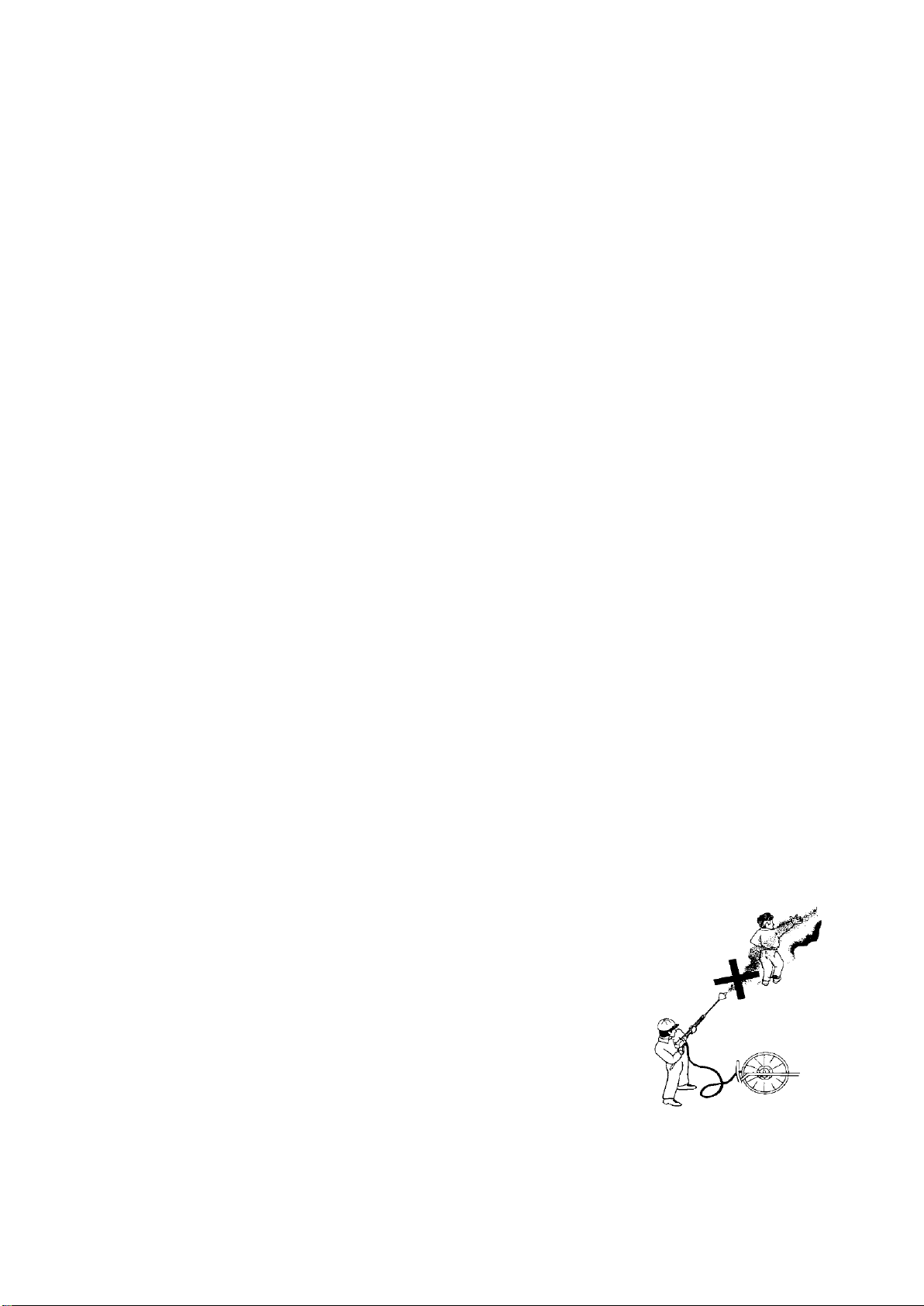

High-pressure water jets can be dangerous if subject to misuse.

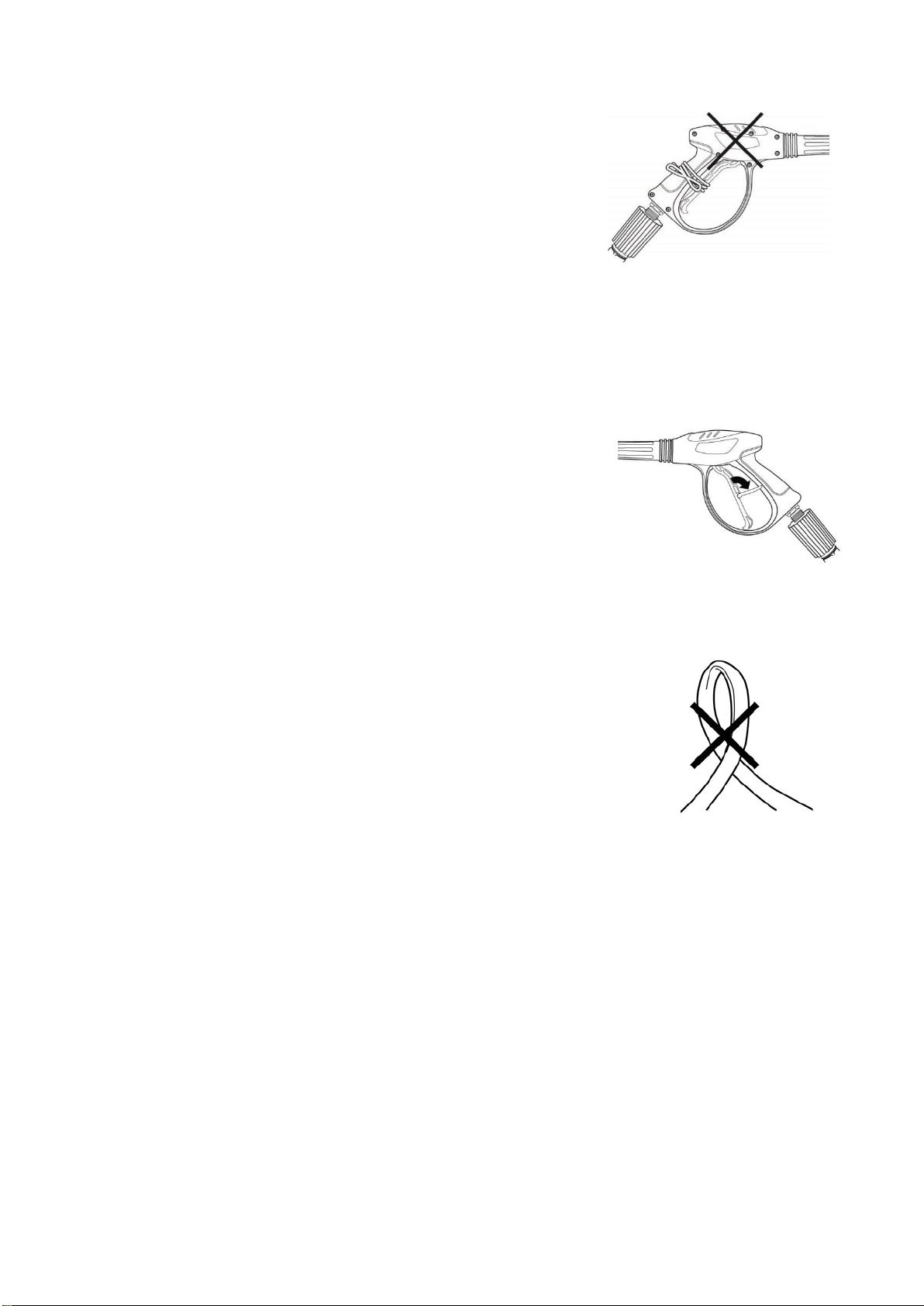

The water jet stream must not be directed at persons, animals,

electrical devices or the machine itself. Water pressure in the

system will not be released even if the engine is stopped. Be

sure to pull the trigger to release the water pressure in order to

avoid accidents due to sudden water jet.

Do not put your hands or feet, the body into the high-pressure

water jet stream. It may cause serious injuries.

Do not operate the equipment while barefoot or when wearing

sandals or similar lightweight footwear. It may cause serious

injury.

Never direct a water jet stream

toward people or animals, or

any electrical device.