Marvel MLCP215-SS01B User manual

OWNER’S GUIDE & SERVICE MANUAL

MARVEL UNDERCOUNTER REFRIGERATION

Model: MLCP215-SS01B

WELCOME

Welcome to the Marvel Experience!

Congratulations on your purchase of the industry’s quietest

clear ice machine with the best ice clarity and purity. Your

new investment is protected by a limited warranty for the

rst year, and hermetically sealed refrigeration system parts

are covered for an additional 4 years.

Here’s your guide to the operation and maintenance of your

Marvel Clear Ice Machine to ensure years of enjoyment. If

you have any questions, please contact Marvel Customer

Service or Tech Support at:

Phone: (616) 754-5601

Email:

Got a Marvelous Design?

We would love to see how your Marvel product looks in its

new home. You can send us photos of your installed

might feature your Marvel home design on our website and

social media!

Warranty Registration

It is important you register your product warranty after

taking delivery of your appliance. You can register online at

www.marvelrefrigeration.com.

The following information will be

required when registering your

appliance:

Serial Number

Date of Purchase

Dealer’s name and address

The serial number can be found on the serial plate which is

located inside the cabinet on the left side near the top.

Online registration

available at

marvelrefrigeration.com

TABLE OF CONTENTS

Tip: Click on any section below to jump directly there

Safety

Important Safety Instructions

Installation

Unpacking Your Appliance

Electrical

Cutout & Product Dimensions

Side-by-Side & Stacking Installations

Door Reversal

Installing The Water Supply

Maintenance

Care and Cleaning

Long-Term Storage/Winterization

Operating Instructions

Using Your Electronic Control

Ice Maker Operation

Service

Obtaining Service

Troubleshooting

Wire Diagram

Product Liability

Warranty Claims

Ordering Replacement Parts

R600a Specifications

System Diagnosis Guide

Compressor Specifications

Control Operation - Service

Thermistor

Warranty

3

IMPORTANT SAFETY INSTRUCTIONS

Important Safety Instructions

Warnings and safety instructions appearing in this guide

are not meant to cover all possible conditions and

situations that may occur. Common sense, caution and

care must be exercised when installing, maintaining or

operating this appliance.

Recognize Safety Symbols,

Words and Labels

!WARNING

WARNING - You can be killed or seriously injured

if you do not follow these instructions.

!CAUTION

CAUTION -Hazards or unsafe practices which could

result in personal injury or property/product damage.

NOTE

NOTE -Important information to help assure a

problem-free installation and operation.

!WARNING

State of California Proposition 65 Warning:

This product contains one or more chemicals known

to the State of California to cause birth defects or

other reproductive harm.

!WARNING

State of California Proposition 65 Warning:

This product contains one or more chemicals known

to the State of California to cause cancer.

!WARNING

WARNING - This unit contains R600a (isobutane)

which is a ammable hydrocarbon. It is safe for

regular use. Do not use sharp objects to expedite

defrosting. Do not damage refrigerant circuit.

4

UNPACKING YOUR APPLIANCE

!WARNING

EXCESSIVE WEIGHT HAZARD

Use two or more people to move product.

Failure to do so can result in personal injury.

Remove Interior Packaging

Your appliance has been packed for shipment with all parts

that could be damaged by movement securely fastened.

Remove internal packing materials and any tape holding

internal components in place. The getting started guide is

shipped inside the product in a plastic bag along with the

warranty registration card and other accessory items.

Important

Keep your carton and packaging until your appliance has

been thoroughly inspected and found to be in good condi-

tion. If there is any damage, the packaging will be needed

as proof of damage in transit. Afterwards, please dispose of

all items responsibly.

!WARNING

WARNING - Dispose of the plastic bags which can

be a suocation hazard.

Note to Customer

This merchandise was carefully packed and thoroughly

inspected before leaving out facility. Responsibility for its

safe delivery was assumed by the retailer upon acceptance

of the shipment. Claims for loss or damage sustained in

transit must be made to the retailer.

DO NOT RETURN DAMAGED MERCHANDISE TO THE

MANUFACTURER - FILE THE CLAIM WITH THE

RETAILER.

NOTE

!CAUTION

If the appliance was shipped, handled or stored in other

than an upright position for any period of time, allow the

appliance to sit upright for a period of at least 24 hours

before plugging in. This will assure oil returns to the

compressor. Plugging the appliance in immediately may

cause damage to internal parts.

!WARNING

WARNING - Help Prevent Tragedies

Child entrapment and suocation are not problems of

the past. Junked or abandoned refrigerators are still

dangerous, even if they sit outside for “just a few hours”.

If you are getting rid of your old refrigerator, please

follow the instructions below to help prevent accidents.

Before you throw away your old refrigerator or freezer:

• Take o the doors or remove the drawers.

• Leave the shelves in place so children may not

easily climb inside.

5

ELECTRICAL

Do not remove

ground prong

!WARNING

Electrical Shock Hazard

• Do not use an extension cord with this appliance.

They can be hazardous and can degrade product

performance.

• This appliance should not, under any

• circumstances, be installed to an un-grounded

• electrical supply. Do not remove the grounding

prong from the power cord.

• Do not use an adapter.

• Do not splash or spray water from a hose on the

appliance. Doing so may cause an electrical shock,

which may result in severe injury or death.

Electrical Connection

A grounded 115 volt, 15 amp dedicated circuit is required.

This product is factory equipped with a power supply

cord that has a three-pronged, grounded plug. It must be

plugged into a mating grounding type receptacle in

accordance with the National Electrical Code and

applicable local codes and ordinances. If the circuit does

not have a grounding type receptacle, it is the responsibility

and obligation of the customer to provide the proper power

supply. The third-ground prong should not, under any

circumstances, be cut or removed.

NOTE

Ground Fault Circuit Interrupters (GFCI) are prone to

nuisance tripping which will cause the appliance to shut

down. GFCI’s are generally not used on circuits with power

equipment that must run unattended for long periods of

time, unles required to meet local building codes and

ordinances.

6

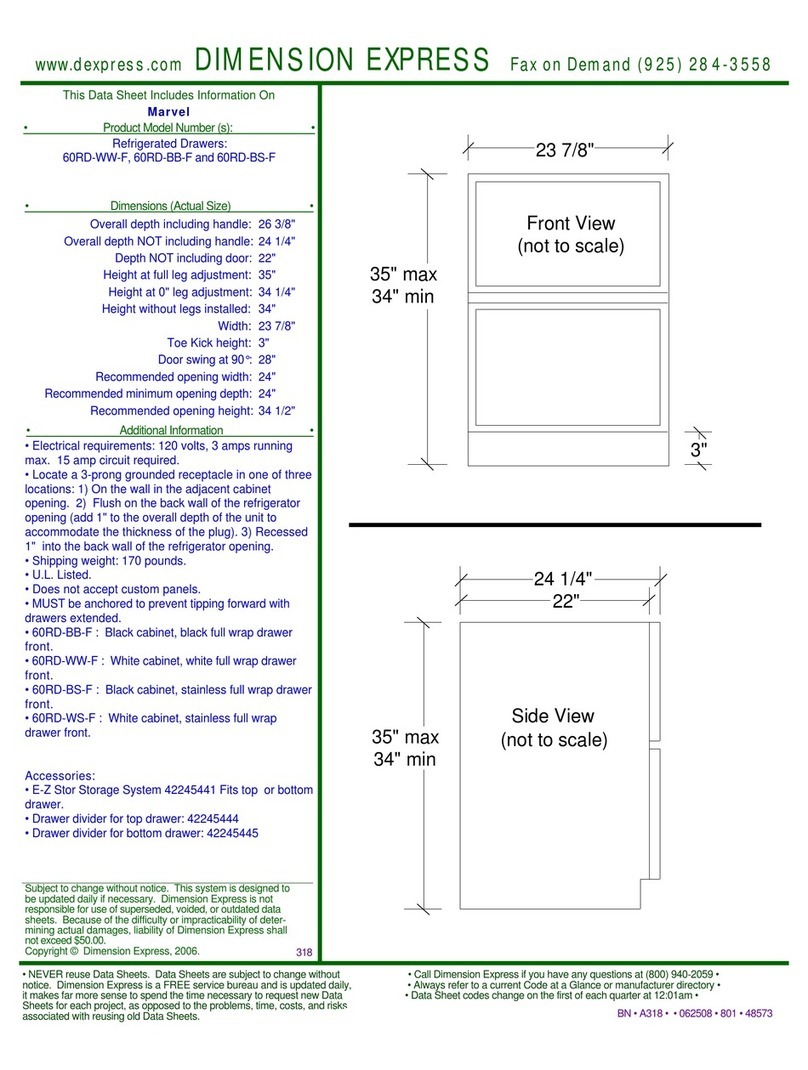

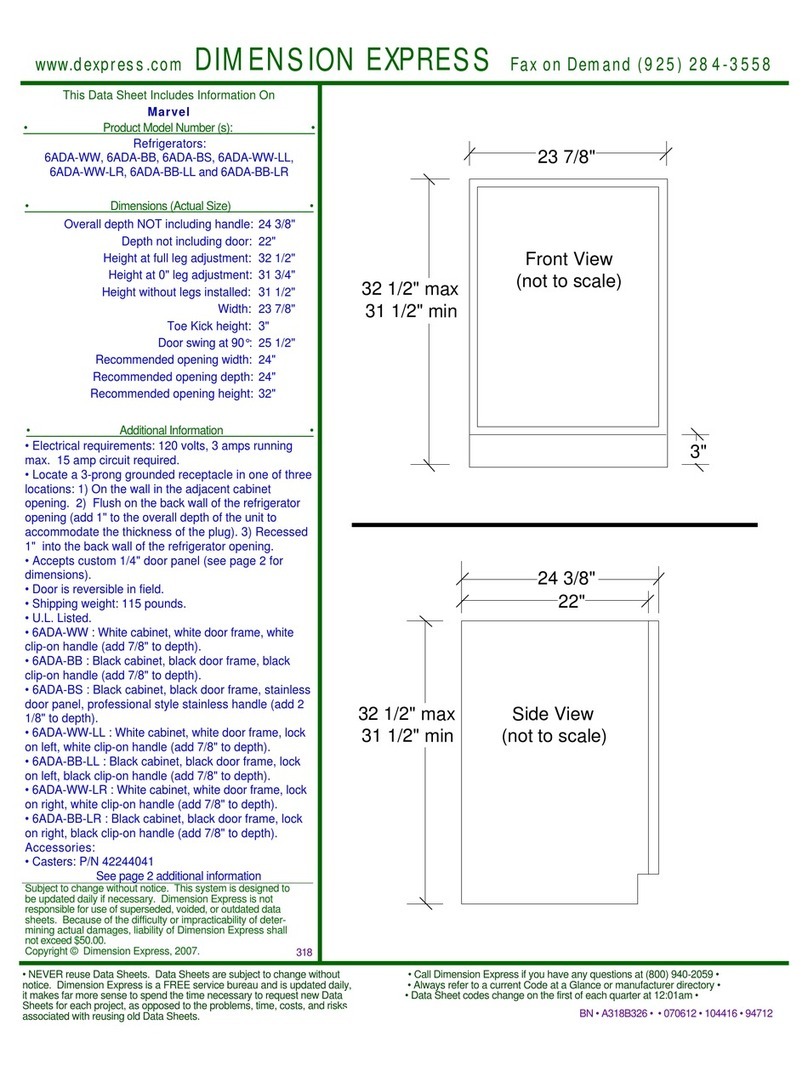

CUTOUT AND PRODUCT DIMENSIONS

ROUGH-IN OPENING DIMENSIONS CABINET DIMENSIONS

"A" "B" "C" "D" "E" "F" "G" "H" "J"

15"

(38.1 cm)

34" to 35"

(85.7 cm to 88.3 cm)

24"

(61 cm)

(37.8 cm)

(86.4 cm to 88.9 cm)

(60 cm)

1/2

(64.8cm)

(94.9 cm)

5/8

(42.2 cm)

Solid Door

Shown

"A"

"B"

"C"

"D"

"E"

If necessary, to gain clearance inside the rough-in

opening, a hole can be cut through the adjacent

cabinet and the power cord routed through this hole to

a power outlet. Another way to increase the available

opening depth is to recess the power outlet into the

rear wall to gain the thickness of the power cord plug.

Not all recessed outlet boxes will work for this applica-

tion as they are too narrow, but a recessed outlet box

equivalent to Arlington #DVFR1W is recommended for

this application.

7

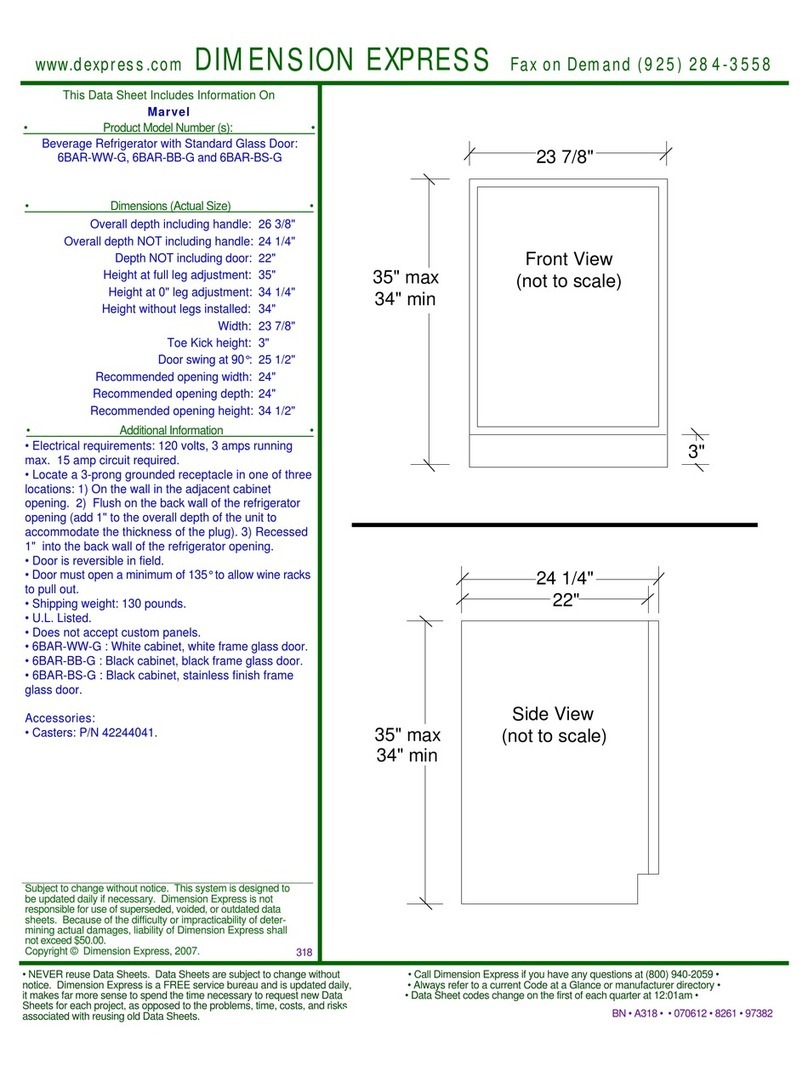

CUTOUT AND PRODUCT DIMENSIONS

PRODUCT DATA

ELECTRICAL

REQUIREMENTS #

PRODUCT

WEIGHT

115V/60Hz/15A 105 lbs

(47.6 kg)

Minimum rough-in opening required is to be larger than the

adjusted height of the cabinet.

A grounded 15 amp dedicated circuit is required. Follow all

local building codes when installing electrical and

appliance.

Glass Door

Shown

"F"

2112"

(54.6 cm)

"D"

"E"

"H"

"J"

"G"

8

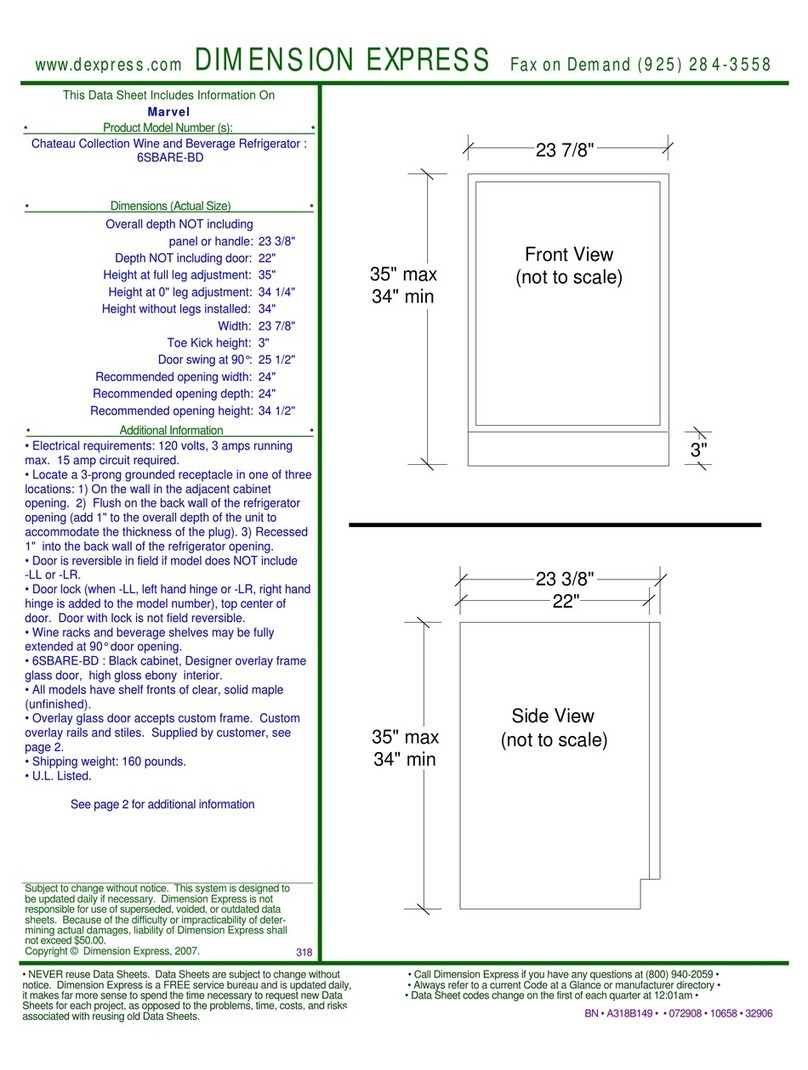

SIDE-BY-SIDE AND STACKING INSTALLATIONS

Side-by-Side Installation

Other Site Requirements

Units must operate from separate, properly grounded elec-

trical receptacles placed according to each unit's electrical

To ensure unobstructed door swing (opening both doors at

the same time), 1/4" (6.4 mm) of space needs to be maint-

ained between the units.

Hinge-by-Hinge Installation (Mullion)

When installing two units hinge-by-hinge, 13/16" (22 mm)

is required for integrated models. Additional space may be

needed for any knobs, pulls or handles installed.

Stainless steel models which include the standard stainless

handle will require 4-9/16" (116 mm) to allow both doors to

open to 90° at the same time.

Figure 10

Figure 11

Figure 12

Figure 13

Hinge-by-Wall Installation

When installing a unit hinge-by-wall or adjacent cabinetry,

7/16” (11mm) is required for integrated models. Additional

space may be needed for any knobs, pulls or handles installed.

¼”

13/16”

7/16”

4-9/16”

9

Door Reversing Instructions

Tools Needed:

• 1/8” Hex Key

• 5/32” Hex Key

• Phillips Screwdriver

Open door and remove Hinge Pin from the Upper Hinge using a 1/8” Hex Key tool making sure to steady the

Using a Phillips Screwdriver, remove the 6 screws from both the Upper and Lower Hinges and save for later steps

Once the Hinges are removed from the unit, using a Phillips Screwdriver, remove the Bushing Screw and Hinge Pin

Screw and save for later steps

On the Bottom Hinge, reattach the Bushing Screw and Hinge Pin Screw to the opposite side

Lower Hinge Bracket

(Before Reversal)

Upper Hinge Bracket

(After Reversal)

Lower Hinge Bracket

(After Reversal)

5. Using a 5/32” Hex Key, remove the Upper and Lower Hinge Brackets from the door saving all components.

screw into place

on the opposite side of the door (where plugs were removed). Remove the Cam Closer from the Lower-Hinge Bracket

and attach it to the opposite side

DOOR REVERSAL

Hinge Pin

Upper Right Hinge

Orientation

(Before Reversal)

Hinge Pin

Screw

Bushing

Screw

Lower Right Hinge

Orientation

(Before Reversal)

pper Left Hinge

Orientation

(After Reversal)

Upper Left Hinge

Orientation

(After Reversal)

Hinge

Bushing

Cam Closer

Upper Hinge Bracket

(Before Reversal)

10

6. Remove the door switch actuator tab from the door and attach it to the opposite side

DOOR REVERSAL

Door switch actuator tab

7. Reattach the Upper and Lower Hinges, and Hinge Brackets to opposite sides. Then install the door.

11

Control Function Guide

Function Command Notes

ON/OFF Press and release. Unit will immediately turn ON or OFF.

Toggle Interior Light - Door

Closed

Press and release to toggle interior light oper-

ation. Press again to deactivate. Light output 50%.

Enable Sabbath Mode Press and hold for 5 seconds and release.

The oF / oC symbol will fl ash briefl y after 5 seconds. Interior

light and display will go dark and remain so until user resets

mode - unit continues to operate.

Disable Sabbath Mode Press and release. Display and interior light return to normal operation.

Silent Mode (ice production

suspended for 3 hours) Hold and . Display will count down the hours:

Clean Mode Hold for 10 seconds to begin clean cycle. Unit will return to normal operation upon completion of clean-

ing. See “Care and Cleaning” section for more information.

Showroom Mode Hold and for 5 seconds.

The oF / oC symbol will fl ash. Display will be lit and interior light

will function. Unit will not cool. Repeat command to return to

normal operation.

Door Alert Notifi cation

When the door is left open for more than 30 minutes:

• A tone will sound for several seconds every minute

• will appear in display

• Close door to silence alert and reset

will appear in display

First Use

Initial startup requires no adjustments. When plugged in, the unit will

begin operating under the factory default settings. If the unit was turned off

during installation, simply press and the unit will immediately switch on.

To turn the unit off , press .

Electronic Control

Hold for 10 seconds to begin clean cycle.

USING YOUR ELECTRONIC CONTROL

12

ionized water are not recommended as they can adversely

Water

Supply

Line

Clamp and

Screw

Back view of

ice machine

NOTE

!CAUTION

INSTALLING THE WATER SUPPLY

Compression

Water

supply

line

Water supply

service loop

valve

Water valve

inlet

Water Supply

Observe and follow all local building codes when installing

this appliance.

This ice machine must be connected to a potable cold

water supply line. delivering water pressure between a

minimum of 20 psi and a maximum of 120 psi.

Use 1/4" copper tubing for your water supply which is

available at any local hardware or plumbing supply store.

Route the 1/4" copper tubing to suit your installation being

sure not to kink the tubing. Purchase enough copper tubing

length to allow a coil to be formed behind the unit for a

"service loop" which will allow the appliance to be pulled

out from the installation for servicing or cleaning. Connect

the copper tubing to the "top side" of a cold water pipe to

prevent the ice-maker from plugging with sediment.

ease servicing the appliance. NOTE: A SELF-PIERCING

TYPE VALVE IS NOT RECOMMENDED as they are prone

to clogging with sediment which will create pressure drop

reducing the water supply to the unit.

Connect the copper tubing water supply to the water valve

IMPORTANT: Secure the water supply line to the back of

the cabinet with the screw and strain relief clamp provided

in the corner of the back panel.

Make certain all connections are watertight after

installation. Form the tubing so that it will not vibrate

against the cabinet body or kink when your appliance is

moved in and out of position.

This ice machine is designed to make clear ice from the

majority of water sources on a daily basis. If your results

treated. A water specialist can recommend proper water

treatment.

!CAUTION

•

only. Do not use with plastic tubing.

•

13

The Ice Making Process

fractional freezing to form a slab of ice that is clear and

has less dissolved solids than the water it is produced

from. This is accomplished by running water over the cold

evaporator plate which gradually freezes

leaving the

dissolved solids in the residual reservoir water to provide

clear ice.

sheet is released and slides onto the grid cutter

cutter’s heated

wires. The water containing the dissolved minerals is

drained after each freezing cycle. Fresh water enters the

machine for the next ice making cycle.

Water distributor

Water

reservoir

Evaporator

Circulation

Pump

Reservoir

drain plug

Front

panel

Bin Level

Sensor

Ice

Grid Cutter

ICE MAKER OPERATION

14

when the ice supply is low or full and starts or stops the ice

making process accordingly.

power to the unit.

New Sounds

your household refrigerator. Because these sounds are

new to you they may be of a concern but are most likely

normal. The ice production process will make noises that

valves opening and closing. Following are some of the

A buzzing sound will be heard when the water valve

water line.

evaporator plate and into the water reservoir.

A "thud" when the ice slab is released from the

evaporator plate and slides onto the grid cutter.

"Clicks" when the cubes fall into the ice storage bin.

machine.

An air noise from the condenser fan.

Ice Production

In normal mode the ice machine will produce up to 39

pounds (17.7 kg) of clear ice in a 24-hour period when

installed in a 72°F ambient with a 55°F water supply.

24-hours of operation the unit will produce up to 39 lbs of

the ice storage bin is maintained at a temperature slightly

production rate will overcome the ice melt and the storage

NOTE

NOTE

The ice machine will keep producing ice until the ice

machine’s bin is full and will restart automatically when

ice needs to be replenished in the bin. The ice bin is

machine to run for 24-48 hours to accumulate ice in the ice

machine’s bin.

ICE MAKER OPERATION

15

!CAUTION

Forcing ice through the grid cutter will break the grid cutter

wires.

!CAUTION

Remove all ice

from the evaporator

plate and grid cutter

area that is not

embedded in wires

Clean reminder: CLEAN

NOTE

OFF

dependent on

your water source and usage. Normal ice production will

continue while the "CLEAN" reminder is displayed.

When

another

. If you choose to clean the appliance at

Clean mode:

recommended to clean your ice machine once every six

months. This simple cleaning routine will also ensure

water

Once you have your cleaner:

the

"ON/OFF" icon for 3 seconds. "OFF" will be displayed on

the control.

Use only Marvel-approved ice machine cleaner and follow

all label warnings and directions. Incorrect chemical

warranty.

To clean your ice machine you will need to purchase a

"nickel safe" ice maker cleaner. You can order ice machine

cleaner (part # S41013789) at marvelrefrigeration.com.

machine is ready to be cleaned.

While cleaning is needed, UI will alternate between "CL"

and "ICE" every 3000 cycles to indicate that the unit needs

to be cleaned. Over time, mineral build-up on the cold

evaporator plate can occur which can adversely affect the

quality of your ice. This build-up is dependent on your

water source and usage. Normal ice production will

continue while the "CLEAN" reminder is displayed. The

"CL" clean reminder will reset after your ice machine has

completed the cleaning cycle and will not occur for another

3000 cycles.

16

CARE AND CLEANING

Remove all of

the ice from

the ice bin

Remove the

black reservoir

drain plug from

the bottom of

the reservoir.

Splash shield

brackets

After the cleaning cycle is completed, verify that all build-up

has been removed. If not, repeat the clean cycle procedure.

Clean inside of unit with a clean, damp rag before ice mak-

ing cycle begins.

Replace the splash shield if removed.

Clean cycle time is approximately 45 minutes.

Ice maker will automatically return to ice making once clean

cycle is complete.

Pour cleaning solution slowly

onto the front edge of evaporator

plate behind the grid cutter.

Evaporator

plate

Grid cutter

Splash shield

Lift fascia door up to ac-

cess evaporator plate

Remove ice from bin. Pull plug from the reservoir. Once

reservoir is empty, replace plug. Hold the button for

10 seconds to show "CL" on the display. Lift Fascia door

to access evaporator plate. Lift or remove splash shield to

expose evaporator plate. Using 1-3 ounces of cleaner,

pour cleaning solution slowly on evaporator plate so it

flows down into the fresh water reservoir.

17

18

Draining and Removing Water from the Ice-

Making System with a Gravity Drain.

1.

2.

3.

water valve.

Change the electronic control to the "CLEAN" position

for approximately one (1) minute. This will energize and

open the water valve and remove most of the water

from the water valve and the water valve’s outlet water

line to the reservoir.

4. Change the electronic control to the "OFF" position.

This will energize and open the drain valve to drain the

reservoir and the ice machine drain system.

5. Unplug the ice machine from the electrical outlet.

6. Remove the access cover from the rear of the ice

machine.

water in the ice-making system.

This ice machine must have all water drained and removed

to prevent ice machine damage as well as possible water

damage to the surrounding area in freezing conditions.

These damages are not covered under warranty.

Do not use any type of anti-freeze or other solution as a

substitution for properly draining the ice machine.

Clean the Ice Machine

Cleaning the ice machine will help prevent mold and

mildew growth as well as sanitize the ice machine for

storage or when it is put back into service.

!CAUTION

!CAUTION

Risk of electrical shock or personal injury could occur

access cover is removed before unplugging the ice

machine.

!WARNING

Electrocution Hazard

Back view of

ice machine

Water supply

Water

supply

line

Water valve

inlet

Access

cover

Screw

!CAUTION

Winterization: If the unit will be exposed to temperatures

LONG TERM STORAGE AND WINTERIZATION

19

Reconnect the water valve outlet water line.

Reinstall the ice machine’s access cover.

Clean and dry the ice machine’s storage bin.

Prop the door open for air circulation to prevent mold

and mildew.

Leave the water supply line disconnected or

reconnect

water on and allow water to enter back into the

water valve.

White

collar

Plastic outlet

water line

7. Disconnect the water valve’s outlet water line to the

reservoir and drain the remaining water left in the water

line trap area.

To disconnect the water outlet

line: Push up on the white collar

and pull the plastic water line

from the bottom of the water

valve.

To reconnect the water outlet

line: Simply insert the plastic

tubing into the white collar and

push until it stops (about 12

valve).

Draining Water for Factory Installed Drain

Pump Applications

Follow steps 1 through 12 for the gravity drain then do the

13. Install the winterization plug in the water drain hole

inside the ice bin.

Winterization

plug

LONG TERM STORAGE AND WINTERIZATION

20

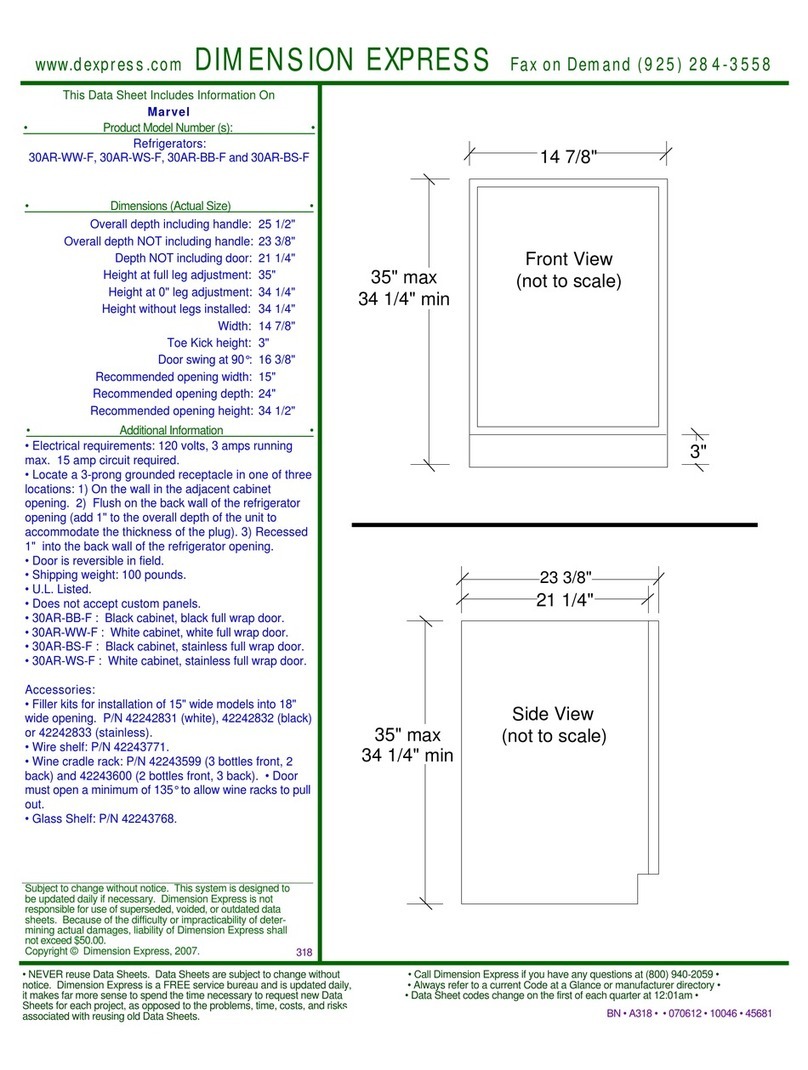

Table of contents

Other Marvel Refrigerator manuals

Marvel

Marvel 60RD-BB-F User manual

Marvel

Marvel MS15RA Manual

Marvel

Marvel 60HK-SS-F Guide

Marvel

Marvel 8SBARE Manual

Marvel

Marvel 60RD Guide

Marvel

Marvel 30AR-BB-F User manual

Marvel

Marvel MPWC424-SG31A User manual

Marvel

Marvel 60RGD-SS-F Manual

Marvel

Marvel MORF224 User manual

Marvel

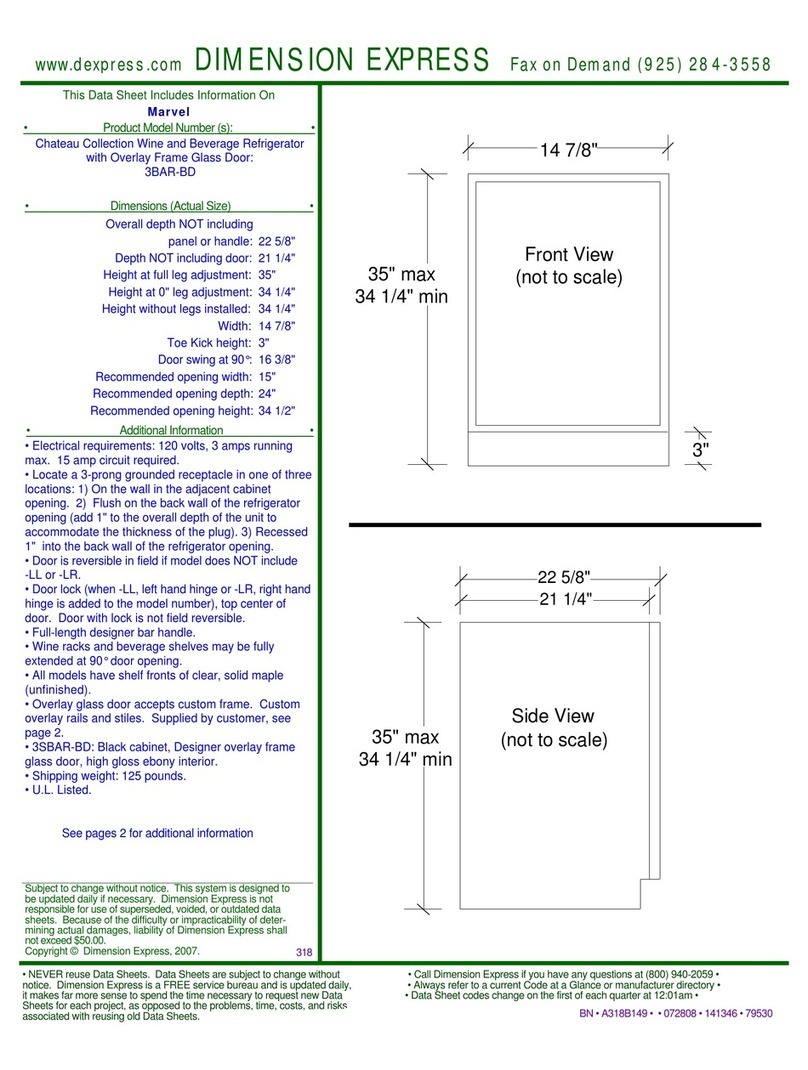

Marvel 3BAR-BD User manual

Marvel

Marvel MS24FASFRW Manual

Marvel

Marvel MOKR124-SSD1A User manual

Marvel

Marvel MLRE024 User manual

Marvel

Marvel 6ADA-BB User manual

Marvel

Marvel 6BAR-BB-G User manual

Marvel

Marvel 6SBARE-BD User manual

Marvel

Marvel 4570105 User manual

Marvel

Marvel MPRE424-SG81A User manual

Marvel

Marvel MLCP215 User manual

Marvel

Marvel MPWD424-SS31A User manual