SPARTAN IRONWORKER TABLE OF CONTENTS

© MARVEL MFG. CO., INC. MANUAL PL/OMIW-2CYL_V2(08/07)

iii

A MESSAGE ON SAFETY ..................................................................................................................... ii

CONTENTS.............................................................................................................................................. iii

SAFETY ................................................................................................................................................. S-1

WHO MAY USE THIS MACHINE? .......................................................................................... S-2

FOLLOW THE INSTRUCTIONS .............................................................................................. S-2

RECOGNI E SAFETY INFORMATION .................................................................................. S-2

SAFETY SIGNAL WORDS ....................................................................................................... S-3

WEAR PROTECTIVE EQUIPMENT ........................................................................................ S-3

STAY CLEAR OF MOVING PARTS ........................................................................................ S-3

HANDLE CHEMICALS SAFELY ............................................................................................. S-4

REMOVING DEBRIS ................................................................................................................. S-4

SAFE MATERIAL HANDLING ................................................................................................ S-5

ELECTRICAL HA ARDS ......................................................................................................... S-5

HA ARDOUS METALS ............................................................................................................ S-6

HIGH PRESSURE FLUIDS ........................................................................................................ S-6

PUNCHING & SHEARING EQUIPMENT ............................................................................... S-6

KEEP THE MACHINE SAFE .................................................................................................... S-7

KEEP THE WORK AREA SAFE ............................................................................................... S-7

OPERATE THE MACHINE SAFELY ....................................................................................... S-7

SERVICE THE MACHINE SAFELY ........................................................................................ S-8

INSTALLATION .................................................................................................................................. A-1

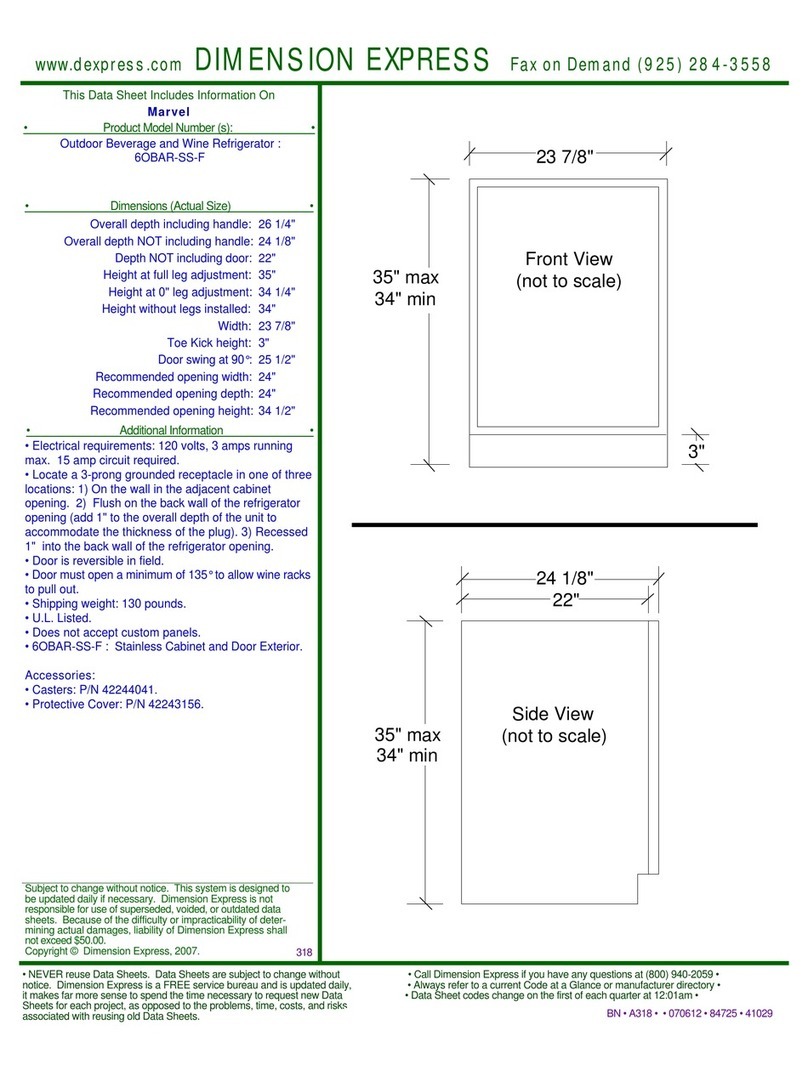

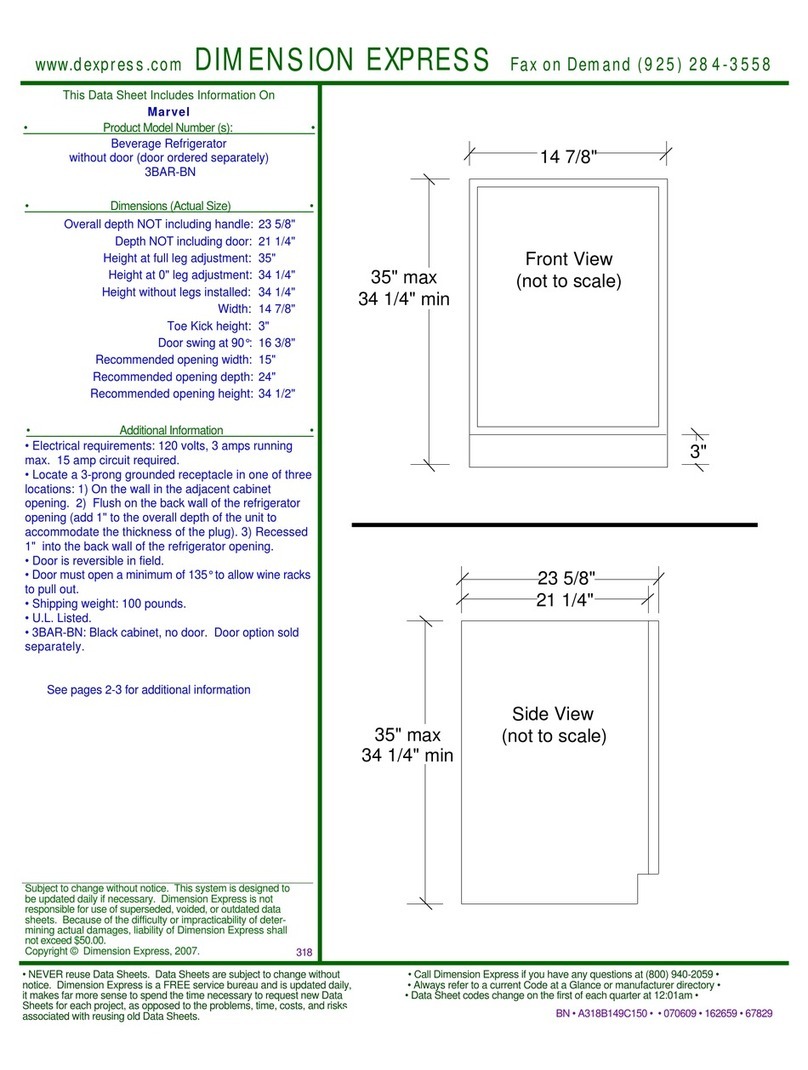

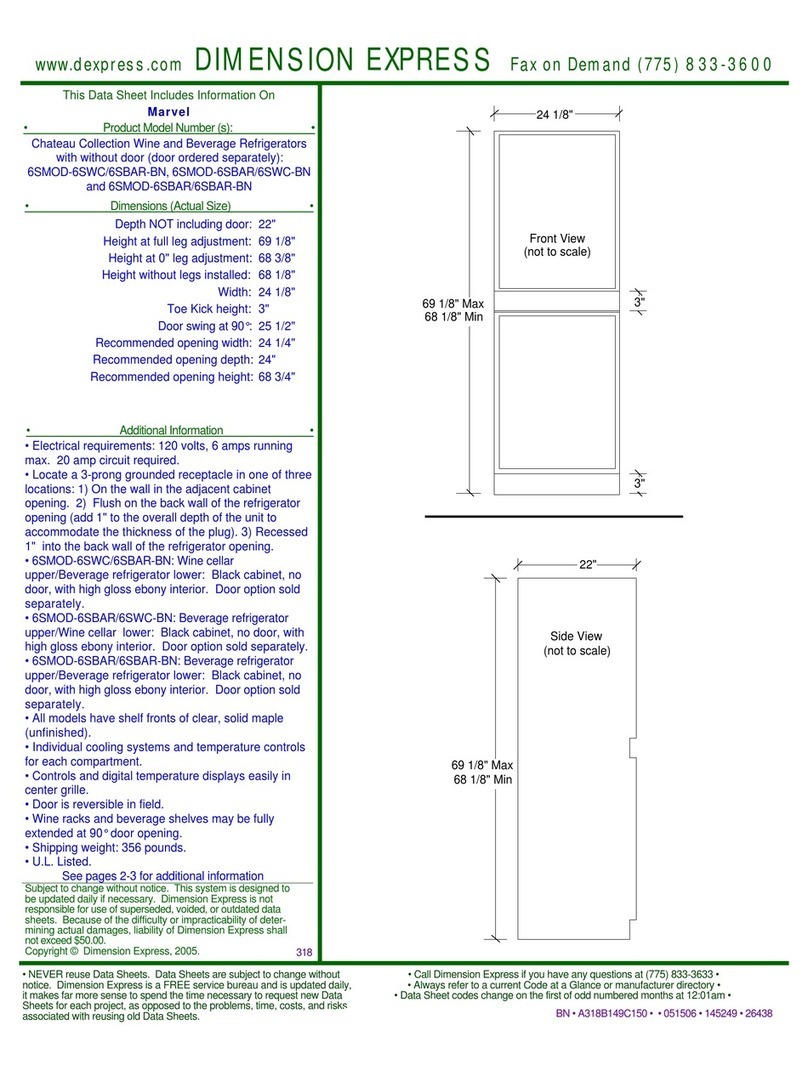

GENERAL SPECIFICATIONS ...........................................................................................................B-1

MACHINE DESCRIPTION ................................................................................................................ C-1

PUNCHING STATION ........................................................................................................................ D-1

NOTCHING STATION ........................................................................................................................E-1

ANGLE SHEARING STATION .......................................................................................................... F-1

BAR SHEARING STATION ............................................................................................................... G-1

FLAT BAR SHEARING STATION ................................................................................................... H-1

MAINTENANCE ................................................................................................................................... J-1

REPAIR PARTS .................................................................................................................................... P-1