89

Assembly

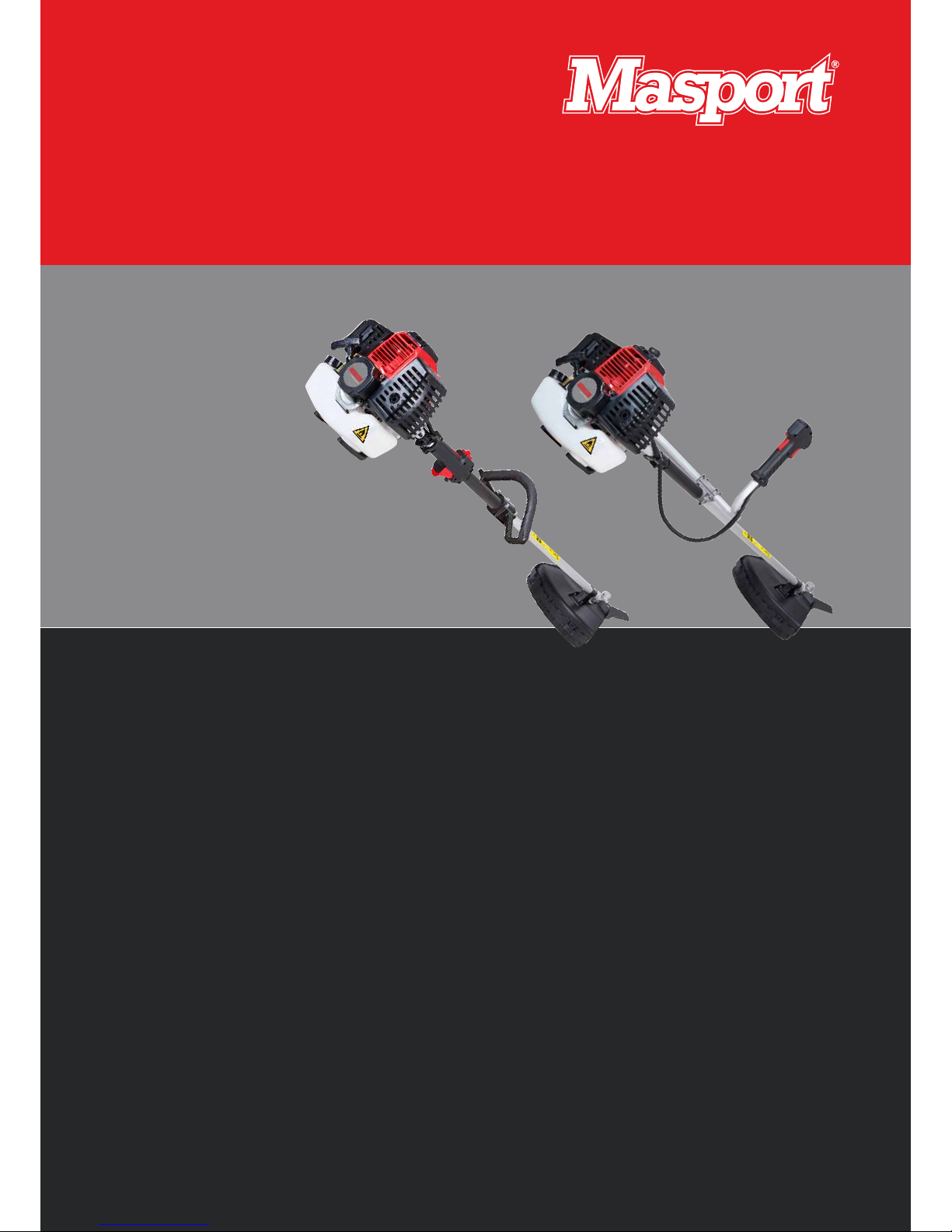

BCL 440 INSTALLING THE HANDLE BARS

Install the handle in bracket. Place handle in a comfortable operating

position and tighten lockscrew.

INSTALLING THE SAFETY GUARD

Install the safety cover on the shaft with the safety cover bracket and the

screws provided.

Tighten the screws after setting the safety cover bracke at the appropriate

position.

GEAR CASE

SHIELD

WARNING!

Do not operate this unit without a safety guard, if the safety

guard is damaged replace immediately. Do not continue with

a damaged guard.

INSTALLING THE BLADE

Install holder A, the tri-blade, holder B, and teeth washer, in this order, and

then clamp with a left-hand thread net.

Align hole of gear case and holder A, and insert S=4mm bar wrench.

Rotate blade-fastening nut with plug box wrench in counter clockwise

direction until securely tightened.

Install the pin 2x6 and disjoin it.

WARNING!

EXCESSIVE VIBRATION - STOP ENGINE IMMEDIATELY

Excessive vibration of the blade means that it is not properly

installed. Stop engine immediately and check blade. Blade

not properly installed can cause injury.

Use only original cutting equipment parts when servicing the

unit.

INSTALLING THE NYLON CUTTER HEAD

Align hole in adapter plate with hole in shaft and install locking tool.

Thread cutter head onto shaft (turning it clockwise) until it is tight. Remove

locking tool.

Fuel

1. Petrol is very flammable. Avoid smoking or bringing any flame or

sparks near fuel.

2. Wipe up all spills before starting the engine.

WARNING!

Stop the engine and allow it cool before refuelling the unit.

WARNING!

Keep open flames away from the area where fuel is handled

or stored.

3. Use only oil intended for 2 stroke air cooled engine use. Other oils

can cause spark plug fouling, exhaust port blocking, or piston ring

sticking.

IMPORTANT!

Fuel mixtures which have been left unused for an extended

period may clog the carburettor or cause hard starting. Store

unused fuel in an air-tight container in a cool place.

E

FUEL

FLAMMABLE

FUEL

4. Fuel mixtures which have been left unused for an extended period

may clog the carburettor or cause hard starting. Store unused fuel in

an air-tight container in a cool place.

5. Mix a regular grade petrol (leaded or unleaded) and a good quality

two stroke engine oil for air cooled engines. Shake them together in

a clean container to ensure thorough mixing before pouring into the

fuel tank. Do not use plastic containers not specifically designed for

use with petrol.

6. Mixing ratio chart:

Unleaded

Gasoline

2 cycle

mineral oil

25:1

2 cycle semi-

synthetic oil

40:1

2 cycle

synthetic oil

50:1

1 L 40mL 25mL 20mL

4 L 160mL 100mL 80mL

5 L 200mL 125mL 100mL

10 L 400mL 250mL 200mL

FUEL

1L

liOl m04

Operating

STARTING THE ENGINE

Before starting the engine, inspect the entire unit for loose fittings or fuel

leaks, and verify that the cutting attachment is properly installed and

securely fastened.

Place the unit on a flat, firm place. Keep the cutting head clear of any

obstructions.

1. Check that there is fuel in the tank and that the fuel cap is screwed

on tightly.

1) Cap

2) Fuel tank

2. When starting a cold engine move the choke lever (behind the air

cleaner cover) to the closed position.

1) Choke lever

2) Closed

3) Open

3. If the engine has been running and is still warm, move the choke

lever to the open position.

4. Press the priming bulb under the carburettor repeatedly until excess

fuel can be seen returning to the tank through the clear fuel return

pipe.

5. Slide the ignition switch (3) on the trigger grip away from the STOP

position (See Diagram .C on the next column).

6. To set the throttle in the start position.

- Depress the safety lever (4)

- Squeeze the throttle lever (1) fully.Hold down the starting button

(3) while releasing the throttle lever.

- The throttle lever will be held partly open until it is squeezed again.

1) Throttle lever

2) Ignition Switch

3) Starting button.

4) Safety Lever

Diagram .C

7. While holding the unit firmly, pull out the starter rope quickly.

8. After the engine has started, open the choke gradually.

9. Allow the engine to run for 2 to 3 minutes to warm up before

starting work.

STOPPING THE ENGINE

1. Release the throttle lever.

2. Slide the ignition switch on the trigger grip to the STOP position.

FITTING THE HARNESS

IMPORTANT!

The harness must always be used as the machine cannot be

operated safely without it.

Diagram .B

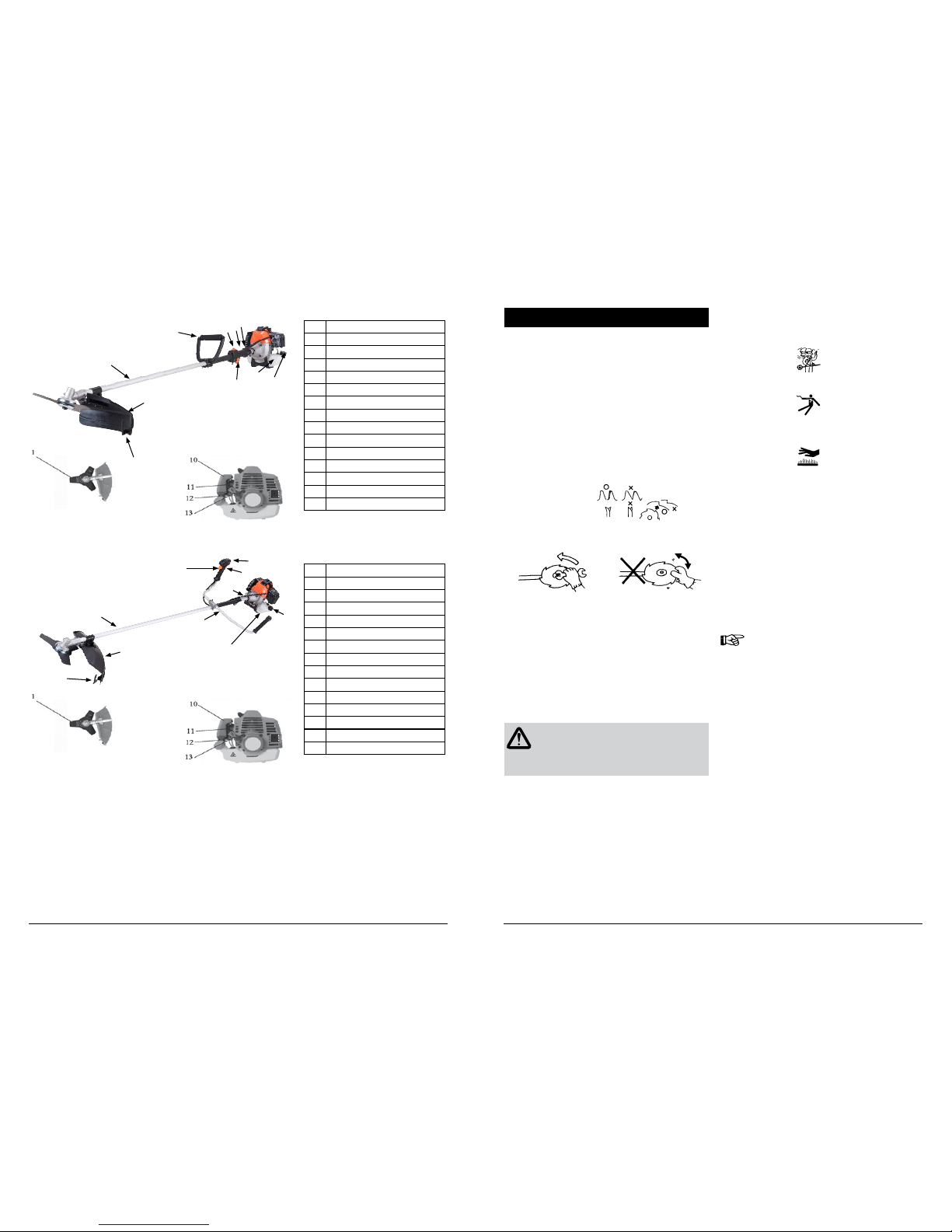

CUTTING USING THE METAL BLADE

1) For shrubs & thick weeds

2) For grass and weeds

3) Direction of cutting

4) Direction of rotation

1. A metal blade cuts best with a swathe up to one third of the cutter

diameter. Use that area for cutting shrubs, tough and thick weeds.

For cutting young grass, you can use up to two thirds of the cutter

diameter.

2. Adjust the engine speed according to the material being cut. Cut the

young grass at middle speed, and shrubs or tough and thick weeds

at high speed.

IMPORTANT!

If the cutting speed is too low, debris can be caught

up in the blade, and if this causes the clutch to slip it

will wear out quickly.

CUTTING WITH THE NYLON CUTTER

• Cutting with the nylon cord consumes more power so the

engine speed should be 50% greater than when using the

metal blade.

• The nylon cord cuts the grass by meeting it at high speed. If you take

too wide a swathe you may slow down the engine and not get clean

cutting. To correct this, retract the cutter from the grass until the

engine regains full speed and then cut using a narrower swathe.

• After a time the nylon cord will wear away. To restore the full cutting

diameter, simply bump the cutter head on the ground while it is

running at full speed. The cords will extend automatically and will be

trimmed to the correct length by the cord trimmer blade mounted on

the guard.

• Cut grass by swinging the brushcutter from left to right. While

you can cut in either direction, if you follow these suggestions the cut

grass will be thrown away from you, and you will avoid getting your

clothes dirty.

Maintenance

BLADE

• Sharpen each cutting edge and make sure the inside corner is

rounded to reduce the risk of cracking.

• Do not quench the blade with water if you are using a grinder as it

may start cracks in the blade.

• The 3 tooth blade may be inverted to utilise a fresh set of cutting

edges.

NYLON CUTTERS

The spools of nylon cord inside these bump-feed cutter heads will

eventually need replacing. While the change can be made with the cutter

head on the machine, it will be more convenient to remove the cutter

head.

CHANGING THE SPOOL

Push the locking latch located laterally on the spool housing (see picture,

action 1). Then turn the cover clockwise by about 1.5 cm (see picture,

action 2). This will unlock the cover and it can be removed. Now remove

the Tap’n go button and then the used-up spool from the spool housing.

Pass the two line ends of the new spool th rough the eyelets in the spool

housing as shown in the picture . The line ends still stay clamped in the

two transpo rt clamps pf the spool.