INSTALLATION AND OPERATION MANUAL

MOBILE EVAPORATIVE COOLER

Circle the model of your cooler and record the serial number.

Encierrre con un circulo el modelo de su enfriador y escribe

el número de série.

MMBT12 MMBT14

DATE OF PURCHASE:

FECHA DE COMPRA: ___________________

SERIAL NUMBER:

NÚMERO DE SÉRIE: _________________

Read carefully all of this manual before installing the unit /

Lea con cuidado todo este manual antes de instalar la unidad.

TABLE OF CONTENTS

SAFETY INSTRUCTIONS...................................................... 1

HOW EVAPORATIVE COOLING WORKS............................. 1

COOLER ASSEMBLY............................................................. 2

OPERATION........................................................................... 2

MAINTENANCE...................................................................... 3

ROUTINE.......................................................................... 3

YEARLY............................................................................. 3

TROUBLE SHOOTING........................................................... 4

SPECIFICATIONS.................................................................. 4

LIMITED WARRANTY............................................................ 5

INSTRUCCIONES EN ESPAÑOL ................................6-9

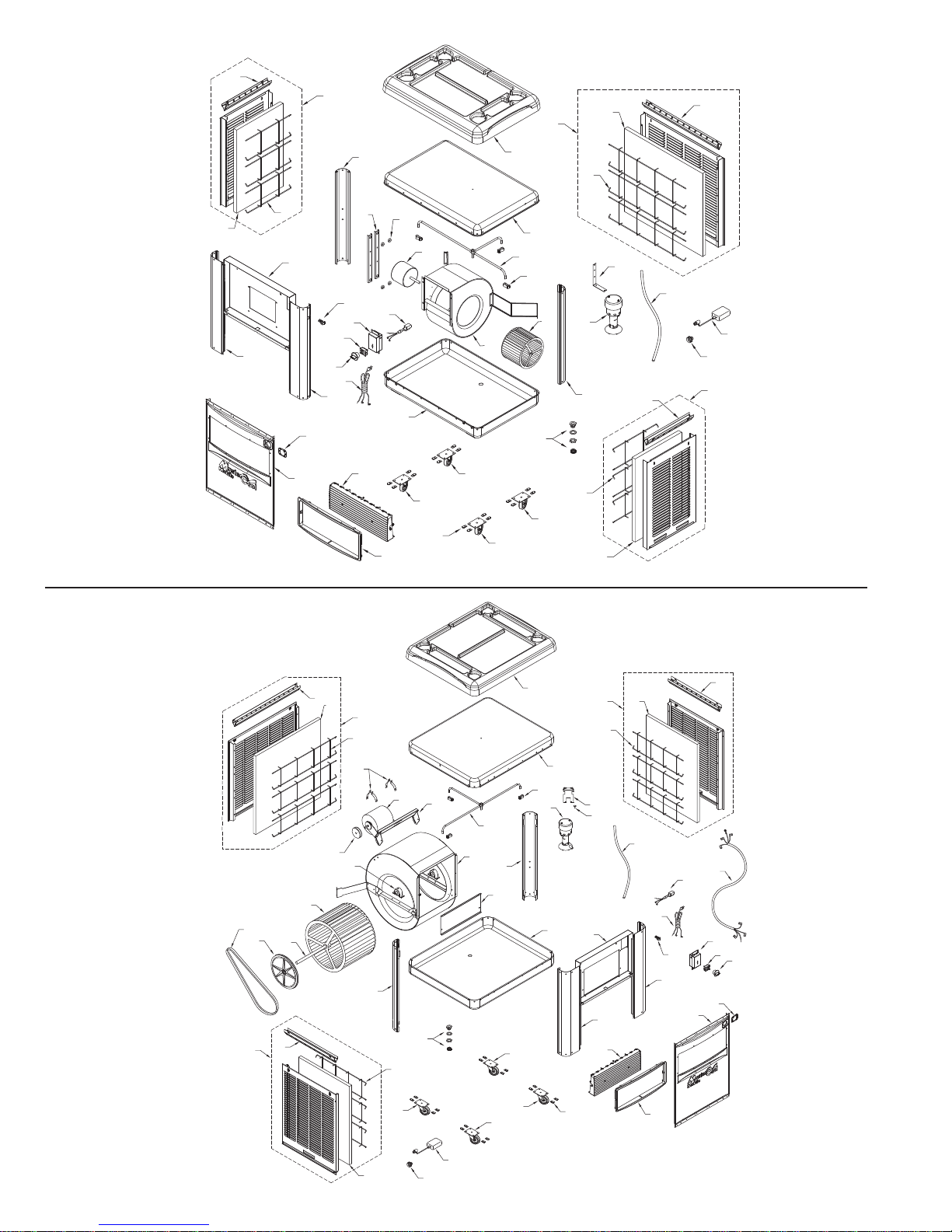

ILLUSTRATED PARTS LIST /

LISTA ILUSTRADA DE PIEZAS DE REPUESTO

(ENGLISH / ESPAÑOL).................................................. 10-11

GARANTIA LIMITADA.......................................................... 12

READ AND SAVE THESE INSTRUCTIONS

1. Read these instructions carefully.

2. Unit must be in the Off Position and Unplugged from power

receptacle when installing or performing any maintenance.

3. This cooler will run on 120 volt A.C., 60 Hz (cycle) current

only.

4. Motor and pump are grounded and have an automatic ther-

mal overload switch which will shut motor off if it overheats.

The motor will restart automatically when it cools down.

5. Pump receptacle is for grounded evaporative cooler pump

only. Do not plug anything else into receptacle.

6. Do Not operate any fan with a damaged cord or plug. Dis-

card fan or return to an authorized service facility for exam-

ination and/or repair.

7

. Do Not run cord under carpeting. Do Not cover cord with throw

rugs, runners or similar coverings. Do Not route cord under

furniture or appliances. Arrange cord away from traffic area

and where it will not be tripped ove

r.

8. Use only in GFCI protected receptacles.

WARNING:To reduce the risk of fire or electric shock,

do not use this fan with any “solid-state fan speed control

device.

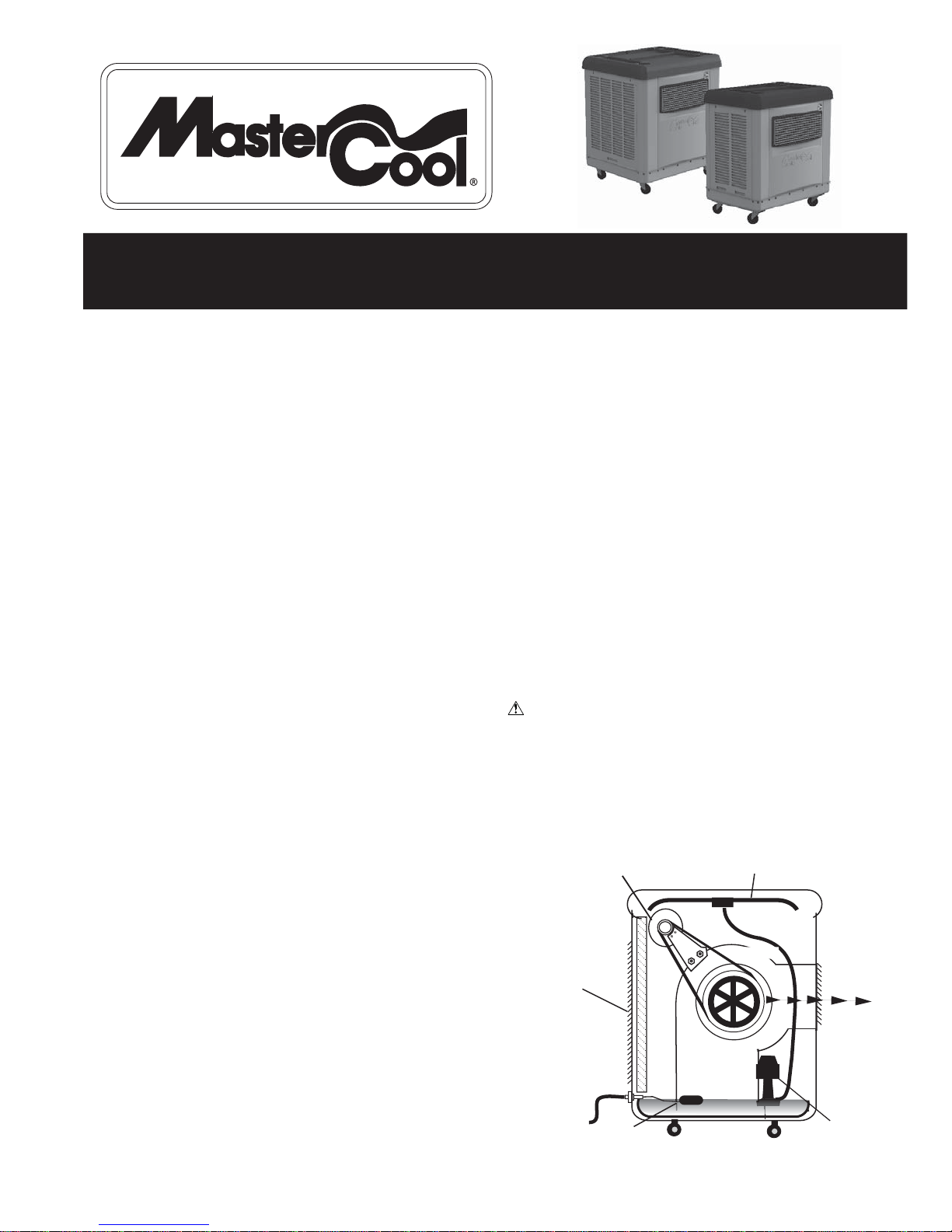

HOW EVAPORATIVE COOLING WORKS

Evaporative cooling is nature’s way of cooling. When air is

moved over a wet surface, water is evaporated and heat is

absorbed. When stepping out of a swimming pool with the wind

blowing, evaporative cooling makes you feel cool, even though

the air may be warm. The human body itself is cooled primarily

by the evaporation of perspiration.

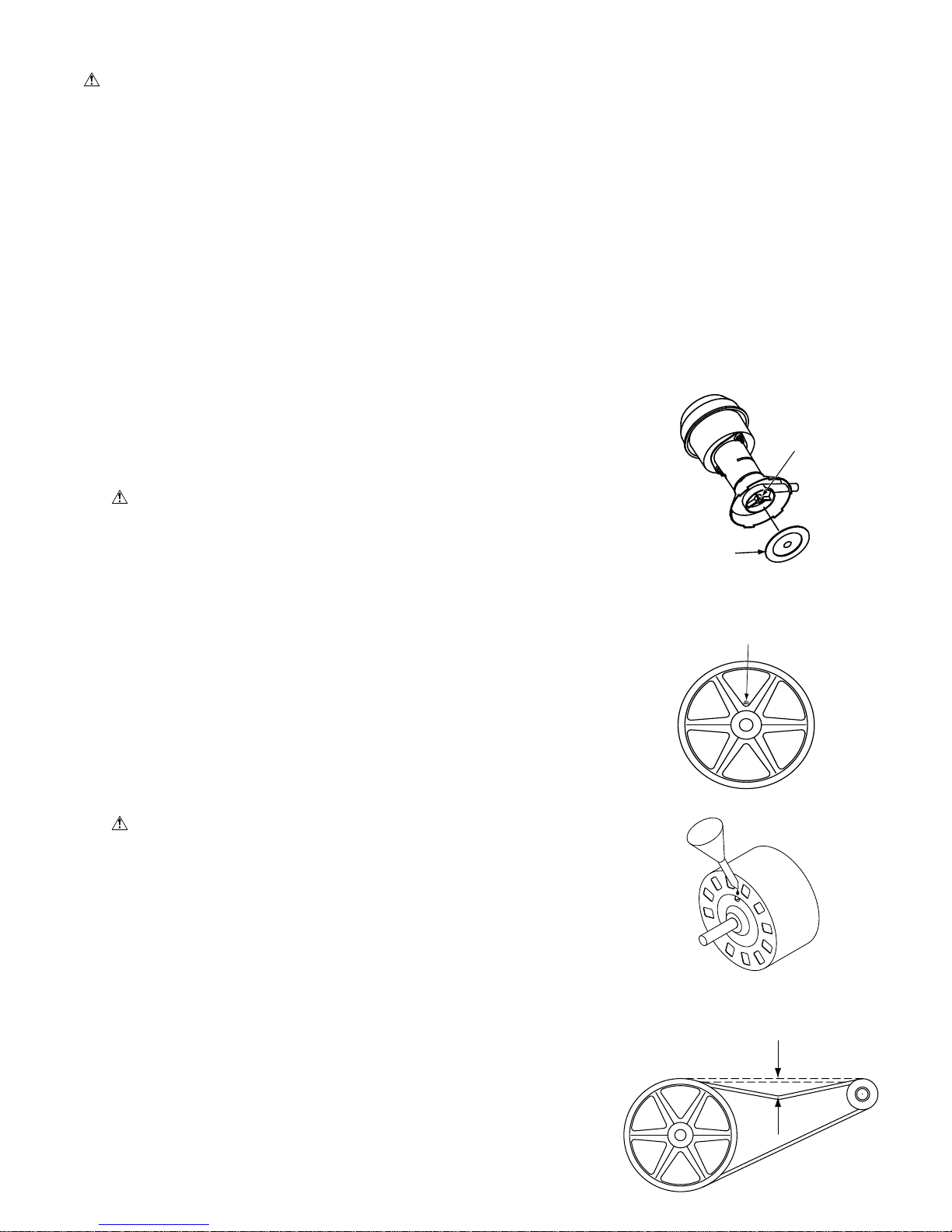

This unit works on the same principle. Air is drawn across

wet filter pads where the air is cooled by evaporation and then

circulated throughout the building. It is this combination of

cooled air and the movement of air over the skin which makes it

feel cool.

Unlike refrigeration systems which recirculate the air, an

evaporative cooler continually brings in fresh air while

exhausting old air. You are completely replacing the air every 2

to 4 minutes by opening windows or doors or a combination of

both. The air is always fresh, not stale, laden with smoke and

odors as happens with refrigerated air conditioning.

WATER

LINE

GRILLE

)

2 SPEED MOTOR WATER DISTRIBUTION HOSE

FLOAT WATER PUMP

WATER-SATURATED

COOLER PADS

3 SIDES

AIR FLOW

BLOWER

PN 110522-3 REV. 11-15