Test

wire

wheel

brush

for

balance

and

loose

or

damaged

wires

by

running

tocl

at

no

load

spd

for

at

least

one

minute

kfore

applying

it

to

your

work.

During

this

time,

no

one

should

stand

in front

of

or

inline

with

it.

When

applying

brush

to

work,

awld

using

too

much

pressure.

This

causes

met-bending

of wires

and

heat

build-up resulting in

premature

wite

breakage,

rapid

dulling

and

reduced

brush

life, Instead

of

using

more

pressure,

try

a

wire

wheel

brush with

more

aggressive

cutting

act~on

(increased

wire

size,

decreased

wire

length or different

brush

type.

E.e.

knot

type

instead

of

crimped

wire

type).

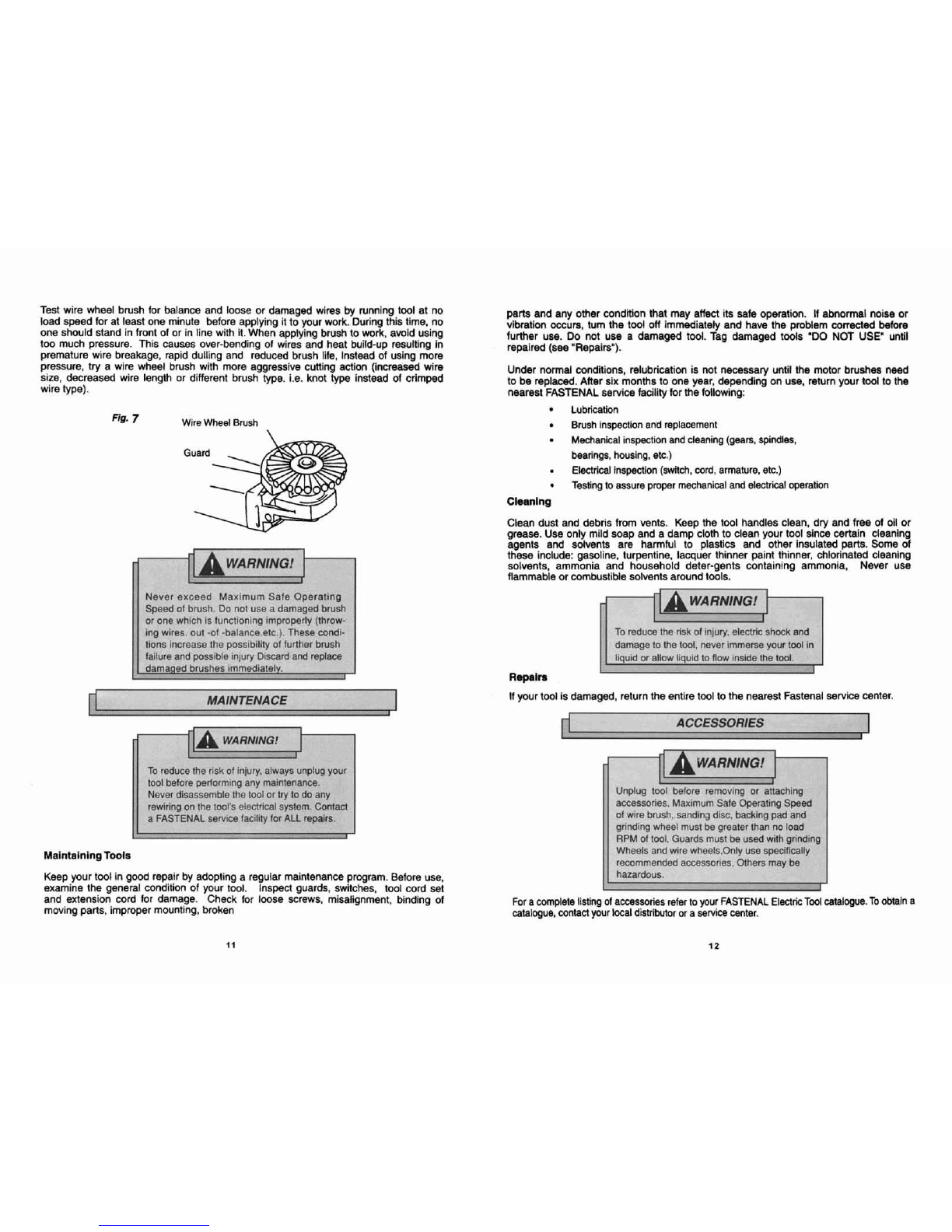

mlm

7

Wire

Wheel

Brush

Never

e:

3fe

Operating

Speed

of

damagedbrush

or

one

whrcn

IS

runcrlonlnglrnproperly

(throw-

ing

wires,

out

-of

-balance.etc.).

These

condi-

t~onsincrease

the

possibility

of

further

brush

failure and

possible

Injury

Discard

and replace

damaqed

brushes immediately.

1

~cceed

ME

brush. Do

..

. .

lr

ALL

repa

-

parts

and

any

otkr

mdMn

that

may

affect

its

aafe

operatiin.

M

abnormal

noisa

w

vibration

occurs,

turn

the

tool

off

immediately

and

hm

the

problem

corrected

before

further

uae.

Do

not

use

a

damaged

tool.

fag

damaged

tmlo

"DO

NQT

USE"

until

repaired

(see

"Repalm").

A

WARNING!

Under

notmar

wndktons,

relubrica#on

is

not

necessary

until

the

Wr

brushes

need

to

be

replaced.

After

six

months

to

one

year,

depending

on

use,

return

your

tool

to

the

nearmt

FASTENAL

service facility

br

the

following:

I

I

To

reduce

the

risk

of

injury,always unptug your

tool

before

pertorrnrng

any

matntenance.

Never

disassemble

the tool or

try

to do

any

rewiringon

the

toof's

electrical

system.

Confacl

a

FASTENAL

servicefacil~ty

fa

is.

1

Lubrication

Brush

inspeetion

anti

replacement

Mdmnical

inspectian

and

cleaning

(gears,

spldbs,

bearings,

housing,

etc.)

Elgctrical

inspection

(switch,

cord,

armature,

ek.)

Testing

to

assure

pmpt

mechanical

and

eteetrtcal

operation

Clean

dust

and

debris

from

wents.

Keep

the

toal

handles

clean,

dr)r

and

free

of

oil

or

grease.

Use

only

mild

soap

and

a

damp cloth

to

clean

your

tool

since

certain

cleaning

agents

and

solvents are

harmful

to

plastics

and

other

insulated

parts.

Some

of

these

include: gasoline, turpentine,

lacquer

thinner

paint

thinner,

chlorinated

cleanlng

solvents, ammonia

and

household

deter-gents

containing

ammonia.

Never

use

flammable

or

combustible solvents aroundtools.

damage

to

the

tool,

never

trnrnerse

your

tool

in

Repairs

If

your

too!

is

damaged,

return

the

entire

tool

to

the

nearest

Fastenal

service

center.

3thers

may

1

I

Keep

your

tool

in

good

repair

by

adopting

a

regular

maintenanm

program.

Before

use,

examine

the

general condition

of

your

tool,

Inspect

guards,

switches.

tool

cord

set

and

extension cord

for

damage.

Check

for loose

screws,

misalfgnment,

binding

of

For

a

complete

listing

of

accessories

refer

to

your FASTENALElectricTool

catabgw.

To

obtain

8

moving

parts,

improper mounting,

broken

catalogue,

contact

ywr

local

distributoror

a

sewice

enter.

Unplug

tool

before

removrng

or

attaching

accessories, Max~murn

Sale

Operating

Speed

of

wire

brush,.sand!ng

disc,

backlng

pad

and

grindrng

wheel

must

be

greaterthan no

load

RPM

of

tool,

Guards

must

be

used

w~thgrlnding

1

I

Wheels

and

wlre wheels.Only

use

specifically

recommended

accessor~es.

(

,

be

hazardous.

-

I