Table

Of

Contents

PAGE

1

. SAFETY

SAFETY

RULES

FOR

POWER

TOOLS

.....................

..

..

...

...........................

1

.......................

..........

ADDITIONAL

SAFETY

INSTRUCTlONS

FOR

BUFFERS

..

3

2

.

CIRCUIT

REQUIREMENTS

............

......................

...................................................

120V

OPERATION

..

...

4

.........................

.....................*.....................................

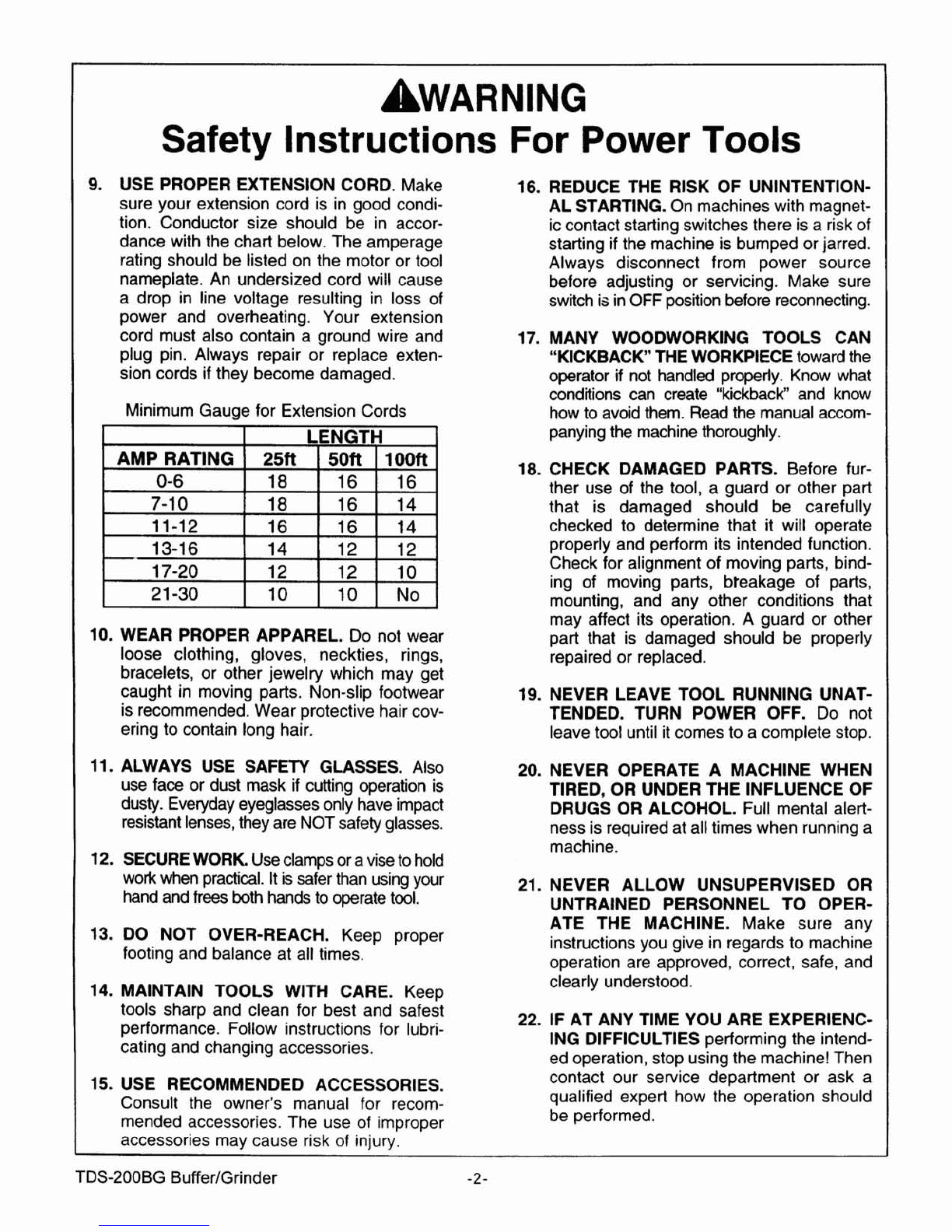

EXTENSION

CORDS

..

4

.........................................................................................................

GROUNDING

5

3

.

INTRODUCTION

........................................................................................................

COMMENTARY

5

....................

UNPACKING

..

............

....

...........................................................

5

..............................

.............*...................................*................*...

MOUNTING

..........

5

4

. OPERATIONS

........................................................

TEST

RUN

....

.............................................

6

........................................................................

GENERAL

....................................

...

6

..........................................................................................

BUFFING&POLTSHING

7

WHEEL

RENOVAL

.................................................................................................

7

.............................................

..........................

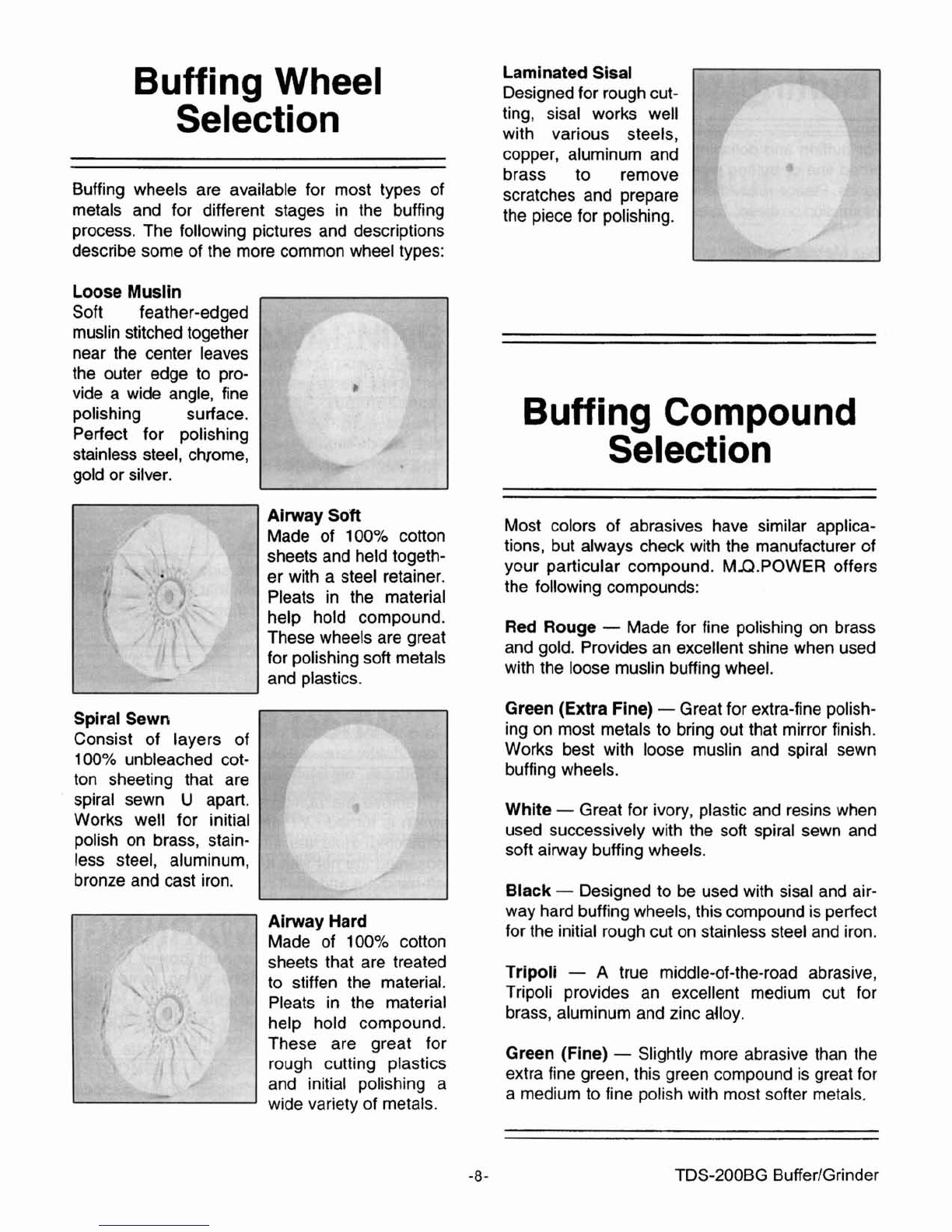

BUFFING

WHEEL

SELECTION

..

8

BUFFING

COMPOUND

SELECTION

...........................

..

......................................

8

.........................................................................................................

8UFFING

TIPS

8

5

.

MAINTENANCE

..........................................................................................................

10

........................................................................

LUBRICAT1ON

.........................

..

10

.......................................................................

MISCELLANEOUS

...................

...

1

0