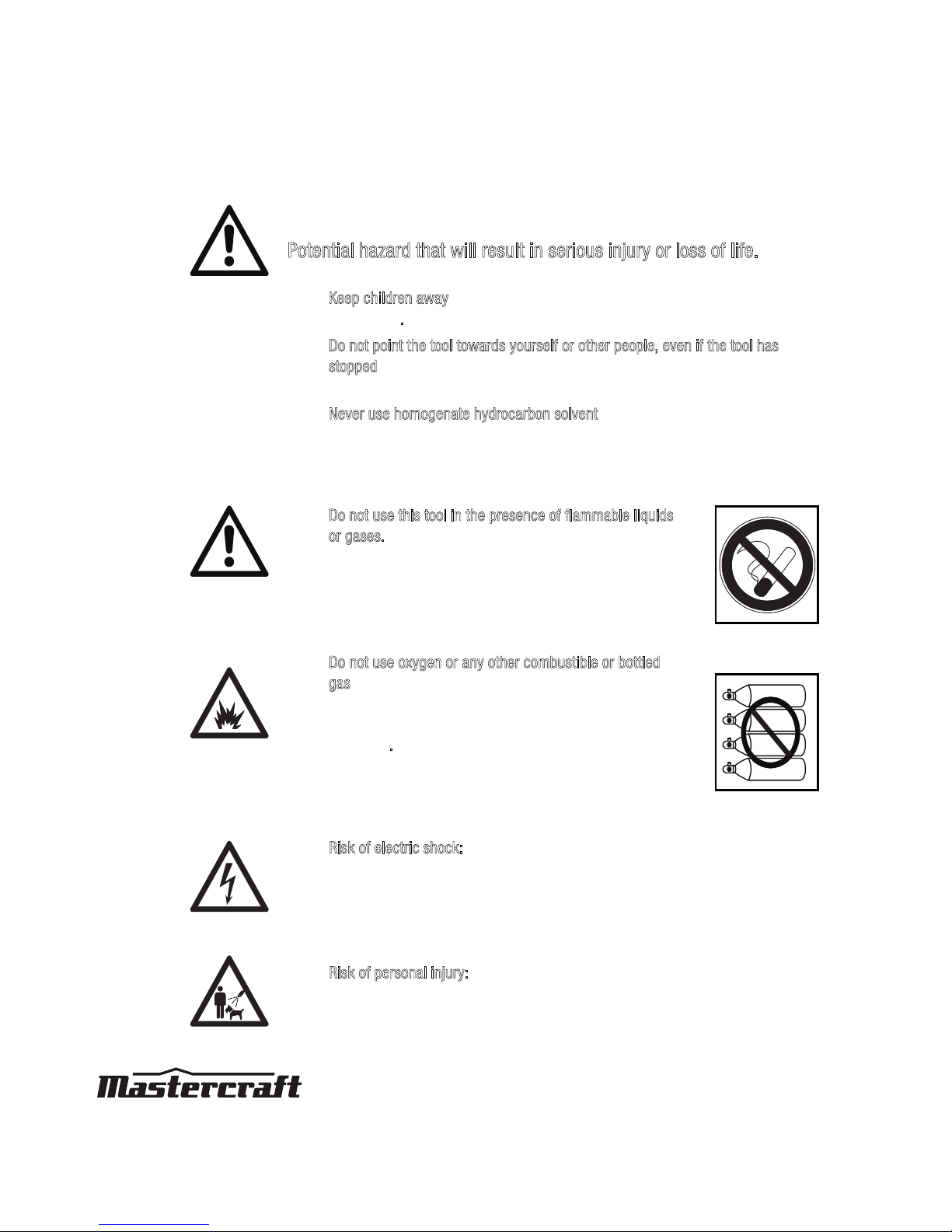

SAFETY GUIDELINES

5

AIR-POWERED SIPHON-FEED SPRAY GUN 058-9336-2

•Risk of inhalation: Never directly inhale the air produced by the compressor

and the spray gun. Always use the spray gun in a well ventilated area.

Use protective respirator: Toxic vapors produced by spray-

ing certain materials can cause serious damage to health.

Always wear safety es, gloves, and respirator to prevent the

hazard caused by inhalation of toxic vapor or contact of sol-

vent and paint with eyes or skin. Failure to comply will result

in moderate injury.

•Risk of burns: The pump and the manifold generate high temperatures. In

order to avoid burns or other injuries, do not touch the pump, the manifold,

or the transfer tube while the compressor is running. Allow the parts to cool

down before handling or servicing. Keep children away from the compressor

at all times.

•Risk of bursting: Do not adjust the pressure switch or

safety valve for any reason. They have been preset at the

factory for this compressor’s maximum pressure.

Tampering with the pressure switch or the safety valve

may cause personal injury or property damage. Make

sure the regulator is adjusted so that the compressor

outlet pressure is set lower than the maximum operating

pressure of the tool. Before starting the compressor, pull

the ring on the safety valve to make sure the valve

moves freely. Drain water from tank after each use. Do

not weld or repair tank. Relieve all pressure in the hose

before removing or attaching accessories.

•Use compressed air at regulated pressure: Always use

clean, dry, and compressed air at regulated pressure. Do

not exceed the maximum operating pressure of 8.3 bar

(120 PSI)

. Failure to comply will lead to serious injury or

loss of life.

MC-OM-04

MC-OM-22

MC-OM-06