OPERATING MANUAL 2000 HG V8.4/20-EN

Page | 4

•Repairs must only be carried out by qualified persons.

The following applies to all maintenance and repair work:

•It is essential to disconnect the spray gun from the com-

pressed air connection.

•Only use original spare parts.

•The maximum working pressure must not be exceeded (see

point 1 "Technical data"). The working pressure must be ad-

justed via a (filter) pressure reducer.

•Only use compressed air as energy source.

•The compressed air connection may only be made via a quick

coupling.

•When working with the spray gun, wear the necessary protec-

tive clothing, protective goggles, work gloves, ear pro-tection

if necessary and a respirator mask.

•If there are leaks in the device or other operating faults, the

device must be disconnected from the compressed air supply

immediately and the cause of the fault must be eliminated.

•Open fire, sparks or smoking is prohibited.

•Beware of flammable materials.

•Stone chip and underbody protection remains as well as

cleaning media must be disposed of in an environmentally

friendly manner.

•The disposal of the compressed air device must be carried

out according to the valid legal regulations.

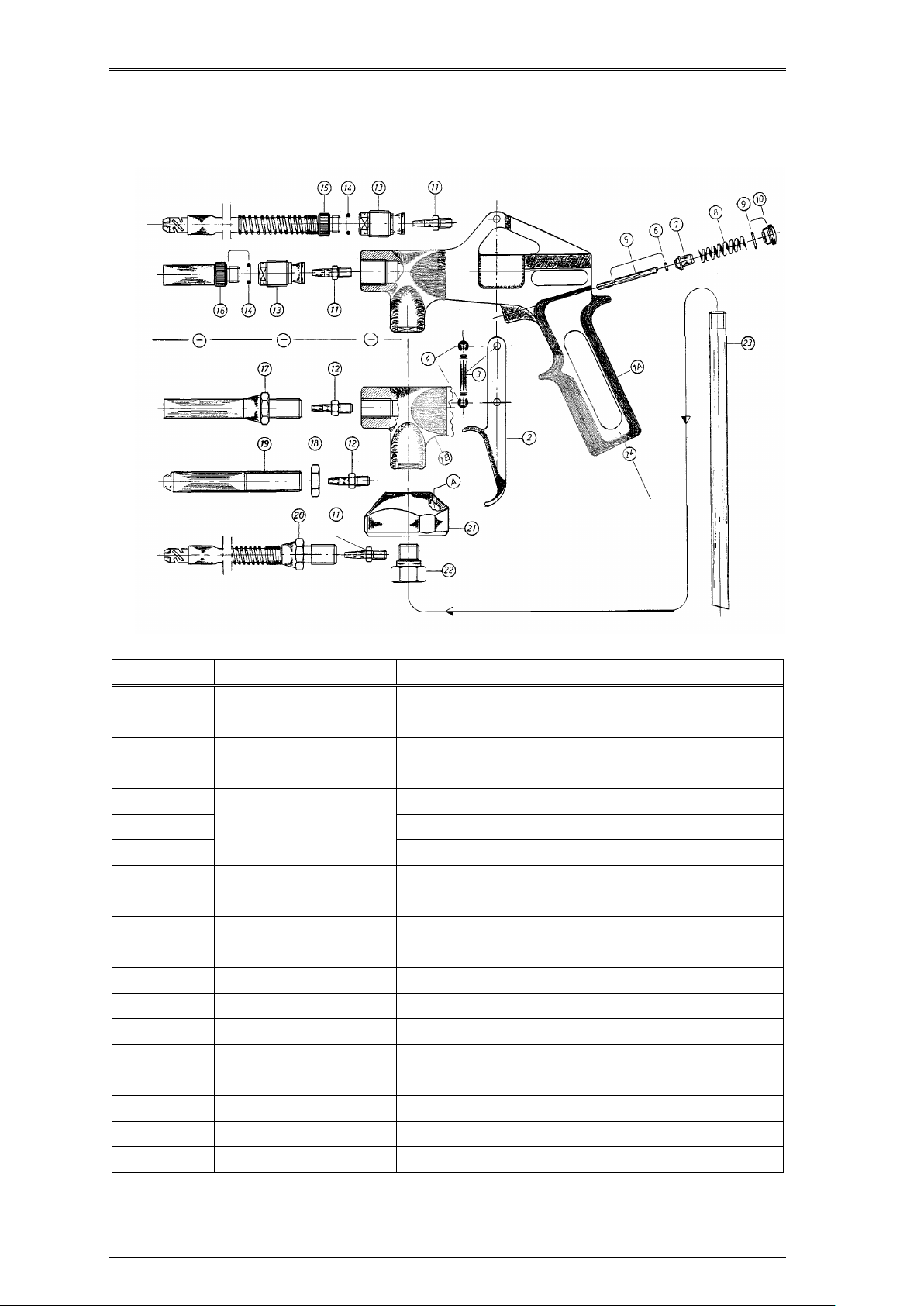

6. Installation

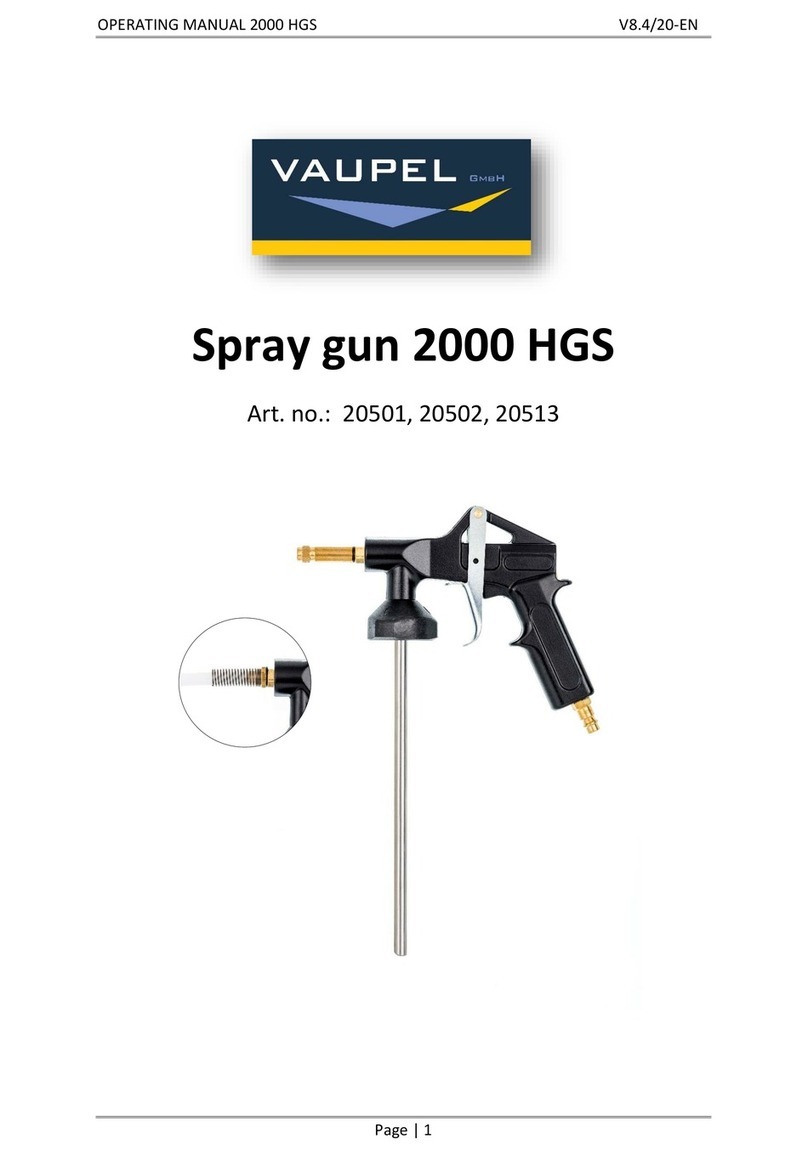

Screw in the supplied steel riser pipe hand-tight. Pierce the protective foil of

the 1 litre can and dip the riser pipe into the spraying material. Screw the 1 litre

can into the plastic threaded cap of the spray gun hand-tight. Take care not to

over-tighten the thread! Screw the cavity spray hose included in the extent of

delivery hand-tight to the connection piece of the spray gun.

Connect the spray gun to the compressed air supply via the quick coupling. By

pressing the trigger you put the spray gun into operation.

Optionally with this spray gun you have the possibility to use stone chip and

underbody protection. The cavity spray hose (2900 H) included in the extent of

delivery must be separated from the threaded connection piece (H26) and re-

placed by an optionally available brass spray pipe (2900 GS).