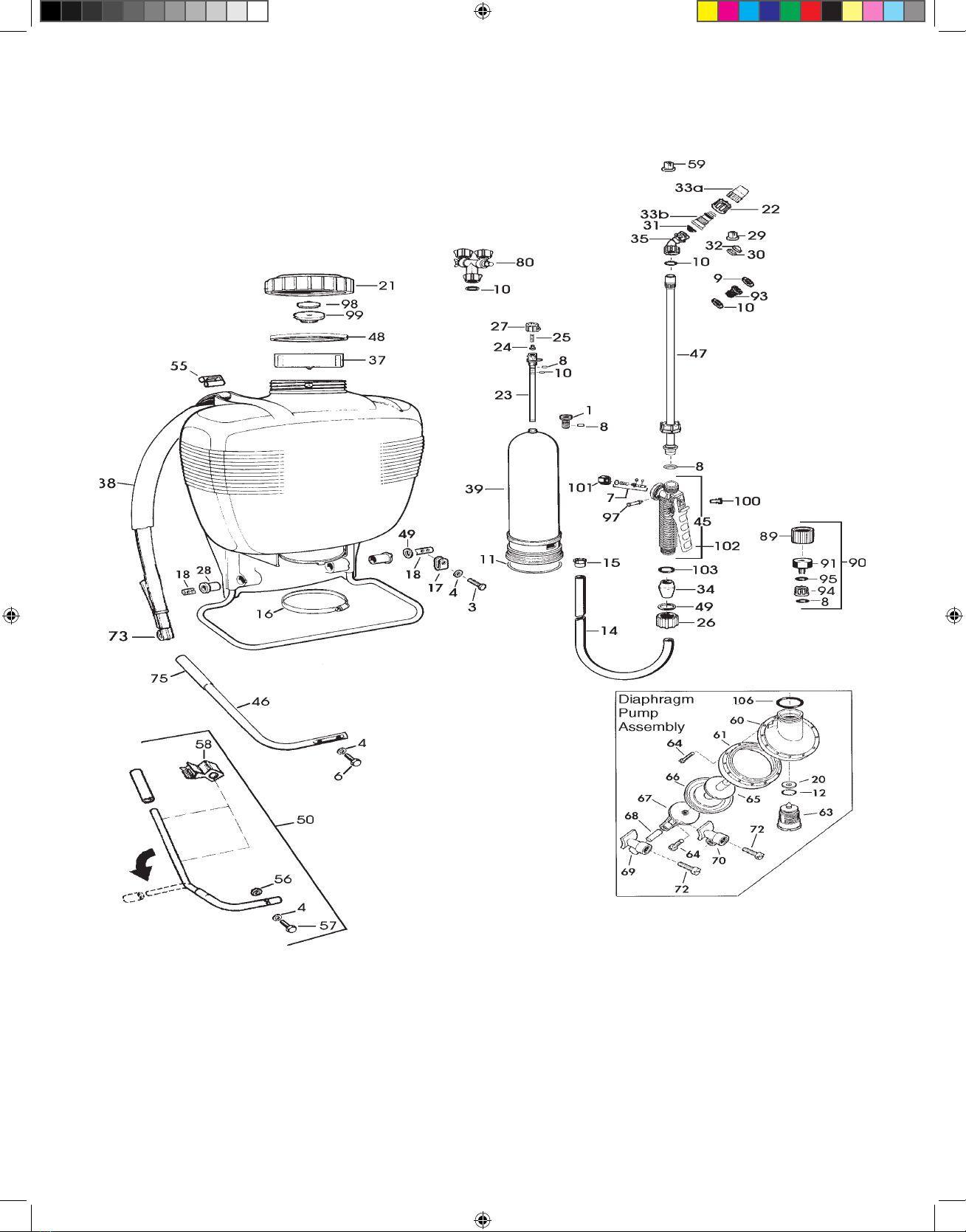

CAN I USE WEEDKILLERAND INSECTICIDE IN THE SAME SPRAYER?

In theory you can, if the sprayer is thoroughly cleaned out with an

ammonia: water solution of 1:25. In practice, the use of both types

of chemicals in the same unit is not recommended as the risk to the

plants can be high. Use caution when handling any type of chemicals

and when cleaning your sprayer.

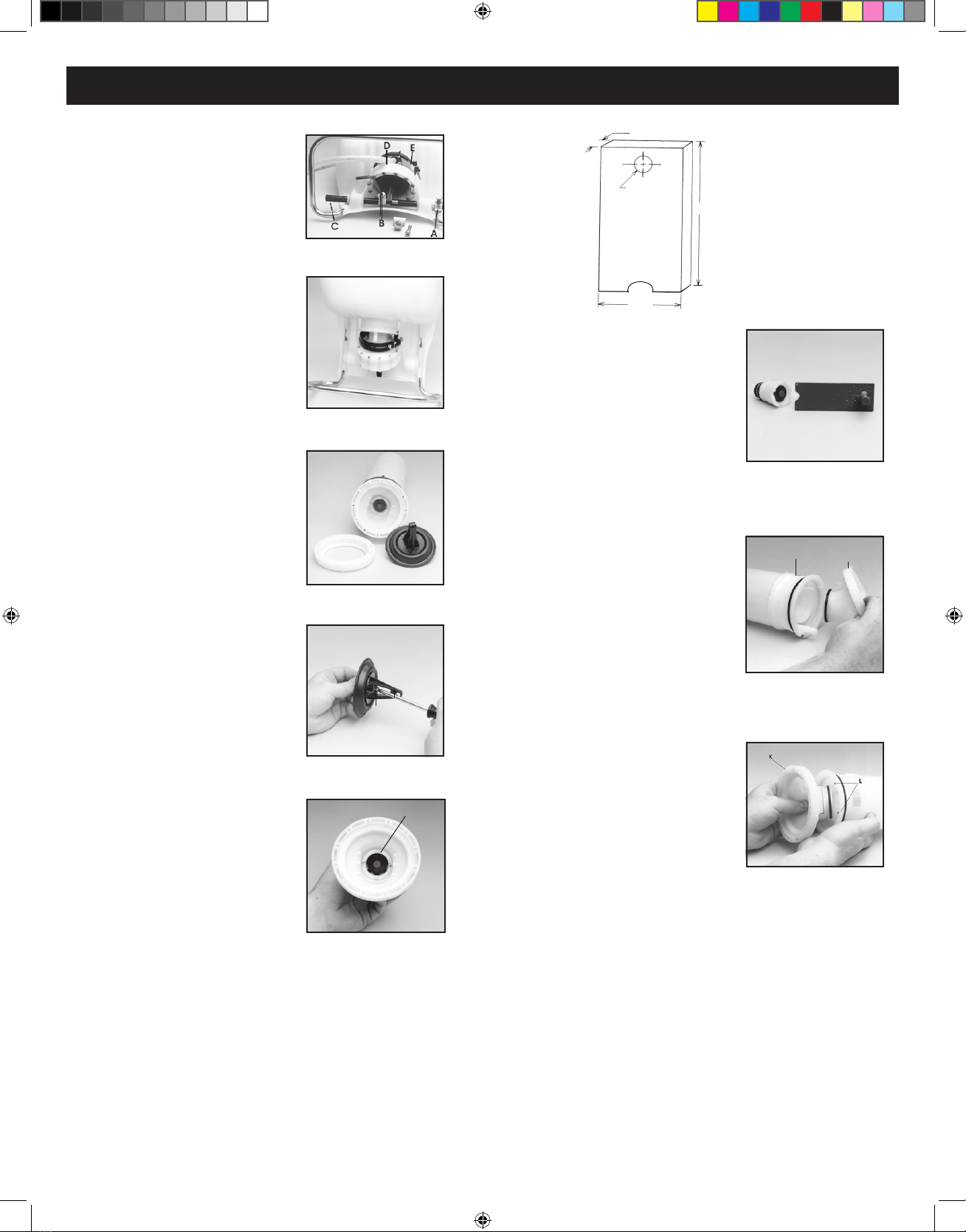

WHAT SPRAY NOZZLE SHOULD I USE?

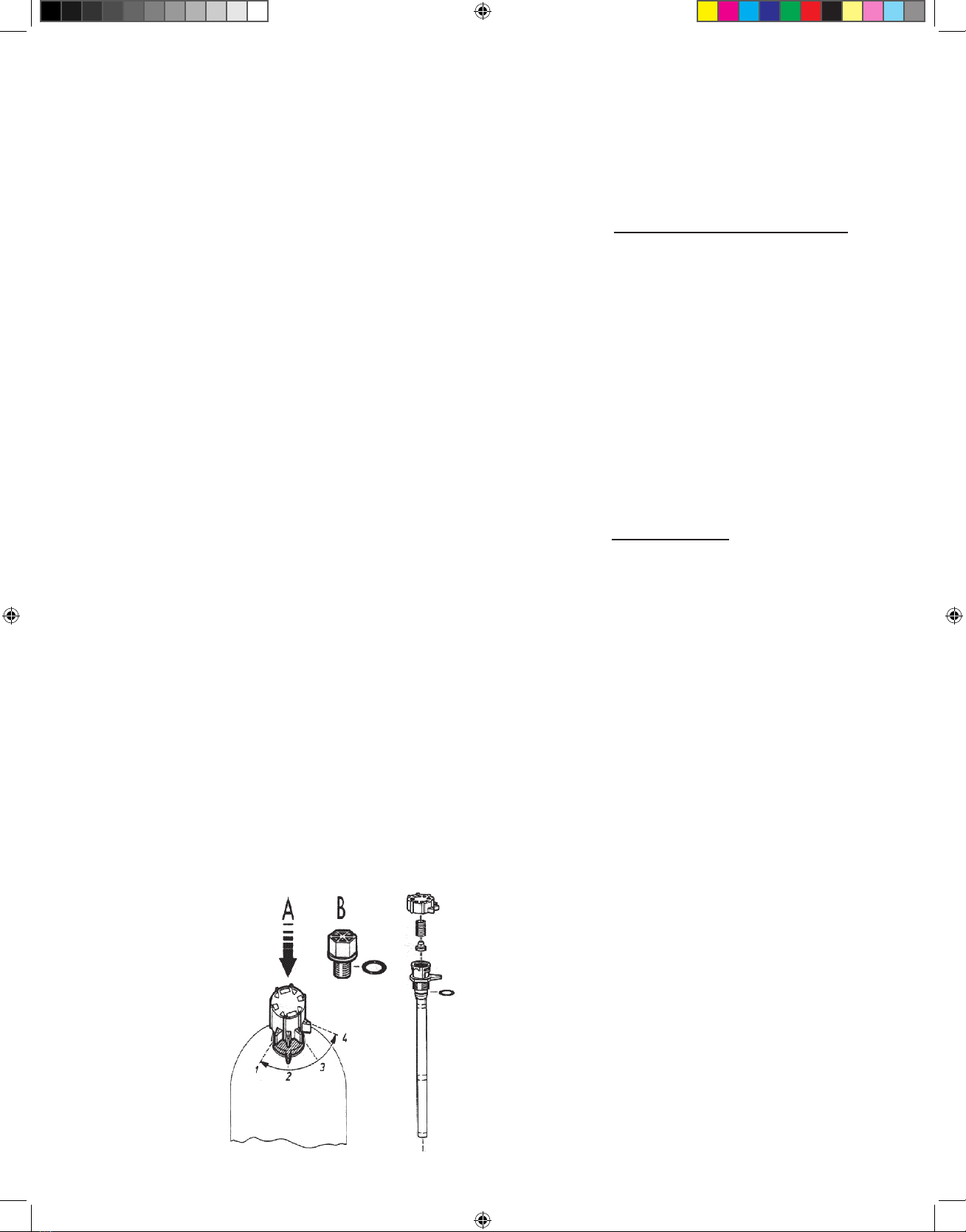

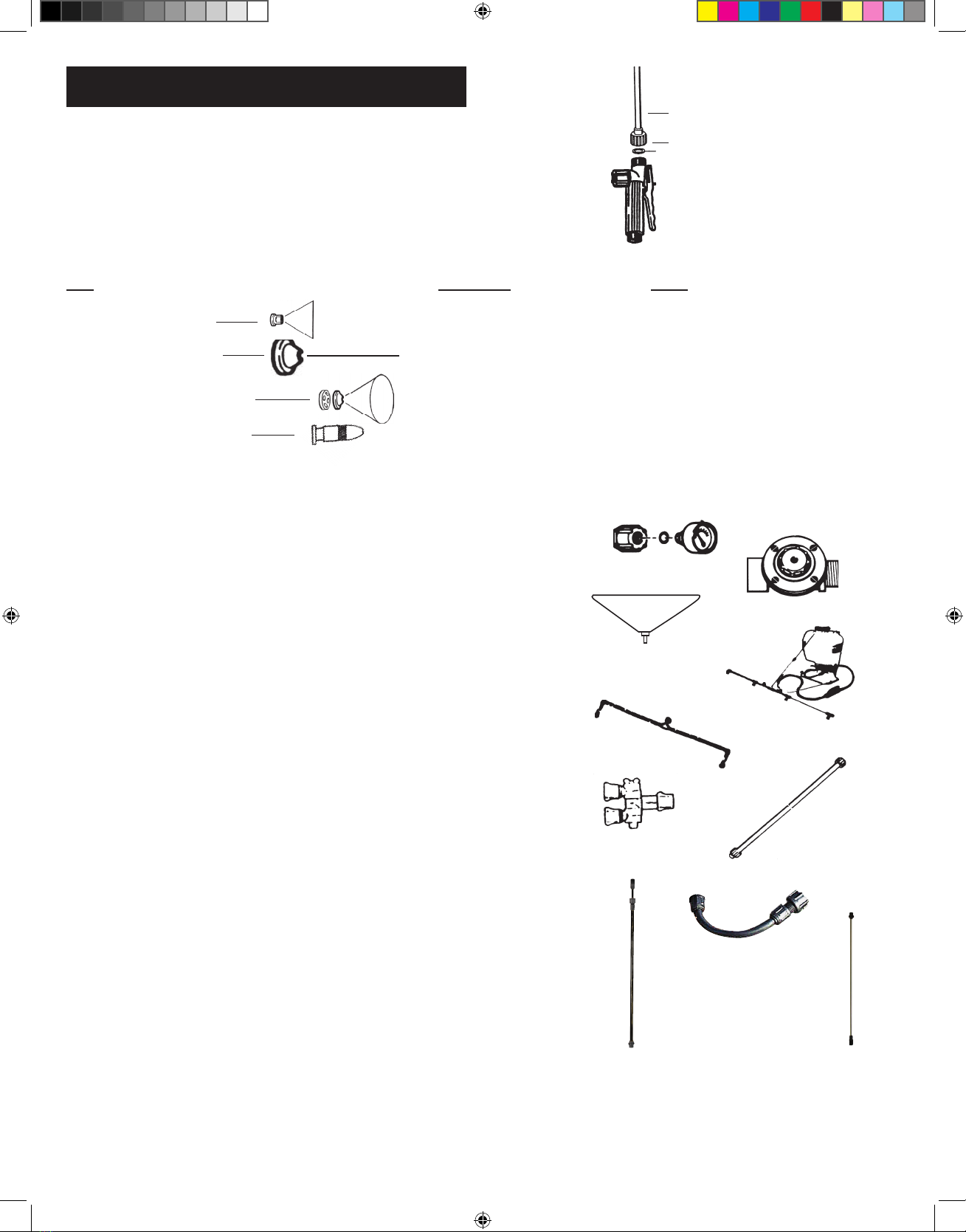

A brass adjustable spray nozzle is supplied for varying the spraying

pattern from a ne mist to a jet stream. A at spray nozzle is supplied

for spraying paths, garden beds, and general area spraying. A cone

nozzle is also supplied for spot spraying and for treatment of bushes

and small trees. For spot spraying, simply remove swirl plate from

behind cone. Save the swirl plate for future use. Standard is a reux

lter with a built-in check valve which opens at 5 psi and closes at

4 psi. This virtually eliminates dripping of uid still contained in the

spray wand. A wide selection of nozzles such as the drift guard and

no-drift nozzles are available

CAN I DO SPOT SPRAYING?

The shut-off valve on the MASTERLINE sprayer is well suited for spot

spraying. It’s almost effortless! The shut-off valve handle incorporates

a clip which holds the trigger valve open for area spraying without

tiring the operator’s hand. A pressure gauge may be added with

increments from 5 psi up to 60 psi.

DOES THE UNIT REQUIRE CONSTANT PUMPING?

NO! The well-designed lever action greatly reduces the pumping

effort. The pressure cylinder within the tank has a hydraulic effect.

Liquid from the pump compresses air in the pressure chamber which

allows irregular pumping action, yet results in steady spray at the

nozzle.

CAN THE SPRAY TANK STAND THE PRESSURE?

Although quite strong, the spray tank itself is intended only as

a container for the spray solution. Pressure is maintained in a

separate pressure chamber. This chamber is injection molded and

built to withstand normal operating pressure. Additionally, an internal

pressure control valve has been tted to the cylinder (see item A). It

has four pressure settings adjustable to specic spraying needs (see

diagram).

3

Gal/Acre = (Gal./min of nozzle) x 43560 Sq. ft./acre

(Sq. ft./min.)

Note: Gal/min for standard nozzles

Flat Spray Nozzle 15 PSI = .22 Gal./min.

29 PSI = .33 Gal./min.

44 PSI = .40 Gal./min.

Hollow Cone Nozzle 15 PSI = .17

29 PSI = .24

44 PSI = .29

Sq. ft., min. = Speed (ft./min.) x Swath Width (ft.)

WARNING: Remember that a sprayer with liquid is a signicant

amount of weight (8 lbs. per gallon). Use caution when bending,

leaning or walking. Bend only at the knees and support yourself as

required to ensure personal safety.

POSSIBLE USES OF SPRAYER:

Plant Feeding and Protection – A variety of spray tips enables user

to perform foliar feeding or apply fungicides and pesticides effectively.

Herbicides – May be applied to reduce pesky weeds and plants;

however, avoid using same sprayer for plant feeding or protection

without rst thoroughly cleaning. (See “Cleaning”.)

Indoor Use – Sprayers may be used to apply detergents, vinegar,

cleaning solutions, warm water up to 110°F (43°C) and other nontoxic

household cleaning and maintenance liquids. Carpets, walls, glass,

oors, ceilings and other surfaces can be treated. Do not use sprayer

which has previously been used with herbicides, pesticides or other

toxic chemicals.

Outdoor Use – Window cleaner, detergent, general purpose

cleaning solutions, certain wood preservatives, waxes, waterproong

are among the many things MASTERLINE sprayers can apply. Avoid

using sprayer for cleaning and other applications once it has been

used for plant protection or herbicide spraying. If sprayer was used

for herbicide or other spraying rst, clean the sprayer as described on

page 2 before using.

Determine the nozzle’s rated capacity. See page 5 of

MASTERLINE parts list for nozzle ratings. Get the capacity in

gallons/minute at the desired pressure. Test the delivery of the

nozzle. Spray for one minute and collect the spray.

Gal/min = oz. collected/minute

128 oz. = 1 gal.

Compute the area covered in square feet per minute. Select a

comfortable walking speed and gure how many feet per minute

you walk. A convenient fast walk for some is 2.5 mph, but this

may vary. One mile per hour equals 88 feet per minute. An easy

way to calculate is to simply measure the distance you walk in

one minute.

Compute the gallons per acre. The above information is used to

compute the gallons of spray that will be applied per acre.

1.

2.

3.

CALIBRATION OF MASTERLINE BACKPACK SPRAYERS

The output of the sprayer should be checked by collecting and

measuring the spray liquid emitted during one minute. Maintain

steady pumping on the pump handle while measuring. Having

determined the output from the nozzle in gallons/minute, the rate

per unit area treated can be calculated knowing the swath width and

walking speed.

Setting #1 15 psi

#2 30 psi

#3 45 psi

#4 60 psi

WILL THE PLASTIC MATERIAL LAST?

Only high-density polyethylene is used. The material is chosen for

high molecular weight, high impact strength, and excellent resistance

to chemicals and stress. Ultraviolet inhibitors are used in the material

to reduce deterioration caused by sunlight.

HOW HEAVY IS THE UNIT?

When empty, Model 475 weighs only 9.5 lbs.

IS THE SPRAYER COMFORTABLE TO CARRY?

MASTERLINE sprayers are probably the most comfortable spraying

equipment on the market. The tank rests comfortably against the

operator’s back and the straps are made from a nylon web and are

padded where they rest on the shoulders. The pump lever is positioned

at the most convenient height and can be varied with adjustment of

the straps.