4.2.9 Display saved bitmap (254 98 [reference number][x][y]) . .............. 13

4.3 Flow Control . . . . . ..................................... 13

4.3.1 Enter Flow Control Mode (254 58 [full][empty]) . .................. 14

4.3.2 Exit Flow Control Mode (254 59) . . . . . ...................... 14

5 Keypad Interface 14

5.1 General . ............................................ 14

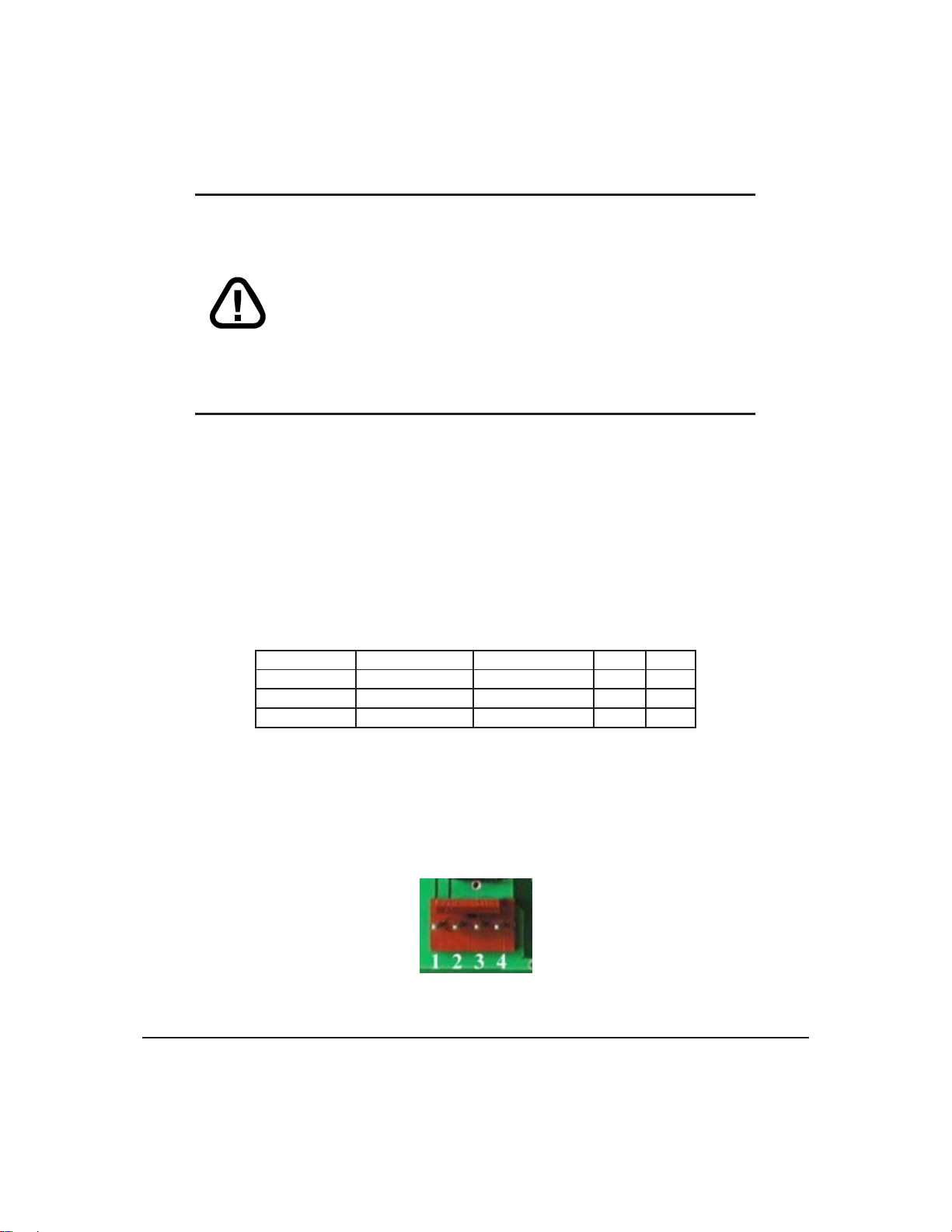

5.2 Connections . . . . . . ..................................... 15

5.3 I2C Interface . . . . . ..................................... 16

5.4 RS-232 Interface . . . ..................................... 16

5.5 Commands . . . . . . ..................................... 16

5.5.1 Auto repeat mode on (254 126 [mode]) . . ...................... 16

5.5.2 Auto repeat mode off (254 96) ............................. 17

5.5.3 Auto transmit keypresses on (254 65) . . . ...................... 17

5.5.4 Auto transmit keypresses off (254 79) . . . ...................... 17

5.5.5 Clear key buffer (254 69) . . . ............................. 17

5.5.6 Poll keypad (254 38) . ................................. 17

5.5.7 Set debounce time (254 85 [time]) . . . . . ...................... 18

6 Fonts and Graphics Files 18

6.1 General . ............................................ 18

6.2 Using mogd.exe . . . . ..................................... 18

6.3 Commands . . . . . . ..................................... 19

6.3.1 Erase file (254 173 [type] [ref]) . . . . . . ...................... 19

6.3.2 Purge memory (254 33 89 33) ............................. 19

6.3.3 Upload Font (254 36 [ref] [file size] [file data]) . . .................. 19

6.3.4 Upload Bitmap (254 94[ref] [file size] [file data]) . .................. 19

6.4 Working with Font Files . . . ................................. 19

6.4.1 Font File in Table Form . . . ............................. 20

6.4.2 Uploading the File to the Module . . . . . ...................... 20

6.4.3 A Sample Font File . . ................................. 21

6.5 Working with Bitmap Files . . ................................. 23

7 Miscellaneous Commands 23

7.1 General . ............................................ 23

7.1.1 Clear display (254 88) ................................. 24

7.1.2 Set contrast (254 80 [contrast]) ............................. 24

7.1.3 Set contrast and save (254 145 [contrast]) . ...................... 24

7.1.4 Backlight on (254 66 [minutes]) . . . . . . ...................... 24

7.1.5 Backlight off (254 70) ................................. 24

7.1.6 General purpose output on (254 86 [gpo #]) ...................... 24

7.1.7 General purpose output off (254 87 [gpo #]) ...................... 25

7.1.8 Set I2C address 254 51 [address]) . . . . . ...................... 25

7.1.9 Read module type (254 55) . . ............................. 25

7.1.10 Set RS-232 port speed (254 57 [speed]) . . ...................... 25

7.1.11 Set Serial Number (254 52 [byte1] [byte2] . ...................... 26

7.1.12 Read Serial Number (254 53) ............................. 26

Matrix Orbital GLK12232-25-WBL iii