Safety Precautions

Be sure to thoroughly read the instruction manual before using the products.

Keep the instruction manual in a safe, convenient location for future reference.

All or part of the contents described in this manual may be changed without any notice.

Due to our constant striving for further improvement of products, parts or products that differ from those

described in this manual may be substituted.

WARNING

(Failure to observe this WARNING may cause a fatal or serious injury.)

Be sure to confirm that any peripheral equipment does not move before installation work.

In addition, observe safety requirements for installation work where high-place work is expected.

Be sure to turn off the power source before wiring, mounting and transportation work. (Failure to observe

this WARNING may result in an electric shock/ injury or equipment damage due to short-circuit.)

Carry out wiring work correctly with reference to a proper drawing.

Never disassemble the equipment. (Failure to observe this WARNING may result in an electric shock.)

Do not open the cover under an explosive environmental condition when power is entered. (Failure to

observe this WARNING may result in an injury or equipment damage.)

Do not place or store the equipment in any hostile environmental place where it will be subjected to direct

sunlight, rain, water droplet, hazardous gas/water, etc..

CAUTION

(Failure to observe this CAUTION may cause a moderate injury or equipment damage.)

Do not use the equipment for any purpose other than the original purpose of use.

Be sure to confirm the specification of equipment and use the equipment within the range of specification.

(Mounting conditions such as temperature, power source, frequency, etc.)

Make sure a correct wiring before applying power source.

Do not have a shock or strong impact to the equipment.

(Failure to observe this CAUTION may result in equipment damage.)

Be sure to connect necessary terminals (grounding, etc.).

Remove all wiring to the equipment before doing electrical welding work near the equipment.

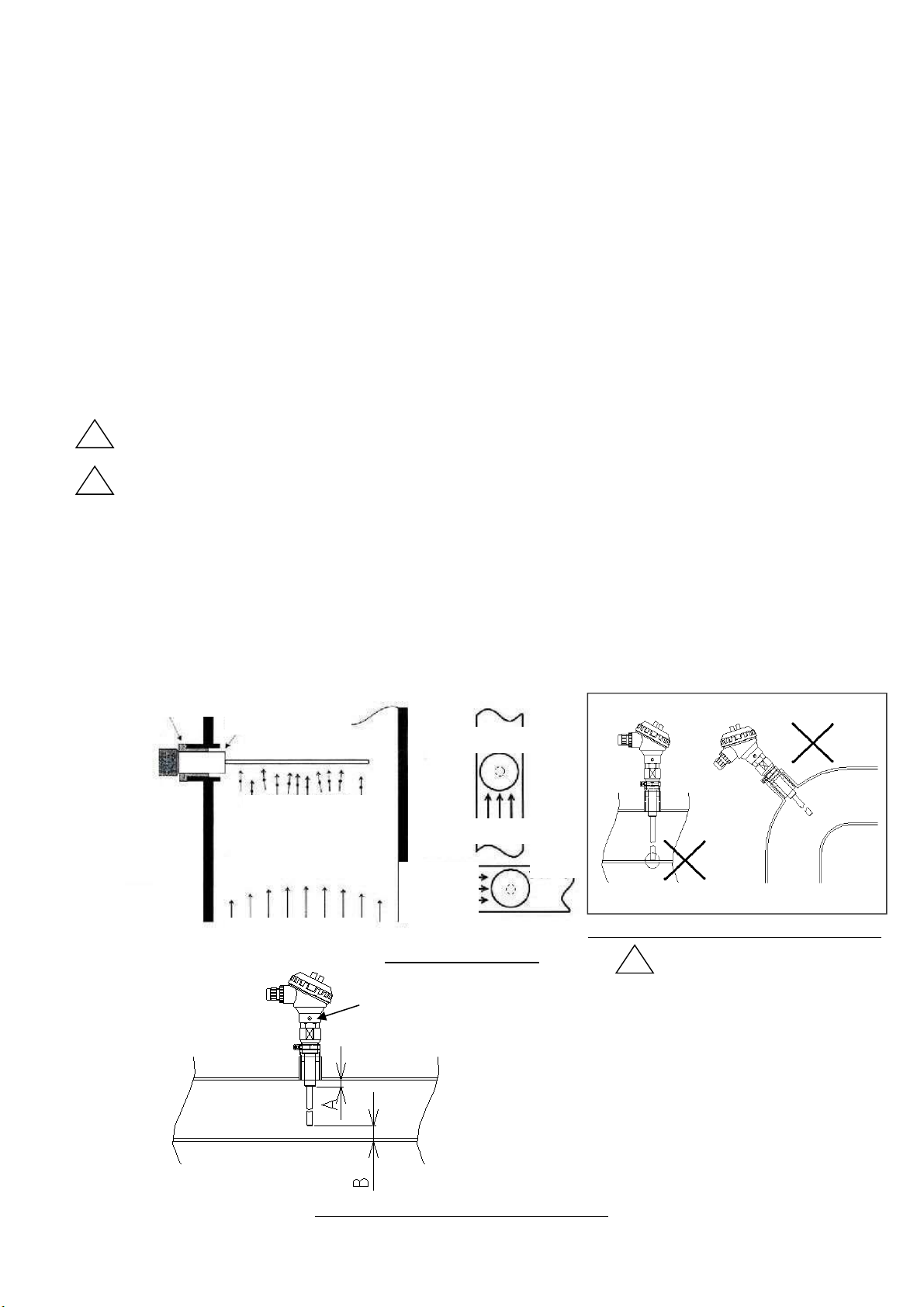

Do not forcedly bend or pull the lead wire also do not use unnecessarily long wire.

Tighten the cover, lead outlet, etc. properly so that dust, rainwater, etc. do not enter inside the equipment.

Do not use the equipment under a corrosive condition (NH

3

, SO

2

, CI

2

, etc.).

Be sure to tighten the cable grand so that outer air does not enter inside the equipment.

When applying piping connection such as conduit, etc. instead of cable grand, apply putty or equivalents

on the cable entry so that outer air does not enter inside the equipment.

IMPORTANT

(indicates notes or information to help customers.)

Limitations of Warranty:

Warranty period shall be one year from the date of delivery (ex-factory).

Any damage of any other products that have occurred for use of the equipment is not covered by

this warranty. Also any loss induced by failure or malfunction of the equipment is not covered by

this warranty.

Failure or malfunction caused by following are not covered by this warranty:

a. Modification or repair by a party other than MATSUSHIMA’s authorized personnel,

or replacement of parts not recommended by MATSUSHIMA.

b. Inadequate storage, installation, use, inspection or maintenance that does not comply

with specifications.

c. Cause for any peripheral equipment or device.

d. Accident beyond control and force majeure (fire, earthquake, flood, riots, etc.).

Lack of instructions to MATSUSHIMA for information or safety requirements that can be predicted only

by customers’ side.

This warranty conditions do not limit customers’ legal right.

Price for the equipment does not include any charge for services such as commissioning,

supervising, etc..